Computer-aided die design apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

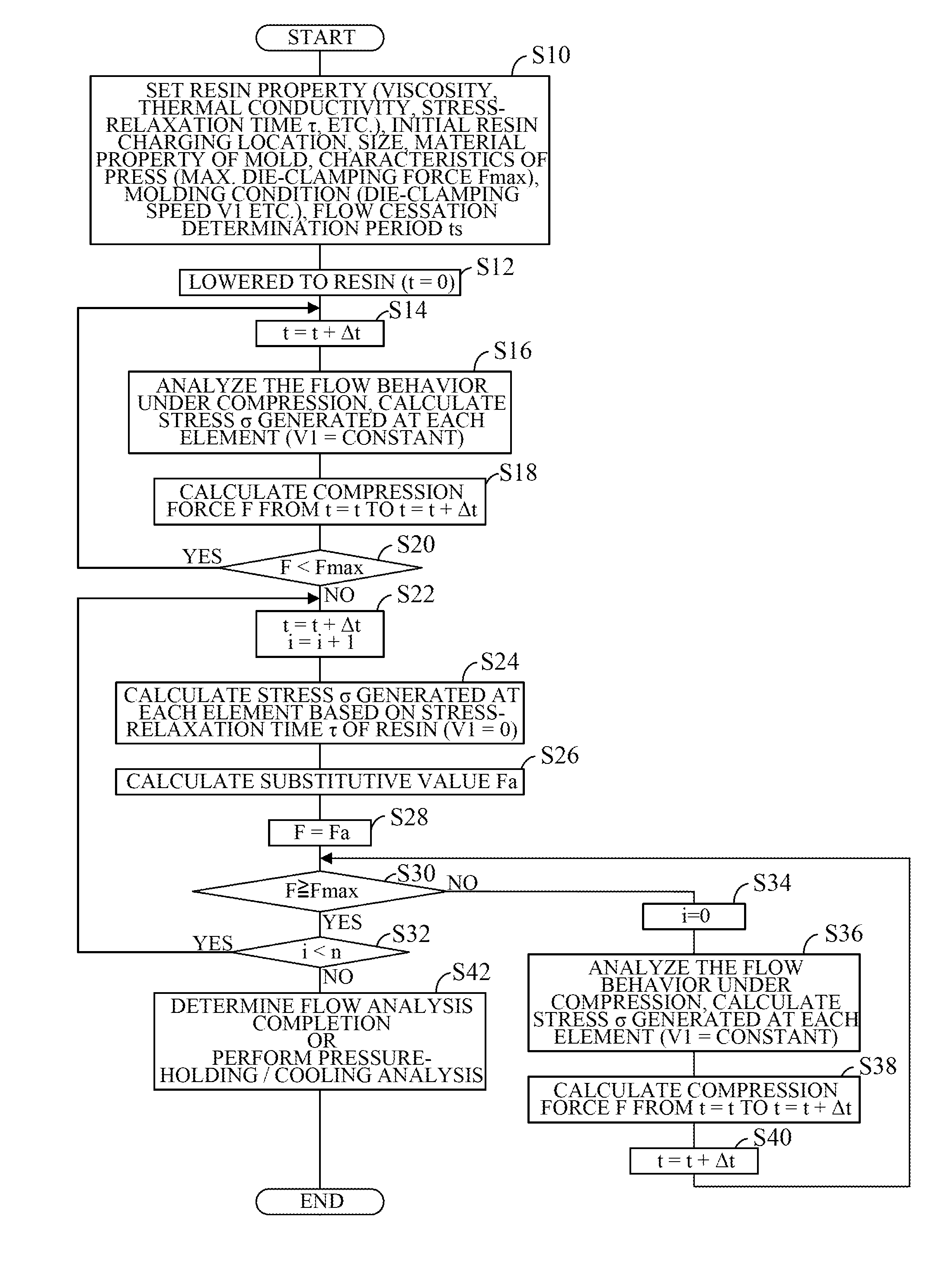

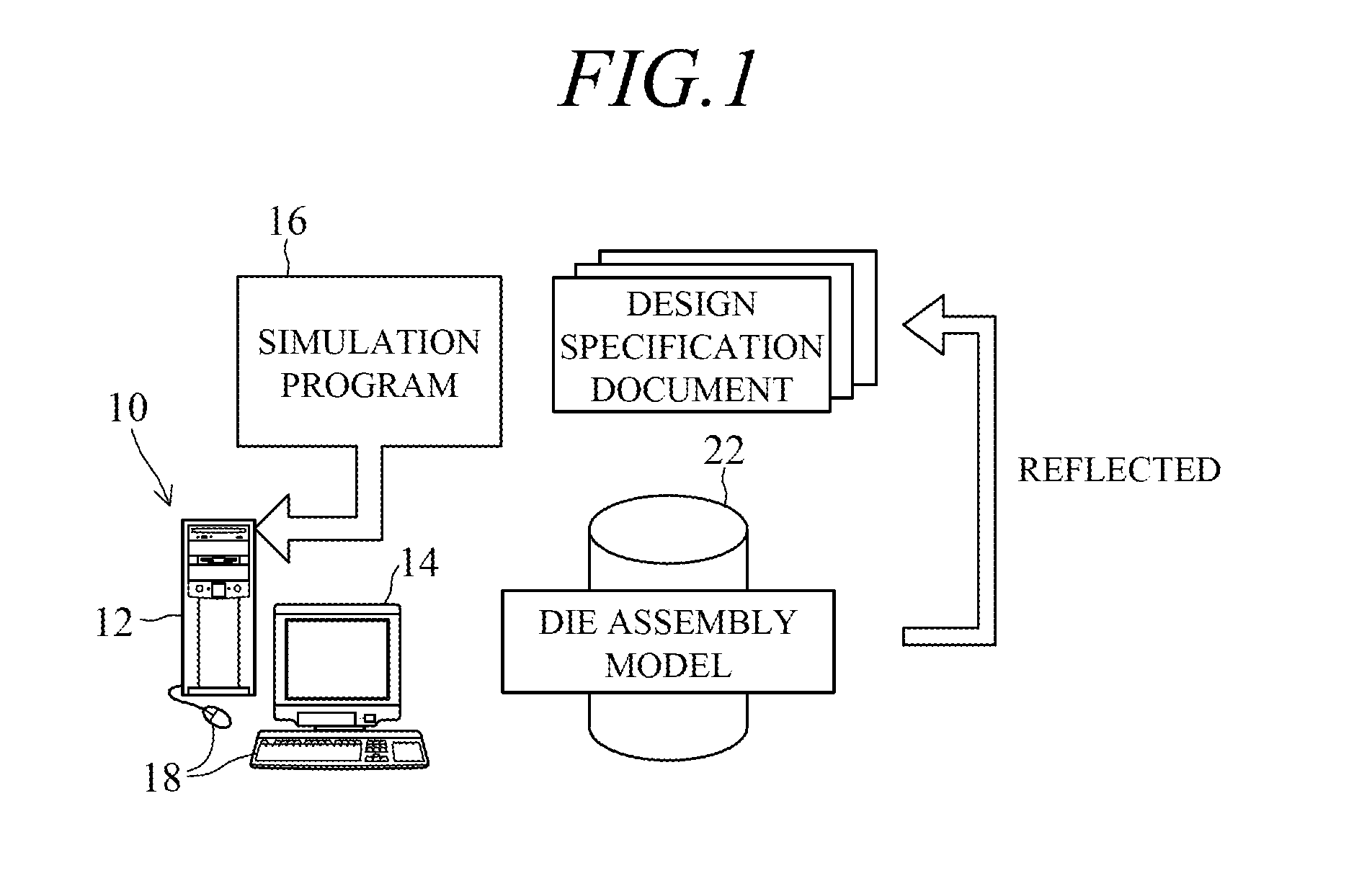

[0016]FIG. 1 is an overall schematic view of a computer-aided die design apparatus according to this invention.

[0017]Reference symbol 10 in FIG. 1 designates the apparatus, and the apparatus 10 comprises a computer 12, a display 14 connected to the computer 12, an interactive simulation program (sumulator) 16 loaded in the computer 12 that analyzes and displays on the display 14 resin flow behavior when resin charged into a die cavity is die-clamped by a press at a compression force F, and input devices 18 such as a keyboard, mouse and the like.

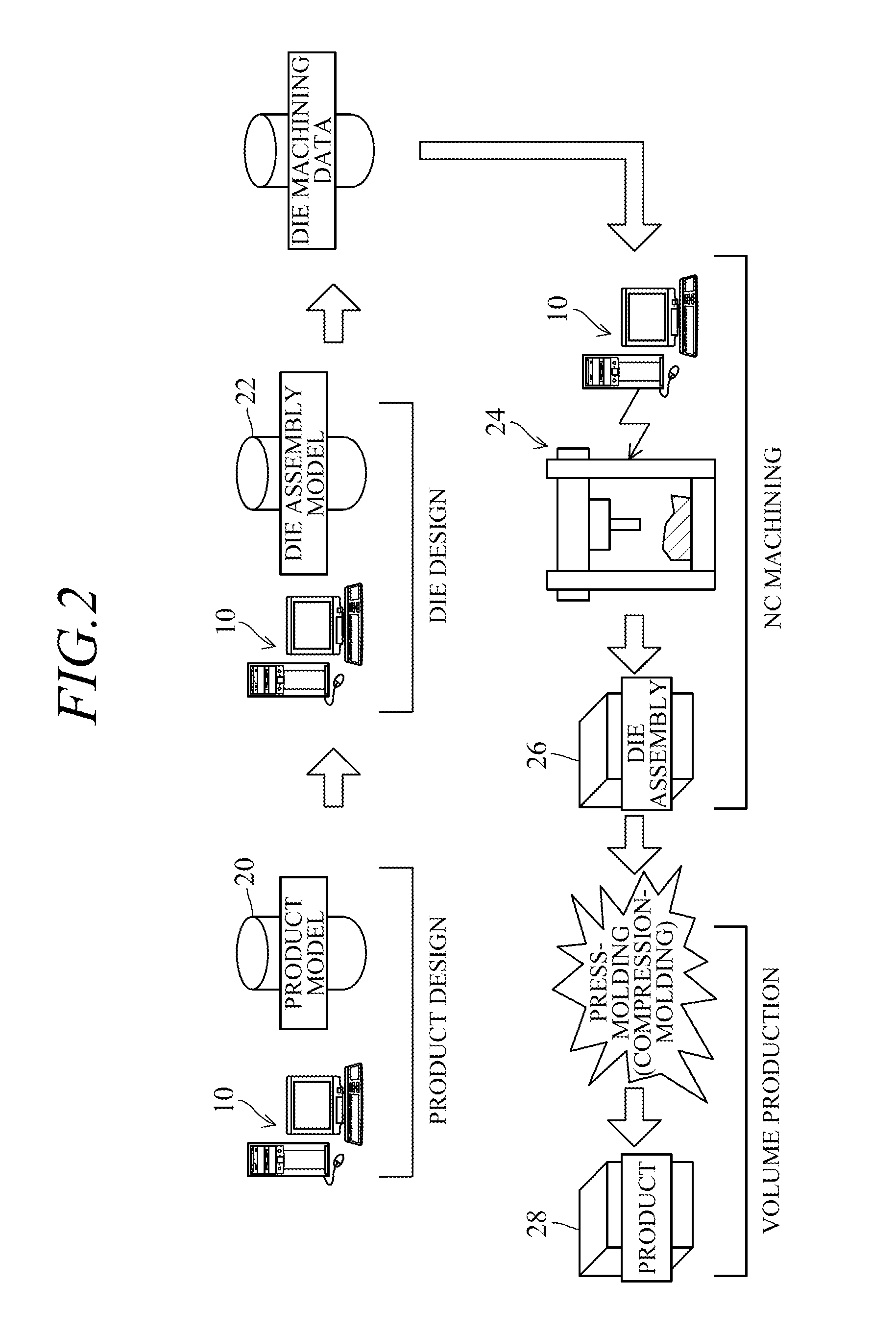

[0018]Thus, the apparatus 10 is configured as a die design apparatus utilizing CAE (Computer Aided Engineering), CAD (Computer Aided Design) / CAM (Computer Aided Manufacturing), or CIM (Computer Integrated Manufacturing).

[0019]In concrete terms, die design is performed as one part of a series of processes extending from product design to volume production, wherein a design engineer uses the input devices 18 to input data into the computer 12 i...

second embodiment

[0059]FIG. 6 is a flowchart, similar to that of FIG. 4, showing operations of the simulation program 16 of a computer-aided die design apparatus according to this invention.

[0060]Processing steps that are common between the flowchart of FIG. 6 and the flowchart of FIG. 4 are not explained in detail and the following explanation is focused on the points of difference from the first embodiment.

[0061]The first embodiment is configured so that in the processing according to the flowchart of FIG. 4, the upper limit value Fmax is set at a fixed value (maximum die-clamping force) determined from the properties of the press, and the die-clamping speed of the upper die 22a is controlled to V1 until the compression force F reaches the upper limit value Fmax.

[0062]In contrast to this, the second embodiment is configured to set the upper limit value at an arbitrary value (set compression force) Fs equal to or less than the maximum die-clamping force determined from the properties of the press.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com