Exhaust-gas heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

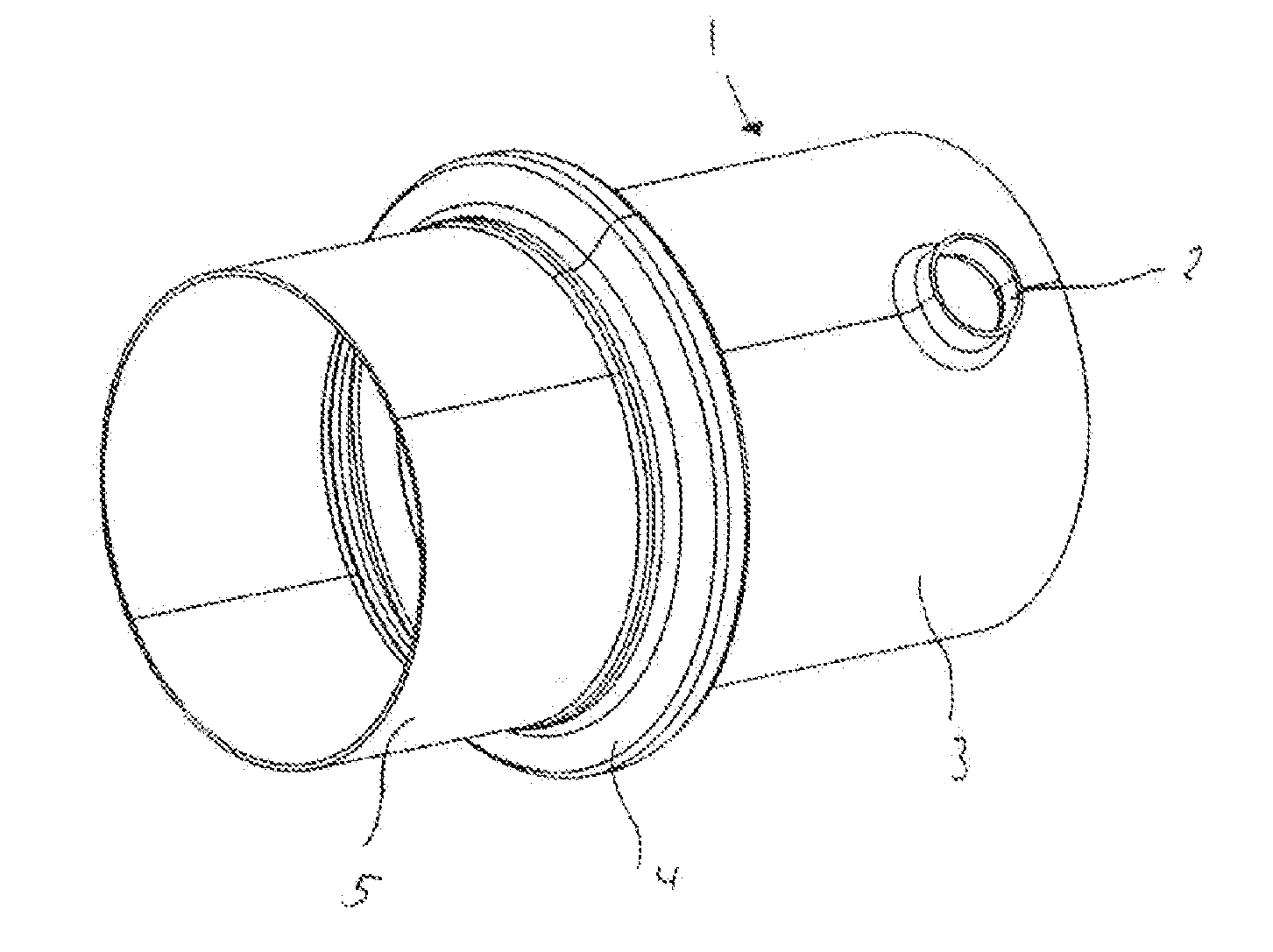

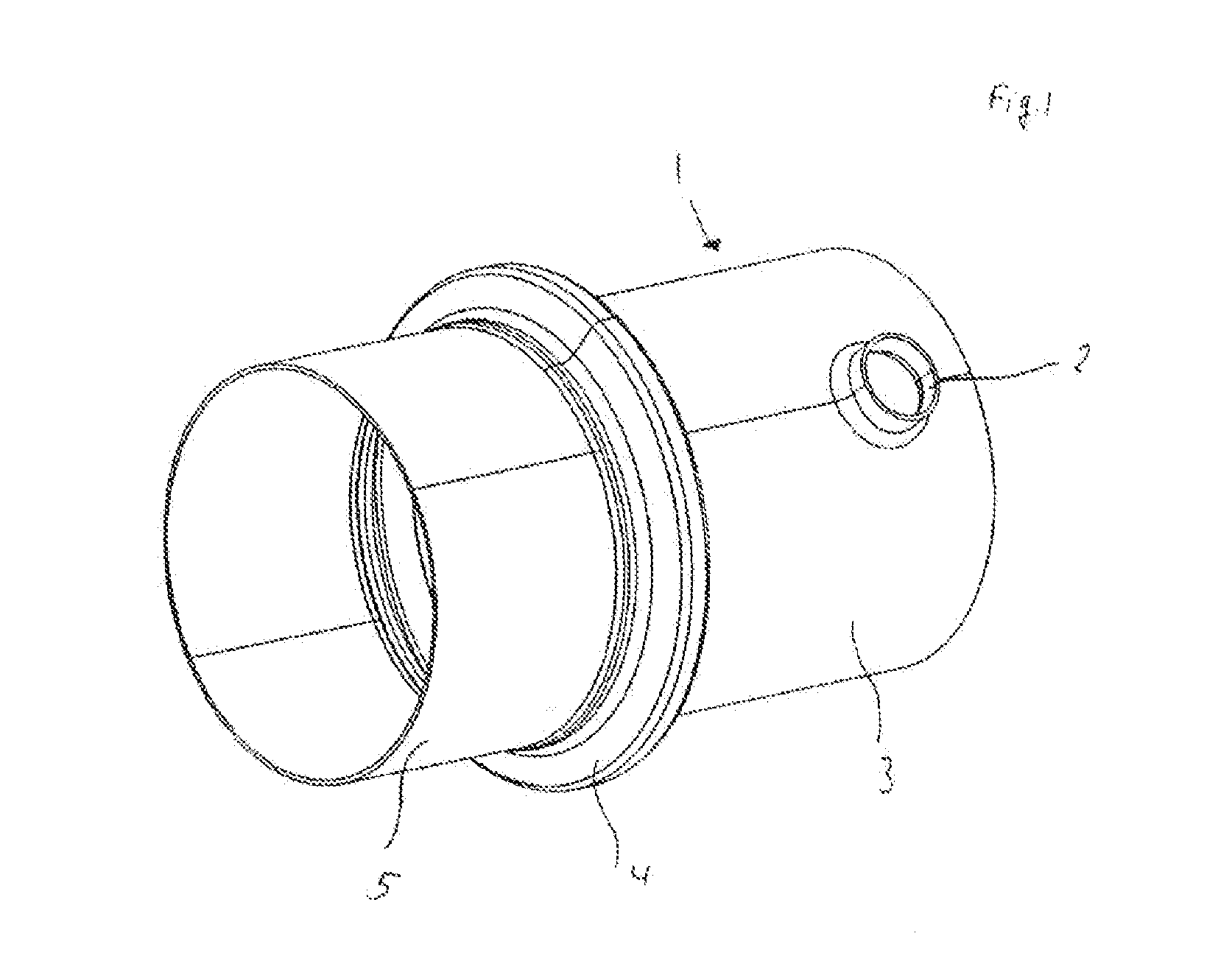

[0024]FIG. 1 shows a perspective view of an exhaust-gas heat exchanger 1. The exhaust-gas heat exchanger 1 is composed substantially of a housing 3 which, in the interior, has a multiplicity of flow ducts which, in their end regions, are received in tube plates. The tube plates and the flow ducts cannot be seen in FIG. 1 owing to the perspective view.

[0025]The housing 3 surrounds the tube plates in such a way that a second flow duct is formed which is separated from the flow ducts enclosed in the tube plates. A fluid can flow into the housing via the fluid inlet 2 and can flow through said housing. Not illustrated in FIG. 1 is the fluid outlet through which the fluid can exit the housing 3 again.

[0026]A further fluid, preferably the exhaust gas in an exhaust tract, flows through the exhaust-gas heat exchanger 1 along the flow ducts enclosed in the tube plates. A second fluid flows through said exhaust-gas heat exchanger through the fluid inlet 2 and the fluid outlet (not shown), whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com