Water Purification Using Energy from a Steam-Hydrocarbon Reforming Process

a technology of water purification and hydrocarbon reforming, which is applied in the direction of energy input, separation process, contaminated groundwater/leachate treatment, etc., can solve the problems of high capital cost, large amount of waste heat, and large amount of high pressure export steam, and achieves greater heat utilization of waste heat and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

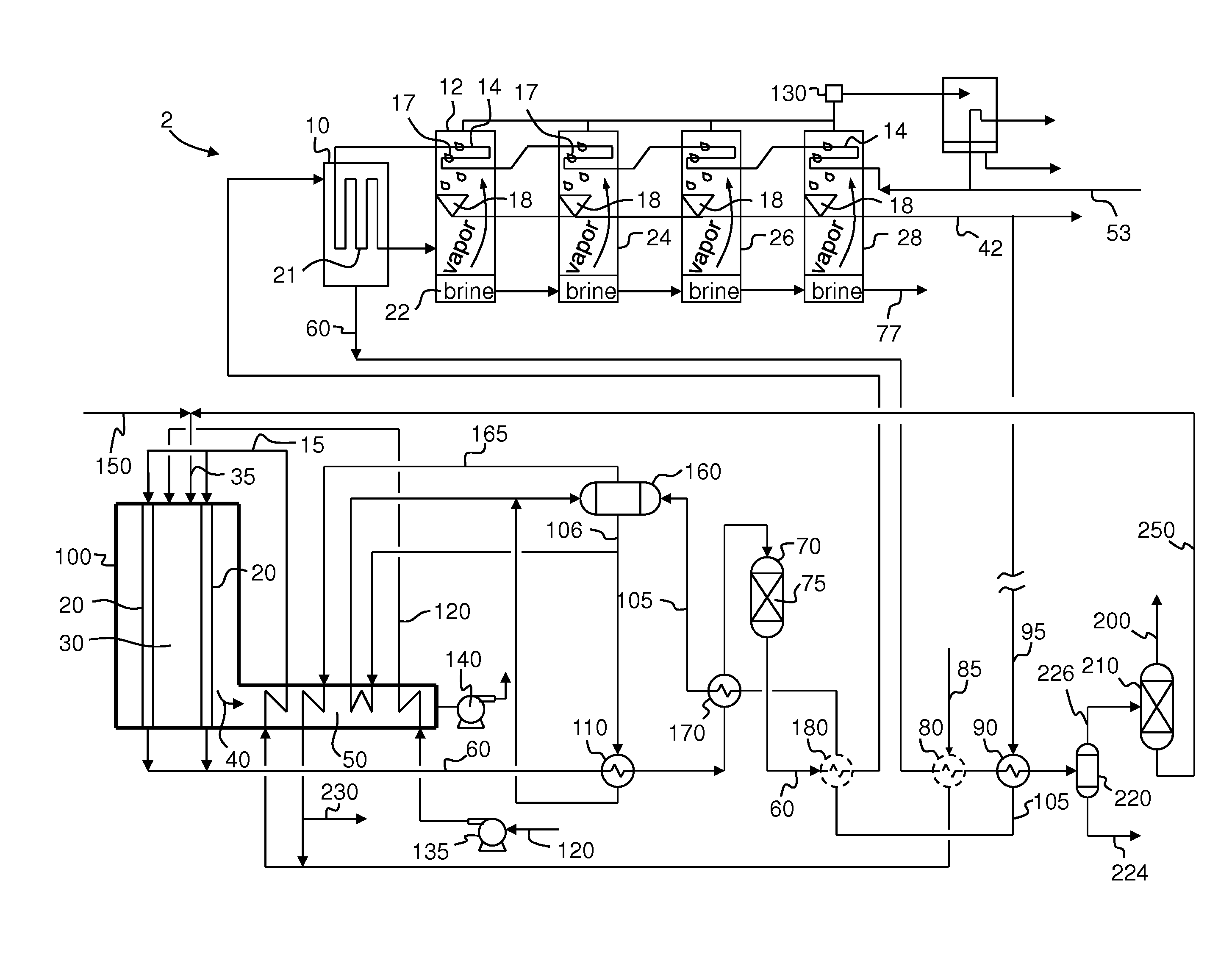

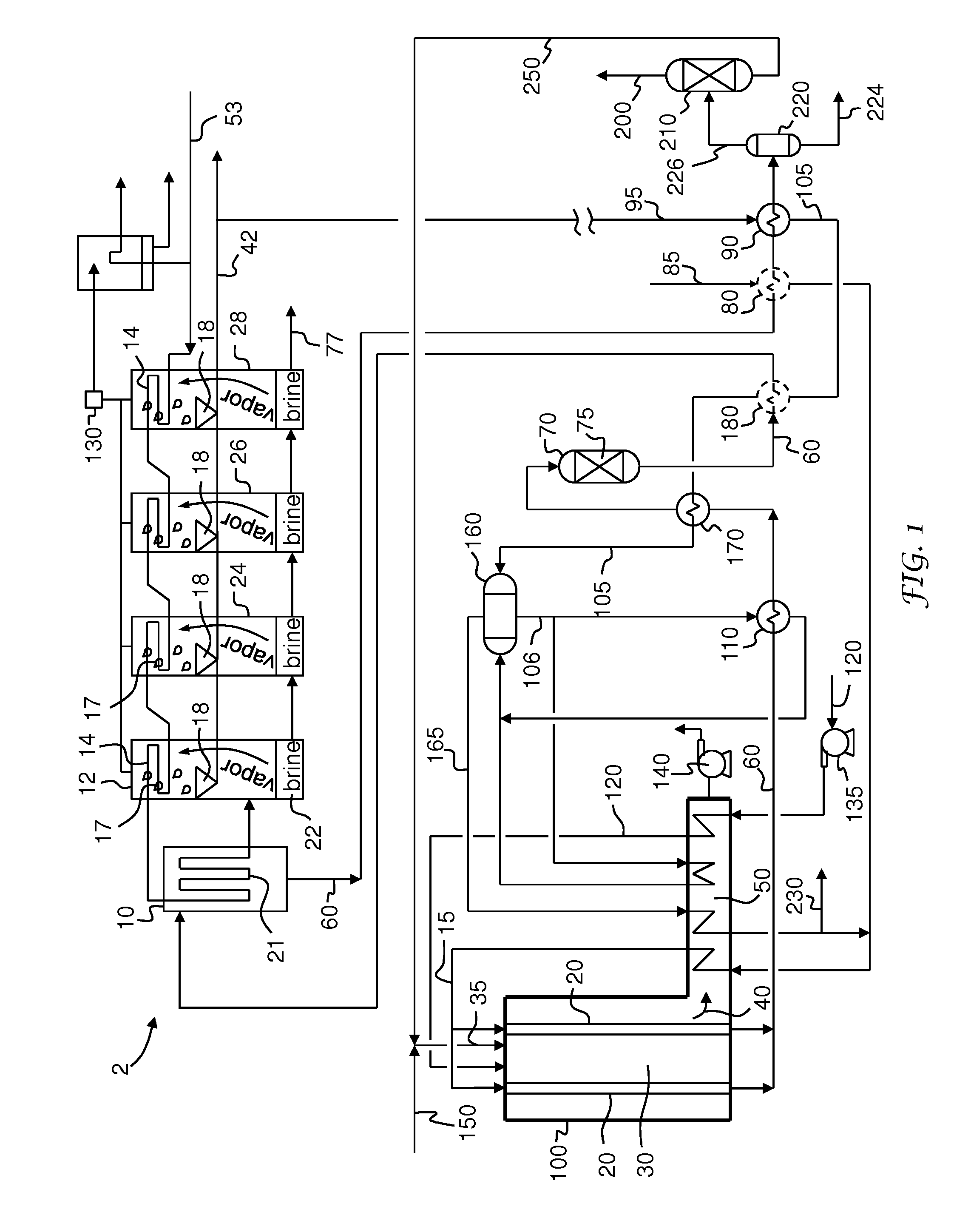

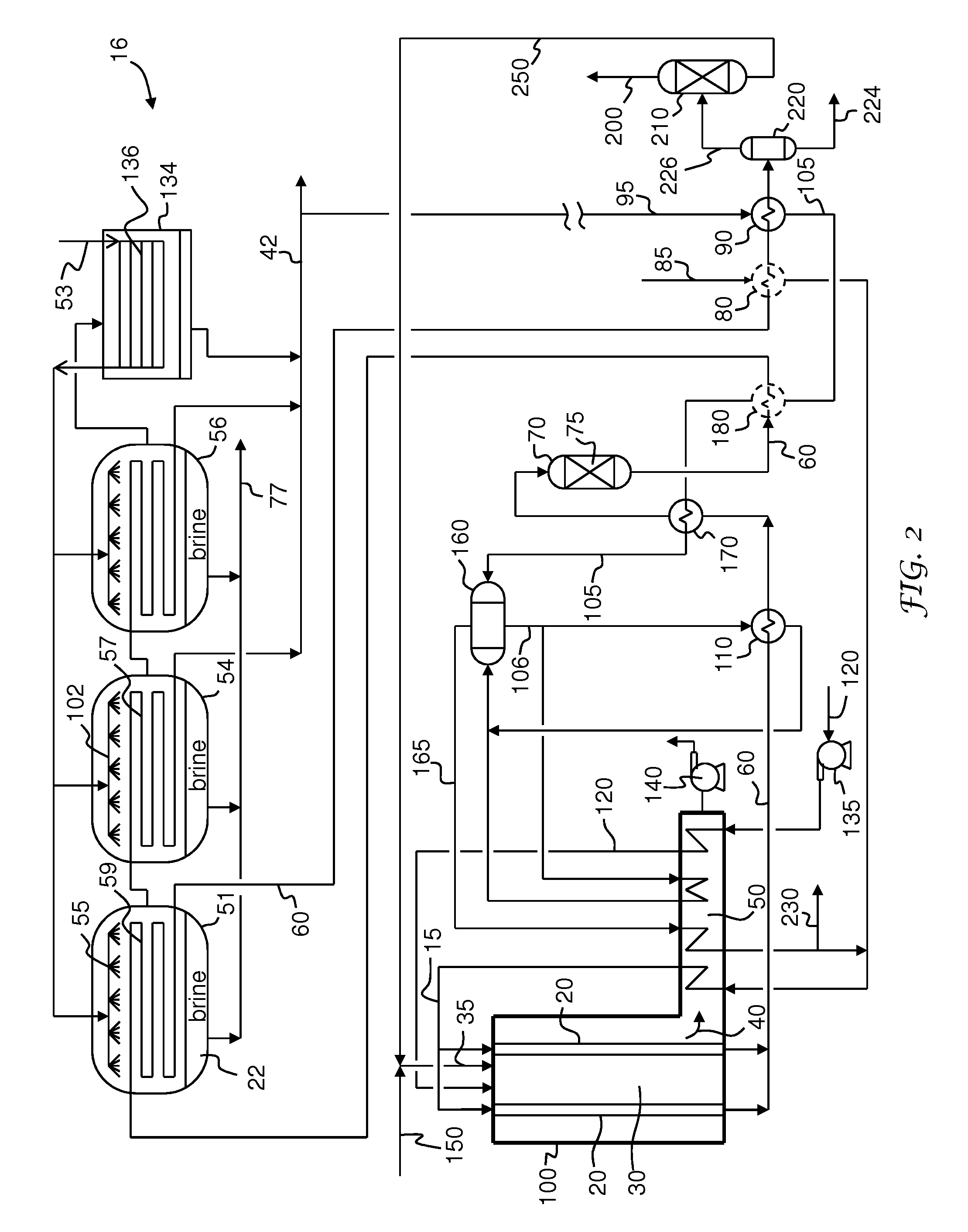

[0230]The following is an example showing the heat utilization of the embodiment of FIG. 2 as compared to the embodiment of FIG. 7. Certain simulation parameters and simulated data have been excluded from the following discussion for clarity.

[0231]Example 1 is based on the embodiment shown in FIG. 2. The reformate is withdrawn from the SMR unit upstream of a heat exchanger (e.g., heat exchanger 90) for preheating SMR make-up water with reformate, and optionally, another heat exchanger (e.g., optional heat exchanger 80) for preheating the hydrocarbon feed with reformate. The reformate is fed to a first evaporator of a series of evaporators of the MED unit at 159 C and returns to the SMR unit at 144 C after providing the heat for water evaporation in the first evaporator of the MED unit. The amount of the reformate heat utilized in the MED unit for producing purified water is 47.9 GJ / hr. The return reformate is used in the SMR unit to heat the make-up water. The reformate is then cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com