Multiple function hydraulic system with a variable displacement pump and a hydrostatic pump-motor

a hydraulic system and variable displacement technology, applied in the field of hydraulic systems, can solve the problems of adding inefficiency to the hydraulic system, reducing the efficiency of the hydraulic system,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The term “directly connected” as used herein means that the associated components are connected together by a conduit without any intervening element, such as a valve, an orifice or other device, which restricts or controls the flow of fluid beyond the inherent restriction of any conduit. If a component is described as being “directly connected” between two points or elements, that component is directly connected to each such point or element.

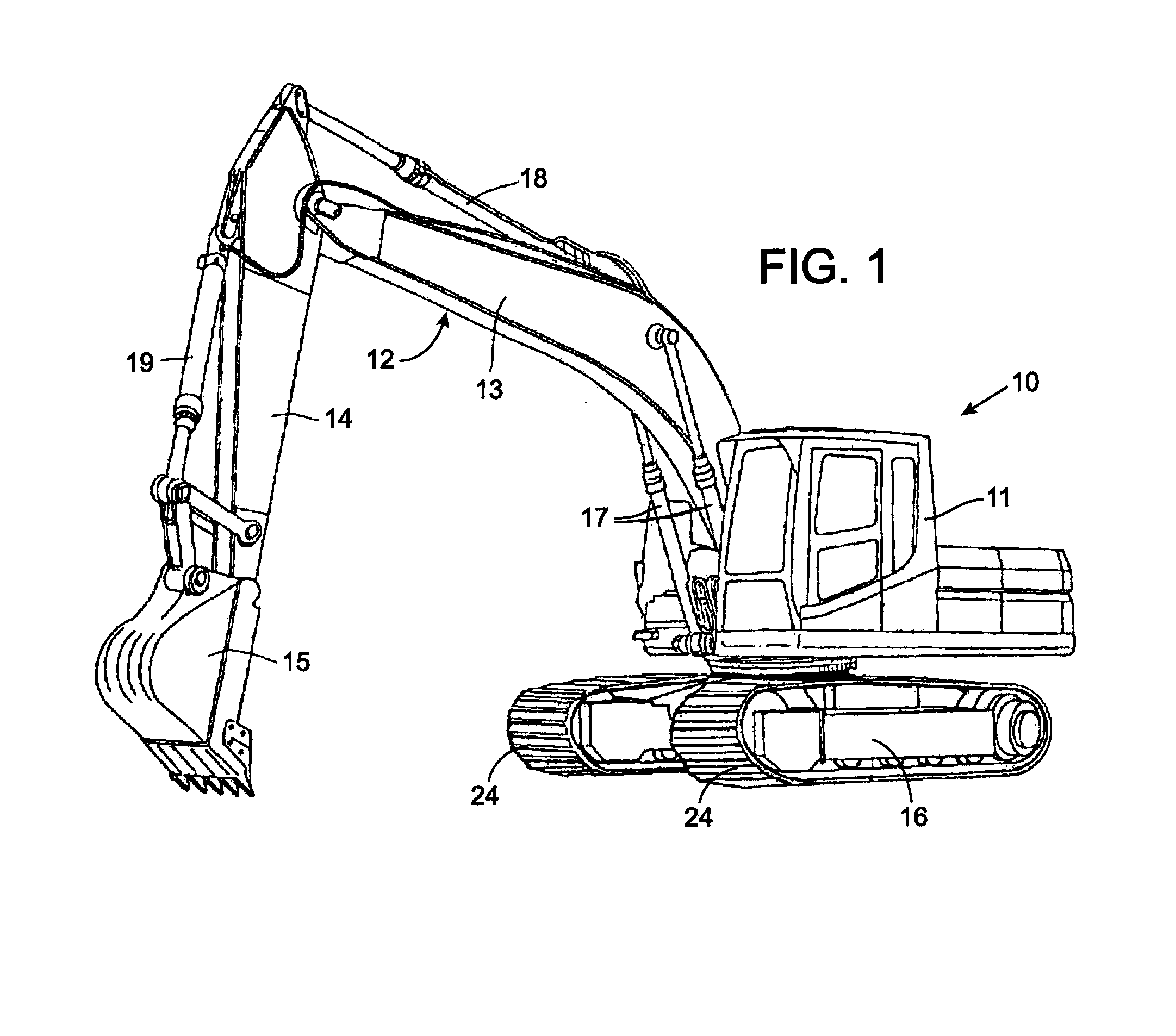

[0020]Although the present invention is being described in the context of use on an earth excavator, it can be implemented on other types of hydraulically operated equipment.

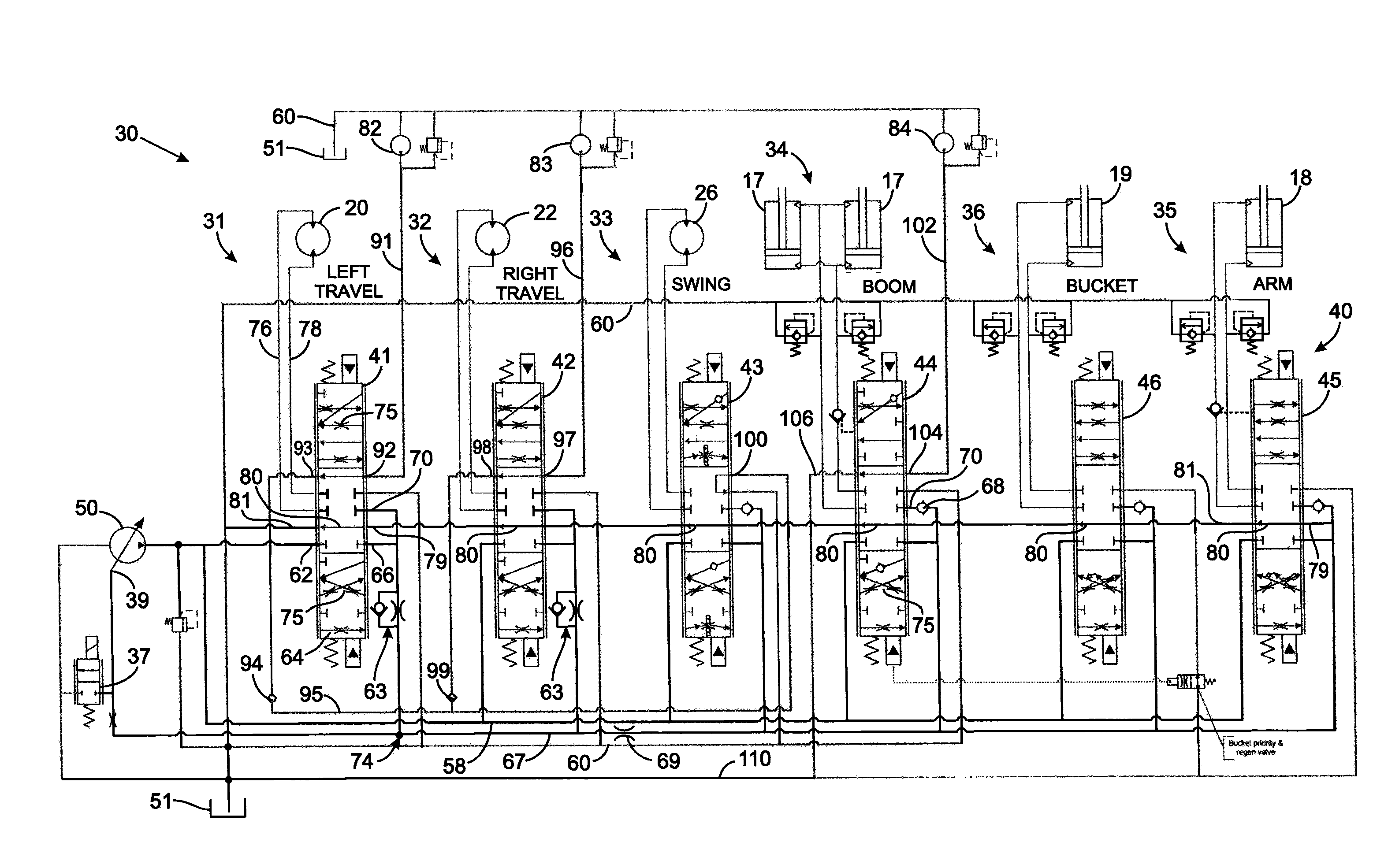

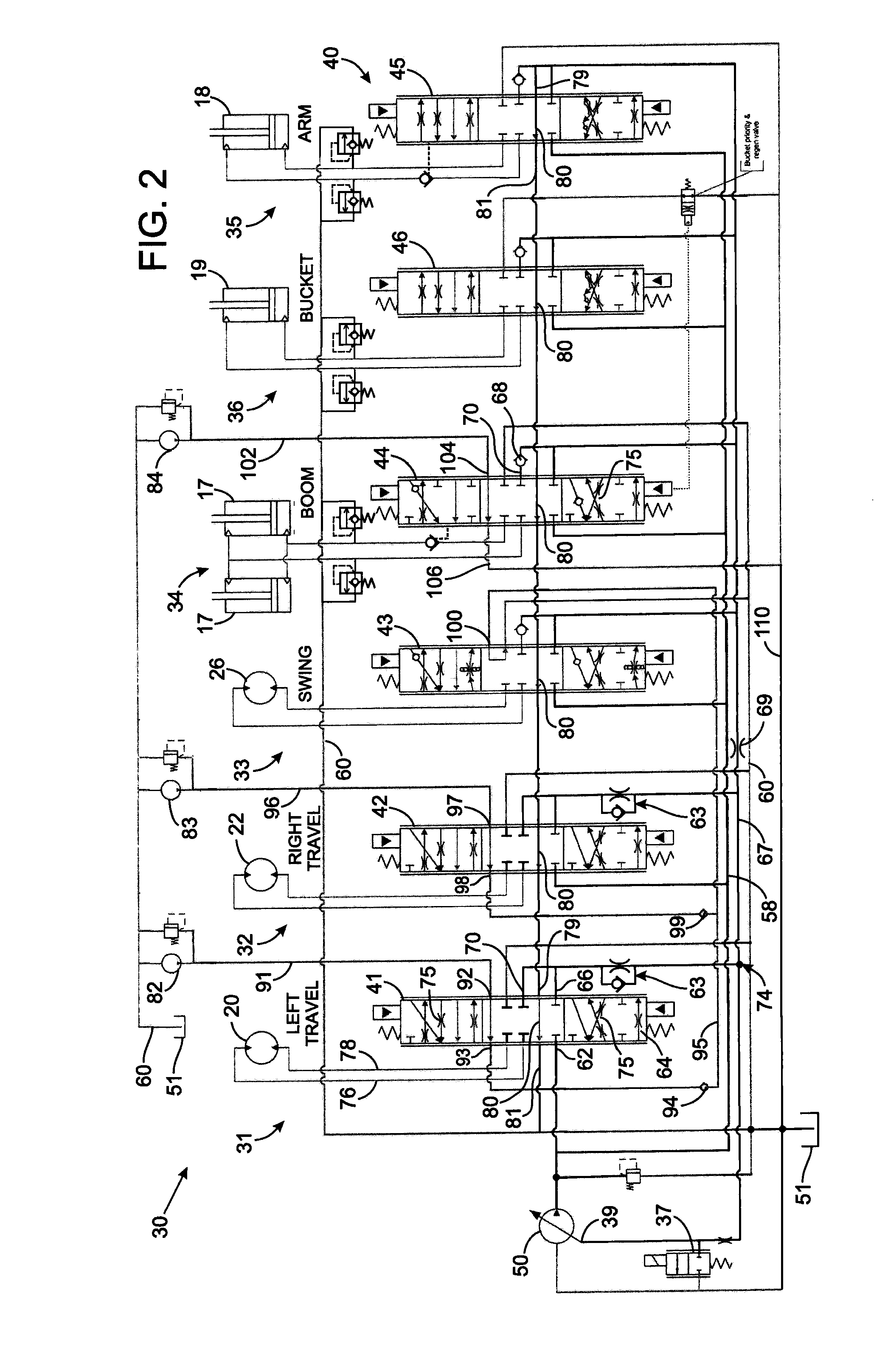

[0021]With initial reference to FIG. 1, an excavator 10 comprises a cab 11 that can swing clockwise and counter-clockwise on a crawler 16. A boom assembly 12, attached to the cab, is subdivided into a boom 13, an arm 14, and a bucket 15 pivotally attached to each other. A pair of hydraulic piston-cylinder assemblies 17, that are mechanically and hydraulically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com