Floor tile with overmold crush pads

a technology of overmolding and crush pads, which is applied in the field of floor tiles, can solve the problems of increasing the cost of manufacturing the resultant tile, the difficulty of manufacturing an injection-molded plastic tile with two or more perceptible colors per tile, etc., and achieves the effect of reducing the coefficient of friction and reducing the rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

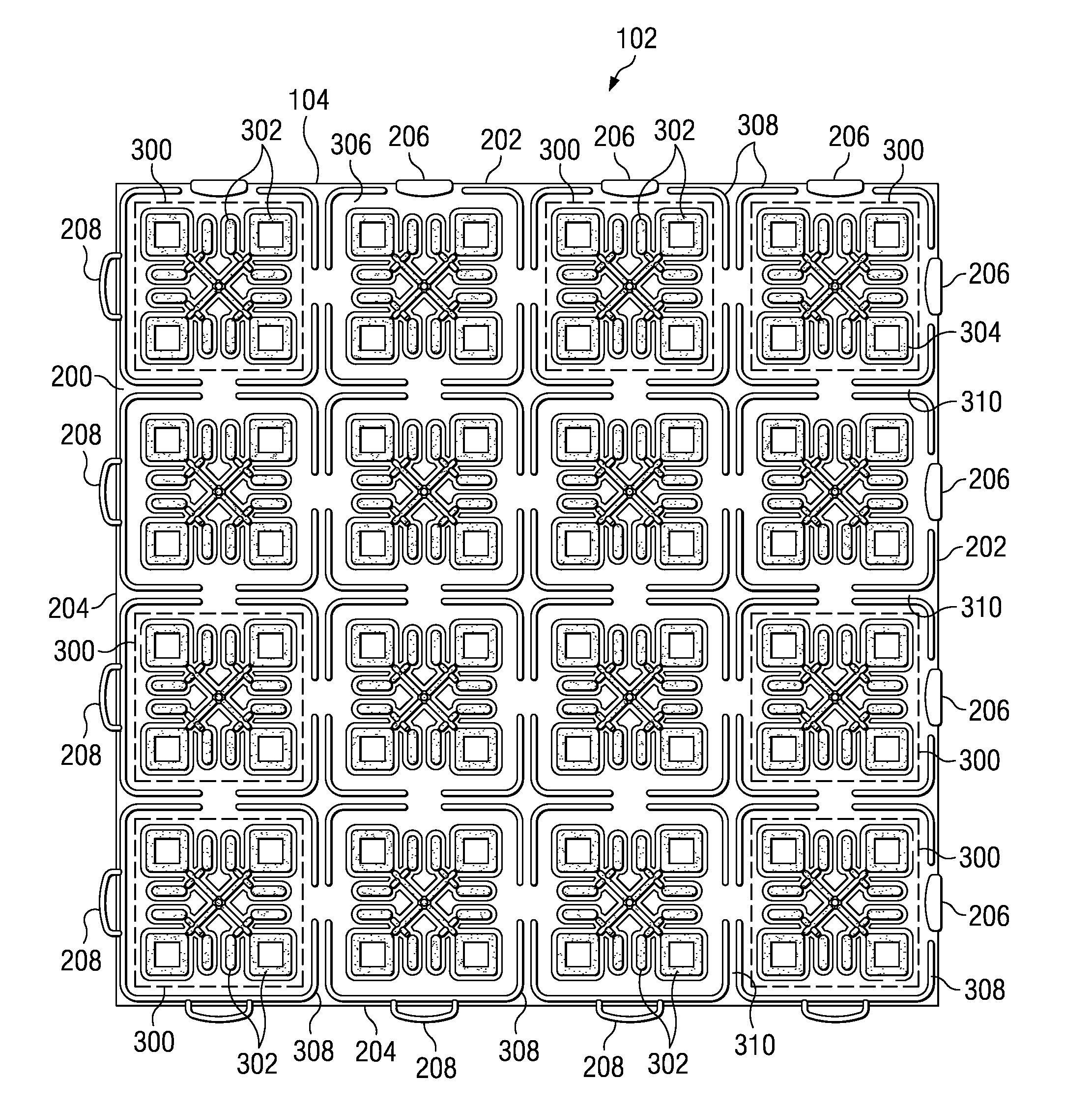

third embodiment

[0043]The differences between the first and second polymer compounds can include color and / or hardness. In one embodiment the second polymer compound, once solidified, is softer or less rigid than the first (once solidified), and has a higher coefficient of friction with respect to most objects than does the first. In another embodiment the hardness of the first and second compounds (once solidified) is about the same, but the colors are distinctly different. In a third embodiment, the hardness (once solidified) of the second compound is greater than that of the first. In a preferred embodiment, the second polymer compound can be selected from the group consisting of styrene ethylene butylene styrene based thermoplastic elastomer (SEBS TPE), other TPEs, soft TPU, or soft PVC. Polypropylene as the principal polymer in the first compound, and SEBS TPE as the principal polymer in the second polymer, are particularly preferred and have demonstrated good adherence to each other.

[0044]One...

fifth embodiment

[0078]FIGS. 21 and 22 show the invention in which modifications to the latch and loop structure have been made. In this embodiment an undercut or trench 2100 is made behind (laterally inwardly from) the lateral edge 204, but laterally outwardly from the rib segment 1022, to approximately fifty percent of the thickness of web 200. The undercut 2100 extends in parallel to edge 204 for the interior length of the wall segment 1022 between its attachment points (1024, 1026; FIG. 10) with female loop 208. The undercut 2100 leaves a downwardly depending flange 2102 which, when surface 2104 of outer wall 2106 slides vertically downward along surface 204, will flex inward (to the left in this picture) in approximately the direction of arrow 2108. The depth of the undercut 2100 is chosen to get a sufficient flexure of the flange 2102 upon snapping the tiles together, and may be more or less deep than shown depending on the flexural modulus of the polymer used to mold tile body 104. Flexing fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com