Integrated power generation and carbon capture using fuel cells

a fuel cell and power generation technology, applied in the direction of fuel cells, electrochemical generators, electrical equipment, etc., can solve the problems of reducing the overall efficiency of the power generation process and the net reduction of the power generation efficiency per unit of fuel consumed, and achieve the effect of reducing the emissions of co2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

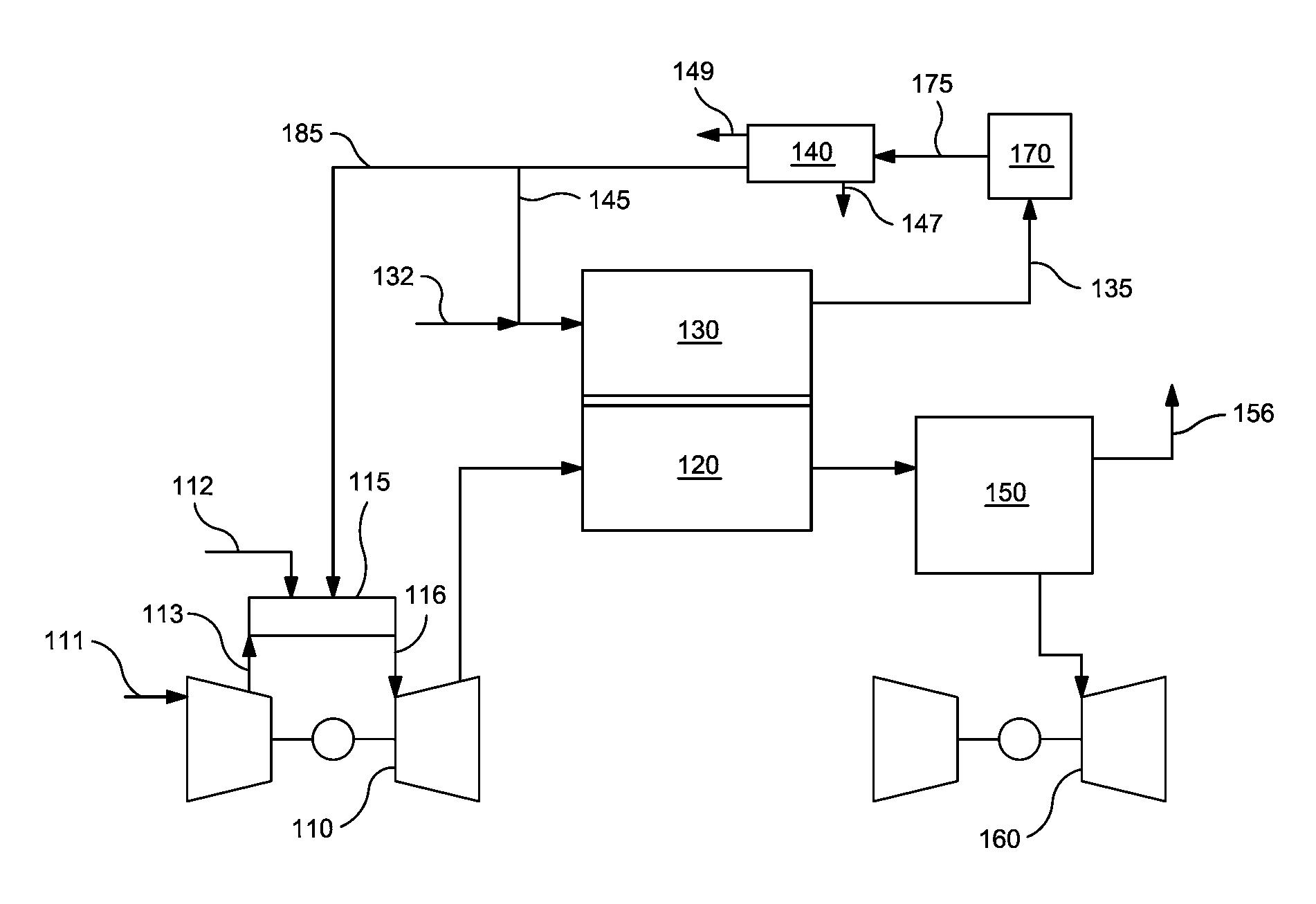

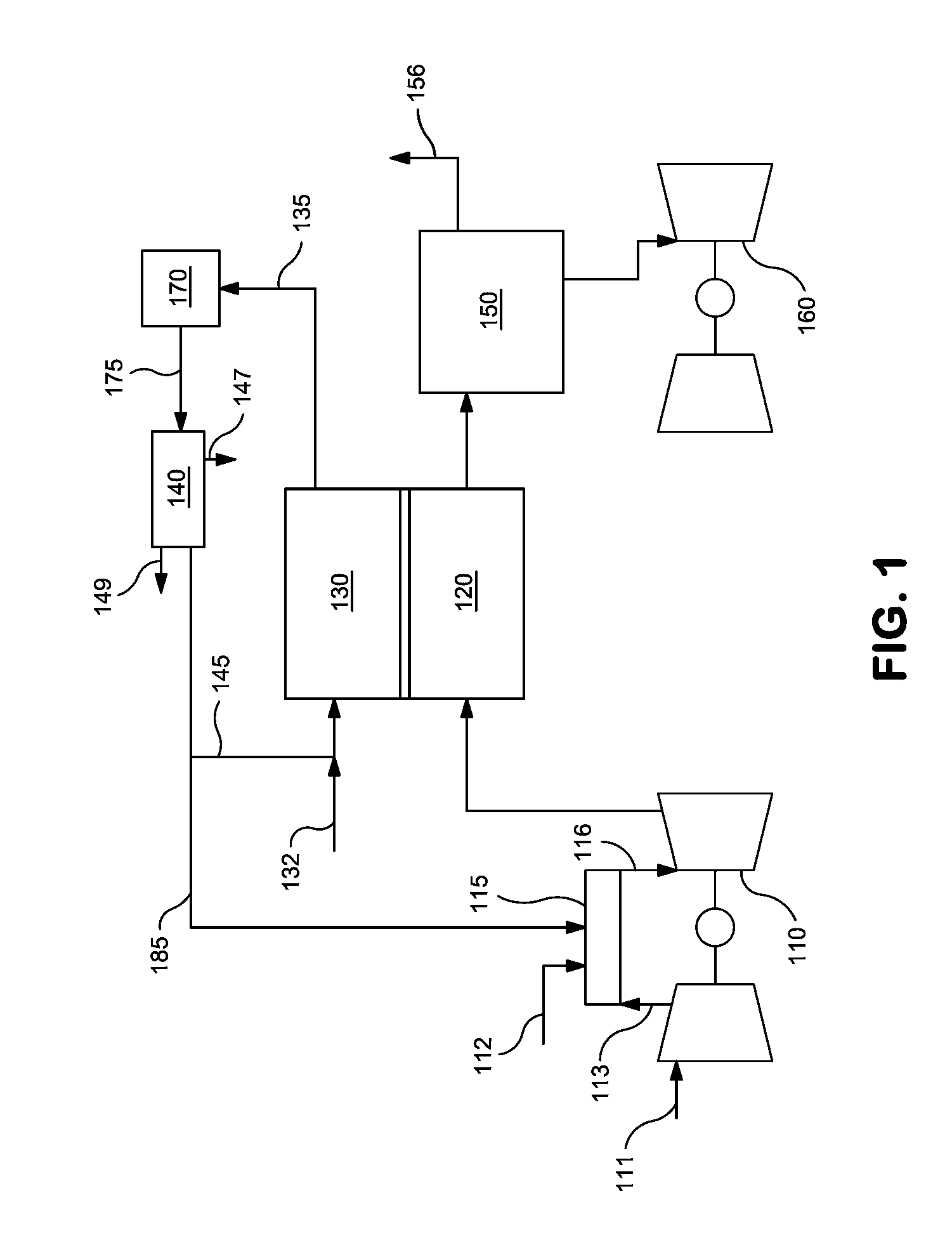

[0171]A series of simulations were performed in order to demonstrate the benefits of using an improved configuration for using a fuel cell for CO2 separation. The simulations were based on empirical models for the various components in the power generation system. The simulations were based on determining steady state conditions within a system based on mass balance and energy balance considerations.

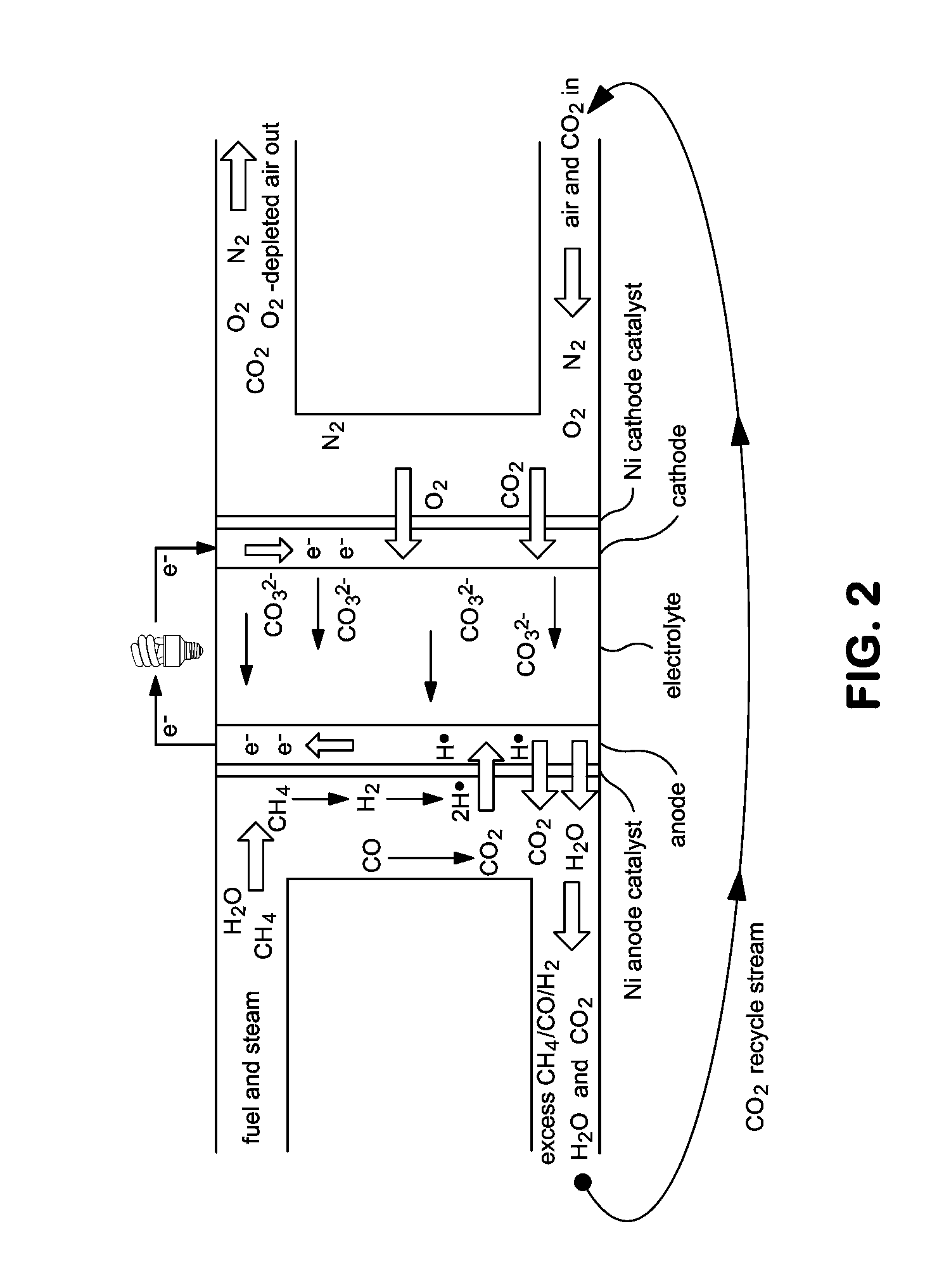

[0172]For the combustion reaction for the turbine, the model included an expected combustion energy value and expected combustion products for each fuel component in the feed to the combustion zone (such as C1-C4 hydrocarbon, H2, and / or CO). This was used to determine the combustion exhaust composition. An initial reforming zone prior to the anode can be operated using an “idealized” reforming reaction to convert CH4 to H2. The anode reaction was modeled to also operate to perform further reforming during anode operation. It is noted that the empirical model for the anode did not require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap