Wig with flex-grip base and components for protection against hair damage

a technology of flex-grip base and components, which is applied in the direction of wigs, hair accessories, headwear, etc., can solve the problems of high cost of human hair, inconvenient maintenance, and inability to adjust the flat configuration of the hairpiece, so as to reduce manufacturing time and cost, and ensure the appearance. , the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Best Mode of Carrying out the Invention

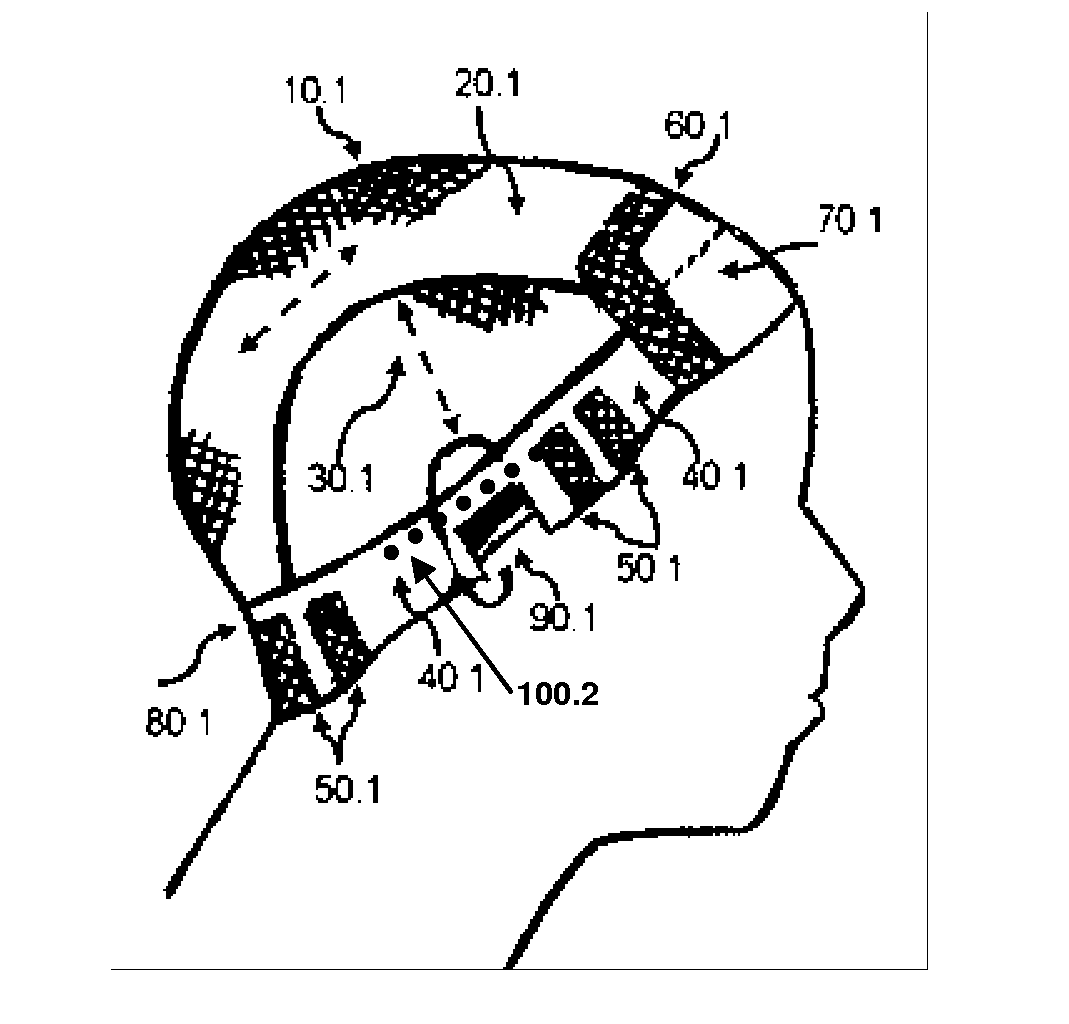

[0041]The drawing in FIG. 1, illustrates the base of the current invention to which human or synthetic hair is attached. The best mode to carry out the new invention is a preferred embodiment with the following components and process:

[0042]The base is 10.1 a lightweight stretchable mesh fabric with a percentage of nylon and spandex. The antiskid reinforcement tabs 50.1 are made of a stiff nylon netting fabric popularly known as crinoline or stiff tulle.

[0043]The center panel 20.1, which is wider at the front that stretches lengthwise and two side panels 30.1 stretch downwards to adapt to the shape and size of the wearer's head.

[0044]The periphery is a band 80.1 made from a stretchable fabric of 85% percentage of nylon and 15% spandex. The band fabric is folded to form a smooth durable edge. The band is 3 inches (7.6 cm) wide. The circumference of the band is based on international hat sizes, for example hat-size 7½ measures 23.5 inches (59.7 cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com