Vapor chamber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The above objective and structural and functional features of the present invention will be described with reference to the preferred embodiments in the accompanying drawings.

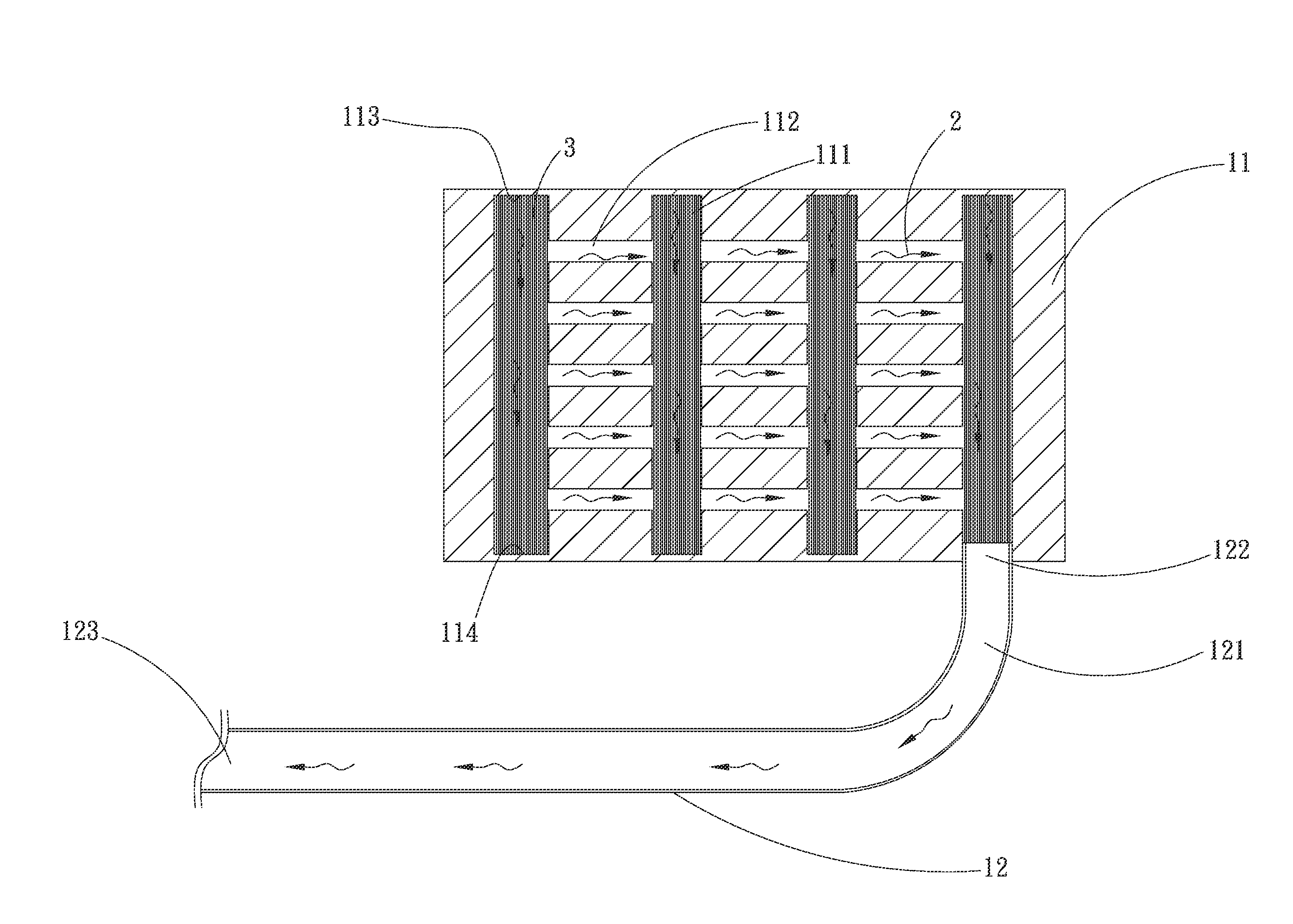

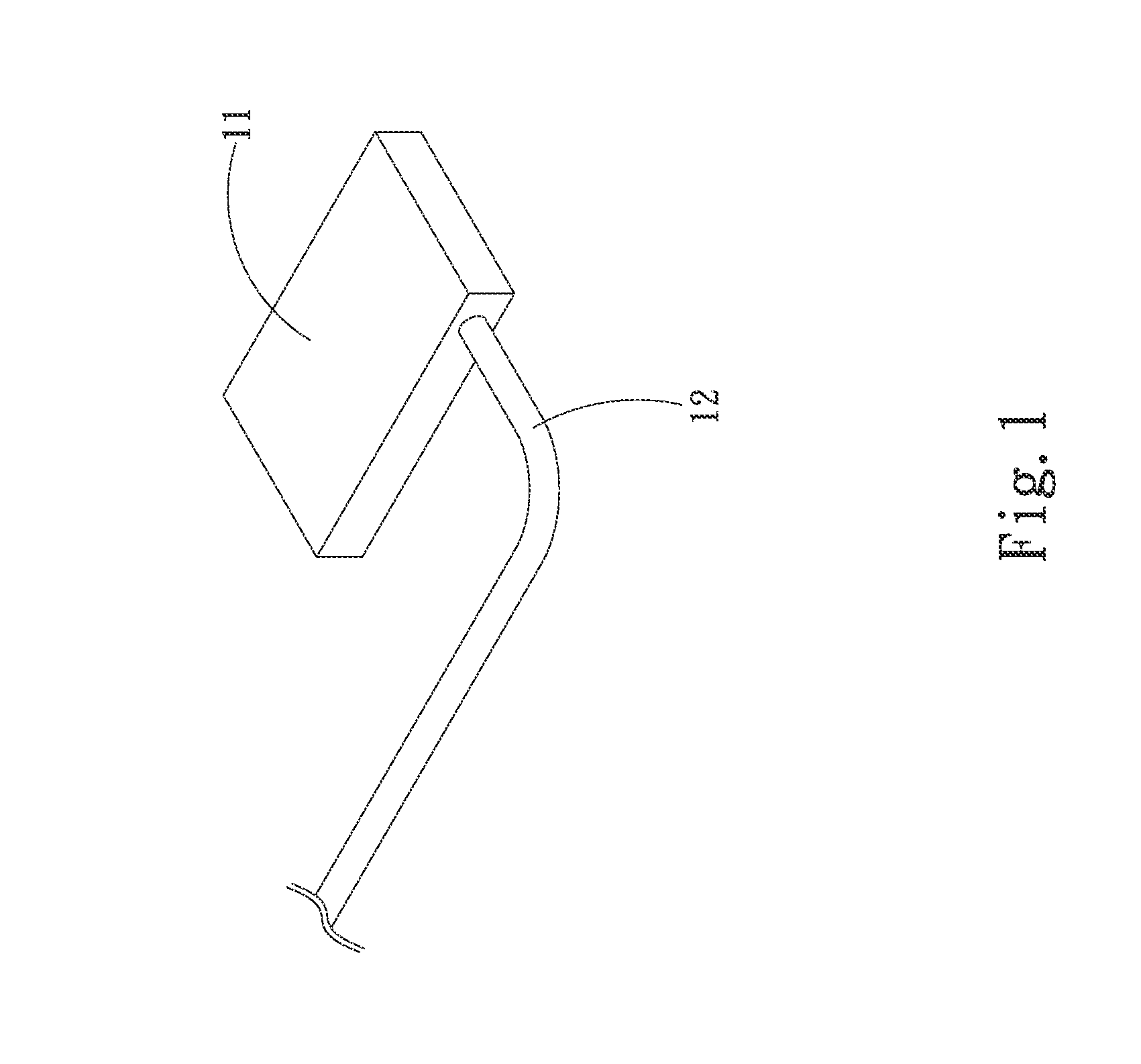

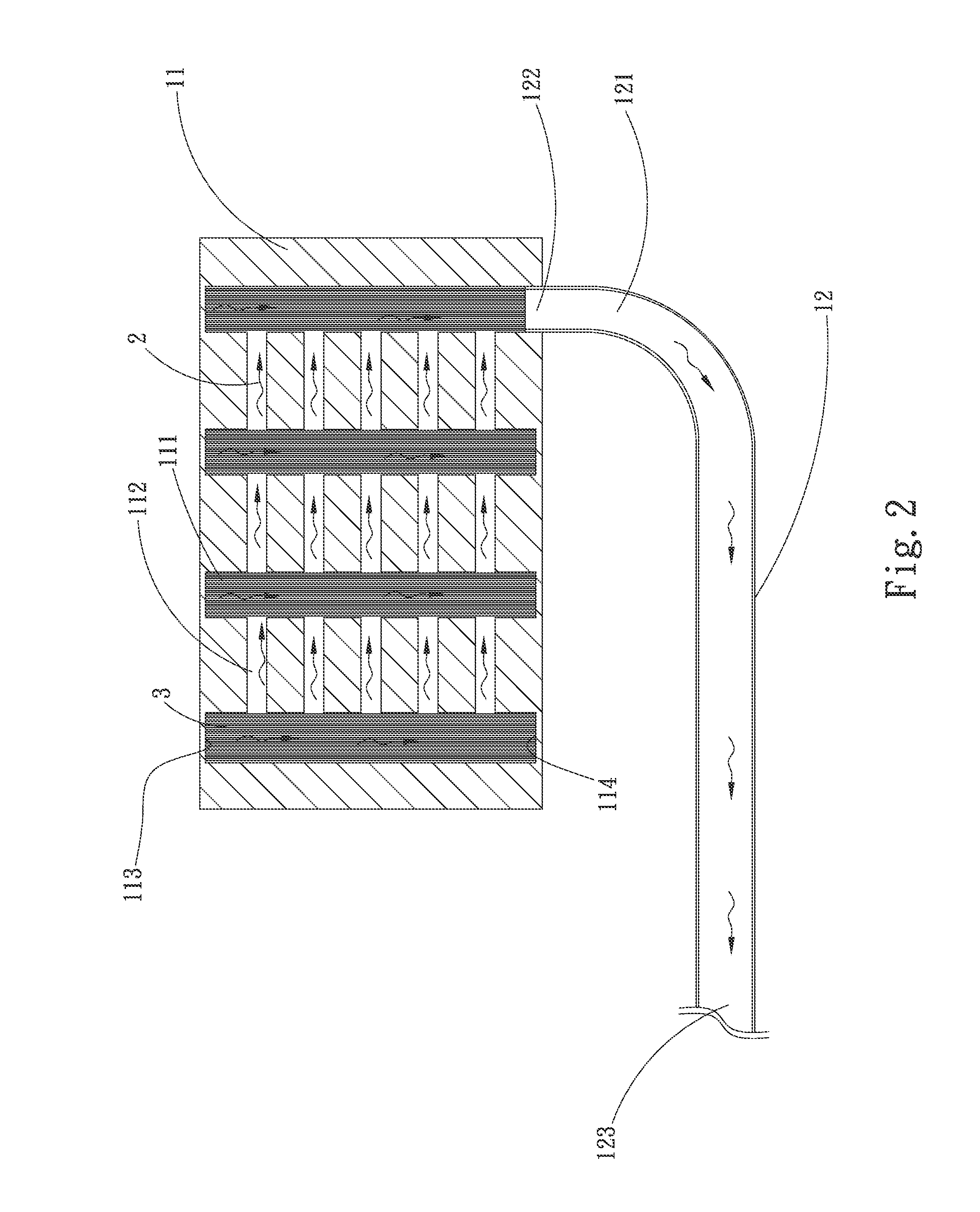

[0017]Please refer to FIGS. 1 and 2, which are the perspective view and cross-sectional assembled view of the improvement to a vapor chamber structure according to the first embodiment. As shown in FIGS. 1 and 2, the improvement to a vapor chamber structure according to the current embodiment comprises a first body 11, a second body 12, and a working fluid 2.

[0018]The first body 11 has a plurality of first channels 111 and a plurality of second channels 112, the first and second channels 111, 112 communicating with one another.

[0019]The first and second channels 111, 112 communicate with and intersect with one another at right angles. The first body 11 comprises a first enclosure side 113 and a second enclosure side 114 which seal two ends of the first channels 111, respectively.

[0020]The second body 12 h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap