Coaxial probe

a probe and coaxial technology, applied in the field of coaxial probes, can solve the problems of low structural strength, easy loosening of the center conductive probe, and inability to assemble correspondingly, and achieve the effect of avoiding the damage of the probe caused by the impact for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

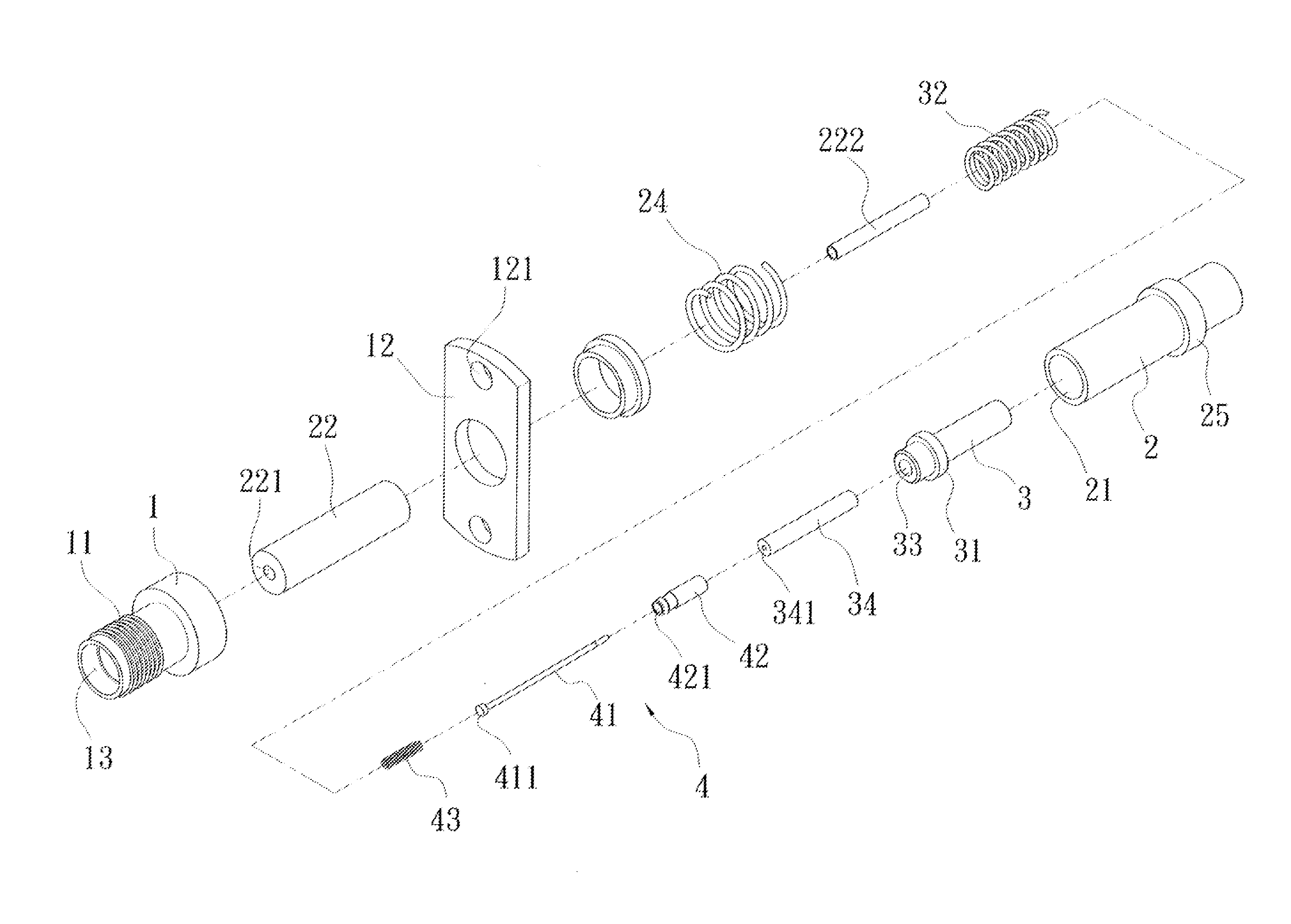

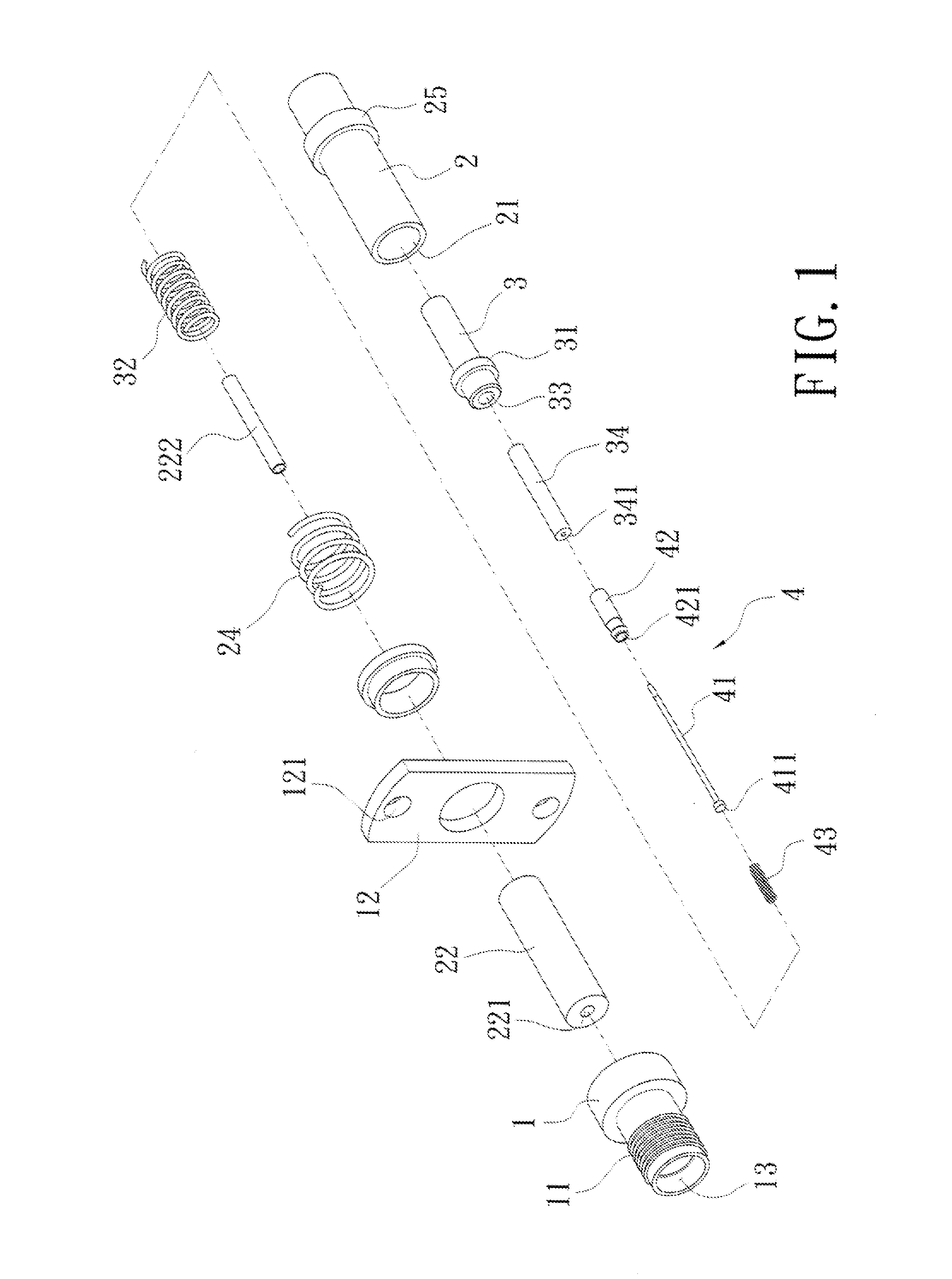

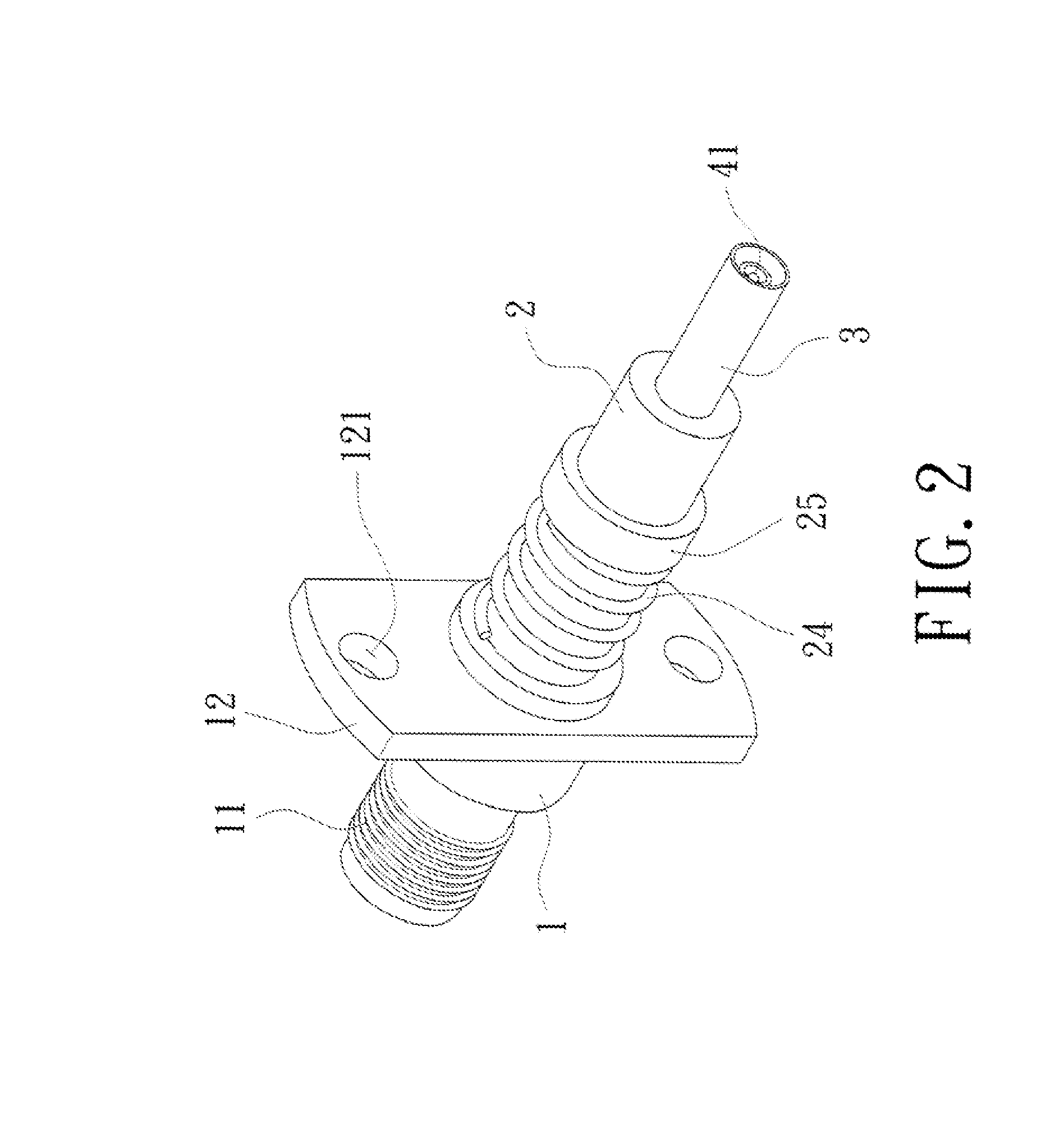

[0015]Refer from FIG. 1 to FIG. 3, a coaxial probe of the present invention mainly includes an assembly base 1, a main sleeve 2, a protective sleeve 3 a probe portion 4.

[0016]The assembly base 1 is disposed with a threaded segment 11 on an outer wall thereof and a through hole 13 on a center thereof. A connection disc 12 with a plurality of fastening holes 121 is arranged at the assembly base 1, under the threaded segment 11.

[0017]The main sleeve 2 is disposed under the assembly base 1 and a top end of the main sleeve 2 is mounted into the through hole 13 of the assembly base 1. A sleeve port 21 is arranged at a center of the main sleeve 2. A connection member 22 is mounted in the sleeve port 21 of the main sleeve 2 and the through hole 13 of the assembly base 1. An insertion hole 221 is located on a center of the connection member 22 and a plunger rod 222 is mounted in the insertion hole 221 of the connection member 22. A connection segment 223 is formed between the bottom edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com