High Denier Per Filament and Low Total Denier Tow Bands

a technology of cellulose acetate and tow bands, which is applied in the direction of bundling articles, manufacturing tools, transportation and packaging, etc., can solve the problems of increasing epd and changing draw characteristics, exacerbated the problem of higher epd, and high total denier tow bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

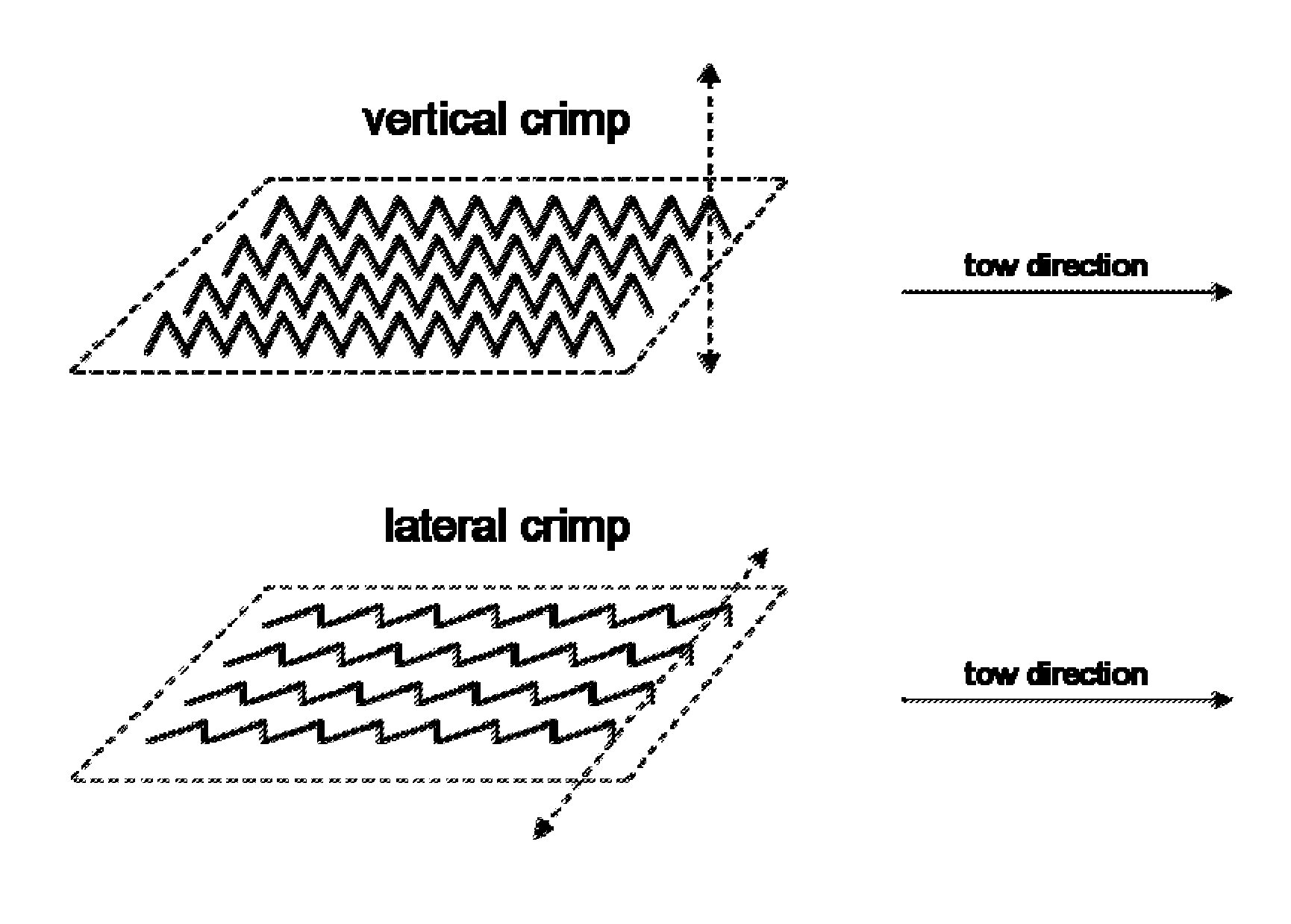

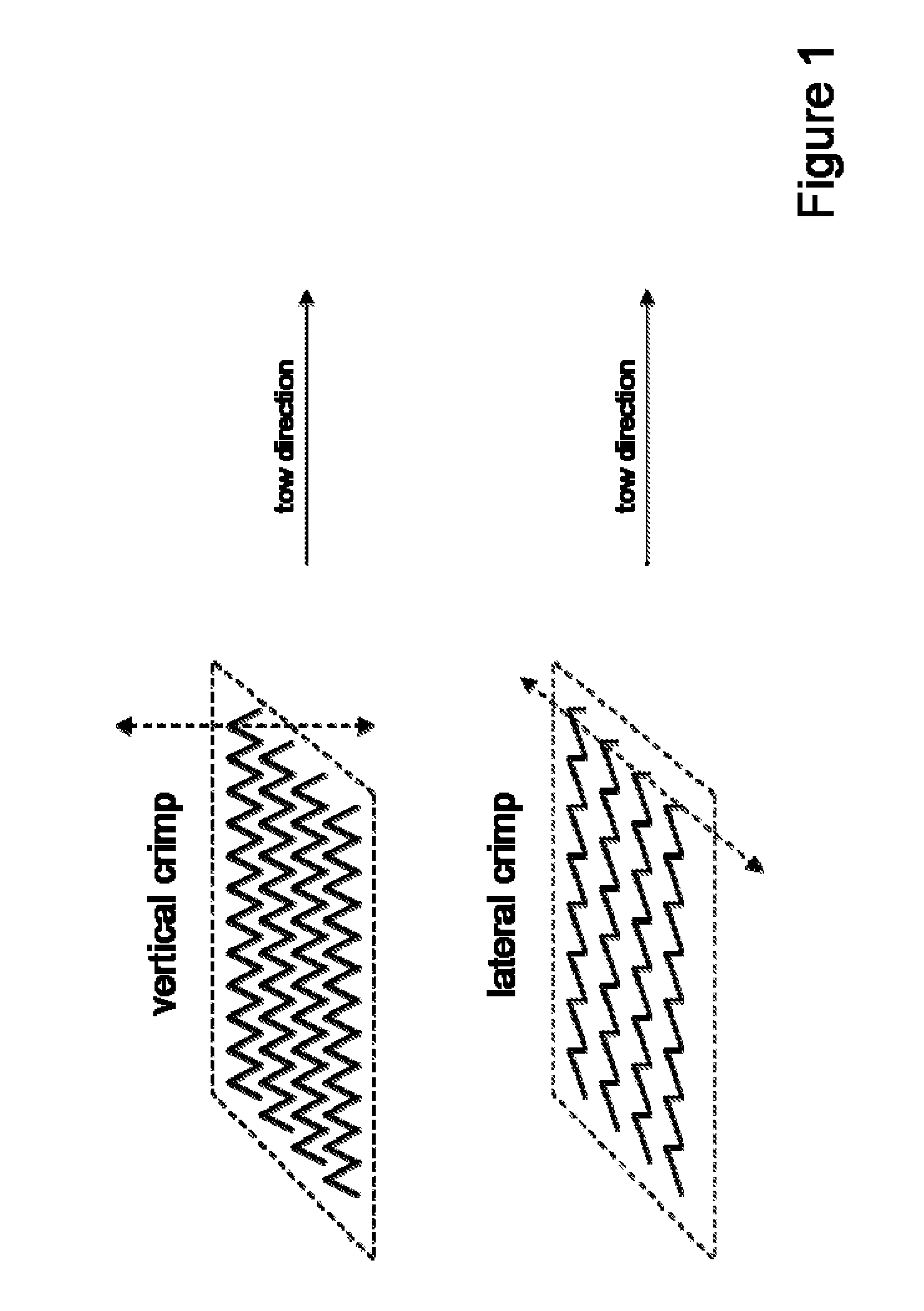

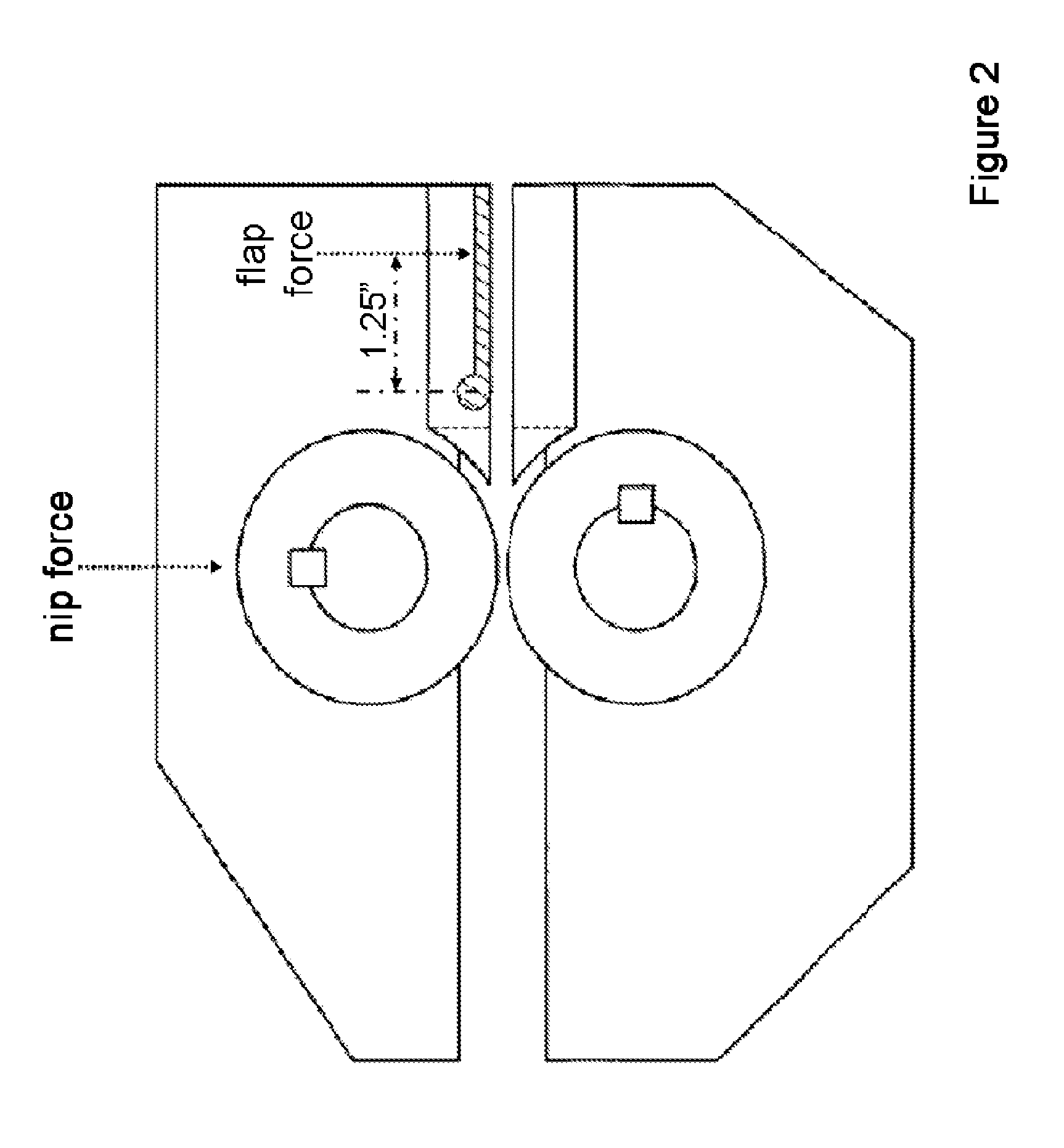

[0034]The present invention relates to high denier per filament and low total denier cellulose acetate tow bands and smoking device filters produced therefrom.

[0035]The present invention provides cellulose acetate tow bands with a high denier per filament (dpf) and a low total denier, which may be useful for producing smoking device filters with previously unrealized encapsulated pressure drop (EPD) and circumference combinations. In some embodiments, the cellulose acetate tow bands of the present invention may be useful for producing regular circumference (e.g., about 26 to about 32 mm) filters with an ultra-low EPD (e.g., about 1 mm water / mm filter or less). In some embodiments, the cellulose acetate tow bands of the present invention may be useful for producing slim to ultra-slim circumference (e.g., about 17 mm to about 26 mm) filters with a low EPD (e.g., about 2.5 mm water / mm filter or less). In some embodiments, the cellulose acetate tow bands of the present invention may be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com