Monolithically Integrated Bi-Directional Heat Pump

a heat pump and monolithic technology, applied in the field of heat pumps, can solve the problems of significantly reducing the maximum power of the heat pump, limiting the performance of most heat pumps, and limiting the performance of some emergent heat pump technologies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

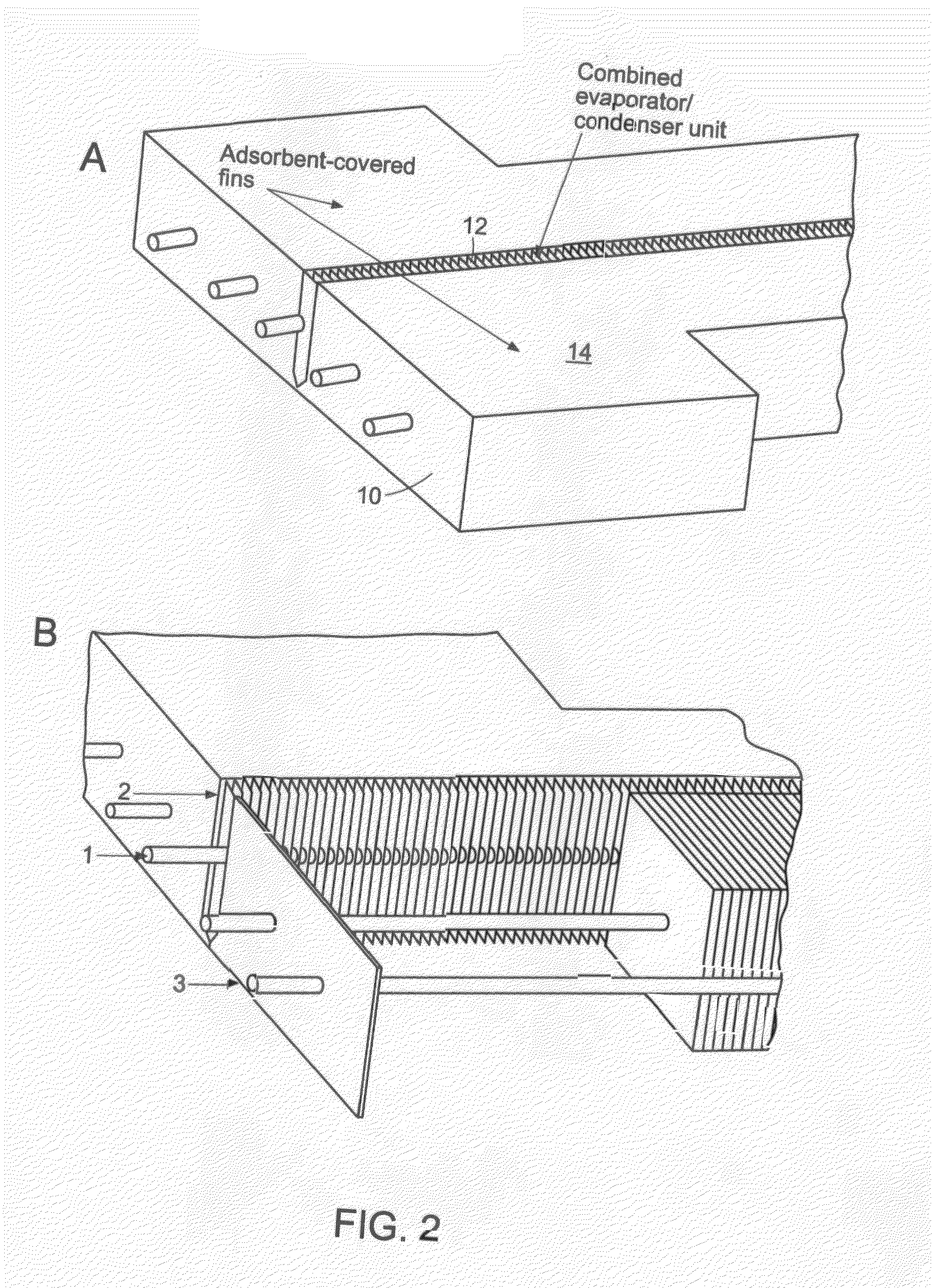

[0046]An embodiment of the invention is shown in FIGS. 2(A) and (B). FIG. 2(A) shows the integrated design in a T-shape particularly adapted for battery electric vehicle integration. The integrated design 10 includes a combined evaporator-condenser unit 12 along with adsorbent-covered fins 14. In the explored view of FIG. 2(B), showing the adsorbent material mounted on liquid-cooled fin tubes, arrow 1 indicates the flow of heat transfer fluid to the evaporator-condesner 12. The arrow 2 indicated the flow of liquid refrigerant into the evaporator-condesner unit during battery discharge. Arrow 3 indicates the flow of heat transfer fluid to the adsorbent fins. The pressure vessel containing these elements is not, itself, shown for the sake of clarity.

[0047]The monolithically-integrated design disclosed herein combines three separate subsystems from traditional adsorption heat pumps—the evaporator, condenser, and adsorbent bed, into a single pressure vessel. This consolidation increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com