System for Mounting an Abrasive Tool to a Drive Plate of Grinding and Polishing Machines

a technology of grinding and polishing machines and mounting systems, which is applied in the direction of metal-working equipment, metal-working equipment, manufacturing tools, etc., can solve the problems of quick change of defective segments or even addition, and achieve the effect of efficient change of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

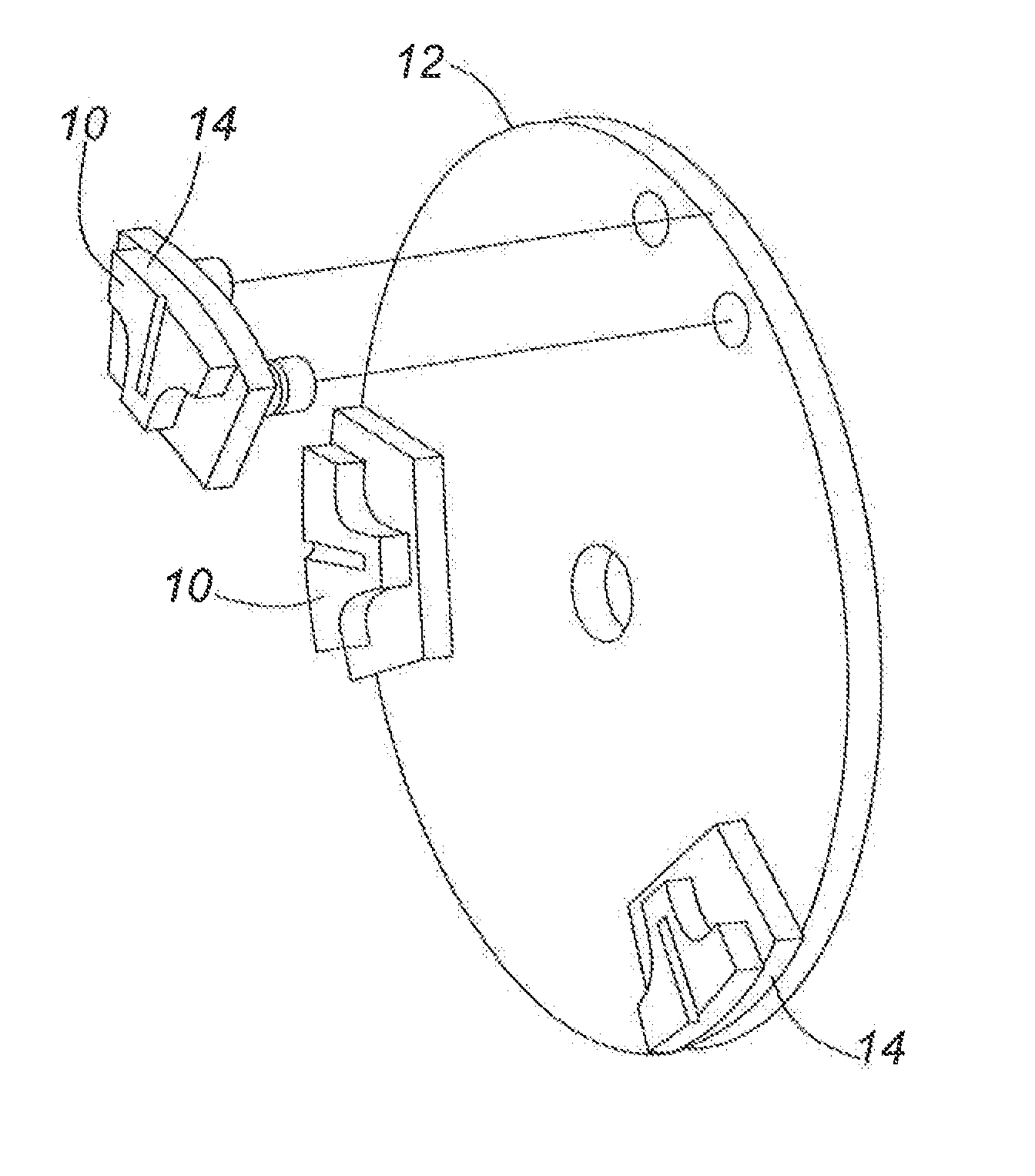

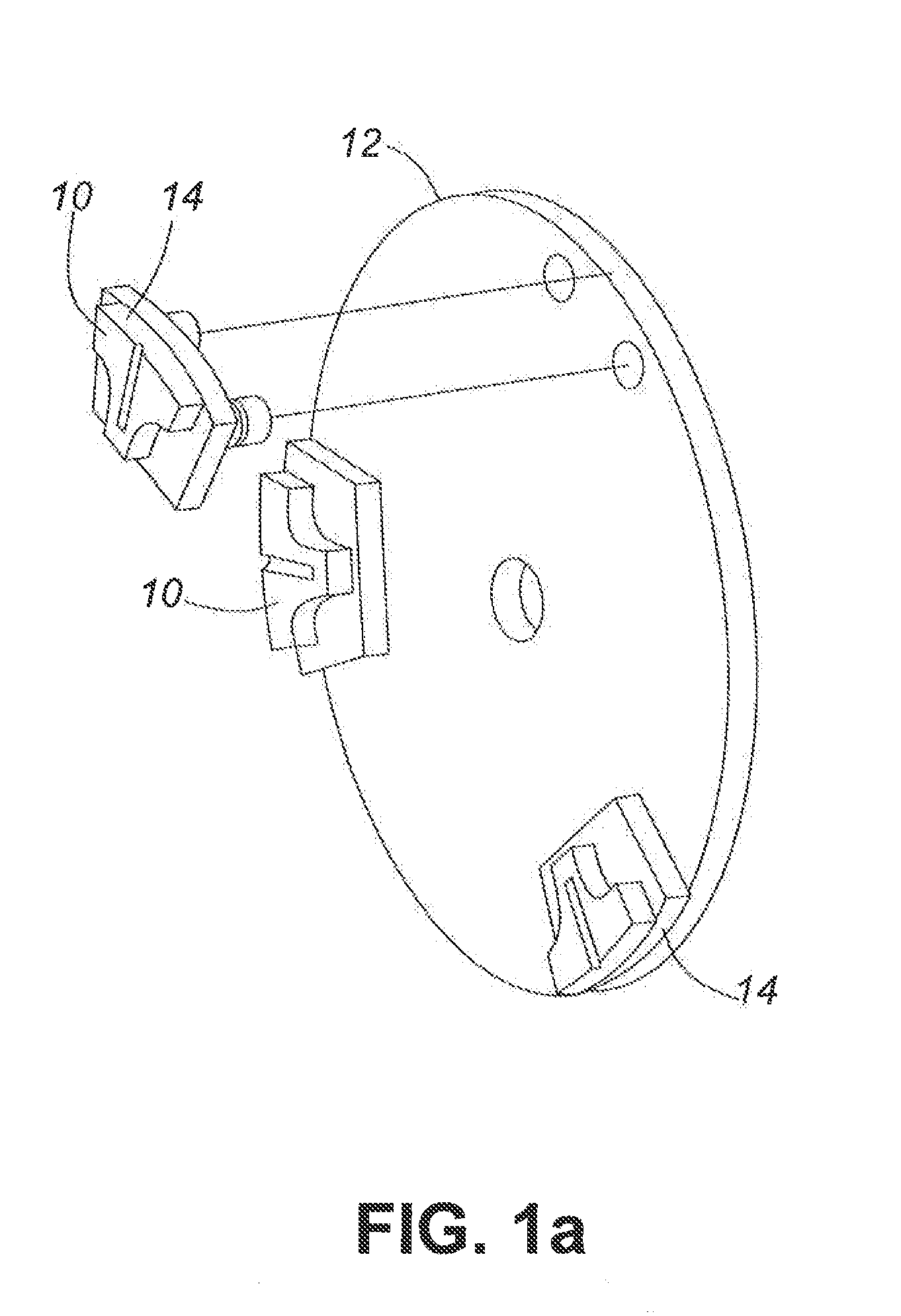

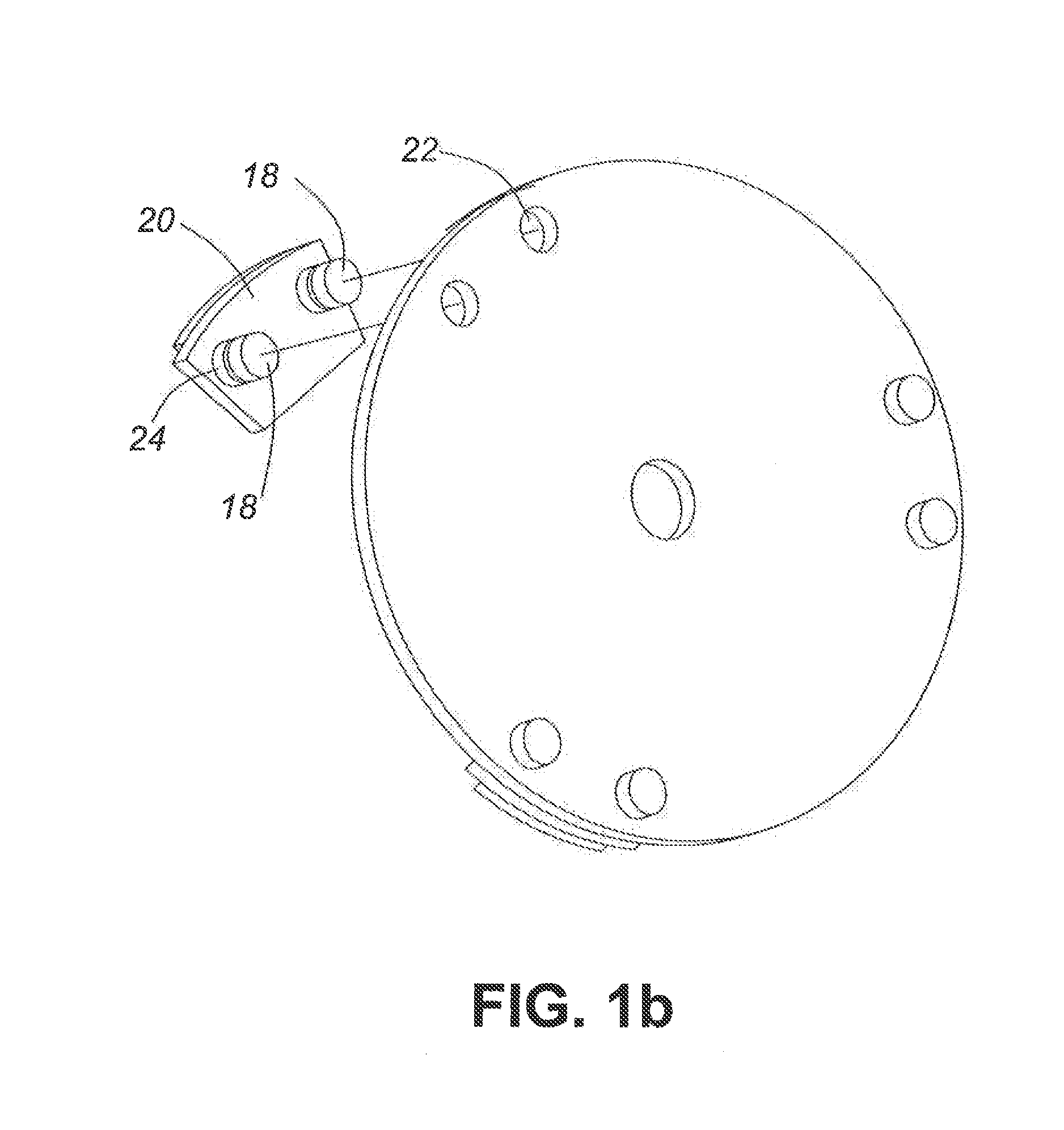

[0027]Disclosed in accordance with the teachings of this present invention is a quick change system to change the polishing or grinding tool for a polisher or grinding machine. The tool can be any suitable tool or abrasive material, such an abrasive diamond in various matrices, sandpaper, Velcro-backed polishing pads, etc. A drive plate is located on the bottom of the polisher or grinding machine. Embodiments of this invention provide an efficient way to attach at least one tool to the drive plate. Embodiments of this invention use an intermediate element between the drive plate and the abrasive tool. A securing means is used to fasten the abrasive tool to the intermediate element and a second securing means is used to fasten the intermediate element to the drive plate.

[0028]In general, embodiments of the invention have been designed to work on Werkmaster™ machines. Werkmaster™ machines use multiple grinding heads that required specific tool plate sizes that are unique to the Werkma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| abrasive | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com