Multiple Ramp Compression Packer

a compression packer and ramp technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of adding additional and unnecessary complexity and cost to the pack off process, and being unable to prevent the migration of fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

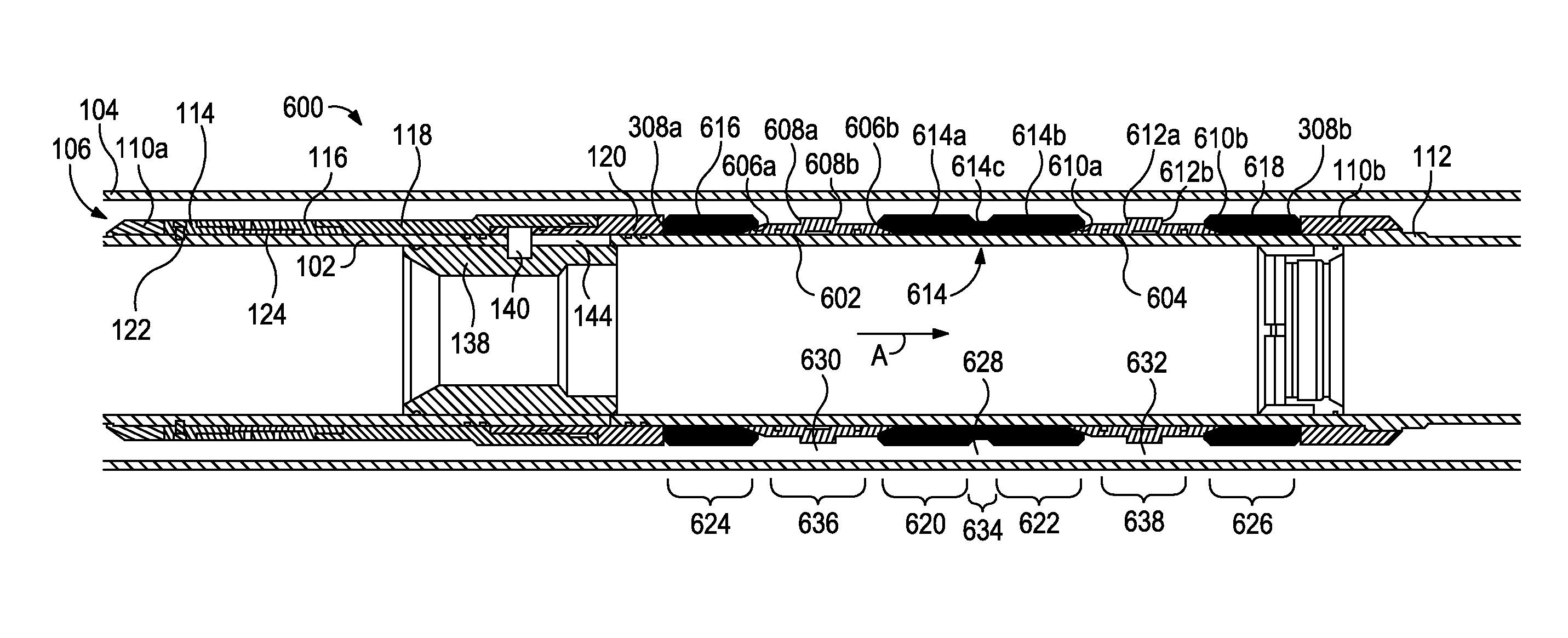

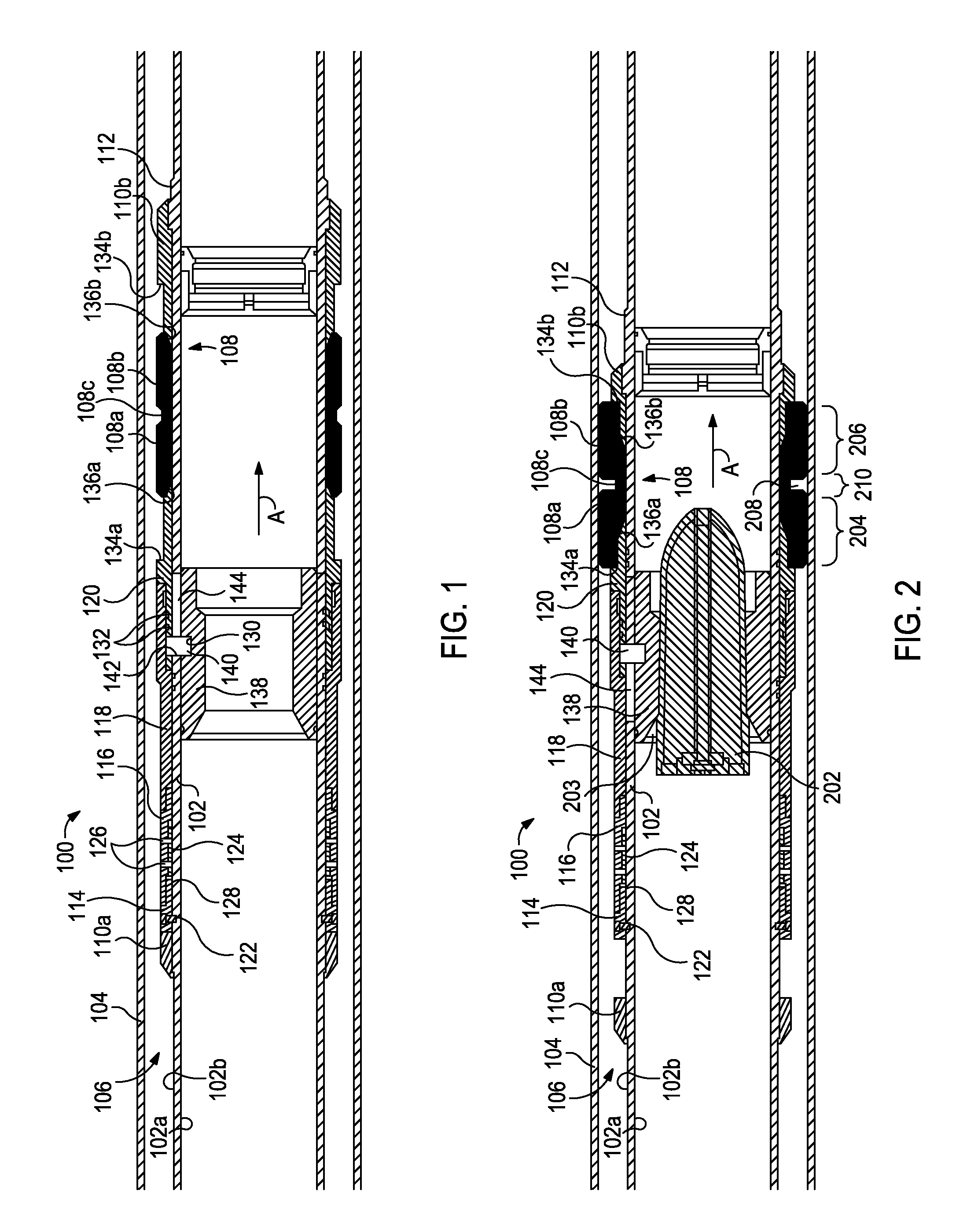

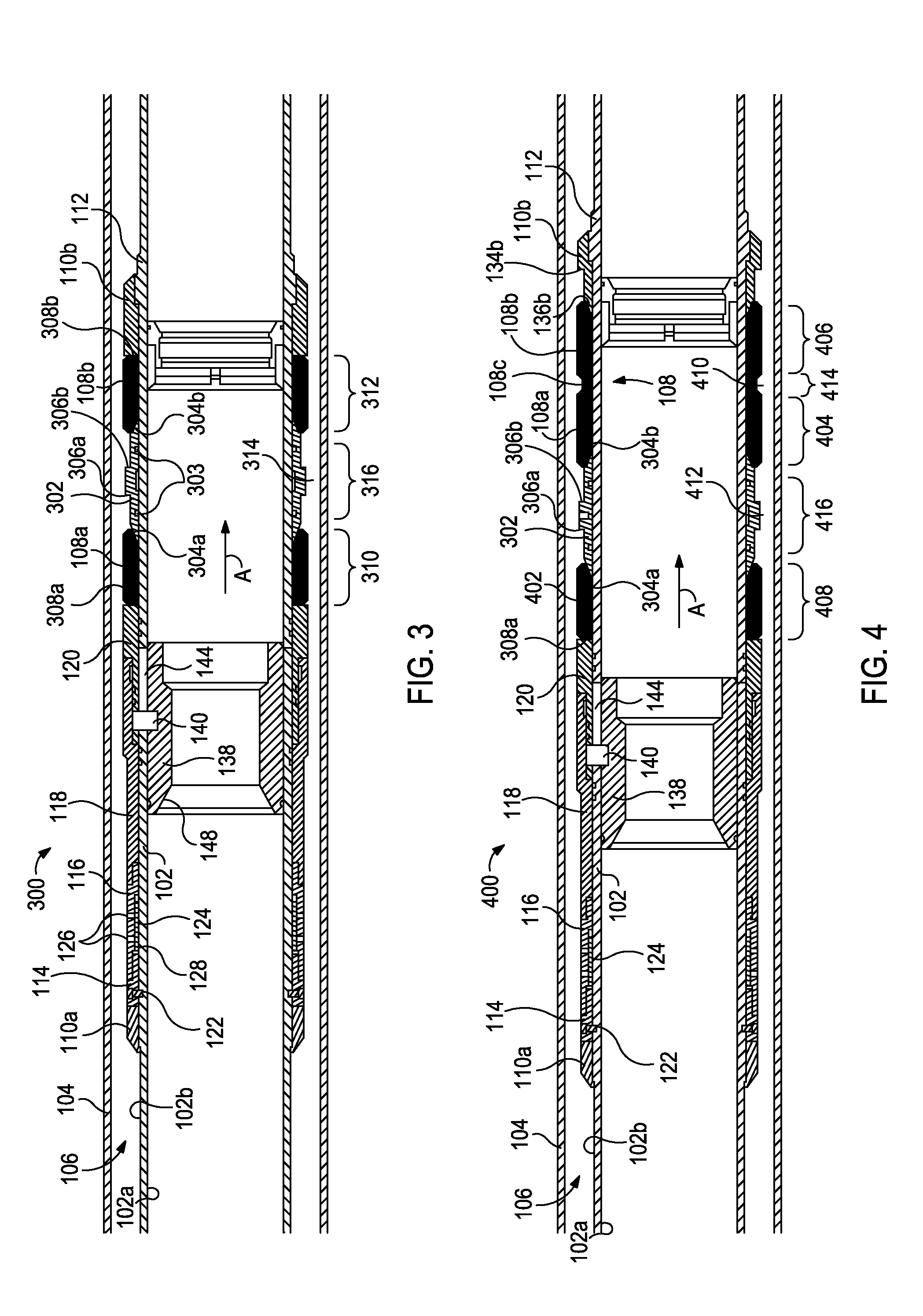

[0019]The present invention relates to systems and methods used in downhole applications and, more particularly, to providing a seal in a casing annulus capable of stopping gas migration.

[0020]As will be discussed in detail below, several advantages are gained through the systems and methods disclosed herein. For example, the disclosed systems and methods initiate and set a downhole tool, such as one or more well packers or packer elements, in order to isolate the annular space defined between a completion casing and a base pipe (e.g., production string). The set packer is able to create a seal that prevents the migration of fluids through the annulus, thereby isolating the areas above and below. The packer may be set using hydraulic and / or mechanical means, and adjacent packer elements may provide one or more hydraulic seals in the annulus that prevent or otherwise eliminate the migration of gases at elevated pressures. To facilitate a better understanding of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com