Polishing device

a technology of polishing head and polishing head, which is applied in the direction of grinding head, grinding machine components, manufacturing tools, etc., can solve the problems of easy wear of the polishing head, easy collapse of the outer edge of the workpiece polished by the polishing head, and complicated polishing procedur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

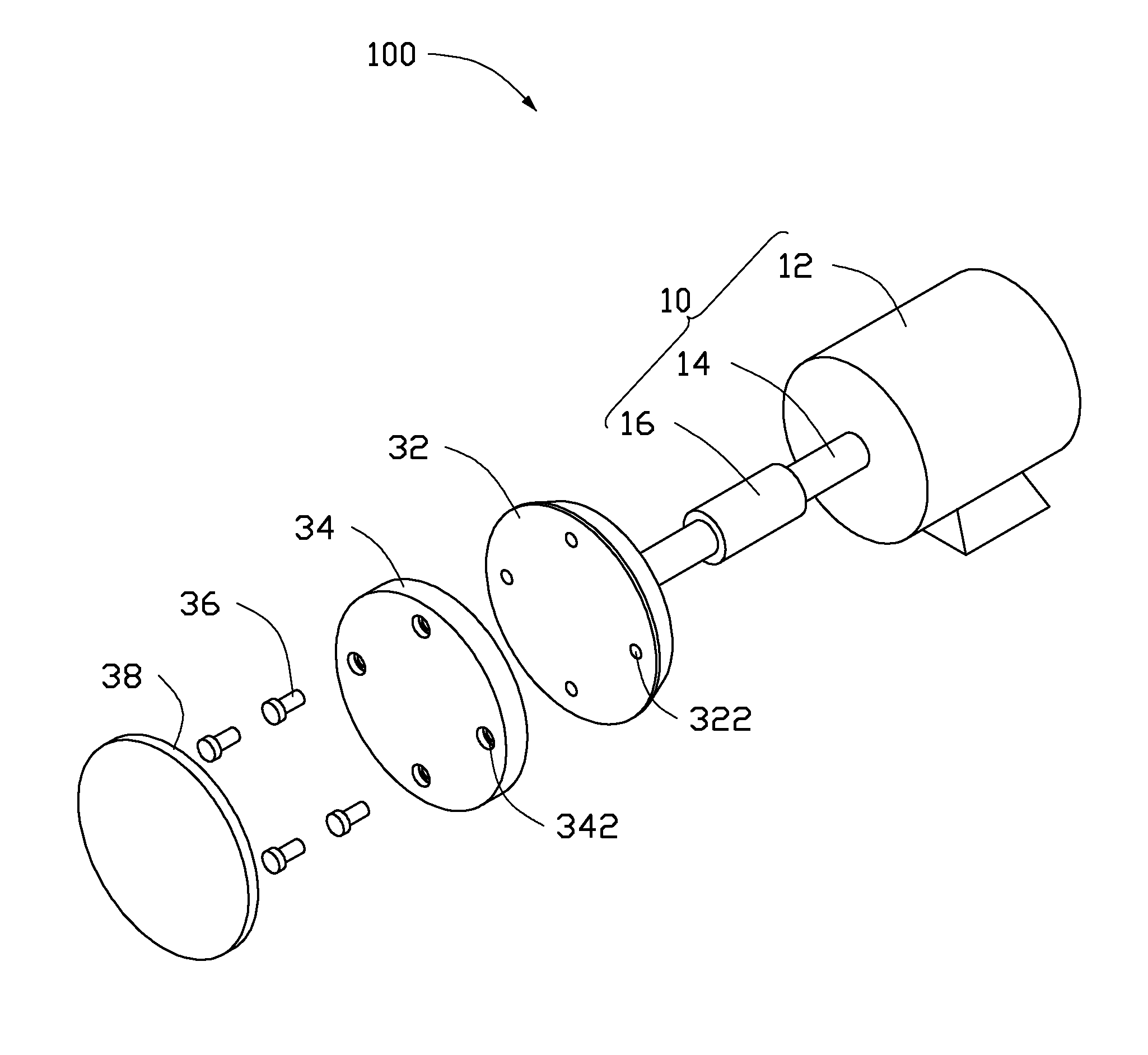

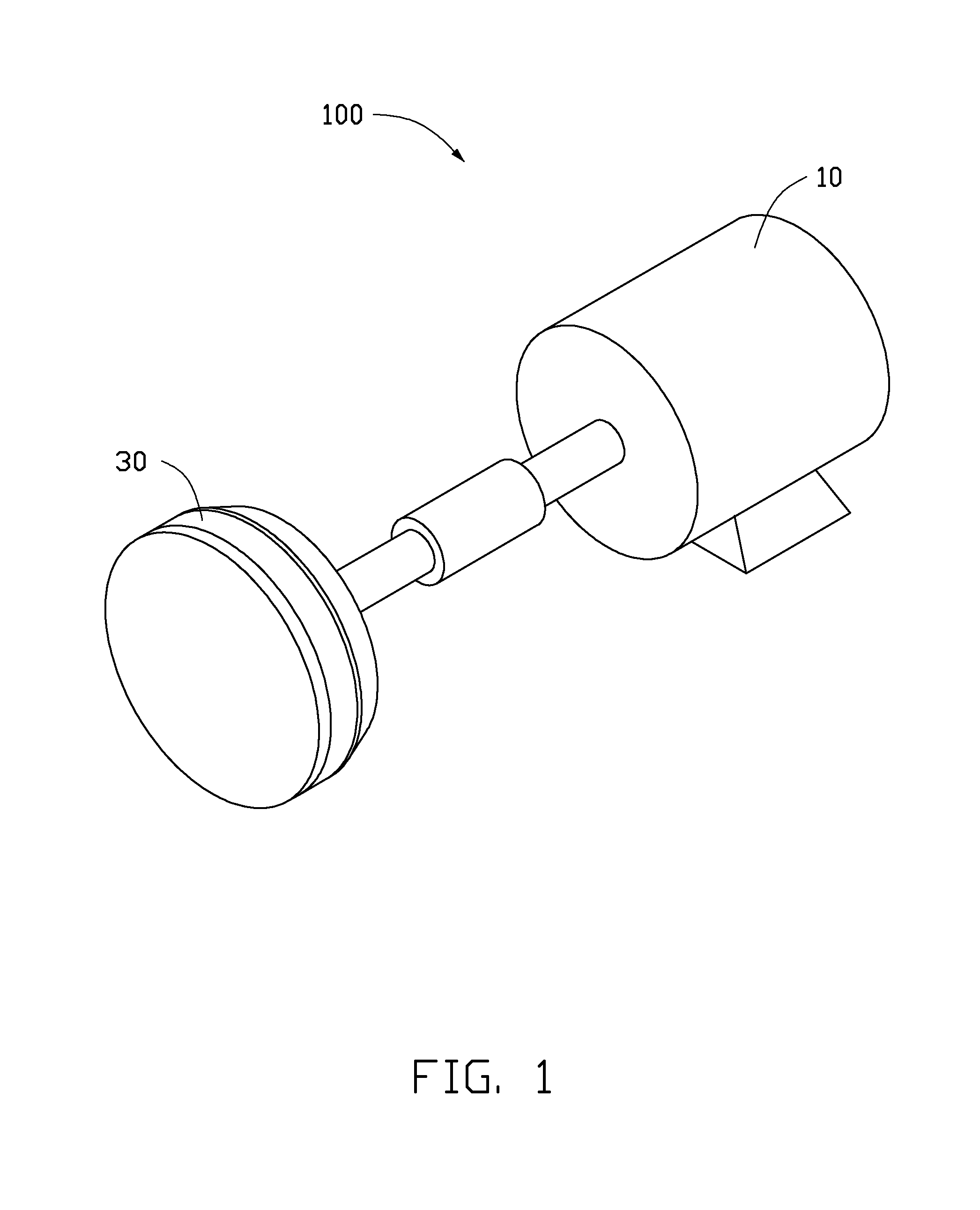

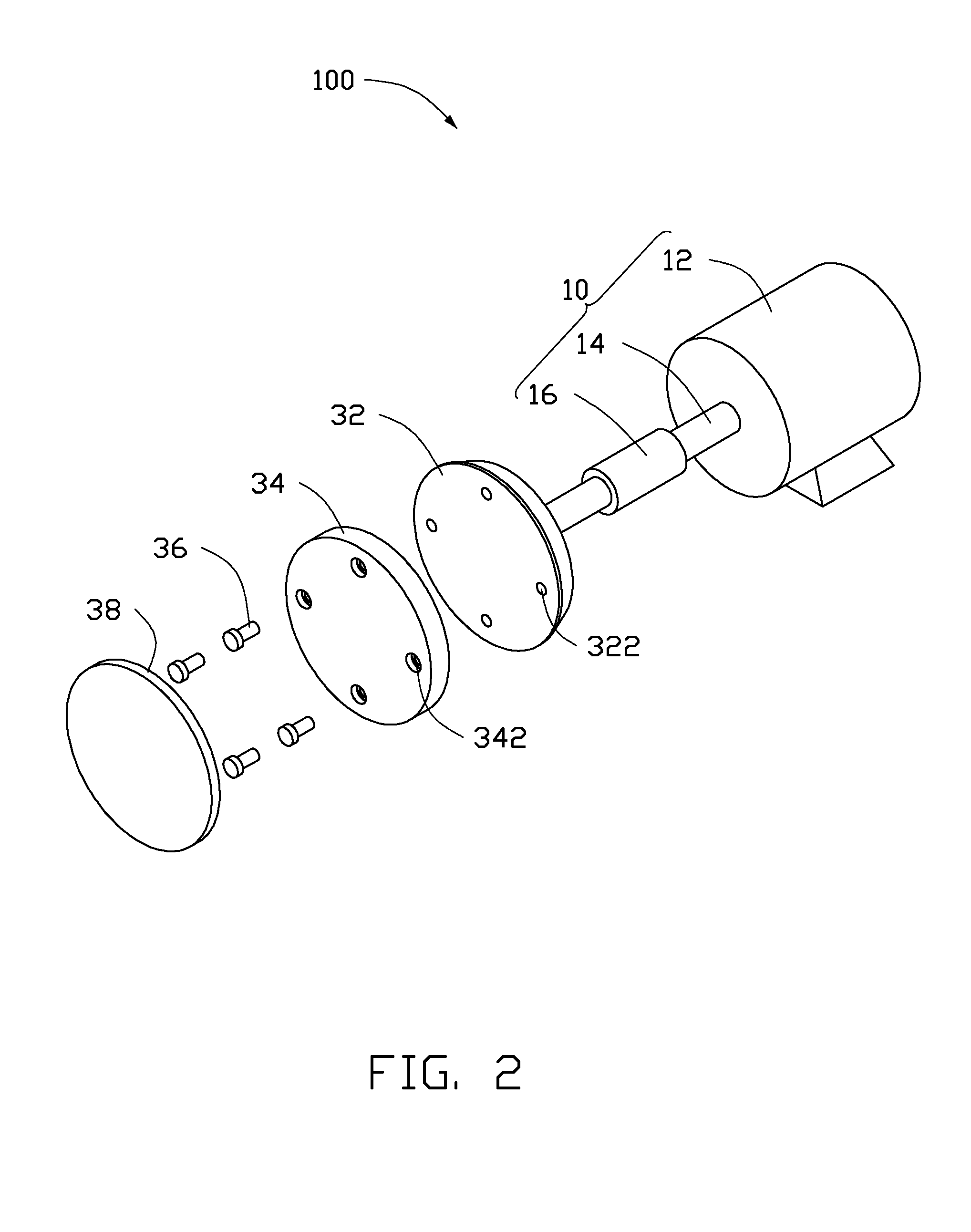

[0009]FIGS. 1 and 2 show an embodiment of a polishing device 100 employed to polish a housing of an electronic device, such as a desktop computer, a notebook, a tablet computer, or a mobile phone, thereby enhancing a finish of the housing. The polishing device 100 includes a driving member 10 and a polishing head 30 connected to the driving member 10. The polishing head 30 is driven by the driving member 10 to rotate and polish a surface of the housing.

[0010]The driving member 10 includes a driving body 12, an elastic coupler 16, and a rotating shaft 14 interconnecting the elastic coupler 16 and the driving body 12. The driving body 12 drives the elastic coupler 16 to rotate via the rotating shaft 14.

[0011]The polishing head 30 is substantially disc-shaped and is connected to the elastic coupler 16. The polishing head 30 includes a rotating body 32, a buffering pad 34, a plurality of fixing members 36, and an abrasive paper 38. In the embodiment, the rotating body 32 is made of meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com