Plant for fluorine production and a process using it

a technology for fluorine production and plant, applied in the direction of separation process, manufacturing tool, electric circuit, etc., can solve problems such as problems to be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

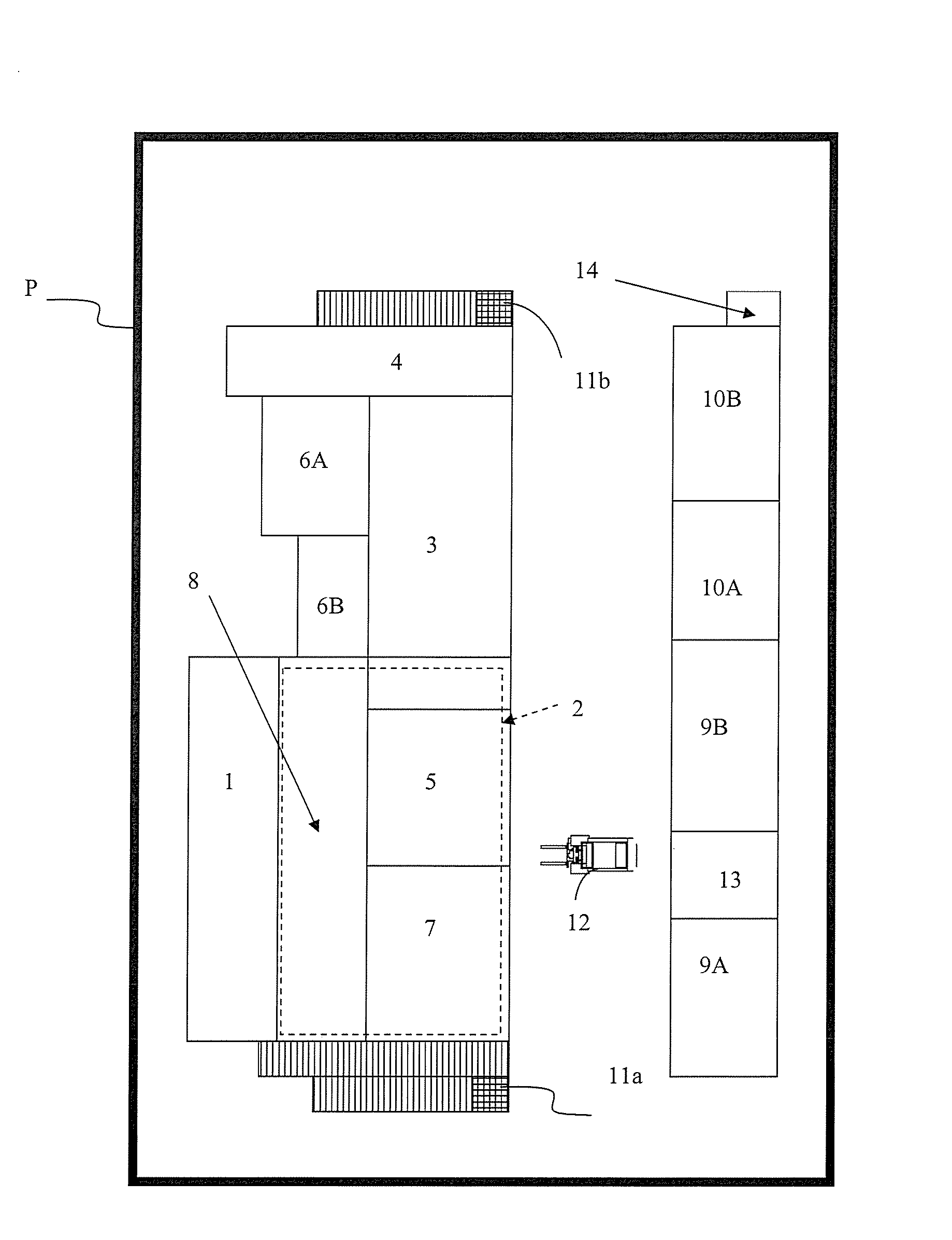

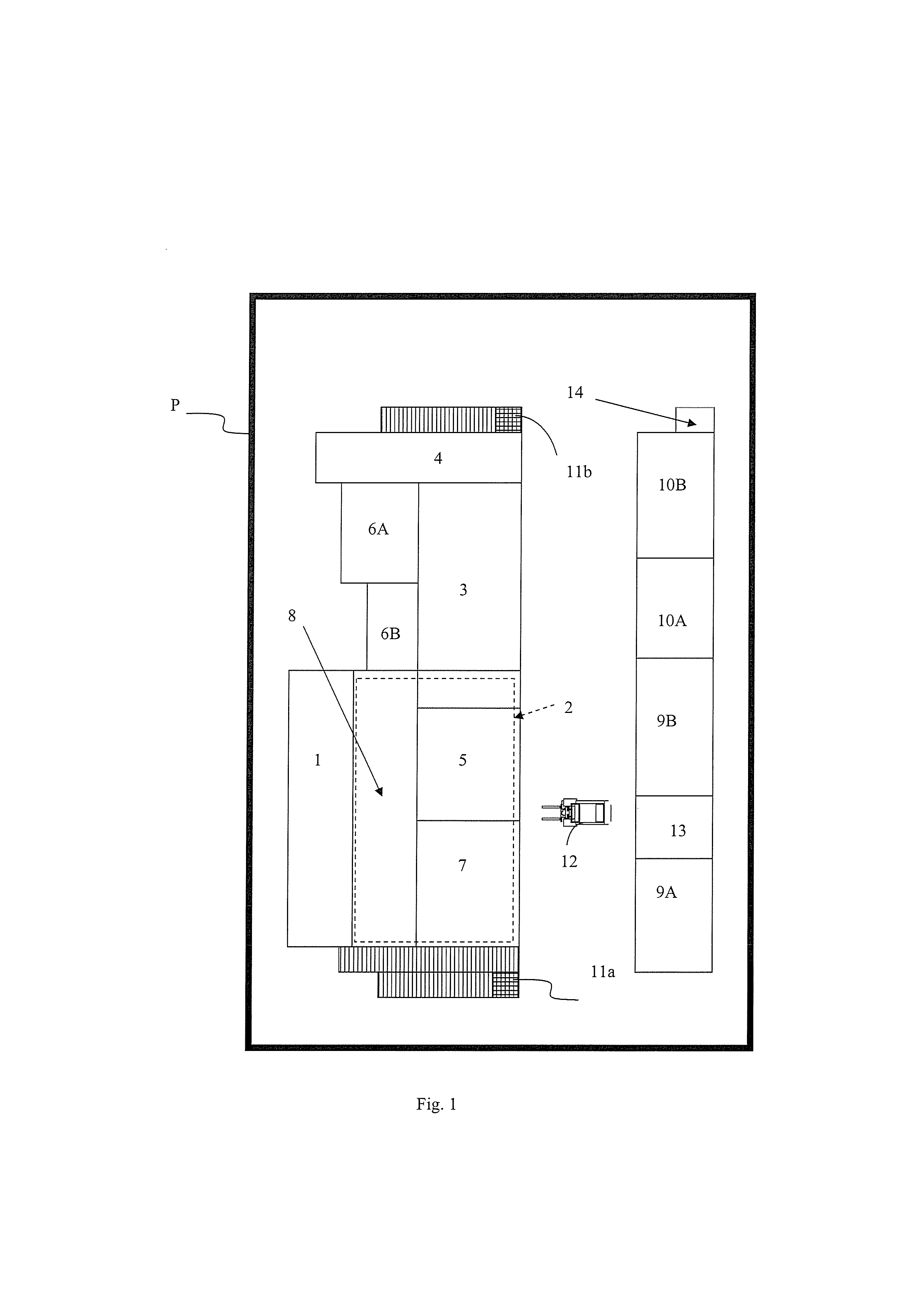

[0017]The preferred plant of the present invention provides fluorine gas to a tool which applies fluorine gas as reactant to perform chemistry in this tool which apparatus comprises skid mounted modules including[0018]a skid mounted module comprising at least one storage tank for HF, denoted as skid 1,[0019]a skid mounted module comprising at least one electrolytic cell to produce F2, denoted as skid 2,[0020]a skid mounted module comprising purification means for purifying F2, denoted as skid 3,[0021]a skid mounted module comprising means to deliver fluorine gas to the point of use, denoted as skid 4,[0022]a skid mounted module comprising cooling water circuits, denoted as skid 5,[0023]a skid mounted module comprising means to treat waste gas, denoted as skid 6,[0024]a skid mounted module comprising means for the analysis of F2, denoted as skid 7, and[0025]a skid mounted module comprising means to operate the electrolysis cells, denoted as skid 8.

[0026]The plant preferably also comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal volume | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap