Patents

Literature

710results about "Analogue computers for distribution networks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

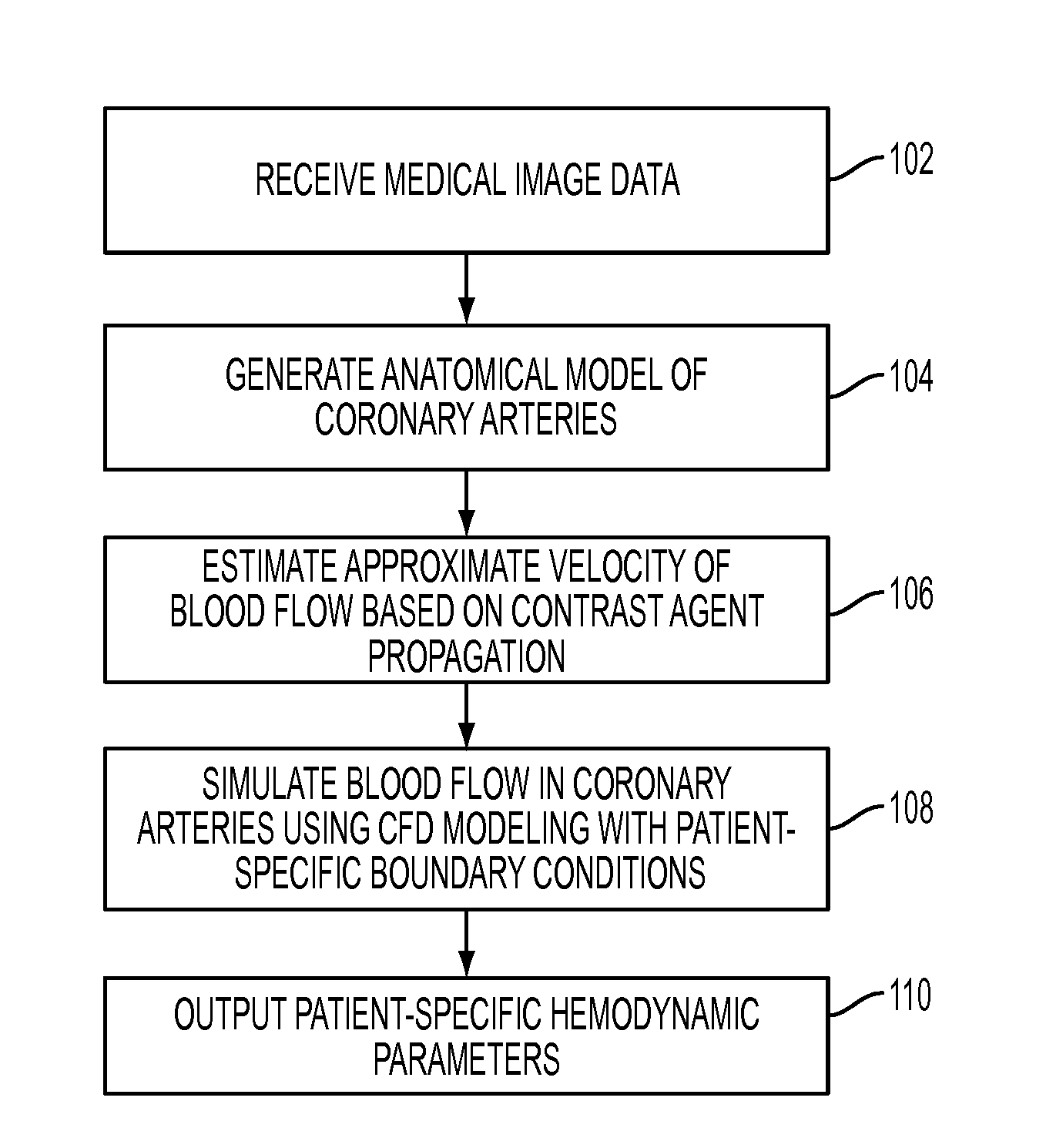

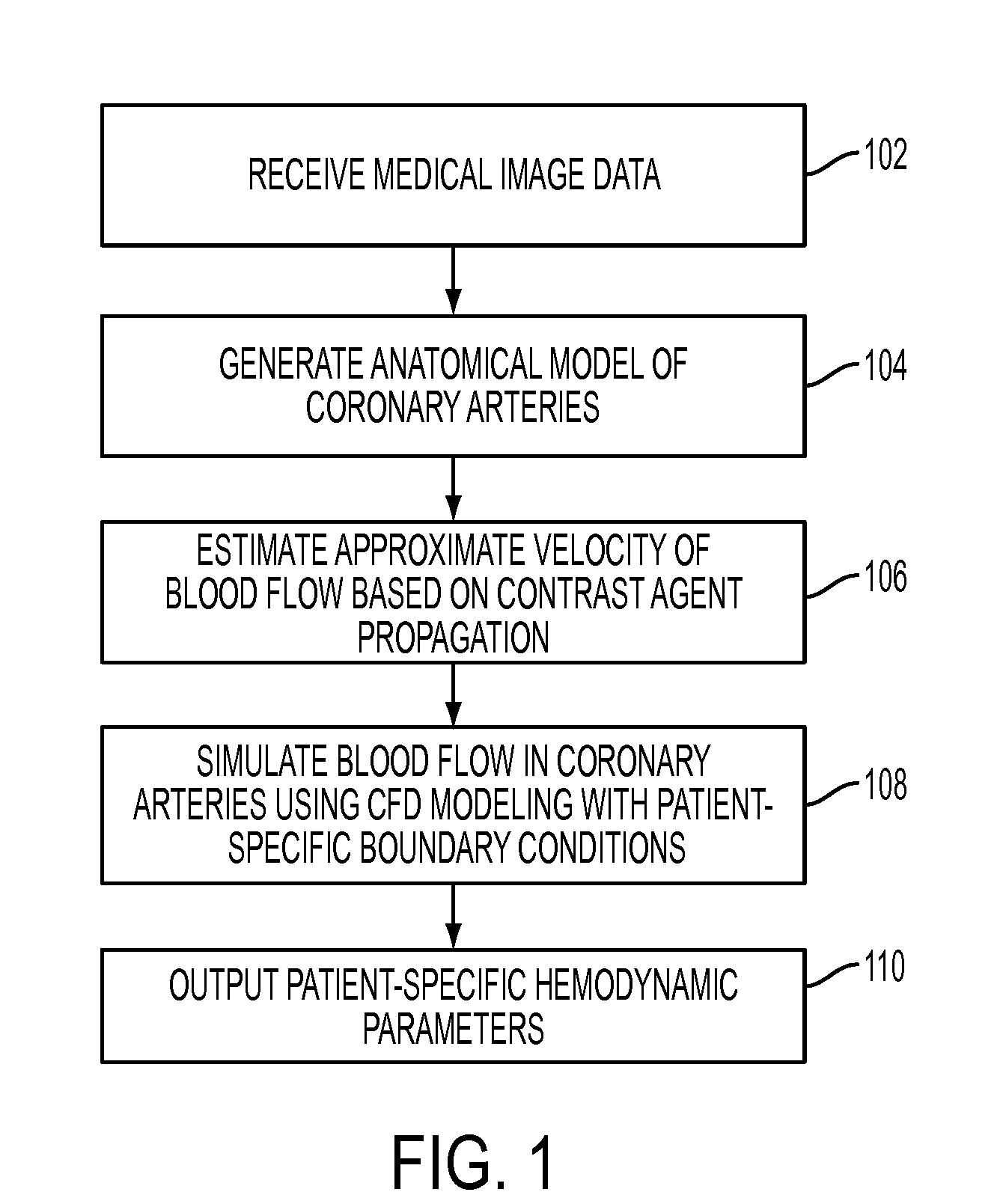

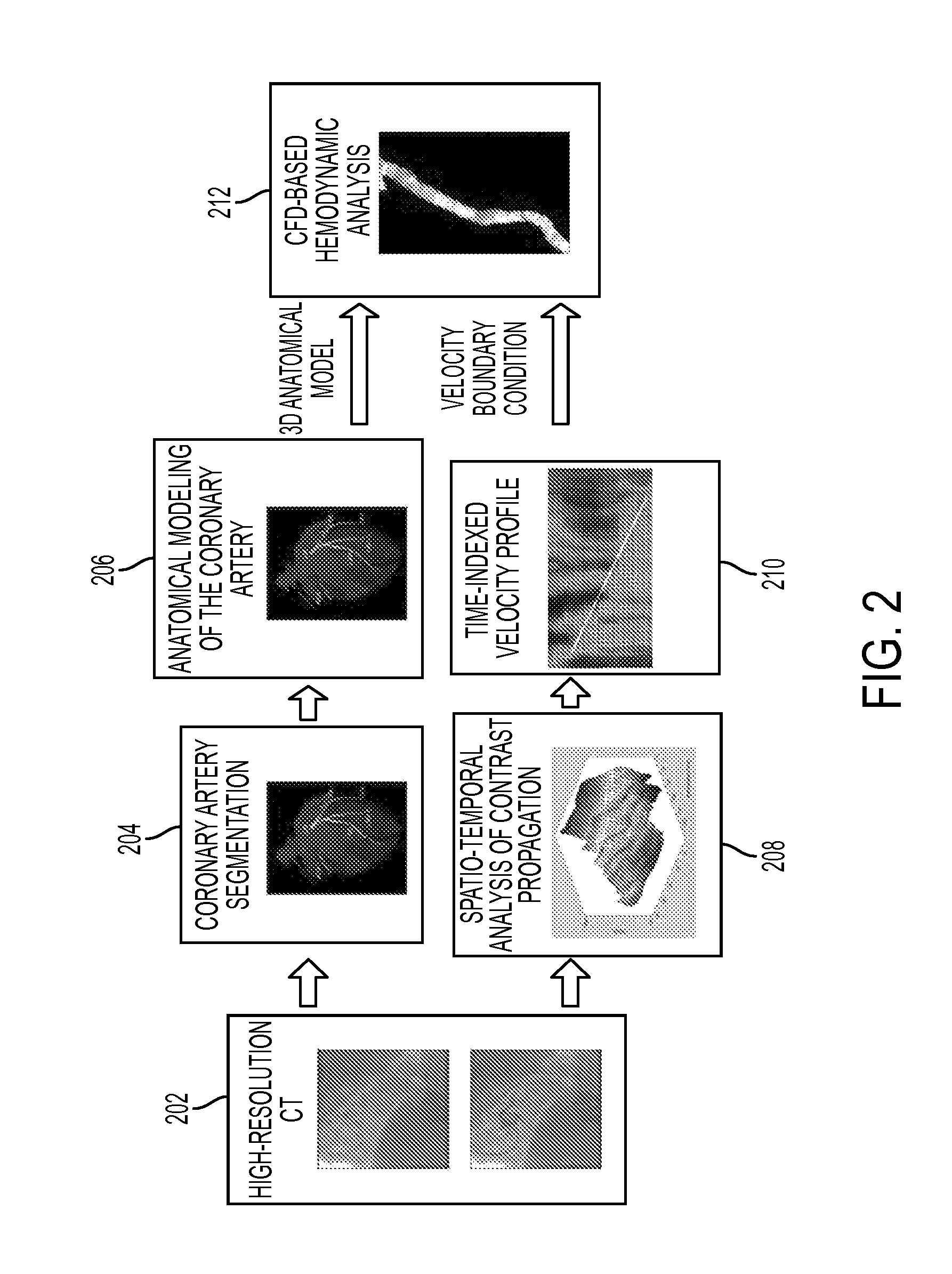

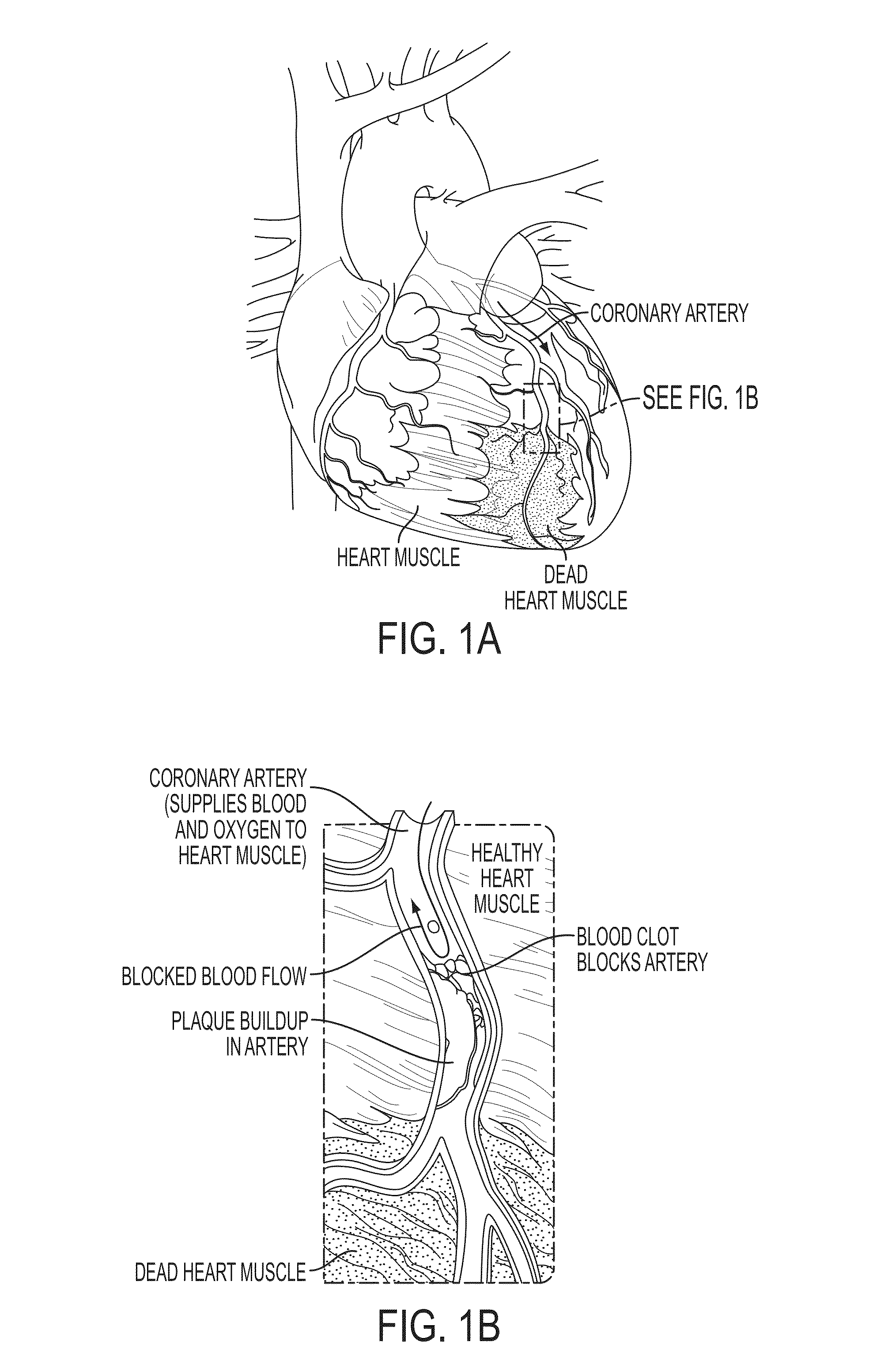

Method and System for Non-Invasive Assessment of Coronary Artery Disease

A method and system for non-invasive patient-specific assessment of coronary artery disease is disclosed. An anatomical model of a coronary artery is generated from medical image data. A velocity of blood in the coronary artery is estimated based on a spatio-temporal representation of contrast agent propagation in the medical image data. Blood flow is simulated in the anatomical model of the coronary artery using a computational fluid dynamics (CFD) simulation using the estimated velocity of the blood in the coronary artery as a boundary condition.

Owner:SIEMENS HEALTHCARE GMBH

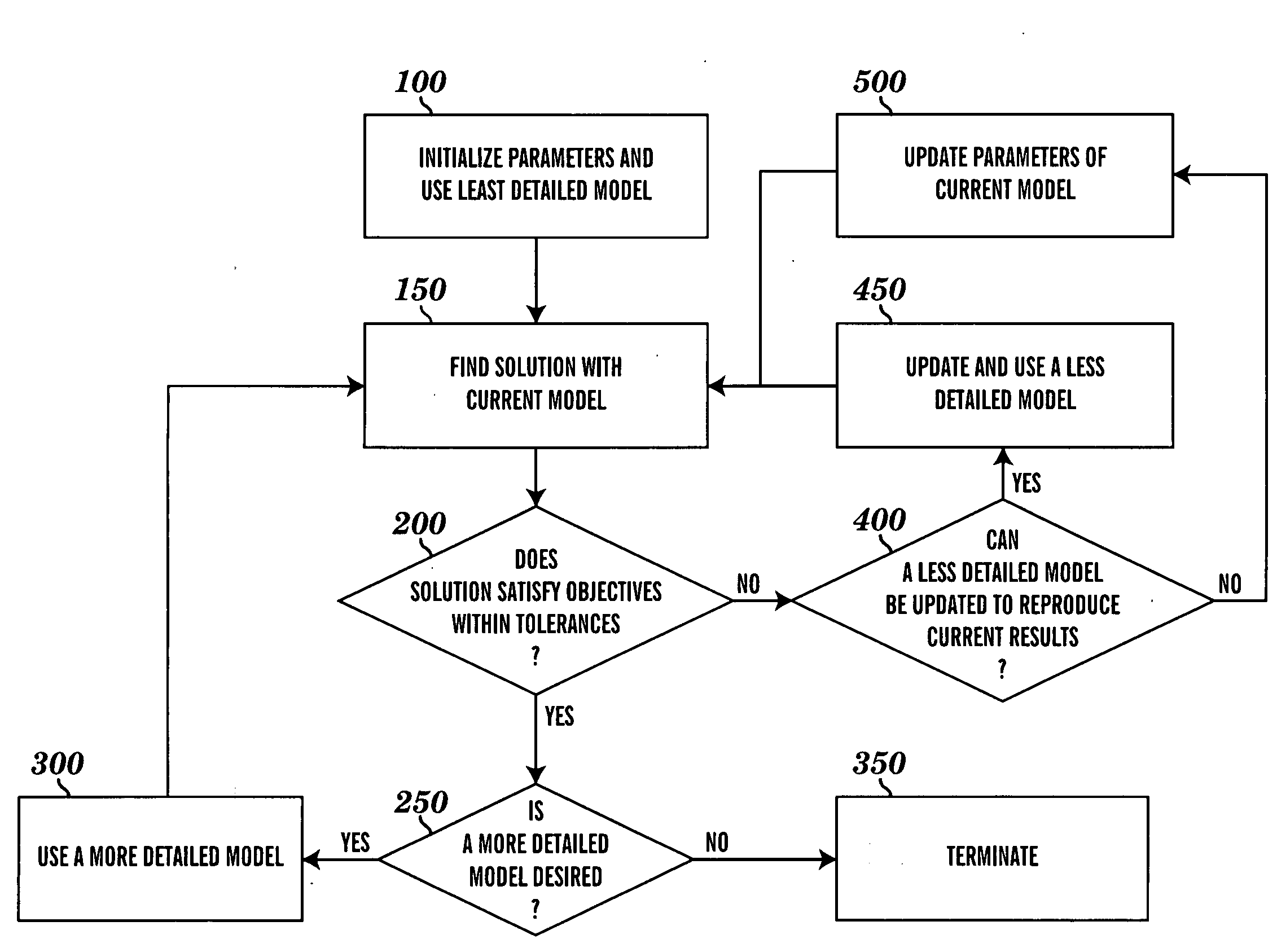

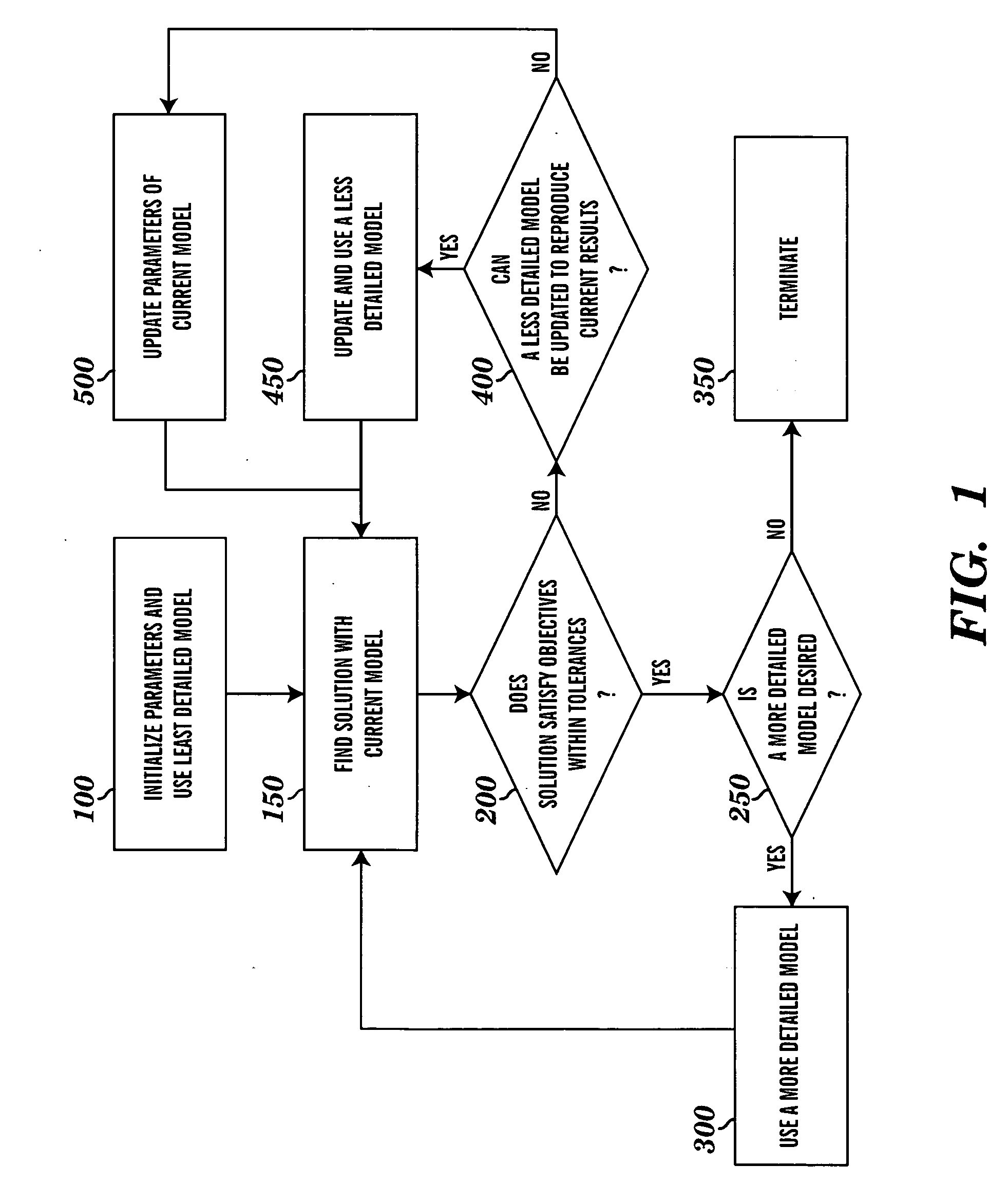

Method for tuning patient-specific cardiovascular simulations

ActiveUS20100017171A1Improve understandingImprove representationMedical simulationAnalogue computers for chemical processesReduced modelComputing Methodologies

Computational methods are used to create cardiovascular simulations having desired hemodynamic features. Cardiovascular modeling methods produce descriptions of blood flow and pressure in the heart and vascular networks. Numerical methods optimize and solve nonlinear equations to find parameter values that result in desired hemodynamic characteristics including related flow and pressure at various locations in the cardiovascular system, movements of soft tissues, and changes for different physiological states. The modeling methods employ simplified models to approximate the behavior of more complex models with the goal of to reducing computational expense. The user describes the desired features of the final cardiovascular simulation and provides minimal input, and the system automates the search for the final patient-specific cardiovascular model.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

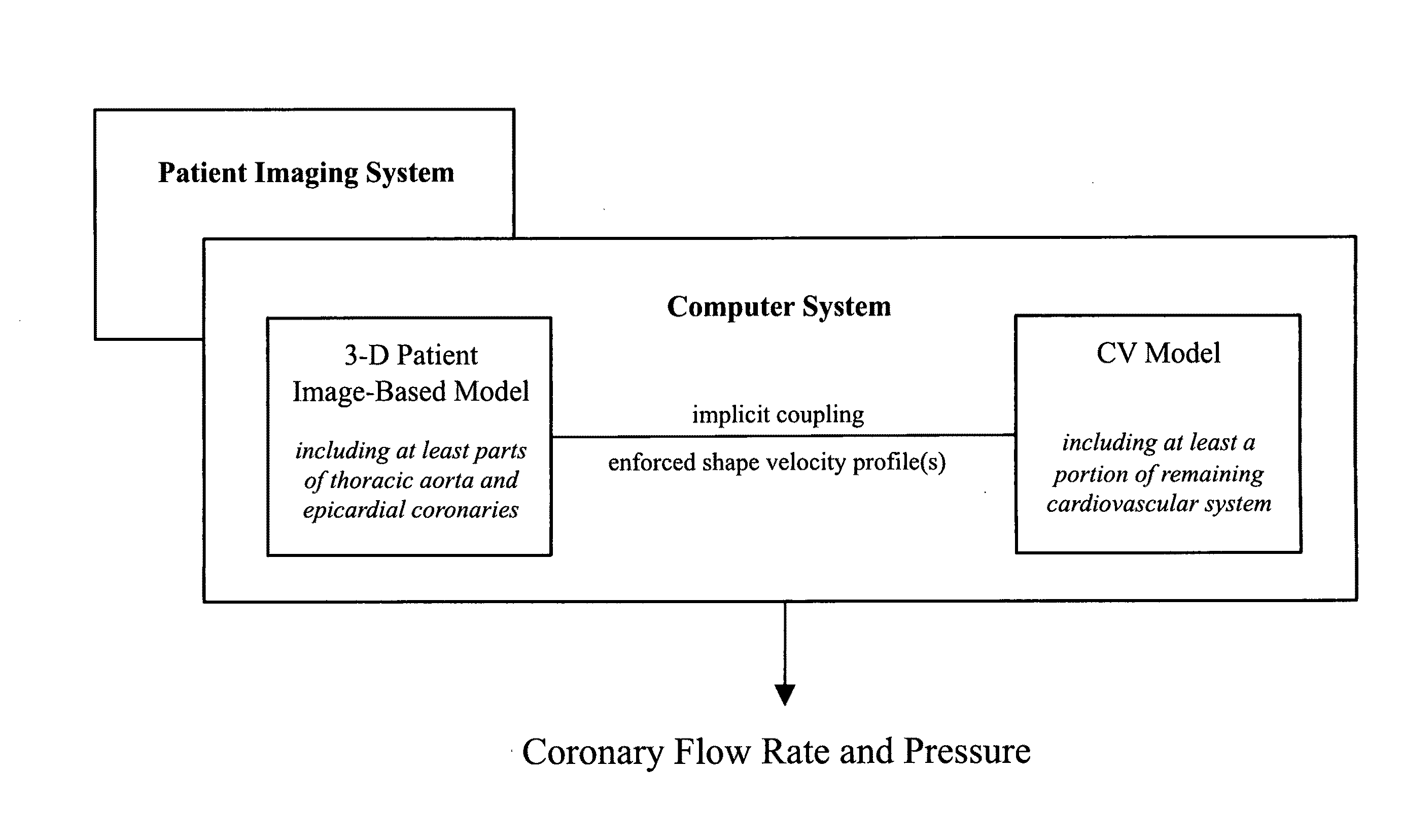

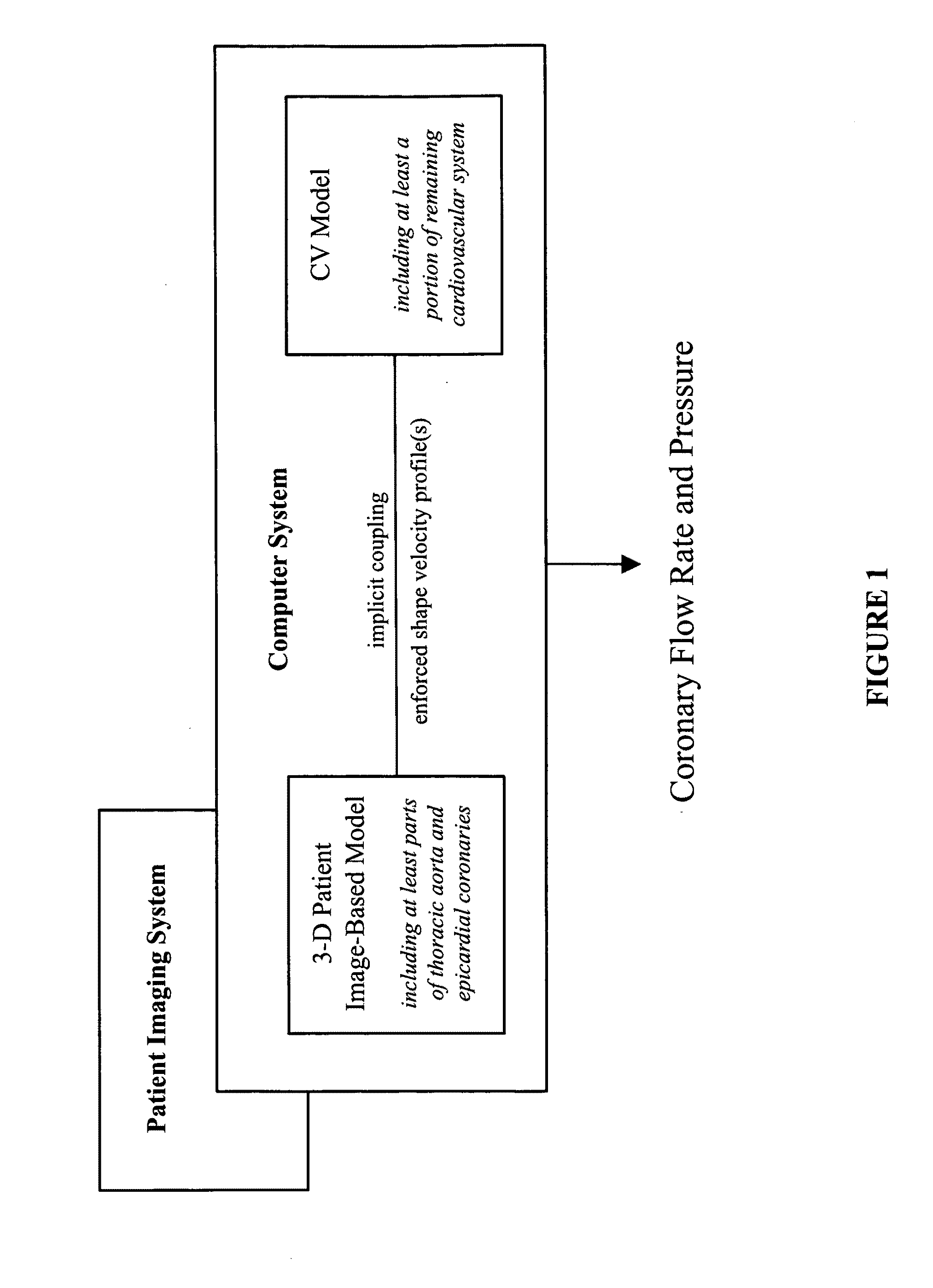

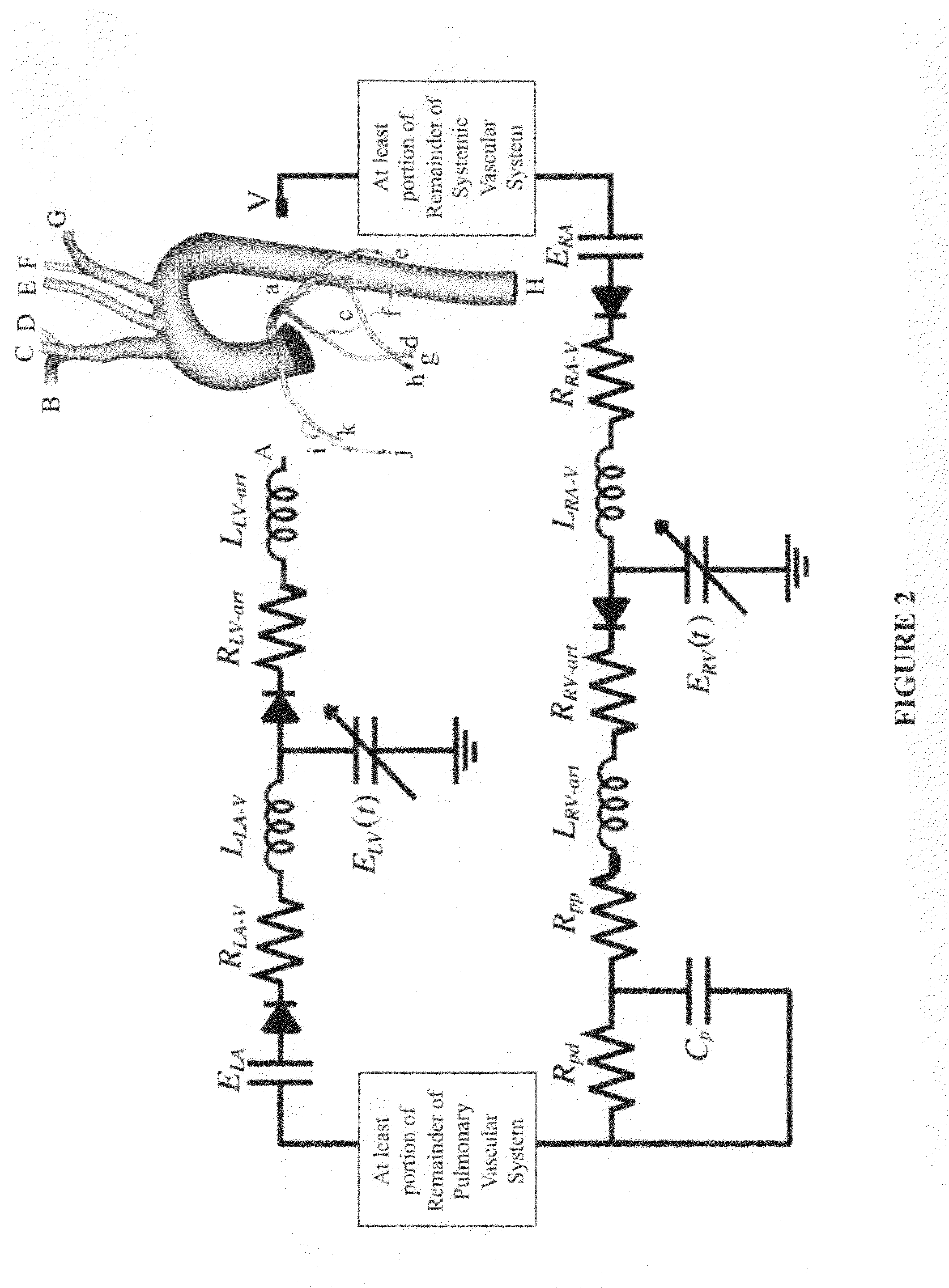

Patient-specific hemodynamics of the cardio vascular system

ActiveUS20100241404A1Minimize model instabilityMore benefitMedical simulationAnalogue computers for chemical processesInstabilityRetrograde Flow

A noninvasive patient-specific method is provided to aid in the analysis, diagnosis, prediction or treatment of hemodynamics of the cardiovascular system of a patient. Coronary blood flow and pressure can be predicted using a 3-D patient image-based model that is implicitly coupled with a model of at least a portion of the remaining cardiovascular system. The 3-D patient image-based model includes at least a portion of the thoracic aorta and epicardial coronaries of the patient. The shape of one or more velocity profiles at the interface of the models is enforced to control complex flow features of recirculating or retrograde flow thereby minimizing model instabilities and resulting in patient-specific predictions of coronary flow rate and pressure. The invention allows for patient-specific predictions of the effect of different or varying physiological states and hemodynamic benefits of coronary medical interventions, percutaneous coronary interventions and surgical therapies.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

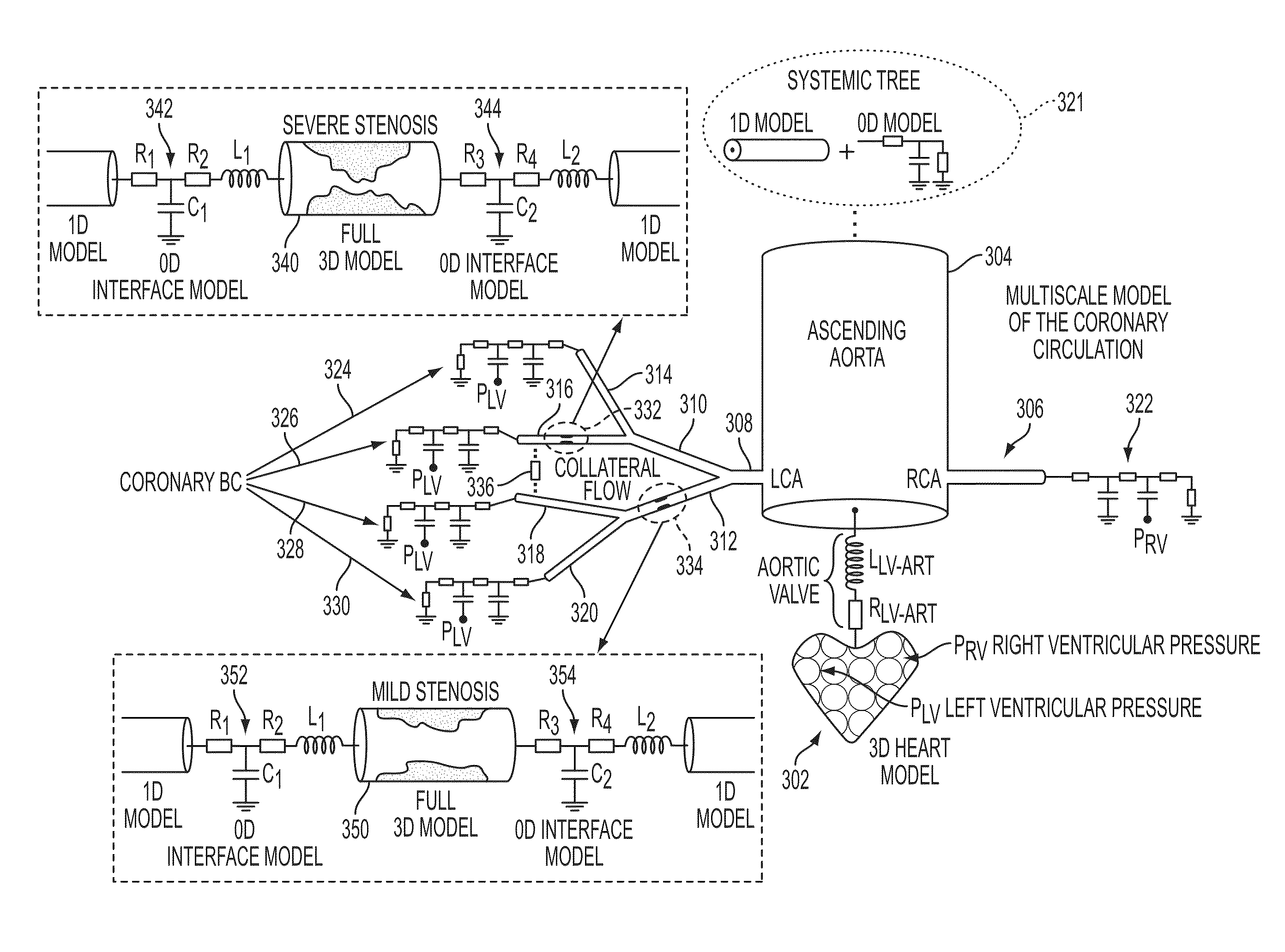

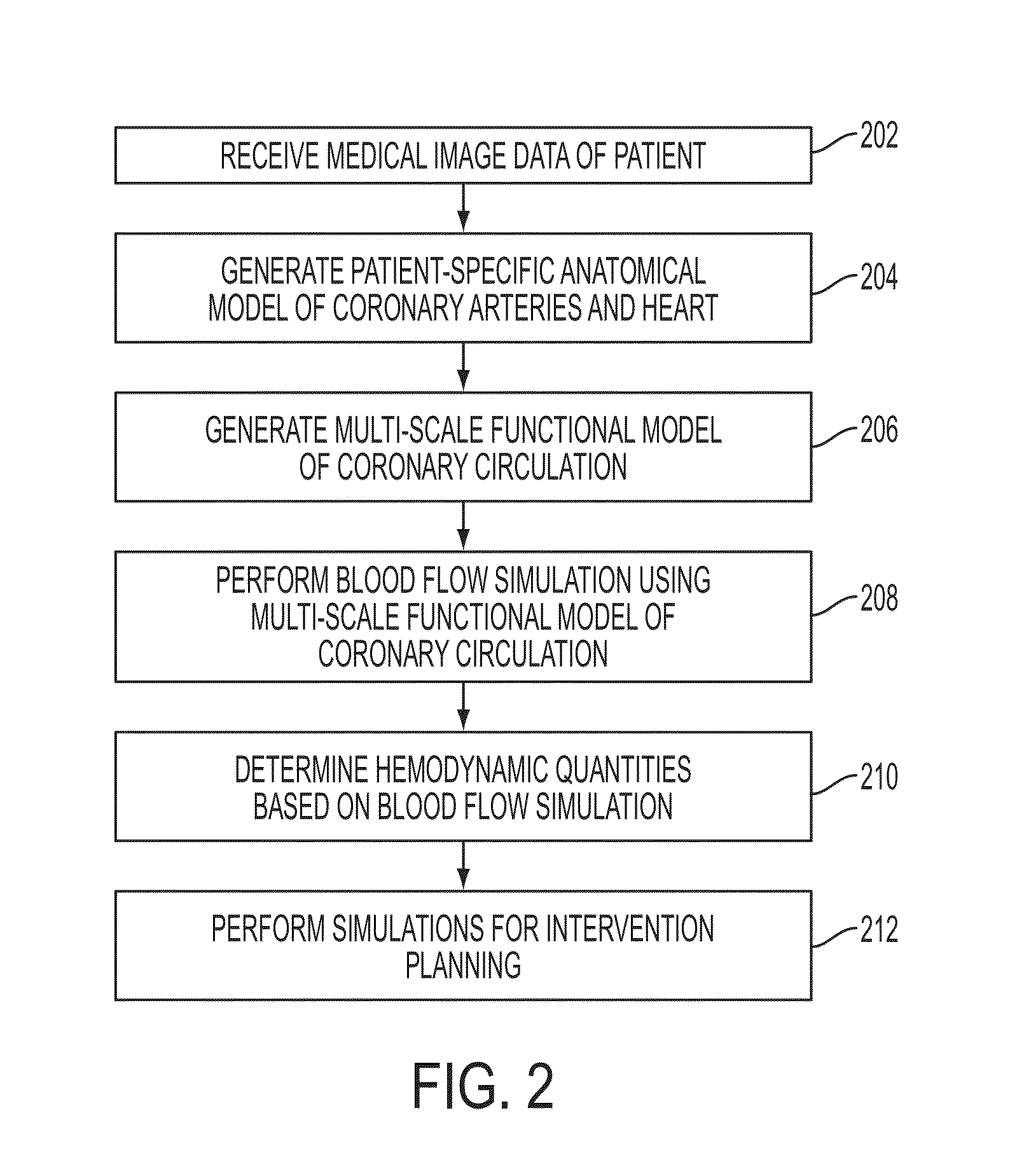

Method and System for Multi-Scale Anatomical and Functional Modeling of Coronary Circulation

ActiveUS20130132054A1Improve predictive performanceImprove clinical managementChemical property predictionChemical structure searchCoronary arteriesIntervention planning

A method and system for multi-scale anatomical and functional modeling of coronary circulation is disclosed. A patient-specific anatomical model of coronary arteries and the heart is generated from medical image data of a patient. A multi-scale functional model of coronary circulation is generated based on the patient-specific anatomical model. Blood flow is simulated in at least one stenosis region of at least one coronary artery using the multi-scale function model of coronary circulation. Hemodynamic quantities, such as fractional flow reserve (FFR), are computed to determine a functional assessment of the stenosis, and virtual intervention simulations are performed using the multi-scale function model of coronary circulation for decision support and intervention planning.

Owner:SIEMENS HEALTHCARE GMBH +1

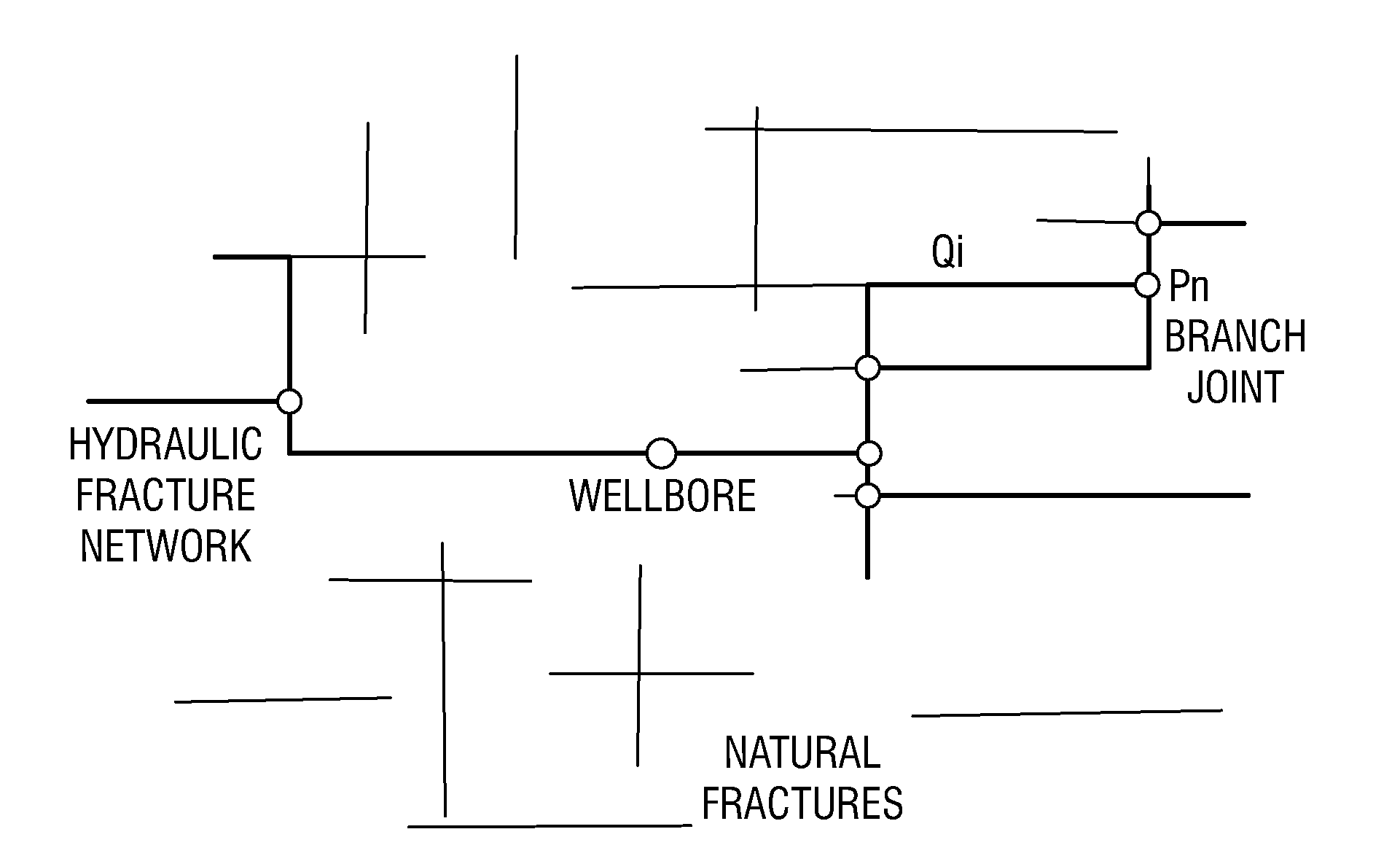

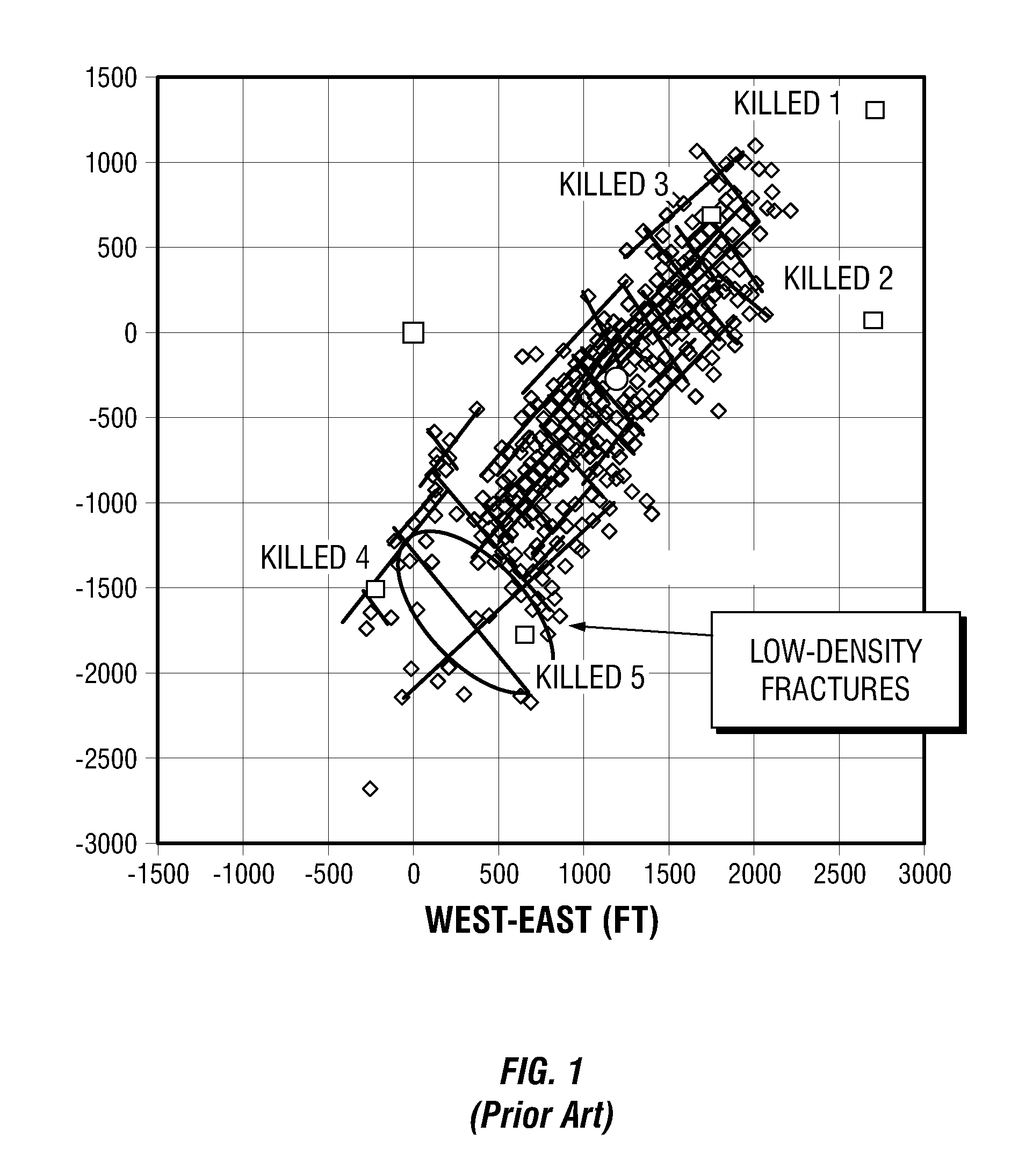

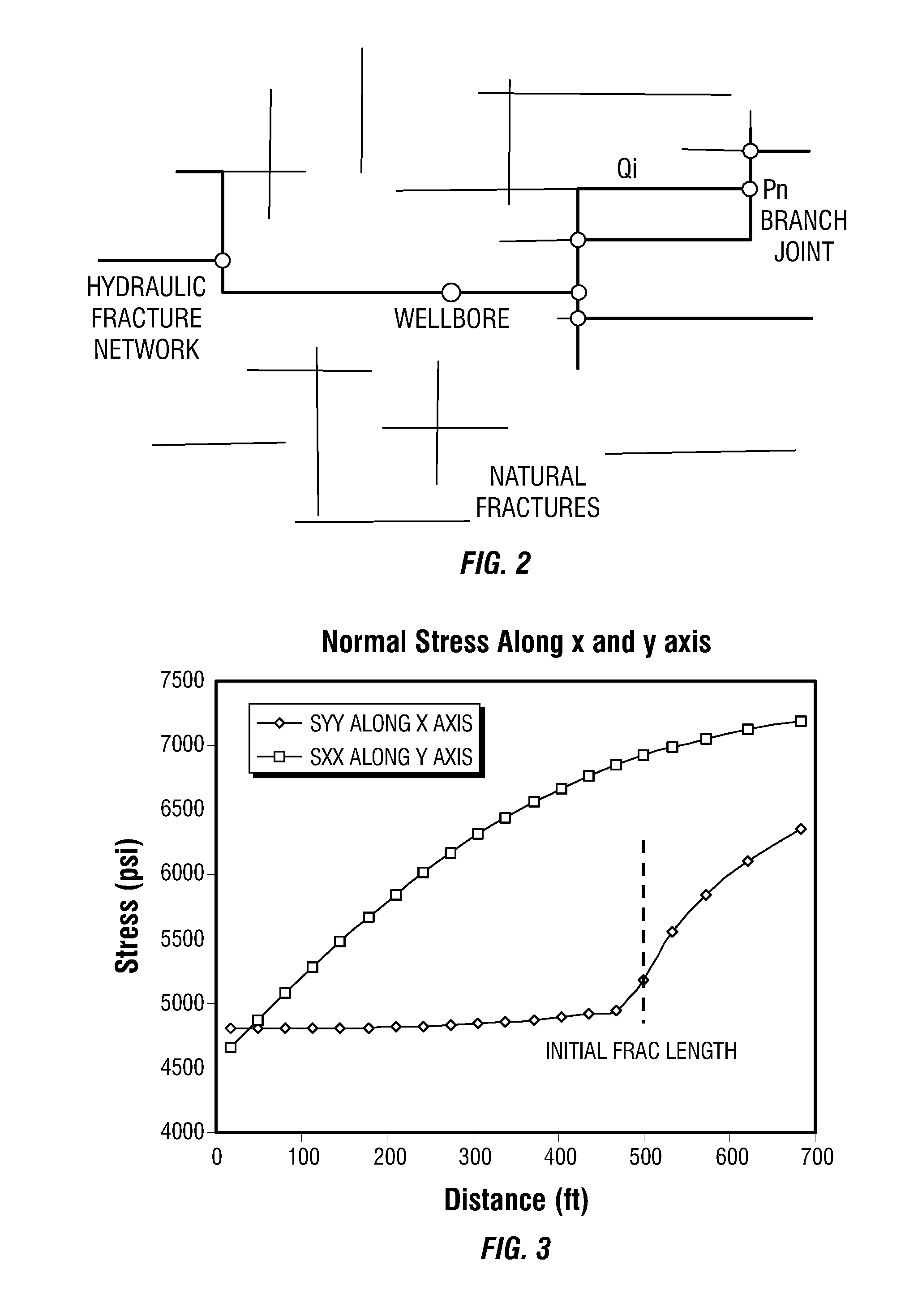

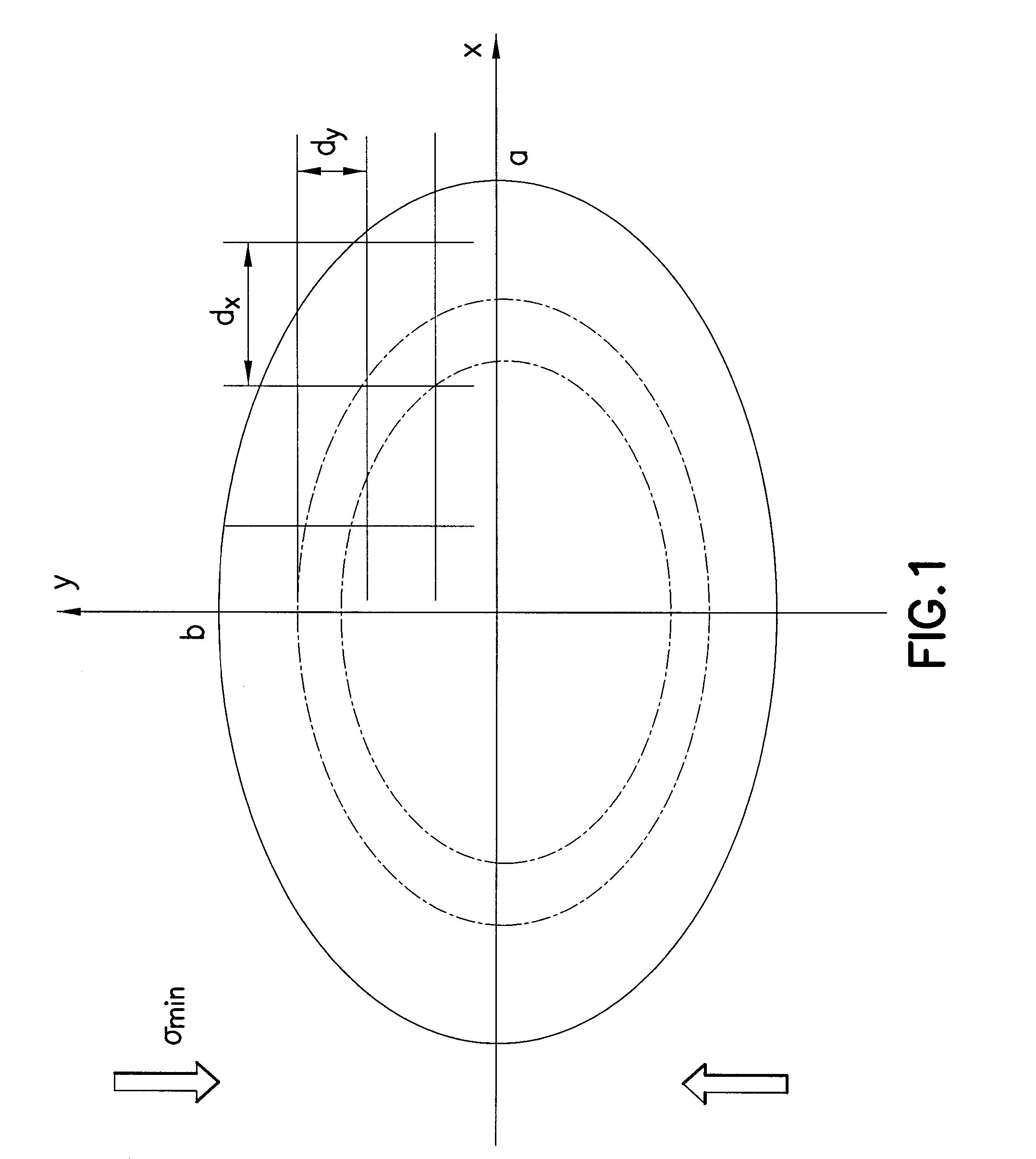

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

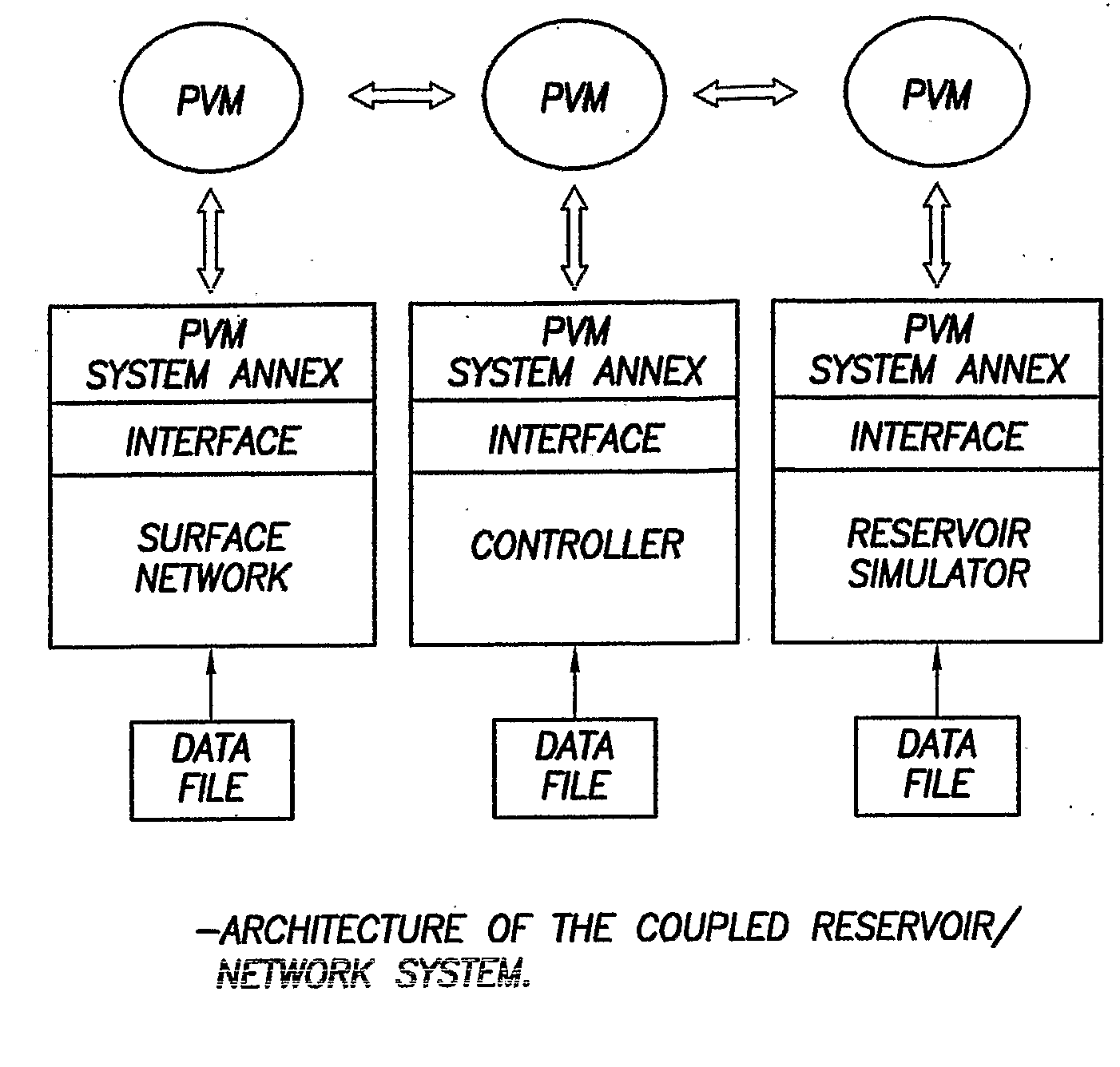

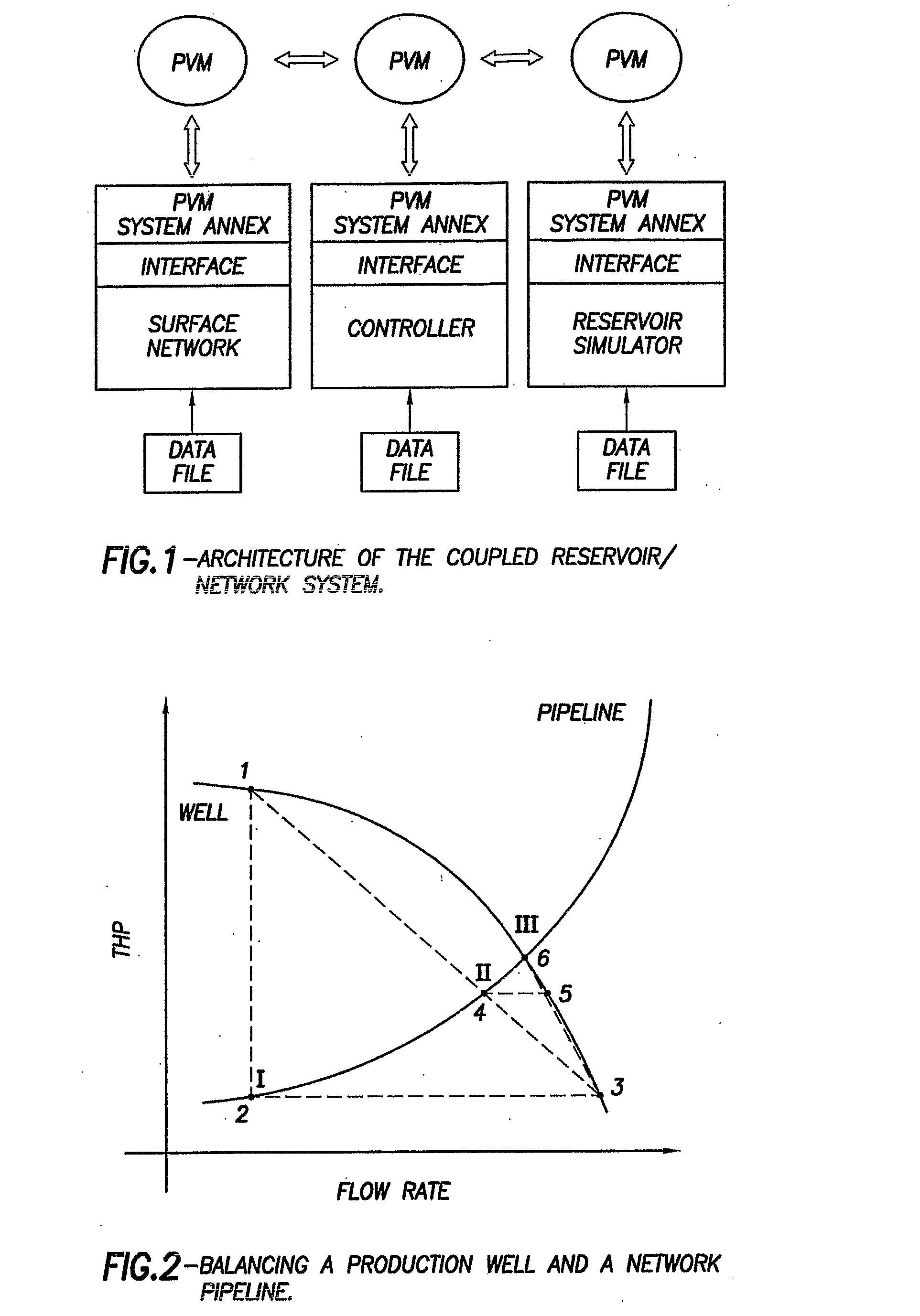

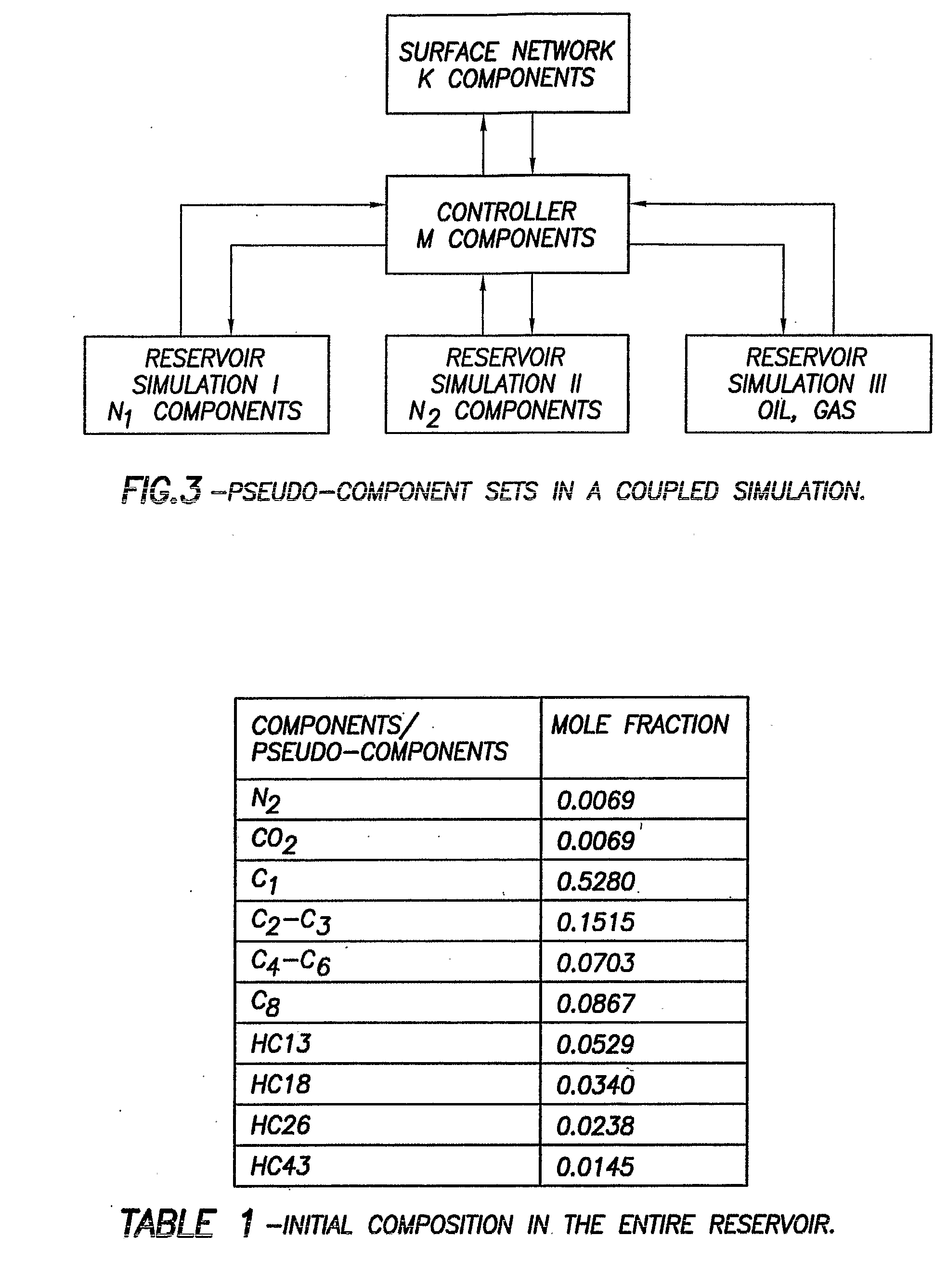

Method and system for integrated reservoir and surface facility networks simulations

InactiveUS20070112547A1Design optimisation/simulationConstraint-based CADMulti platformNetwork model

Integrated surface-subsurface modeling has been shown to have a critical impact on field development and optimization. Integrated models are often necessary to analyze properly the pressure interaction between a reservoir and a constrained surface facility network, or to predict the behavior of several fields, which may have different fluid compositions, sharing a common surface facility. The latter is gaining a tremendous significance in recent deepwater field development. These applications require an integrated solution with the following capabilities: * to balance a surface network model with a reservoir simulation model in a robust and efficient manner. * To couple multiple reservoir models, production and injection networks, synchronising their advancement through time. * To allow the reservoir and surface network models to use their own independent fluid descriptions (black oil or compositional descriptions with differing sets of pseudo-components). * To apply global production and injection constraints to the coupled system (including the transfer of re-injection fluids between reservoirs). In this paper we describe a general-purpose multi-platform reservoir and network coupling controller having all the above features. The controller communicates with a selection of reservoir simulators and surface network simulators via an open message-passing interface. It manages the balancing of the reservoirs and surface networks, and synchronizes their advancement through time. The controller also applies the global production and injection constraints, and converts the hydrocarbon fluid streams between the different sets of pseudo-components used in the simulation models. The controller's coupling and synchronization algorithms are described, and example applications are provided. The flexibility of the controller's open interface makes it possible to plug in further modules (to perform optimization, for example) and additional simulators.

Owner:SCHLUMBERGER TECH CORP

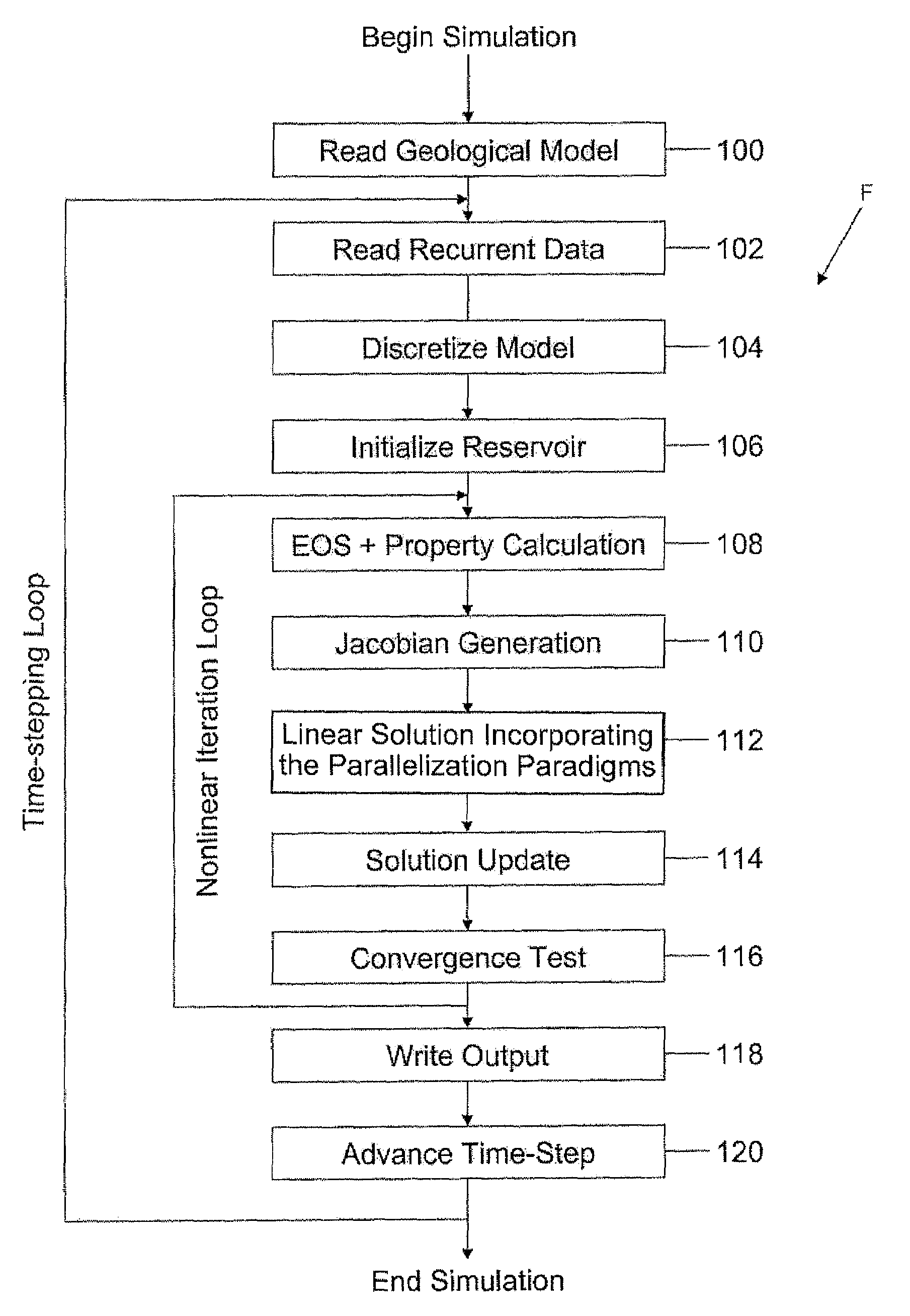

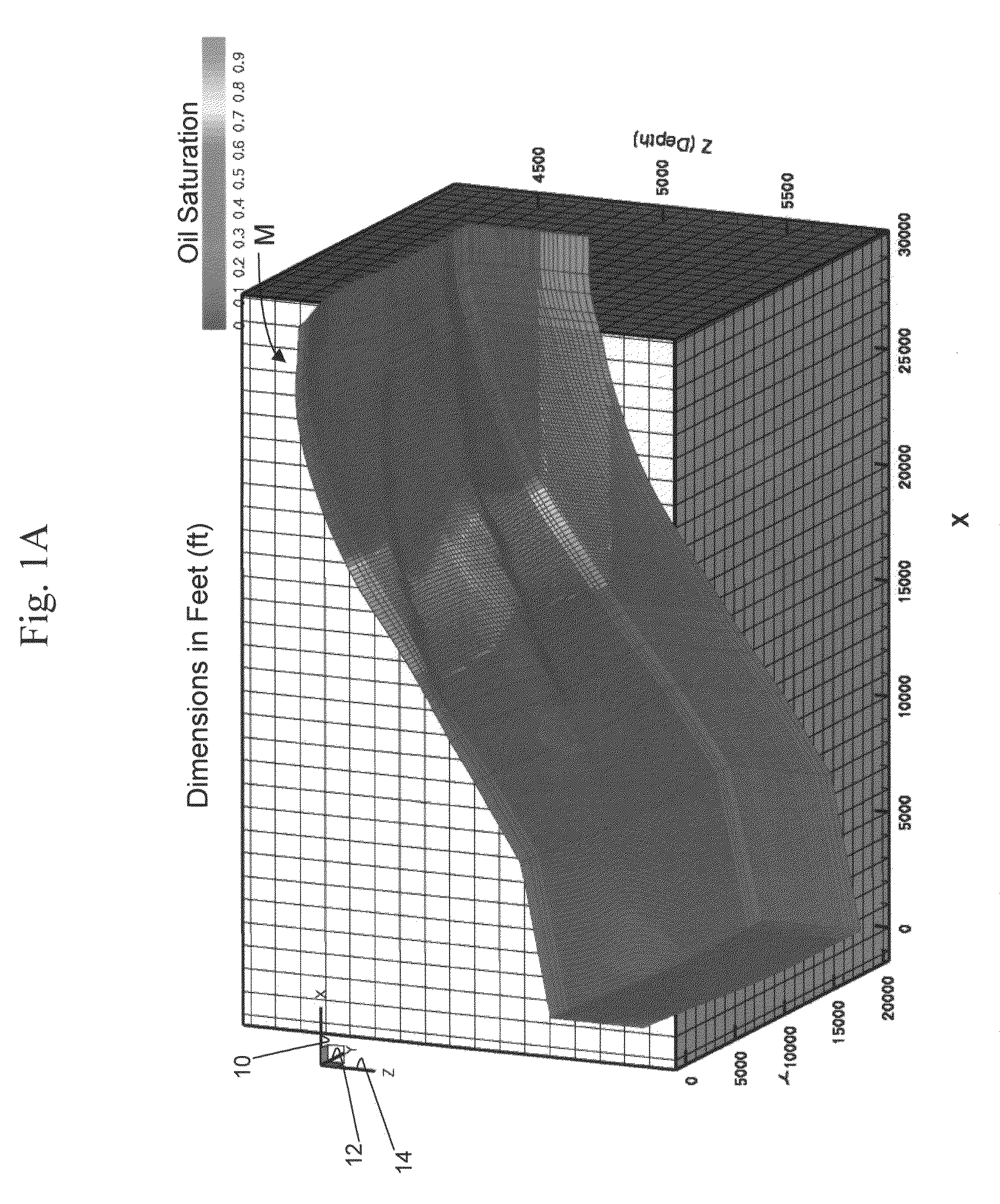

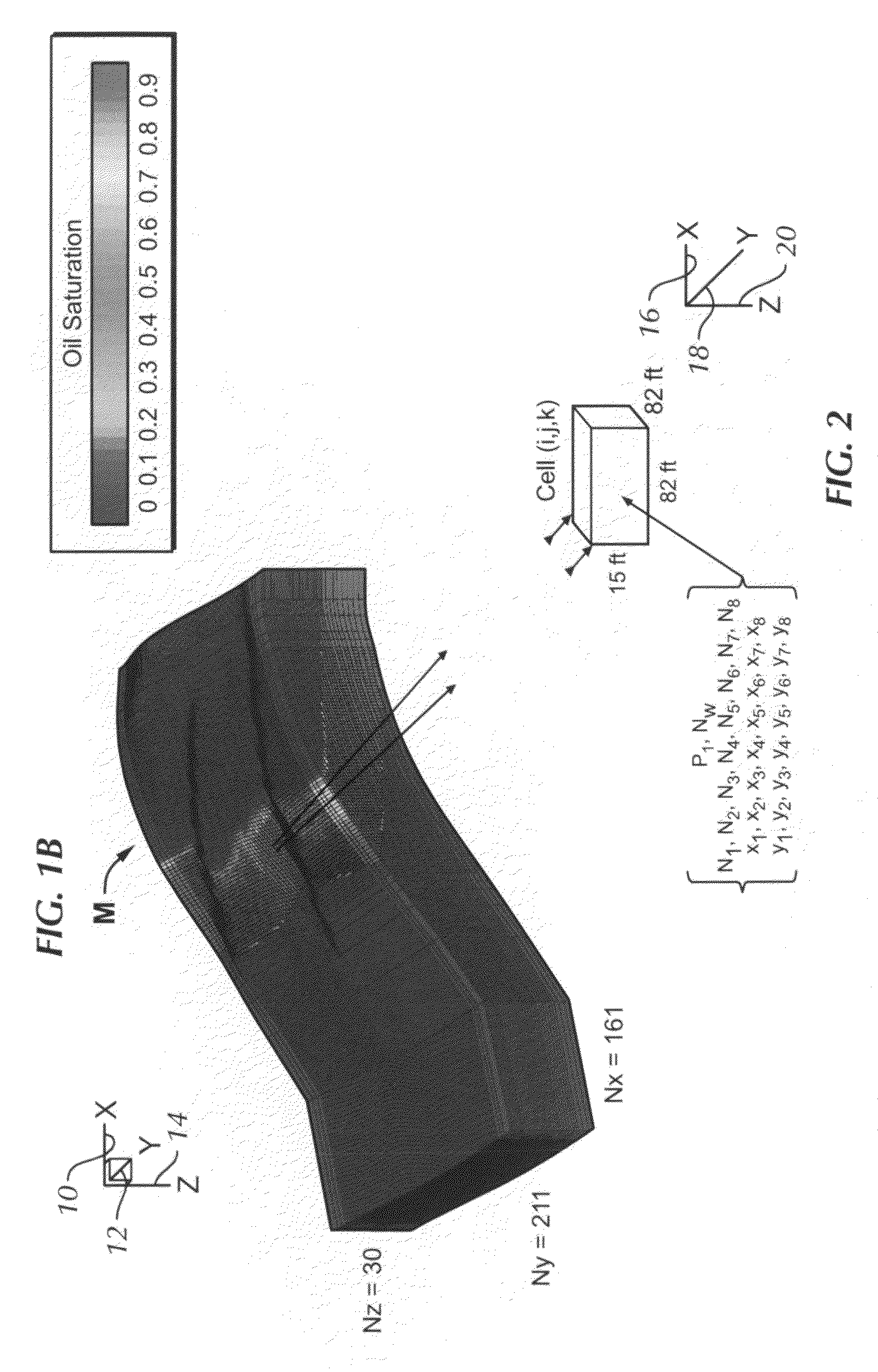

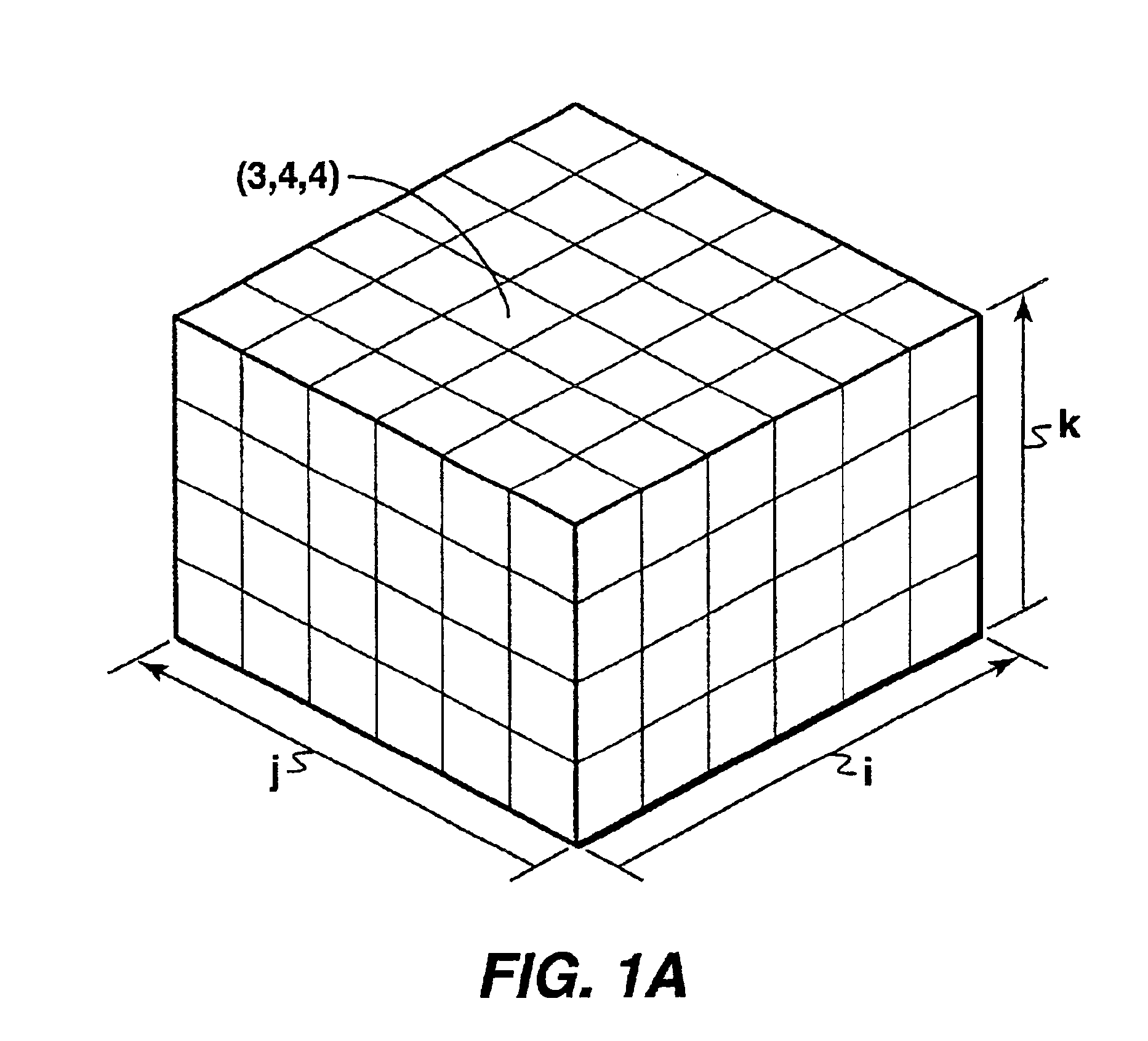

Highly-parallel, implicit compositional reservoir simulator for multi-million-cell models

ActiveUS7526418B2Reduce processing timeElectric/magnetic detection for well-loggingPermeability/surface area analysisSupercomputerDistributed memory

A fully-parallelized, highly-efficient compositional implicit hydrocarbon reservoir simulator is provided. The simulator is capable of solving giant reservoir models, of the type frequently encountered in the Middle East and elsewhere in the world, with fast turnaround time. The simulator may be implemented in a variety of computer platforms ranging from shared-memory and distributed-memory supercomputers to commercial and self-made clusters of personal computers. The performance capabilities enable analysis of reservoir models in full detail, using both fine geological characterization and detailed individual definition of the hydrocarbon components present in the reservoir fluids.

Owner:SAUDI ARABIAN OIL CO

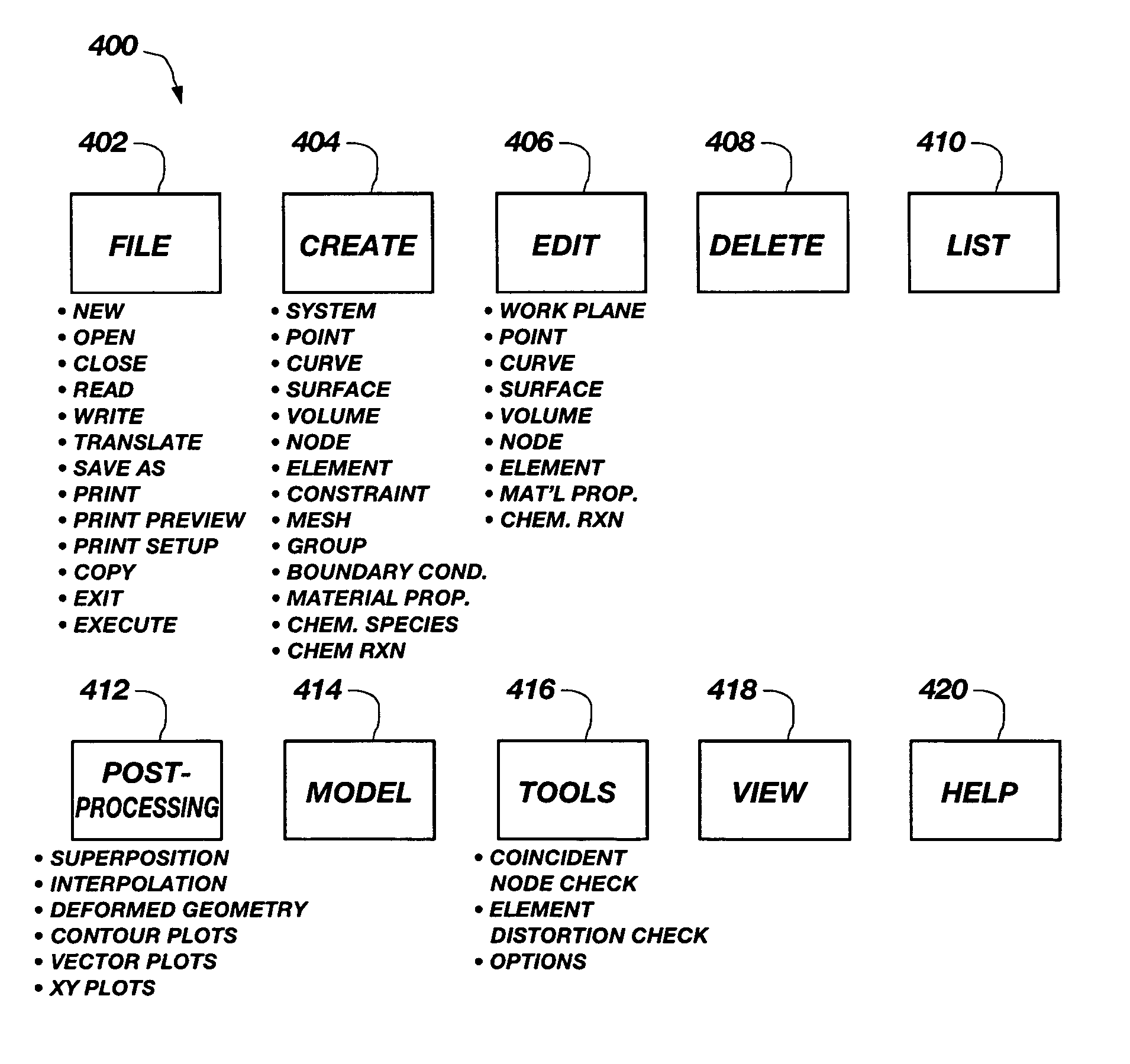

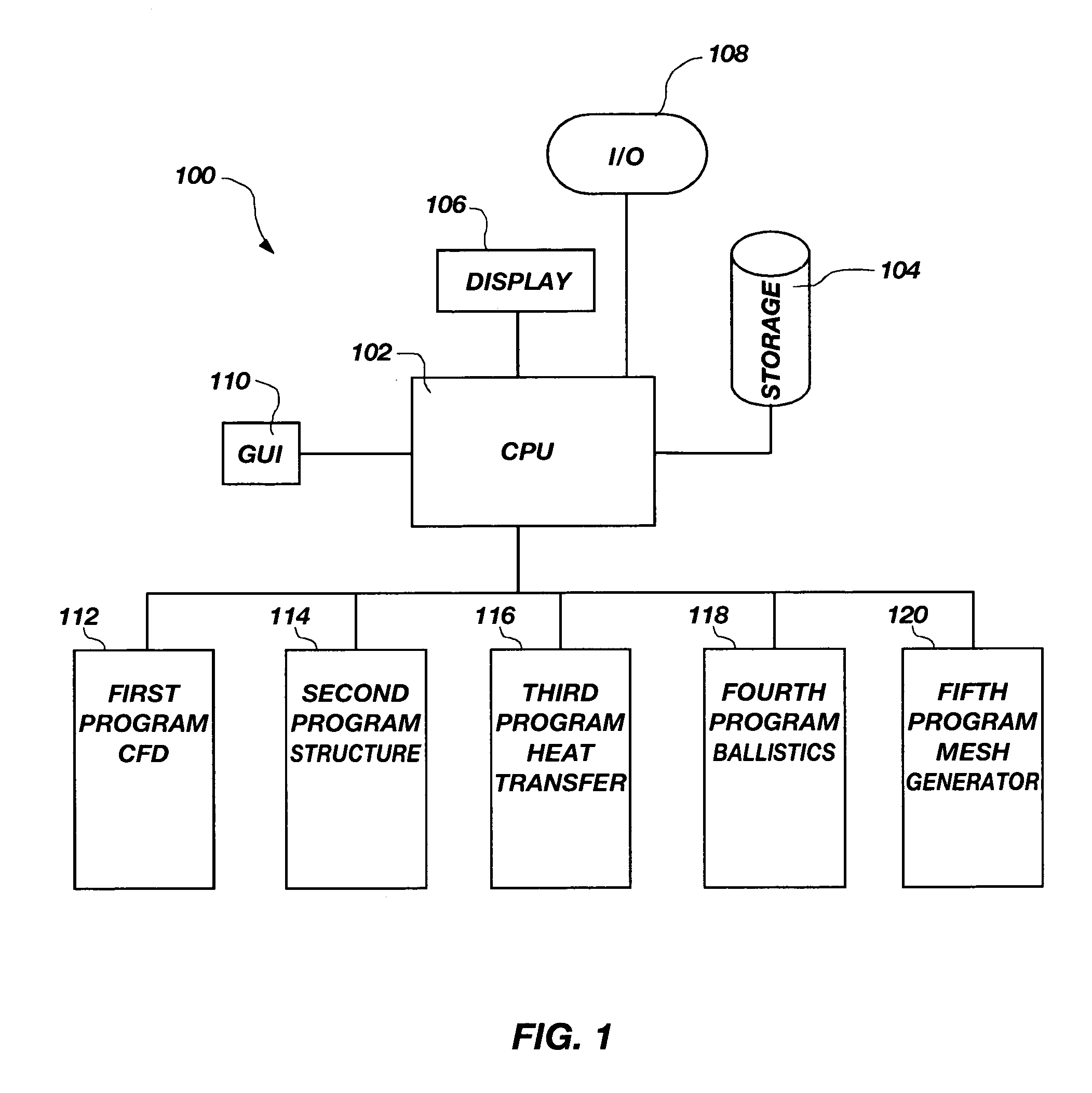

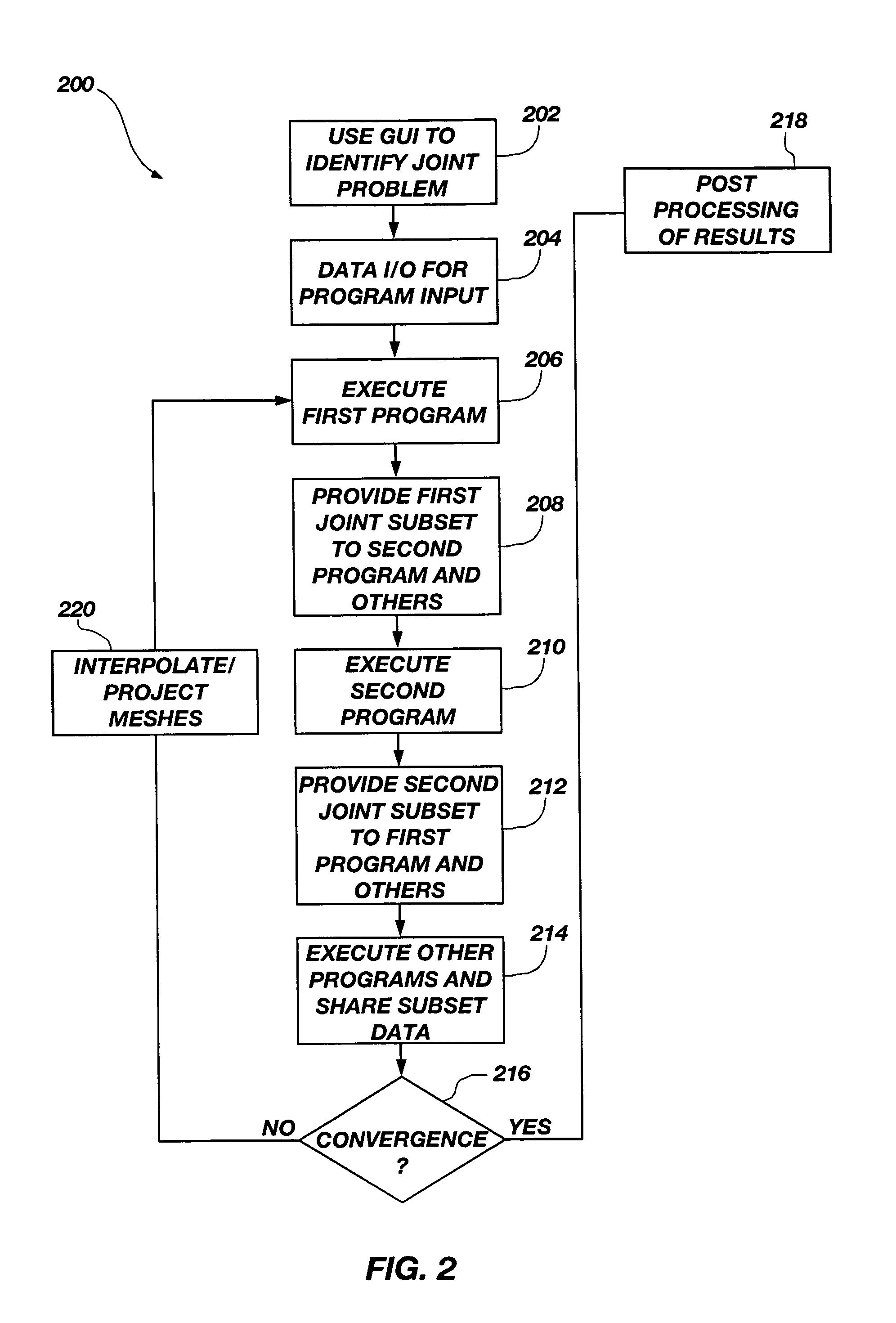

System for performing coupled finite analysis

ActiveUS7127380B1Stay flexibleAccelerated settlementComputation using non-denominational number representationDesign optimisation/simulationComputational scienceGraphics

A graphical user interface, together with a comparable scripting interface, couples a plurality of finite element, finite volume, or finite difference analytical programs and permits iterative convergence of multiple programs through one set of predefined commands. The user is permitted to select the joint problem for solution by choosing program selections. Data linkages that couple the program are predefined by an expert system administrator to permit less skilled modelers access to a comprehensive and multifaceted solution that would not be possible for the less skilled modelers to complete absent the graphical user interface.

Owner:NORTHROP GRUMMAN SYST CORP

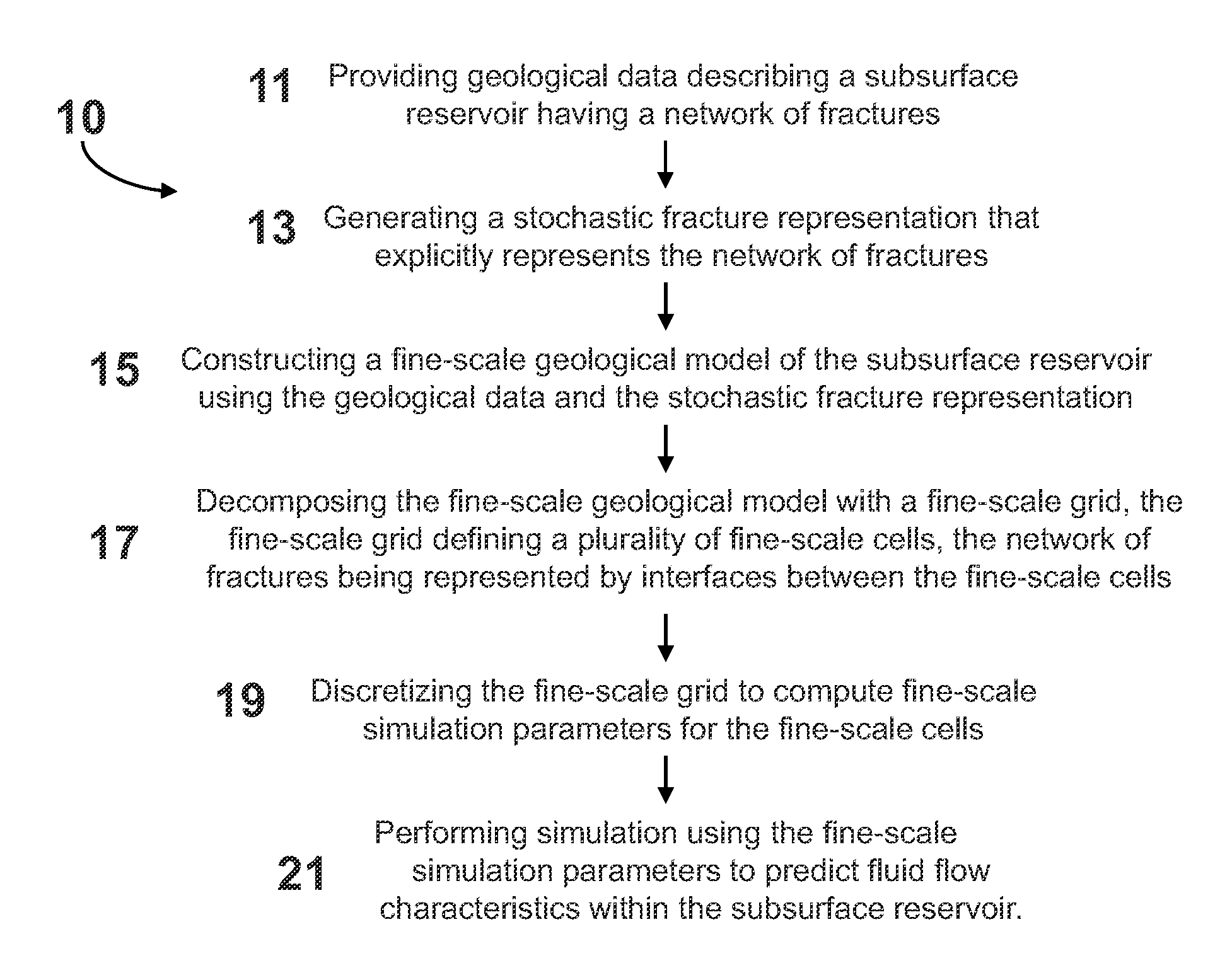

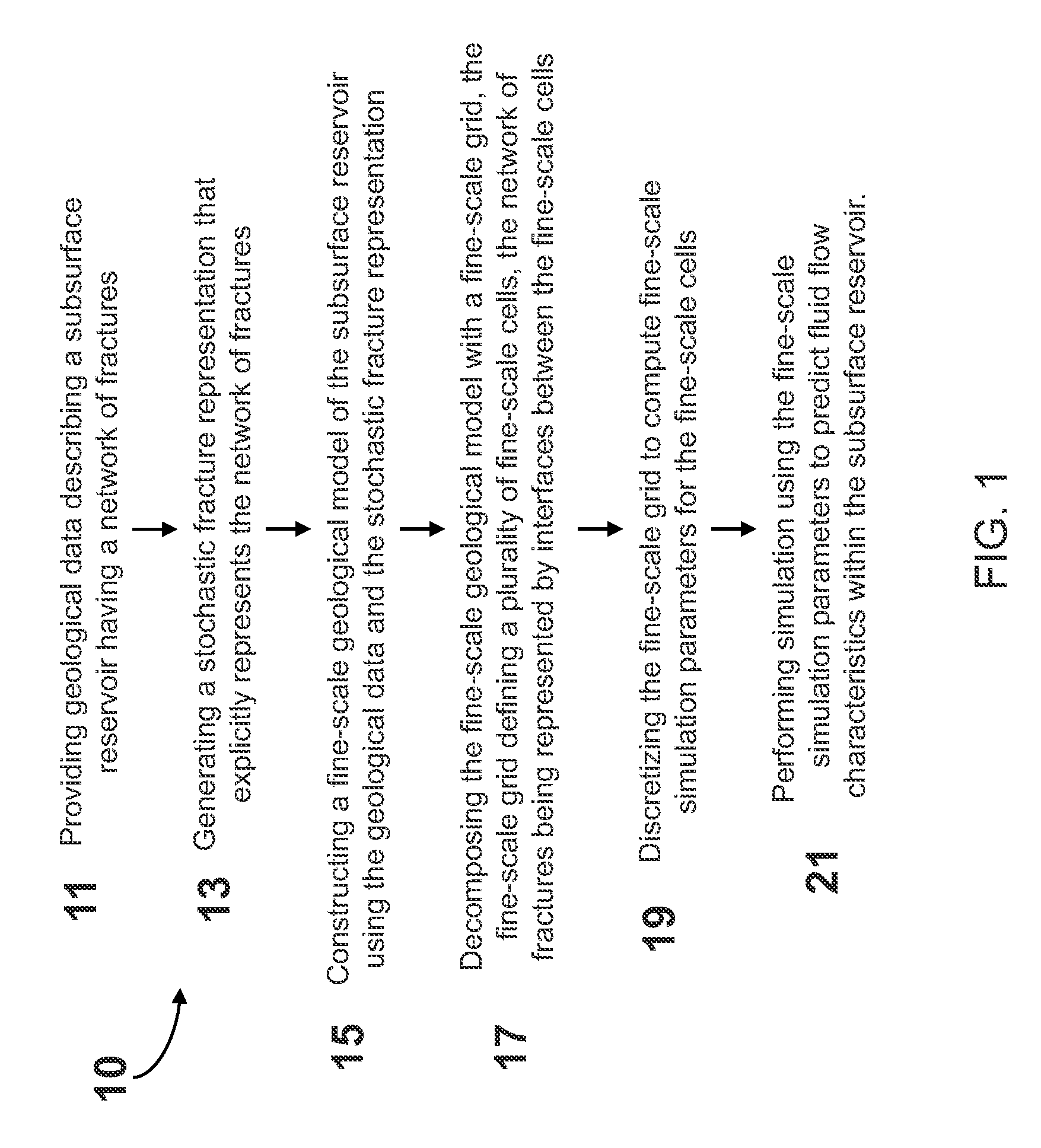

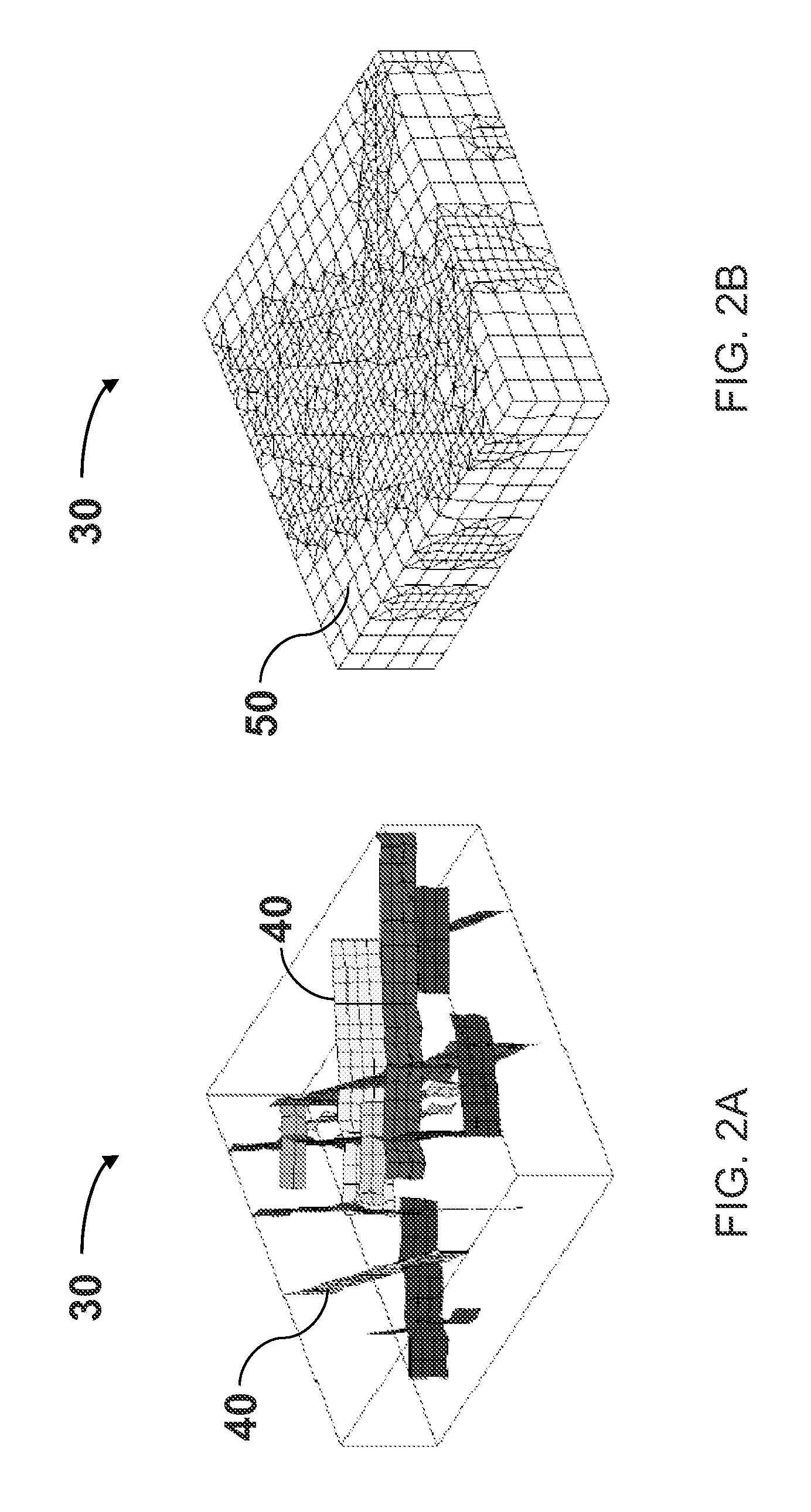

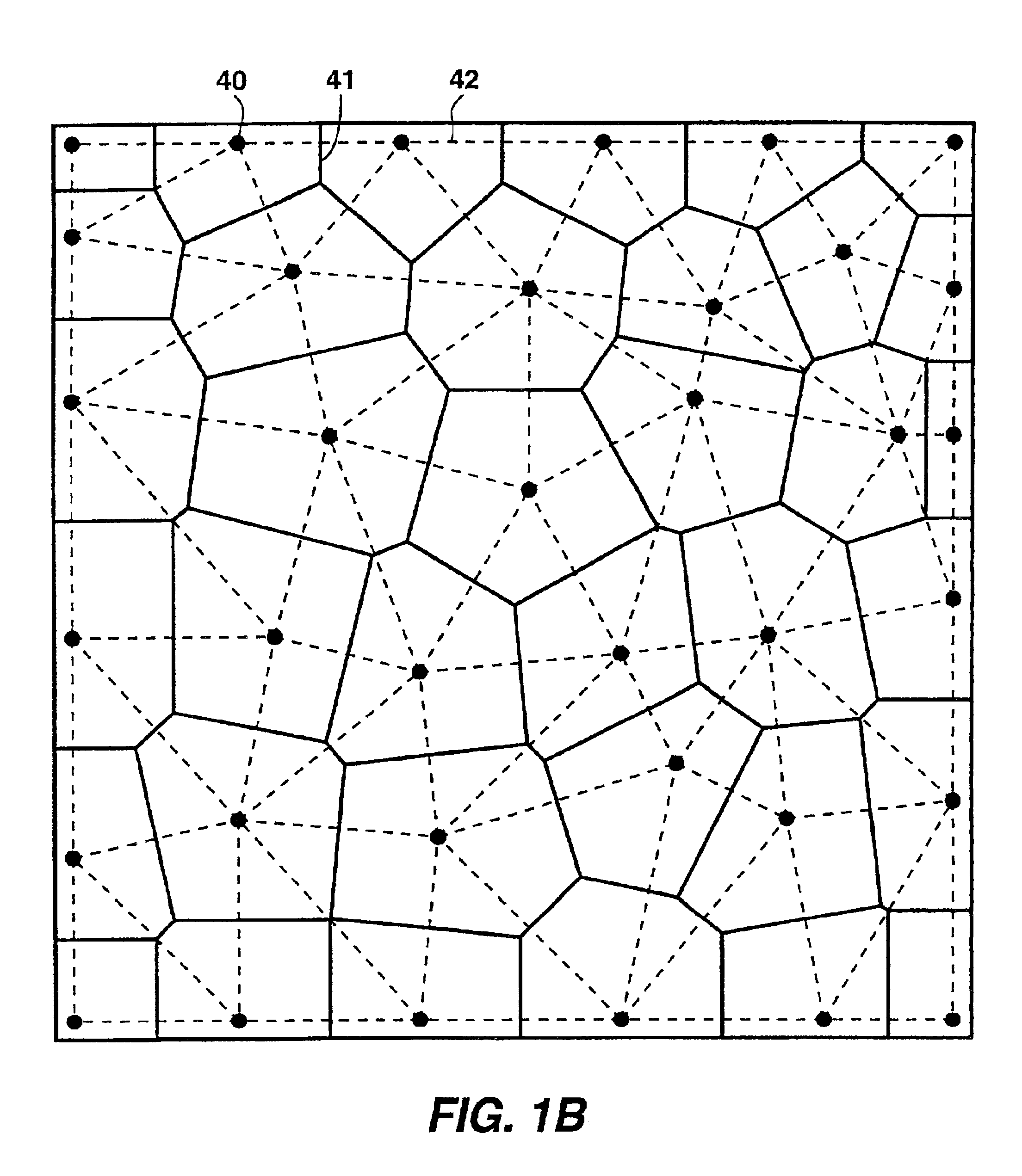

System and method for predicting fluid flow characteristics within fractured subsurface reservoirs

A system and method having application notably towards predicting fluid flow characteristics within fractured subsurface reservoirs. The system and method include steps of reservoir characterization, gridding, discretization, and simulation of geologically realistic models describing the fractured subsurface reservoirs. A stochastic fracture representation that explicitly represents a network of fractures within a subsurface reservoir is constructed and used to build a fine-scale geological model. The model is then gridded such that the network of fractures is represented by interfaces between the fine-scale cells. The model is the discretized and simulated. Simulation can be on a fine-scale or on an upscaled course-scale to produce efficient and reliable prediction of fluid flow characteristics within the subsurface reservoir.

Owner:CHEVROU USA INC

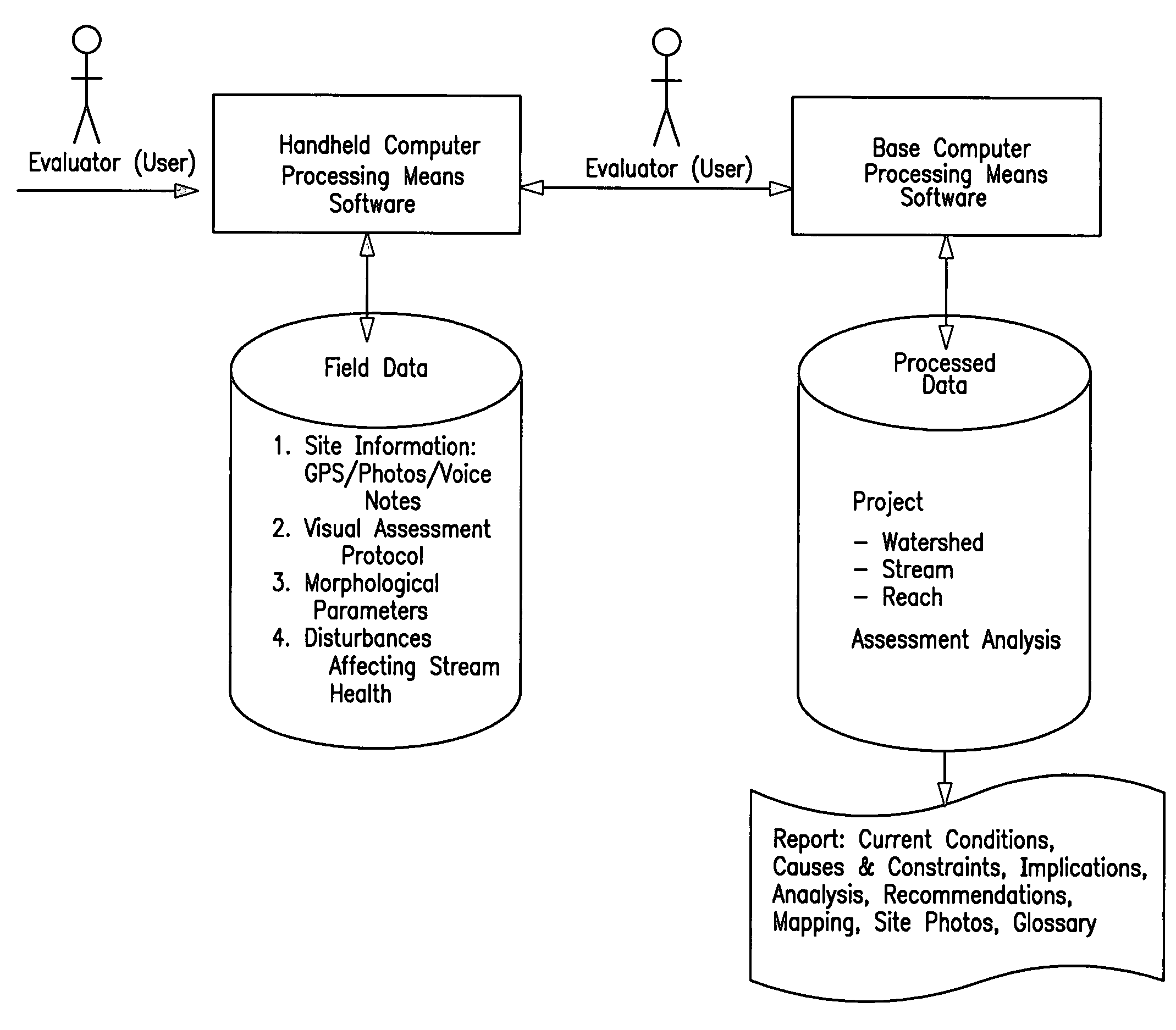

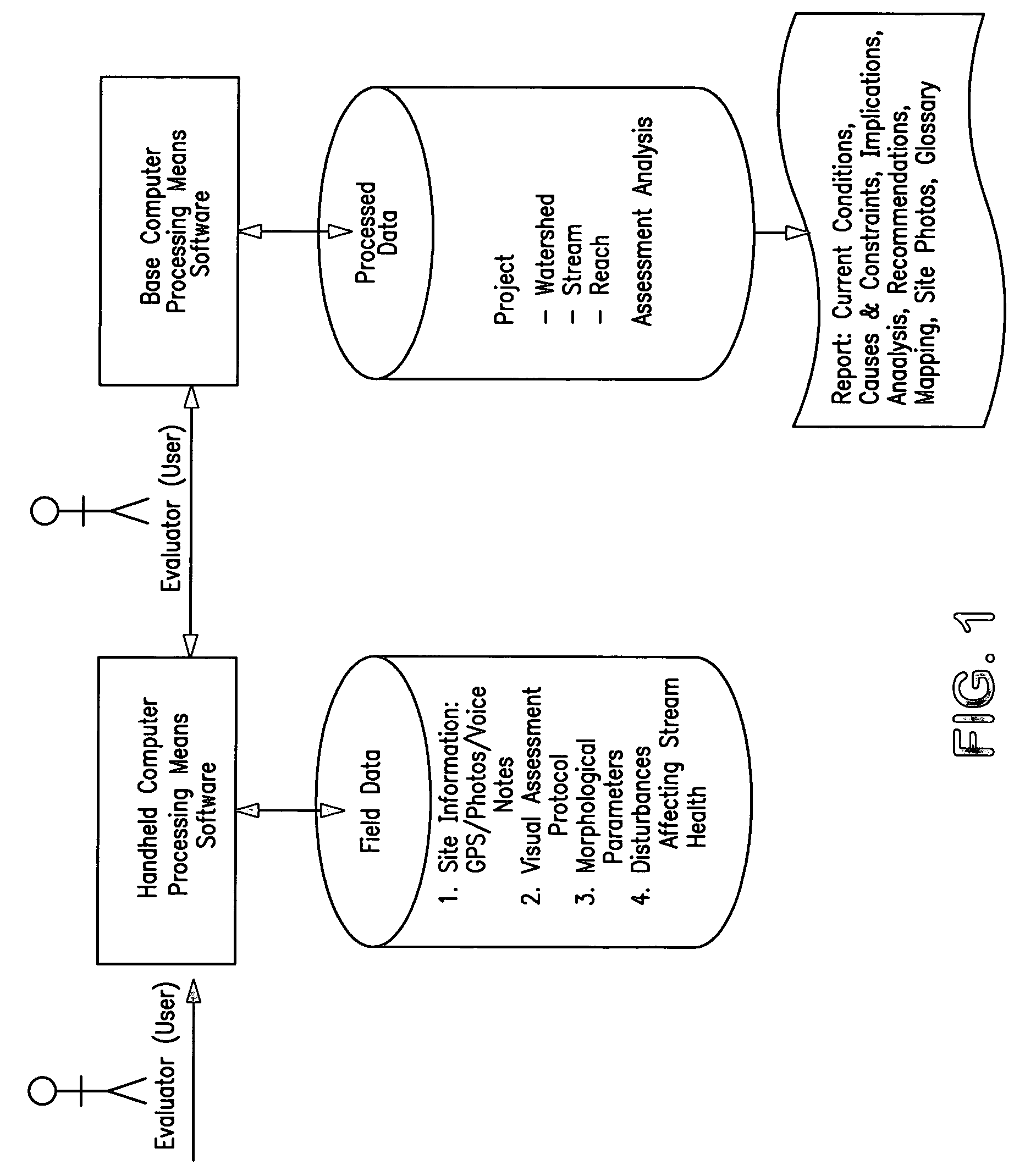

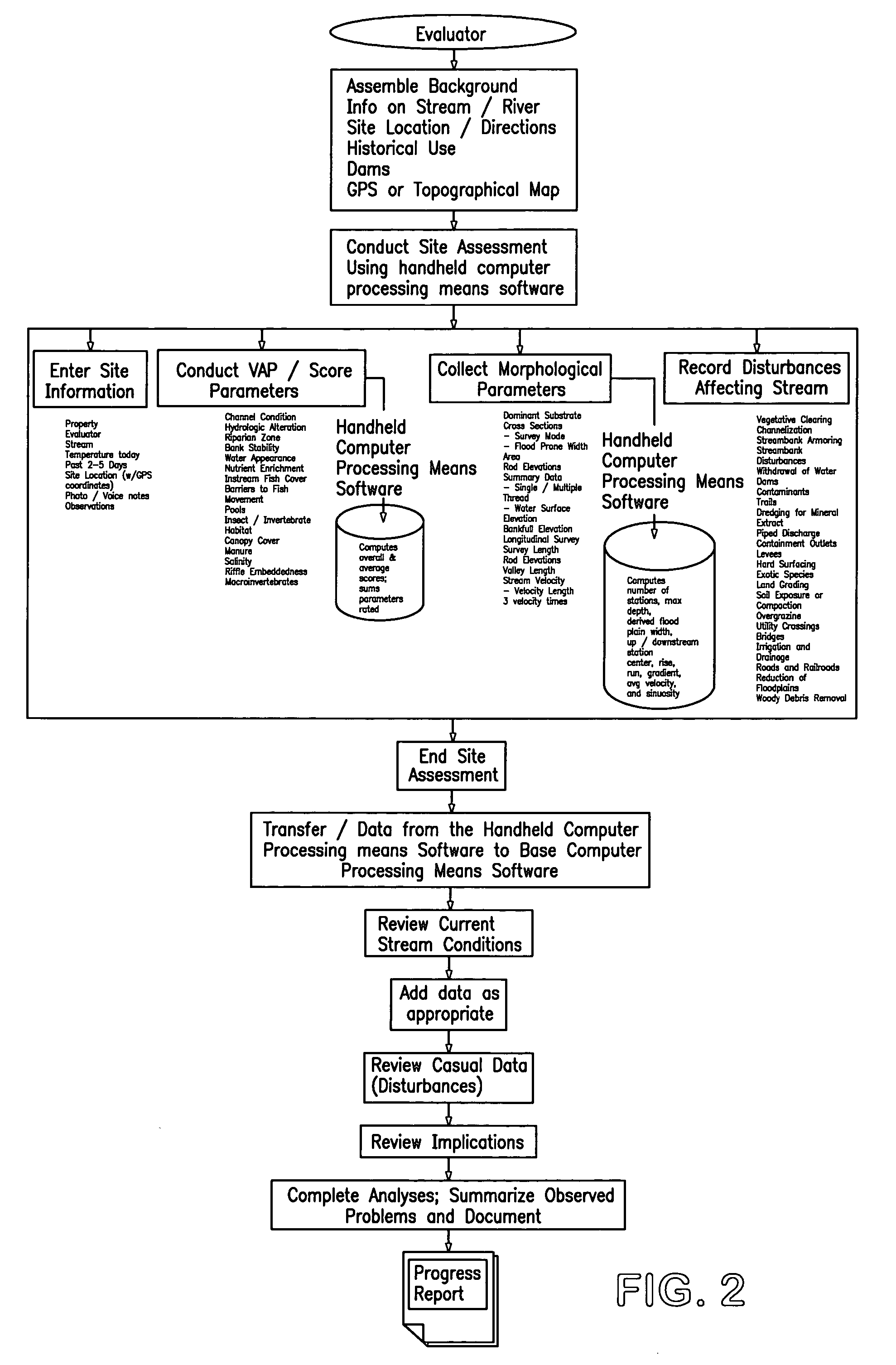

System, method and computer program product for aquatic environment assessment

A system, method and computer program product are provided for assessing aquatic environments. Initially, the user measures biological, morphological and physiological parameters, quantitatively, semi-quantitatively and qualitatively in the field, guided by the computer software o of the present invention, and enters the data obtained from such measurements entered into a handheld computer processing means running the computer software of the present invention. Then, the data is transferred into a desktop computer processing means for automated analysis, processing, reporting of field data, and production of various user reports through the synchronized, compatible desktop software of the present invention.

Owner:THI RIVERWORKS

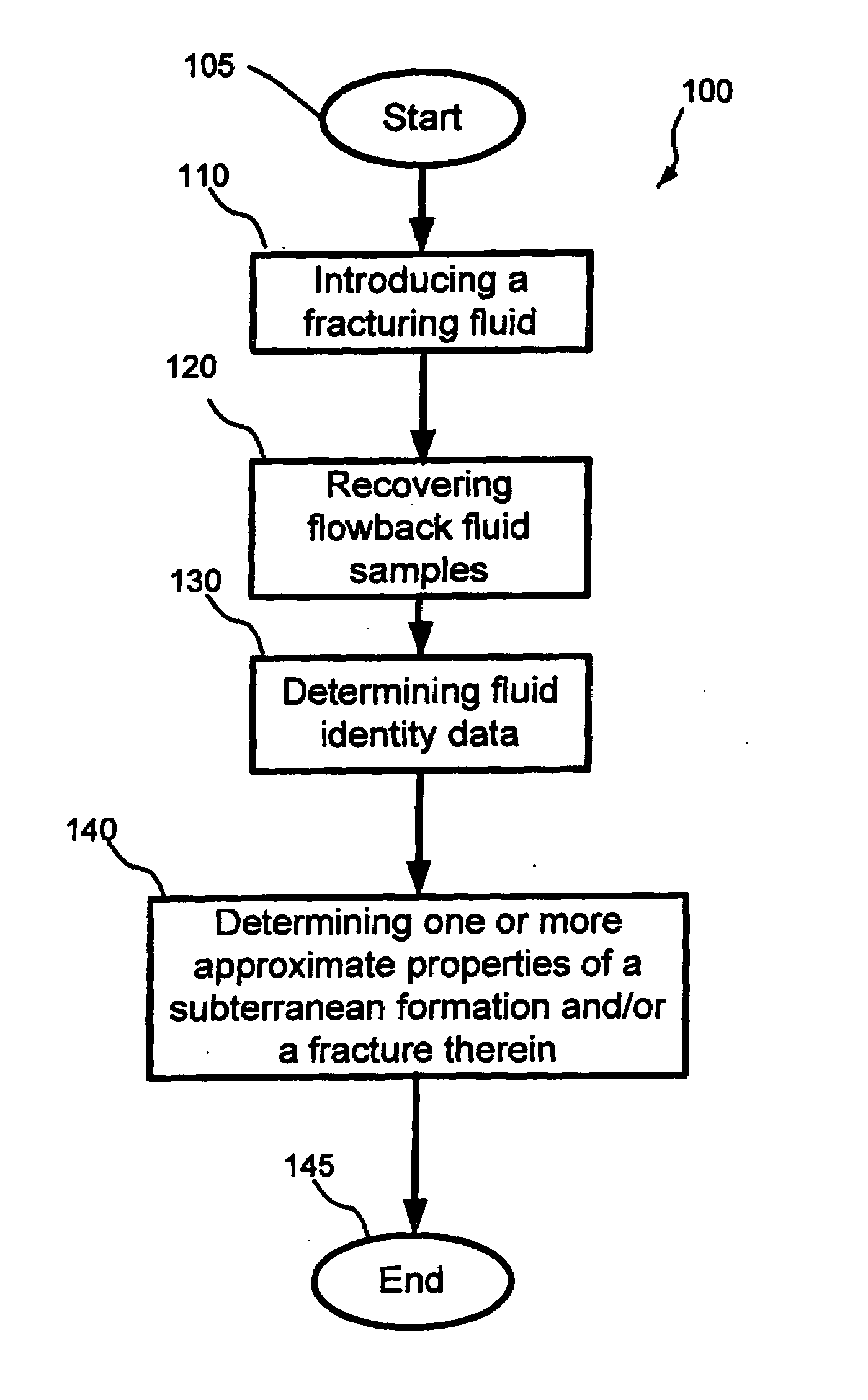

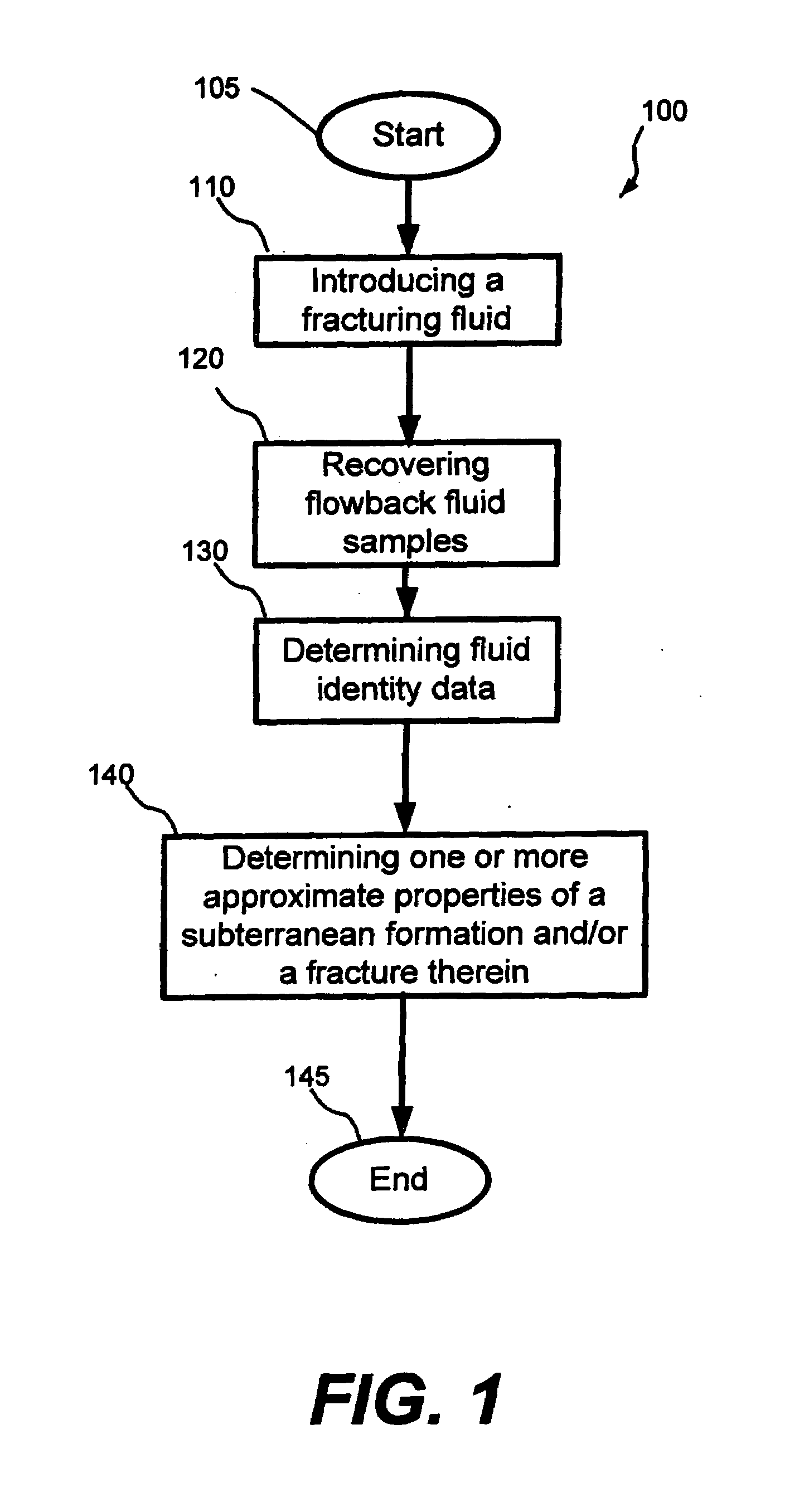

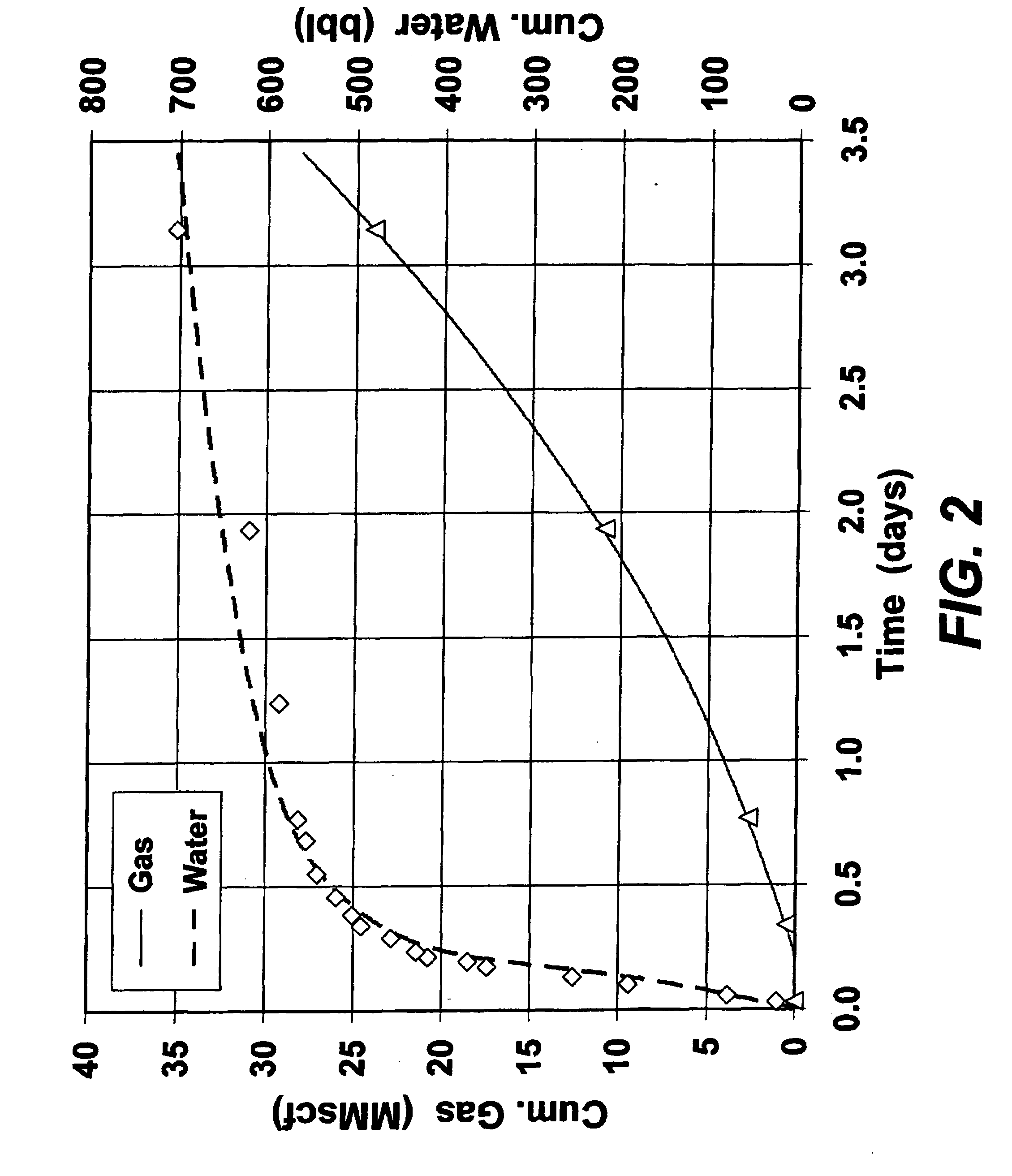

Methods for estimating properties of a subterranean formation and/or a fracture therein

Owner:HALLIBURTON ENERGY SERVICES INC

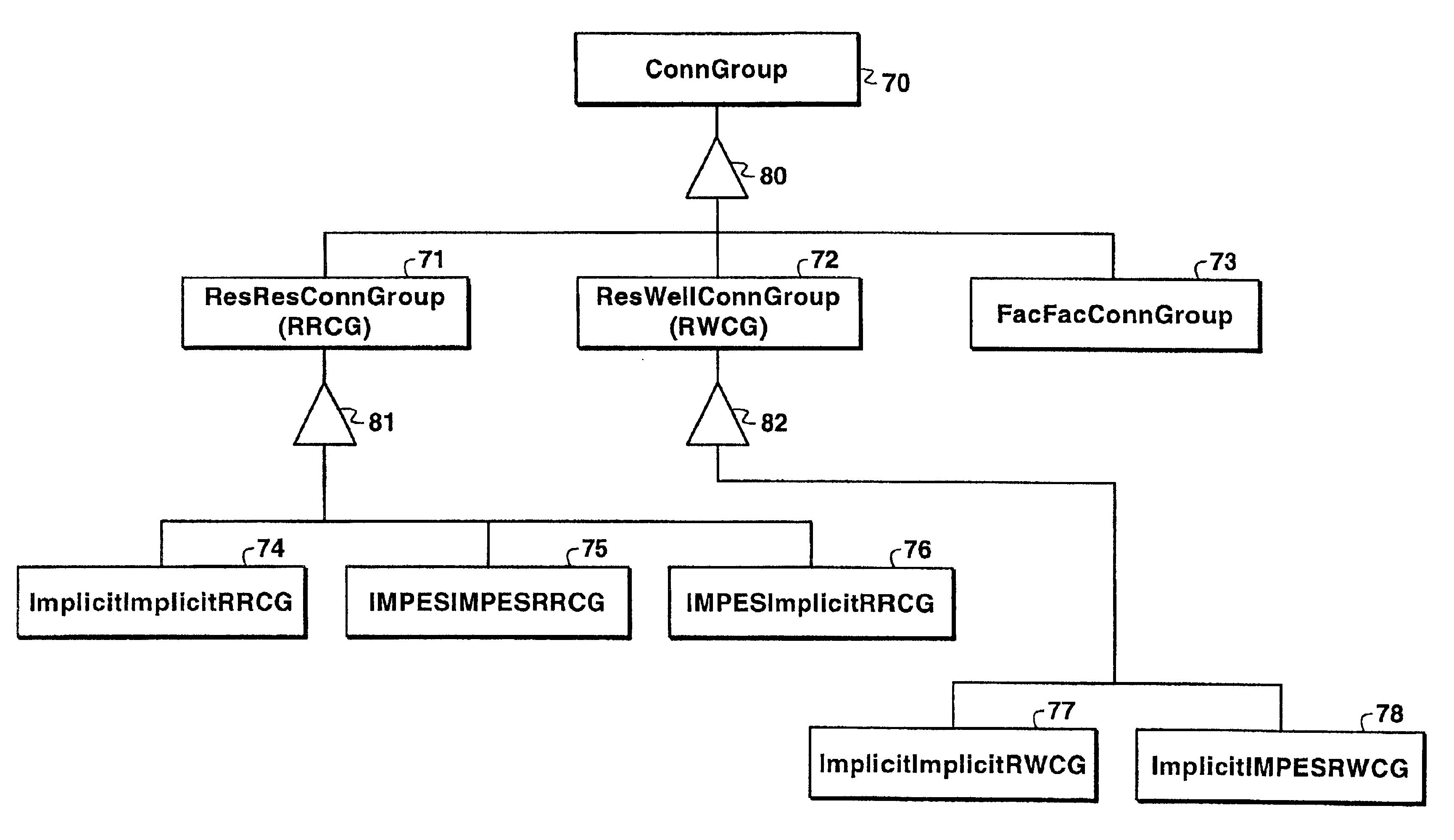

Method and program for simulating a physical system using object-oriented programming

InactiveUS6928399B1Electric/magnetic detection for well-loggingFluid removalPhysical systemComputer science

The invention relates to an object-oriented method for simulating a property of at least one fluid in a fluid-containing physical system in which the physical system is represented by a multiplicity of volumetric cells and a multiplicity of connections between cells. The method uses cell-group objects and connection-group objects in the simulation. The invention can optionally comprise additional objects such as an object containing the entire model of the simulation and another object containing a portion of the entire model.

Owner:EXXONMOBIL UPSTREAM RES CO

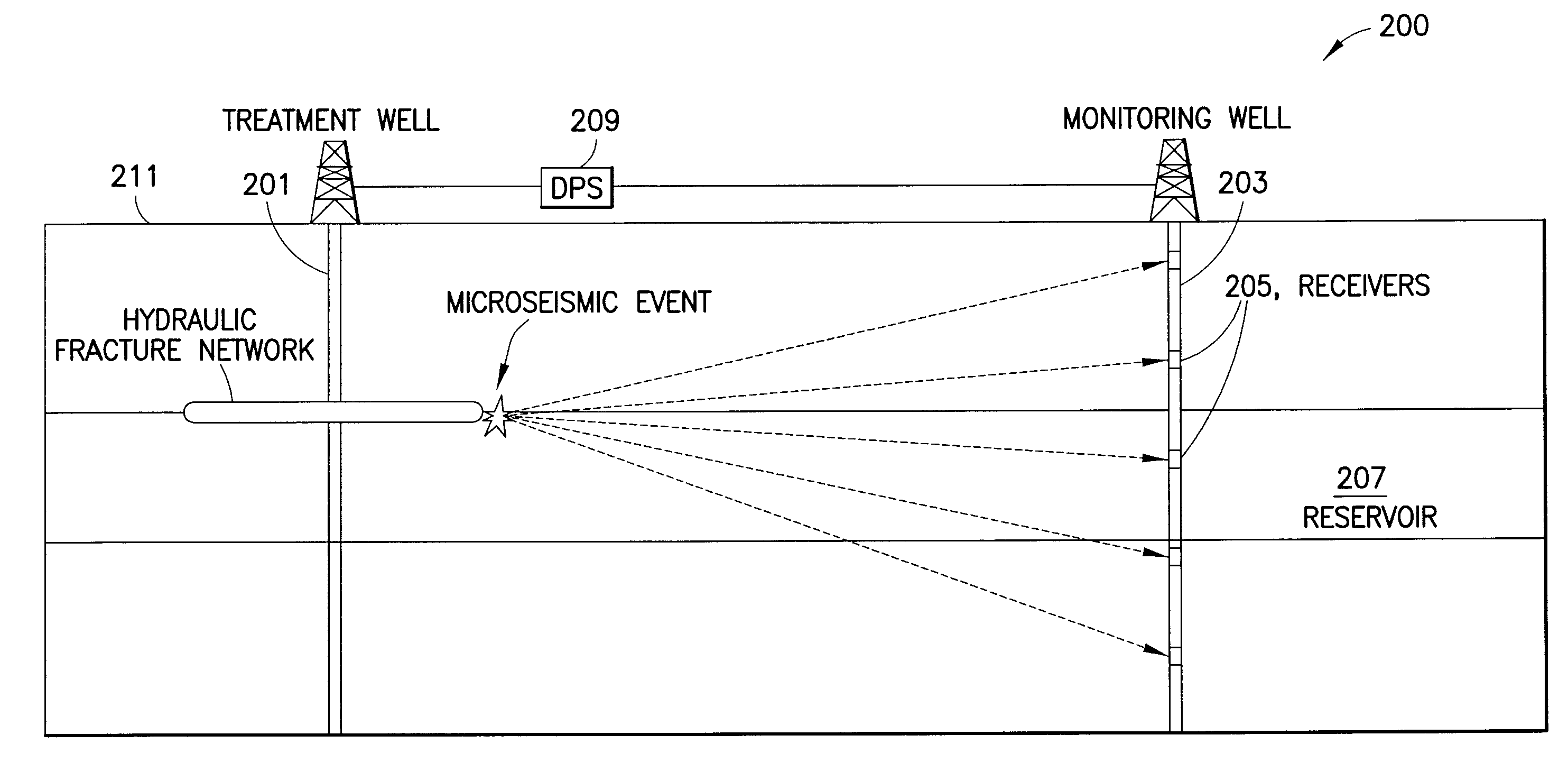

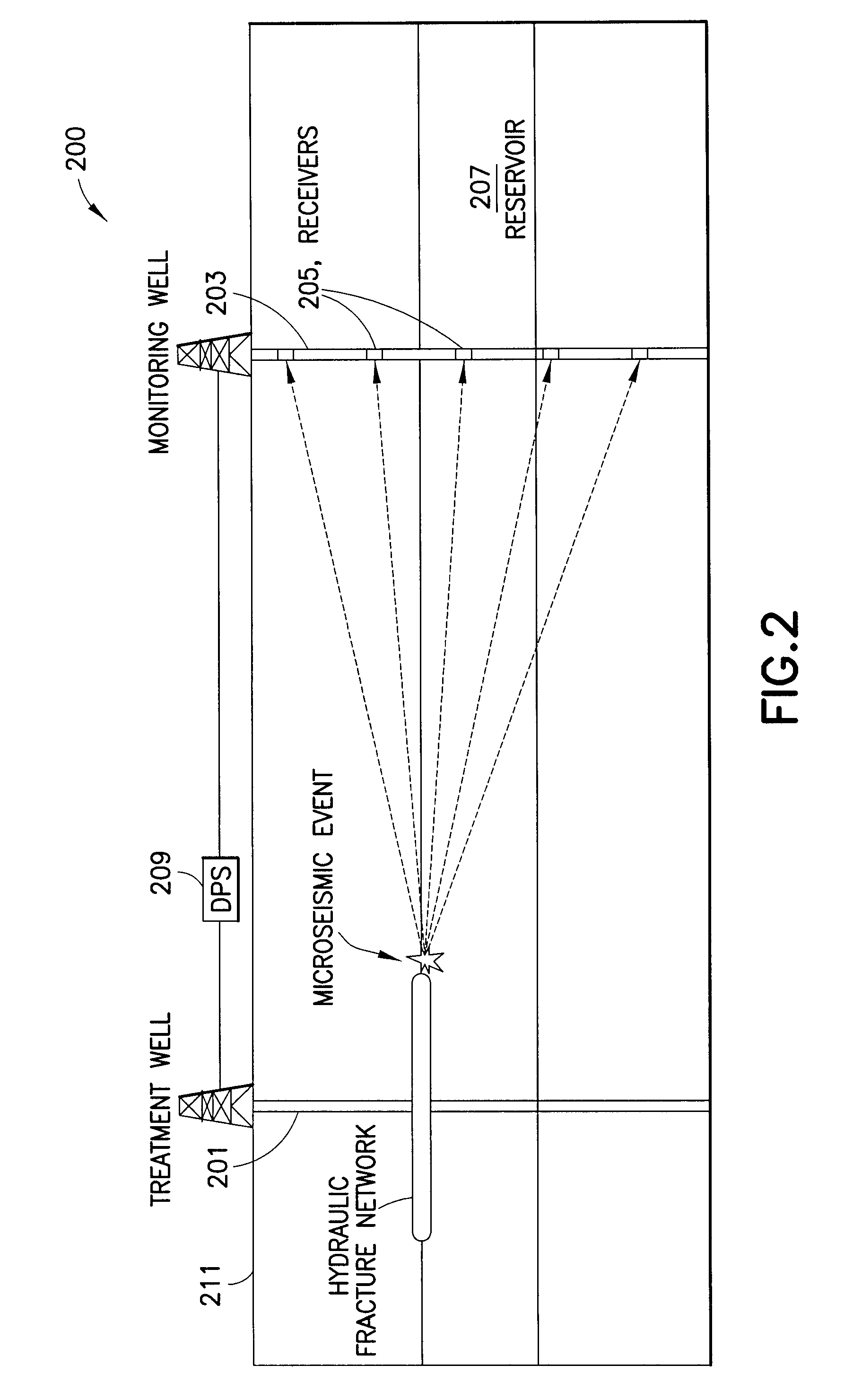

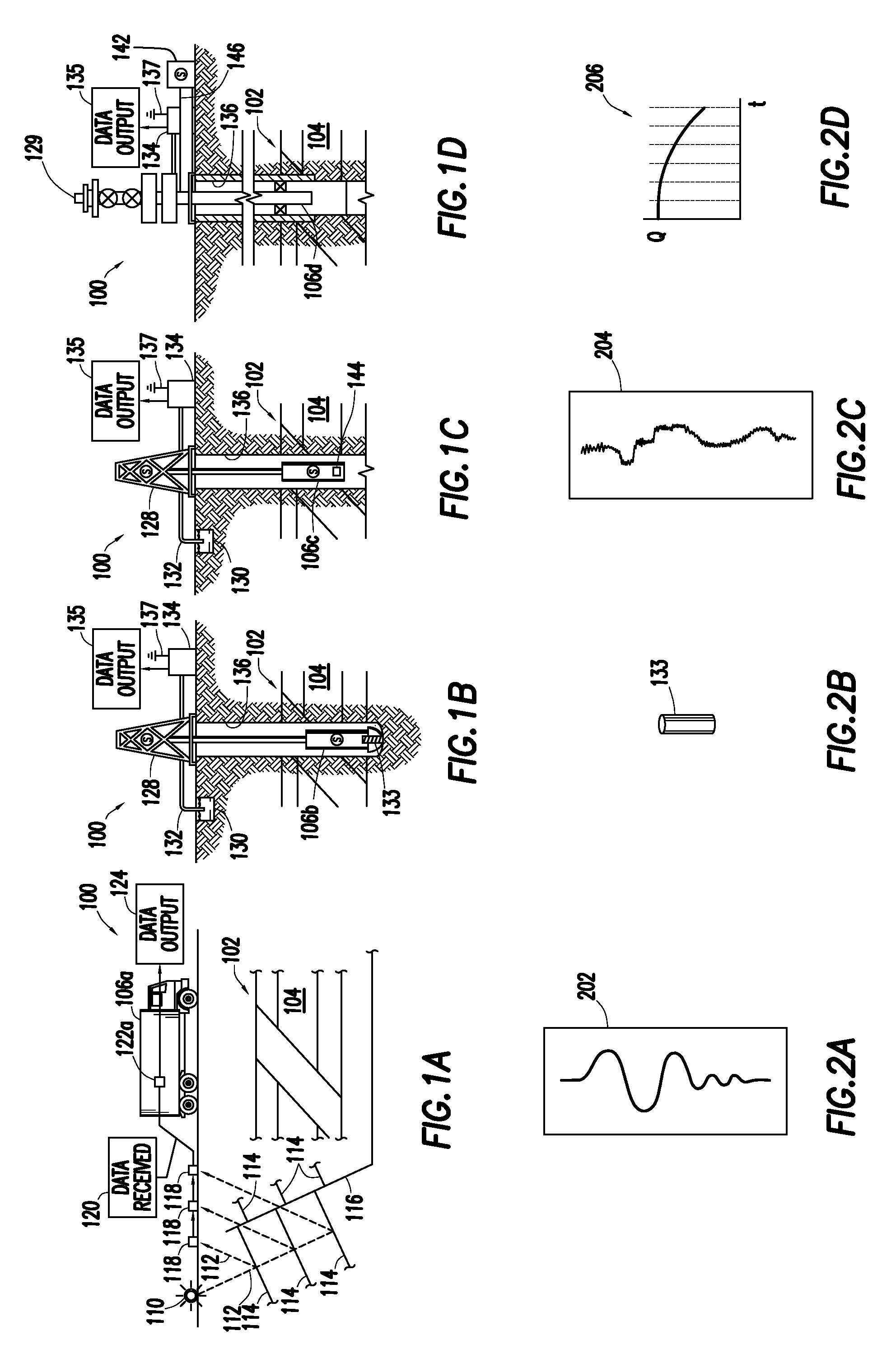

Method and apparatus for efficient real-time characterization of hydraulic fractures and fracturing optimization based thereon

ActiveUS20100307755A1Reduce complexityReducing resourceFluid removalComputation using non-denominational number representationGeomorphologyHydraulic fracturing

Methods and systems for characterizing hydraulic fracturing of a subterranean formation based upon inputs from sensors measuring field data in conjunction with a fracture model. Such characterization can be generated in real-time to automatically manipulate surface and / or down-hole physical components supplying hydraulic fluids to the subterranean formation to adjust the hydraulic fracturing process as desired. The hydraulic fracture model as described herein can also be used as part of forward calculations to help in the design and planning stage of a hydraulic fracturing treatment. In a preferred embodiment, the fracture model constrains geometric and geomechanical properties of the hydraulic fractures of the subterranean formation using the field data in a manner that significantly reduce the complexity of the fracture model and thus significantly reduces the processing resources and time required to provide accurate characterization of the hydraulic fractures of the subterranean formation.

Owner:SCHLUMBERGER TECH CORP

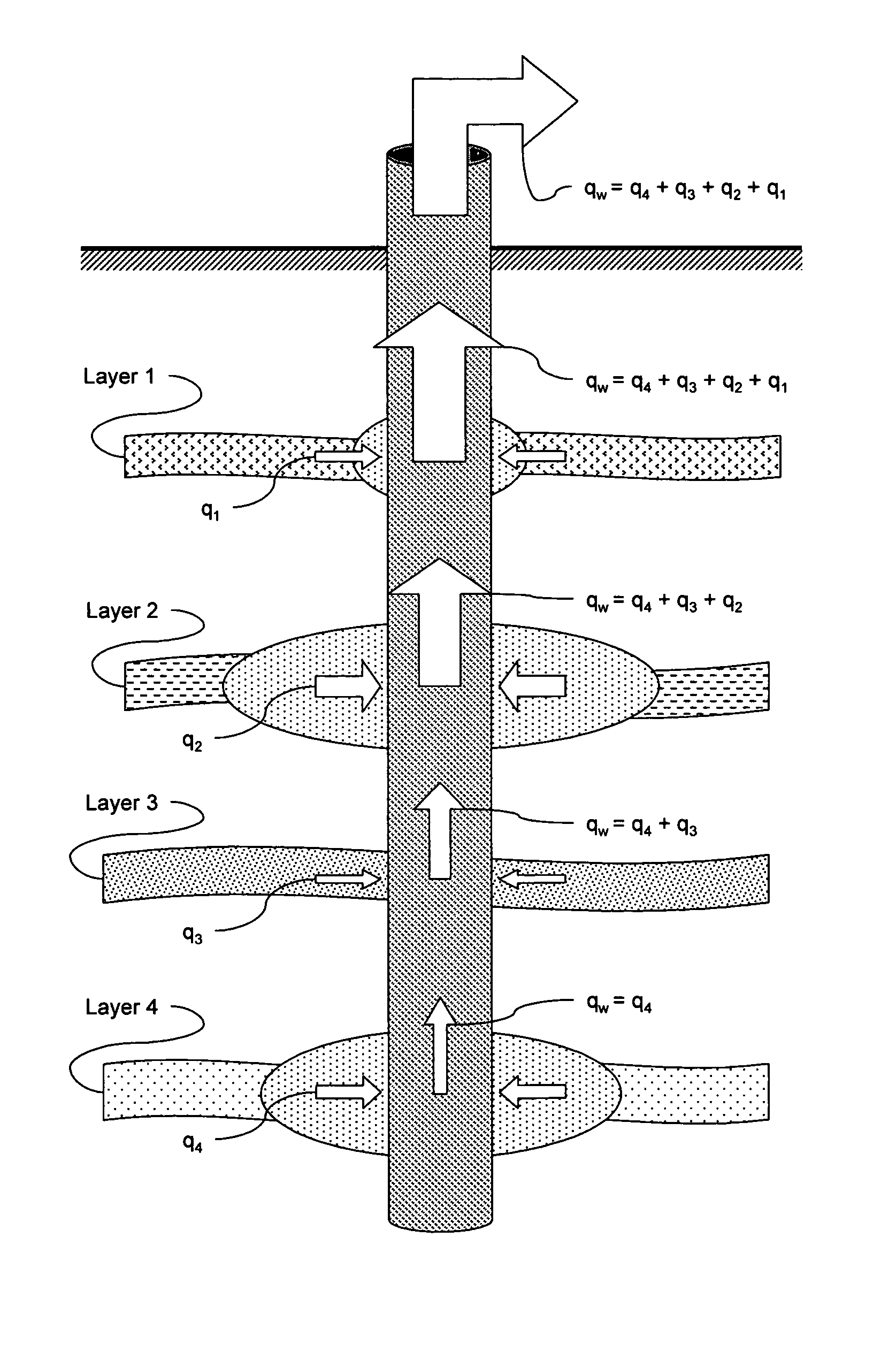

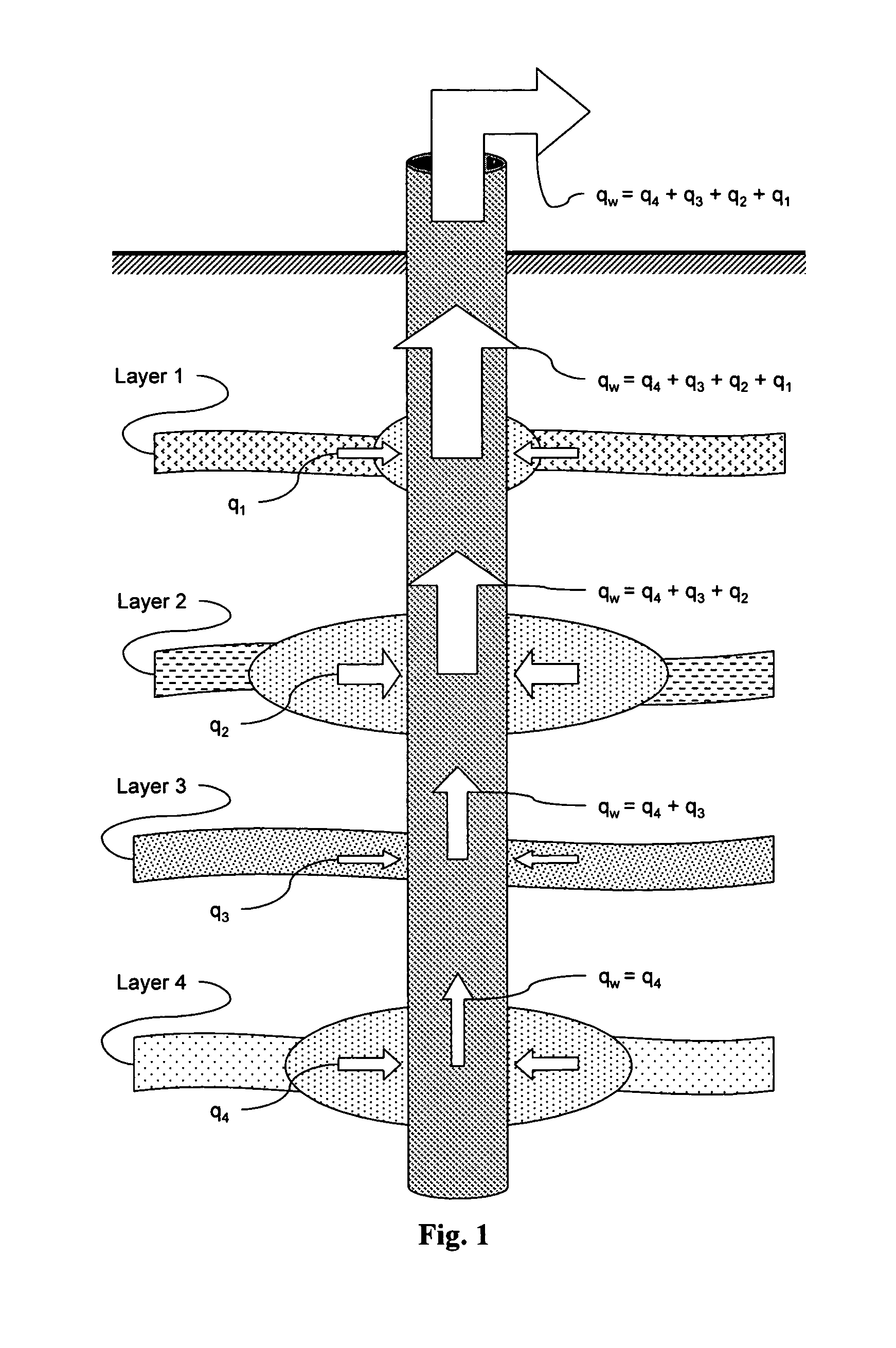

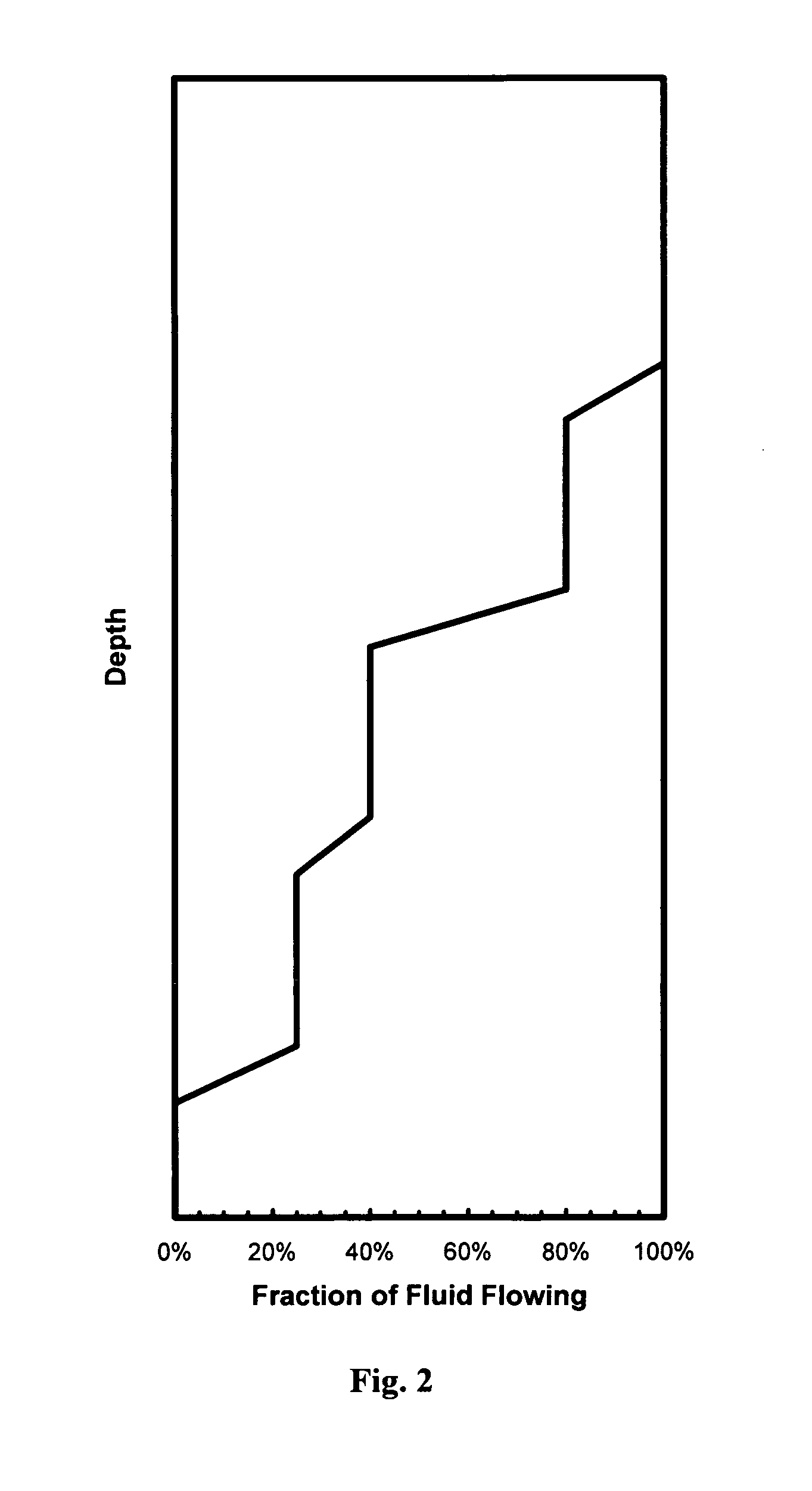

Method for characterizing and forecasting performance of wells in multilayer reservoirs having commingled production

InactiveUS7369979B1Electric/magnetic detection for well-loggingFluid removalSkin factorPredictive methods

A method for forecasting performance for and characterizing the properties of a multilayer low permeability gas reservoir. The method includes a coupled well / reservoir predictive model that accounts for pressure drop between layers, allowing accurate, rigorous, and rapid forecasting of reservoir performance. The method provides estimates of individual layer properties such as in-situ permeability, skin factor, fracture half-length, fracture conductivity, drainage area, etc. by simultaneously history matching production data and production log data using the coupled well / reservoir predictive model.

Owner:SPIVEY JOHN PAUL

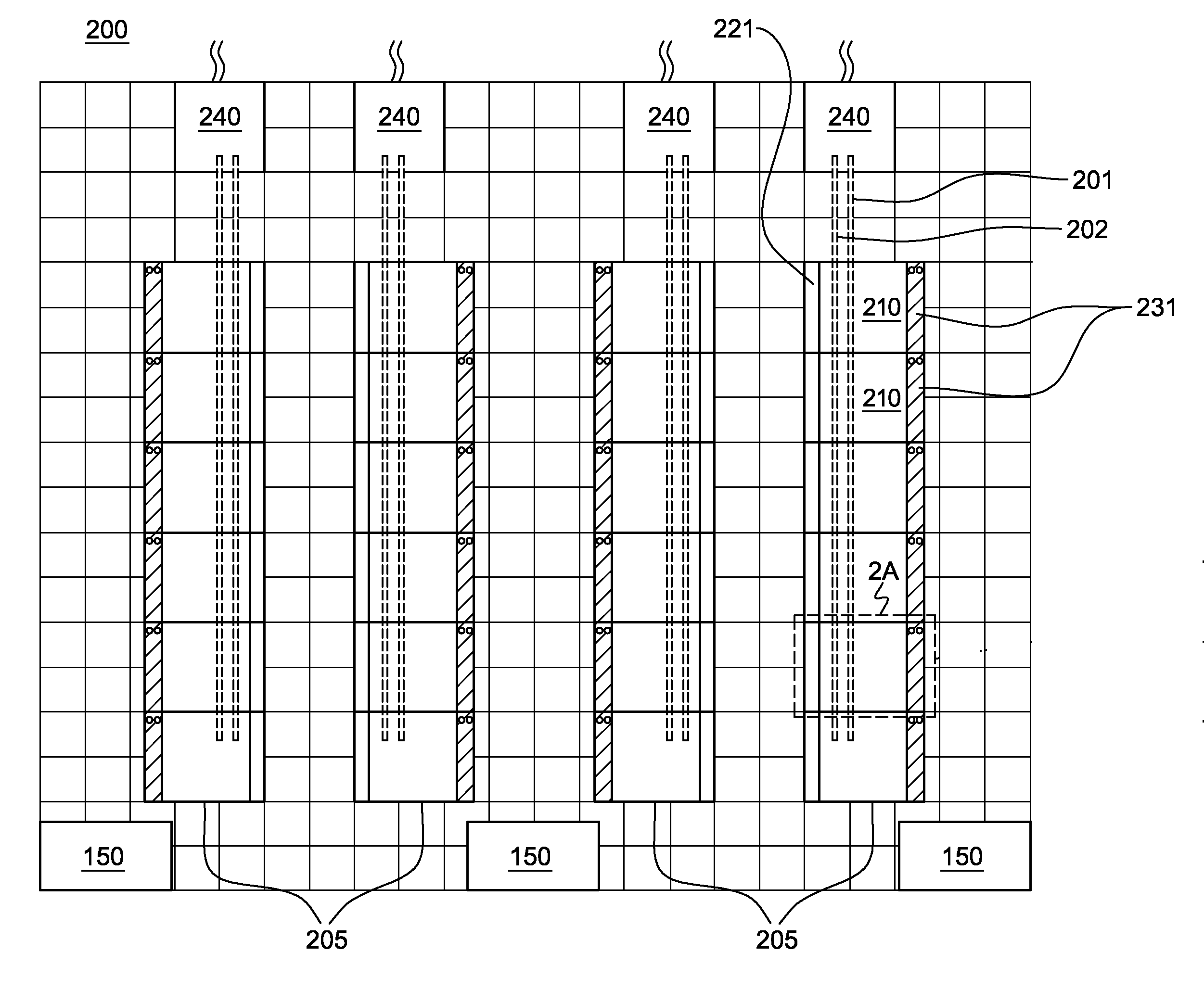

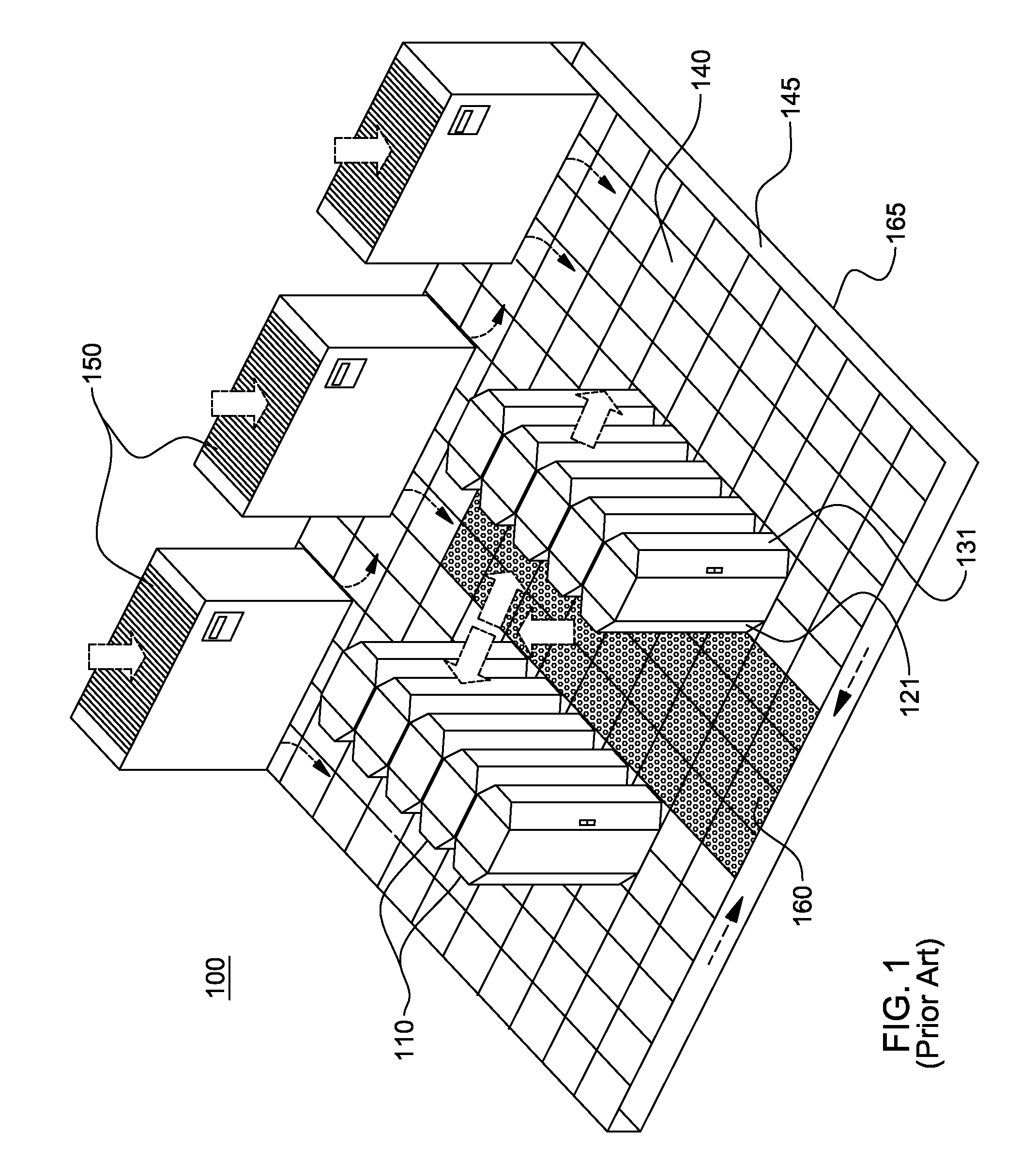

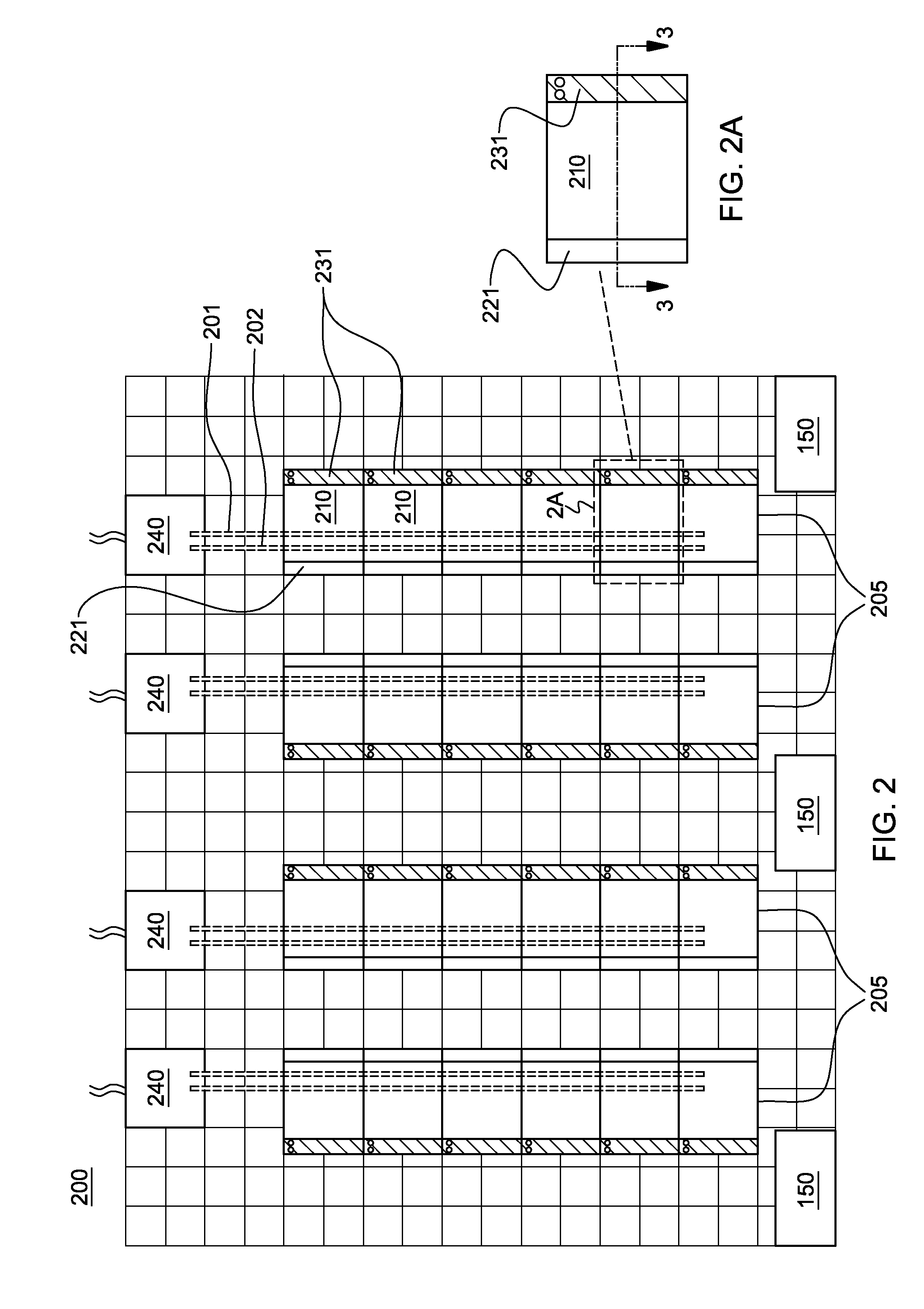

Method of laying out a data center using a plurality of thermal simulators

A method is provided for facilitating installation of one or more electronics racks within a data center. The method includes: placing a plurality of thermal simulators in the data center in a data center layout to establish a thermally simulated data center, each thermal simulator simulating at least one of airflow intake or heated airflow exhaust of a respective electronics rack of a plurality of electronics racks to be installed in the data center; monitoring temperature within the thermally simulated data center at multiple locations, and verifying the data center layout if measured temperatures are within respective acceptable temperature ranges for the data center when containing the plurality of electronics racks; and establishing the plurality of electronics racks within the data center using the verified data center layout, the establishing including at least one of reconfiguring or replacing each thermal simulator with a respective electronics rack.

Owner:GLOBALFOUNDRIES INC

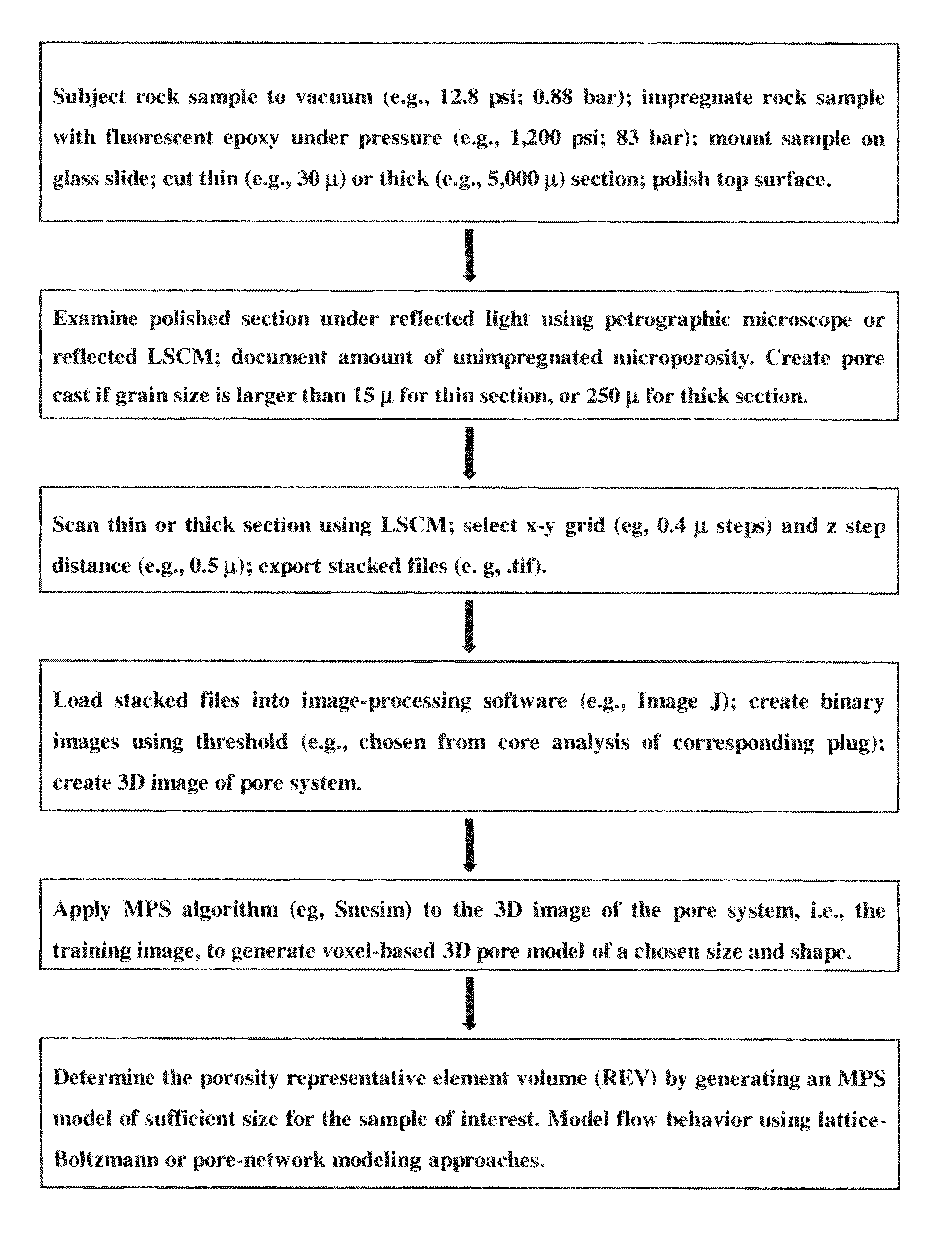

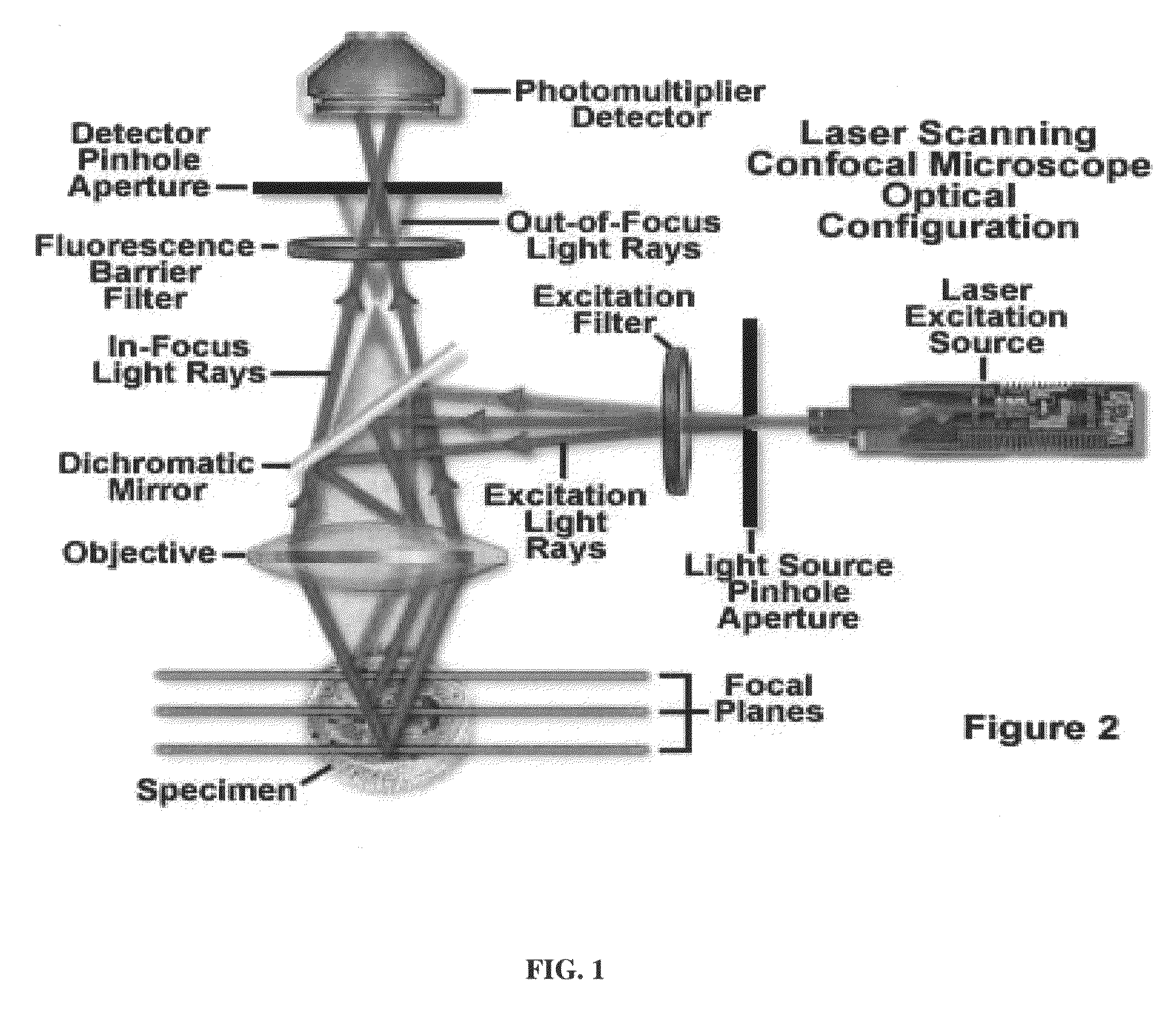

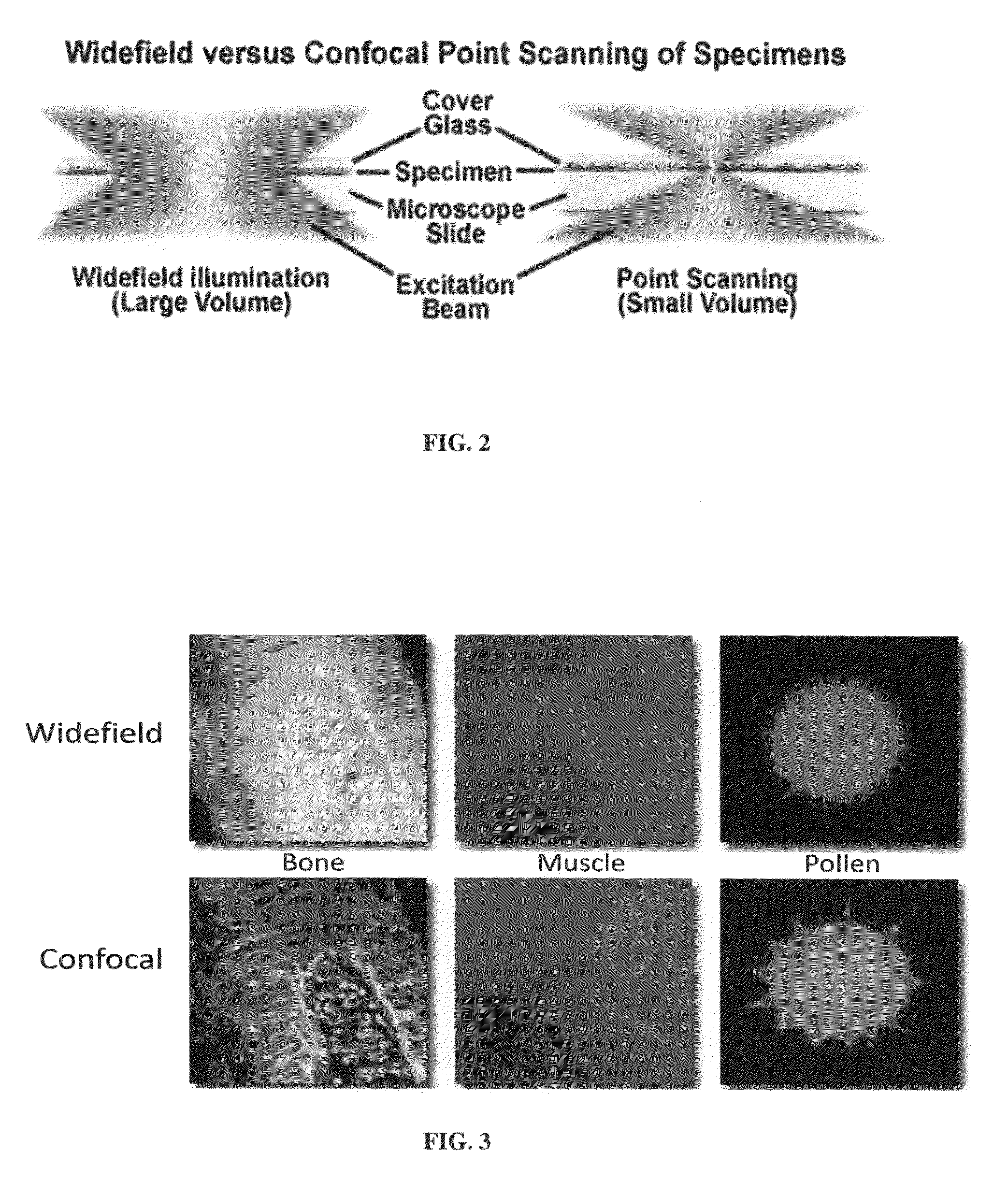

Method to build 3D digital models of porous media using transmitted laser scanning confocal mircoscopy and multi-point statistics

InactiveUS20110004447A1Reduce restrictionsReduce boundary effectsDigital computer detailsCharacter and pattern recognitionPorous mediumLaser scanning

Owner:SCHLUMBERGER TECH CORP

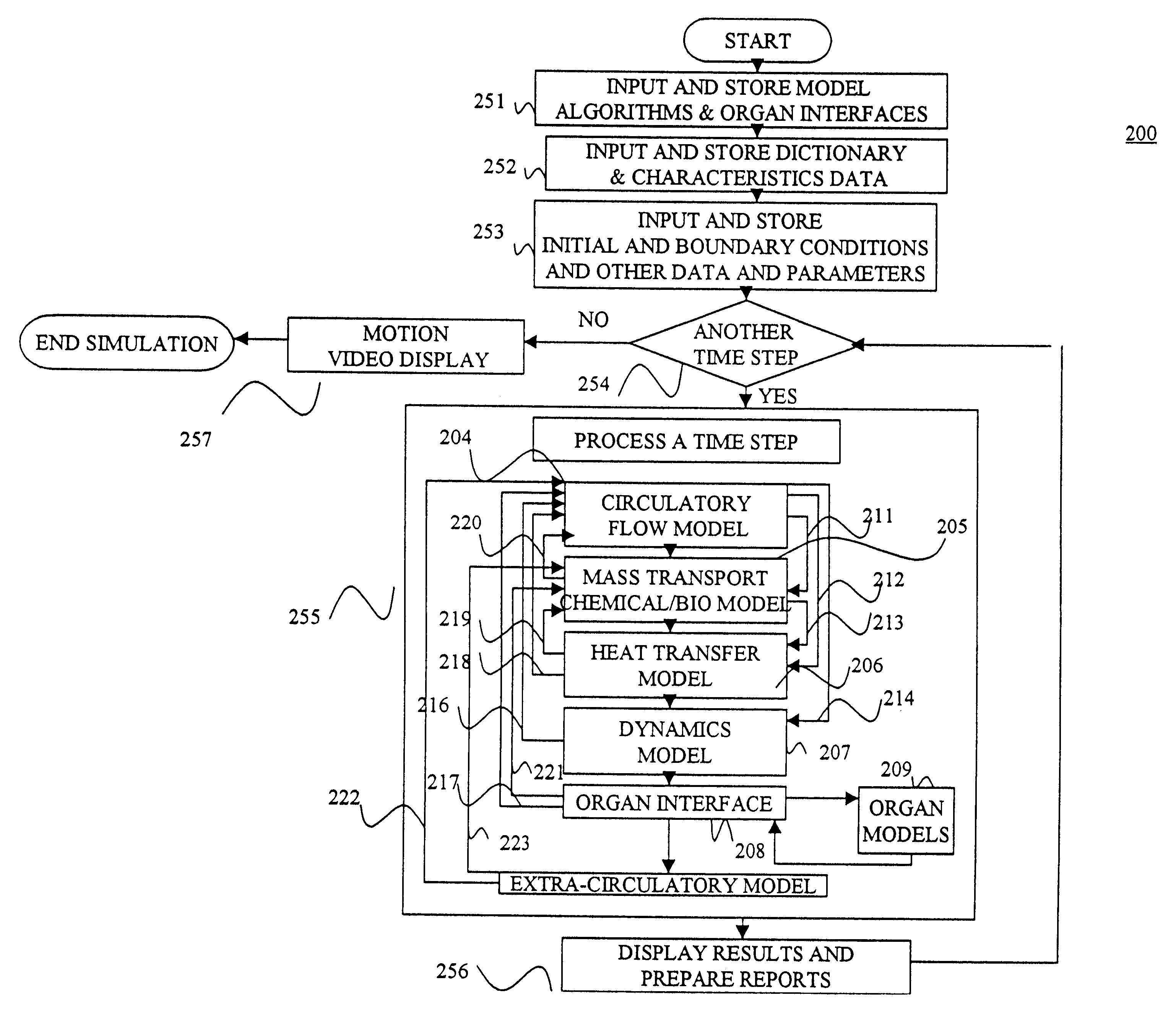

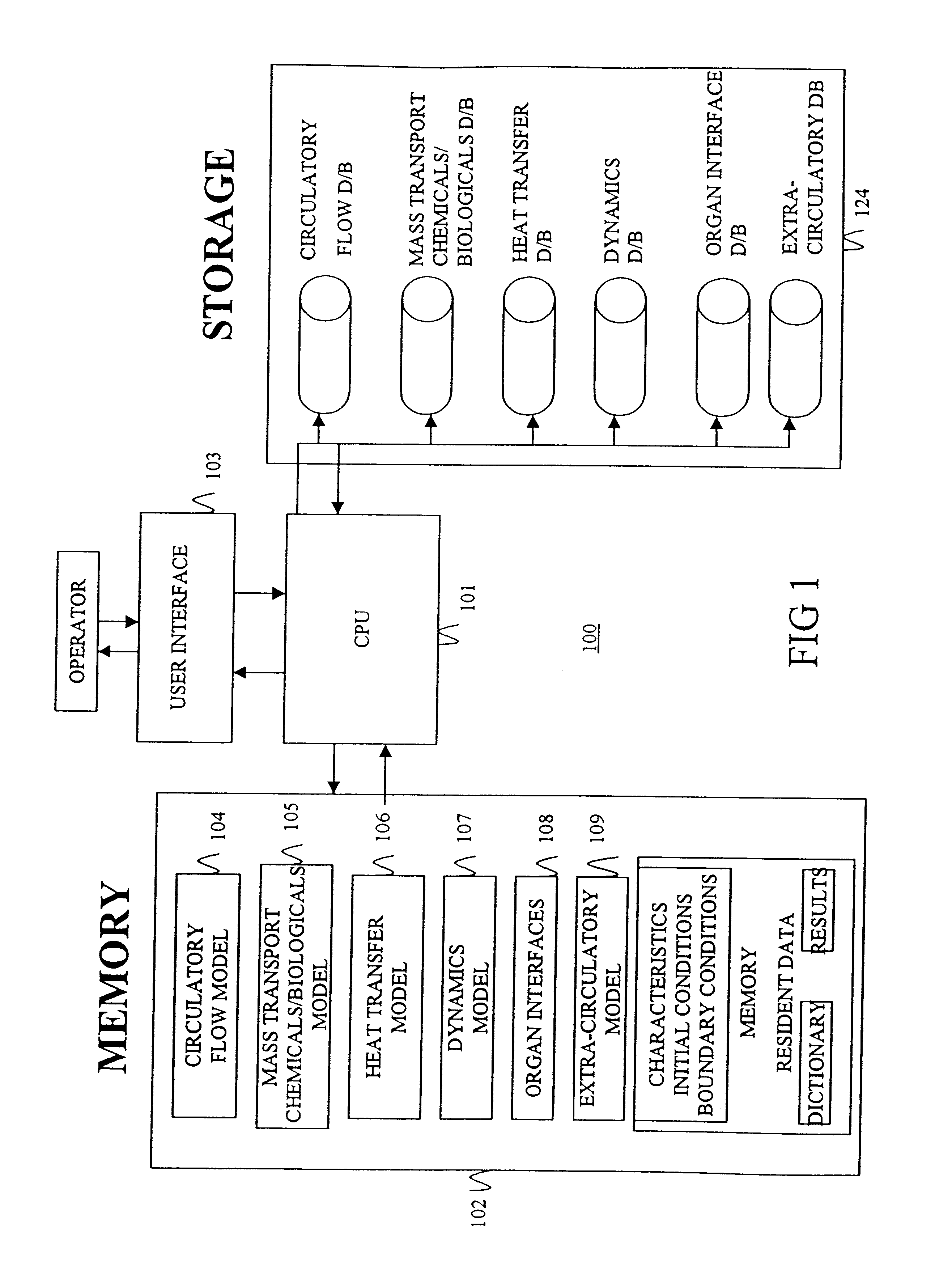

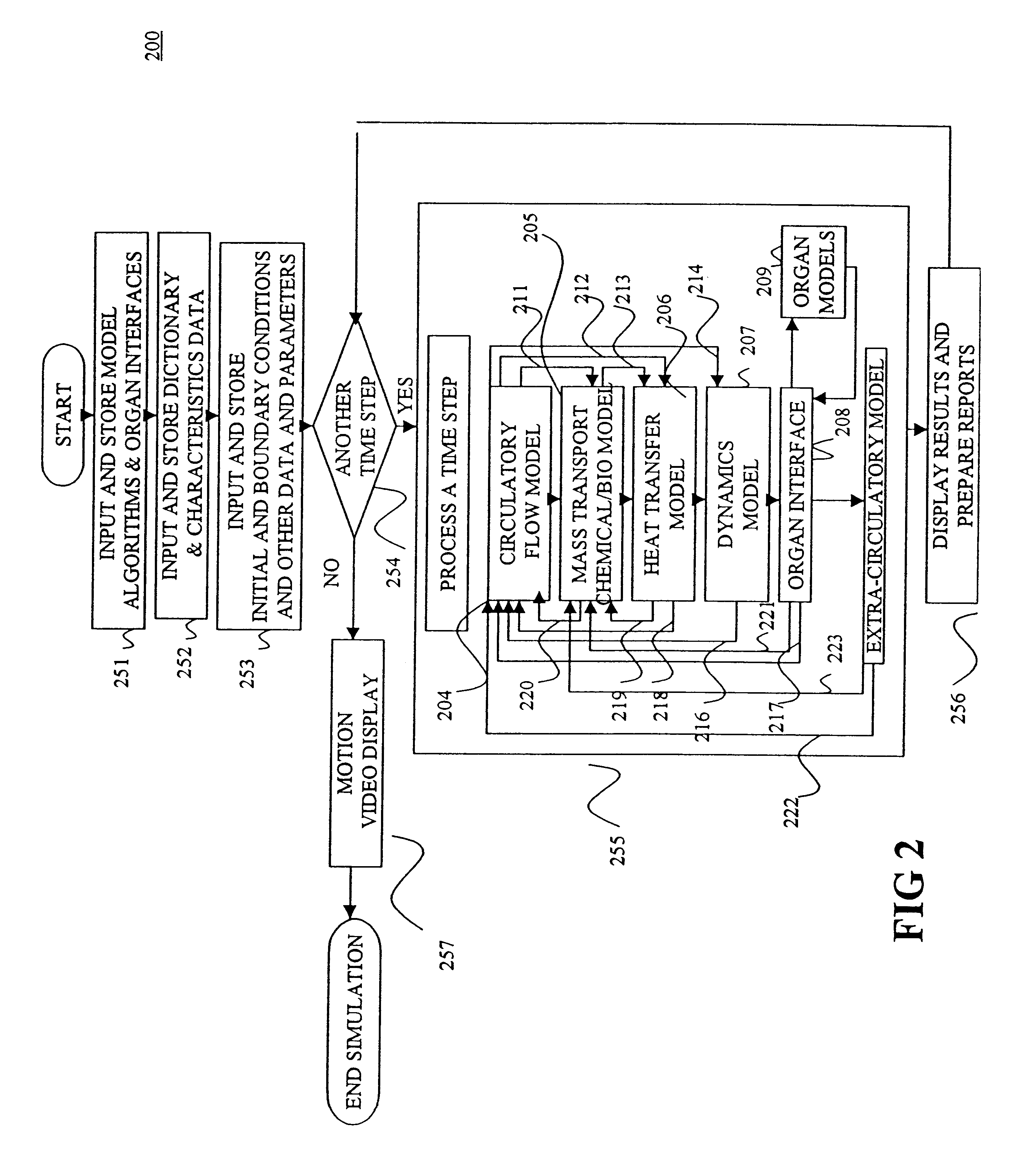

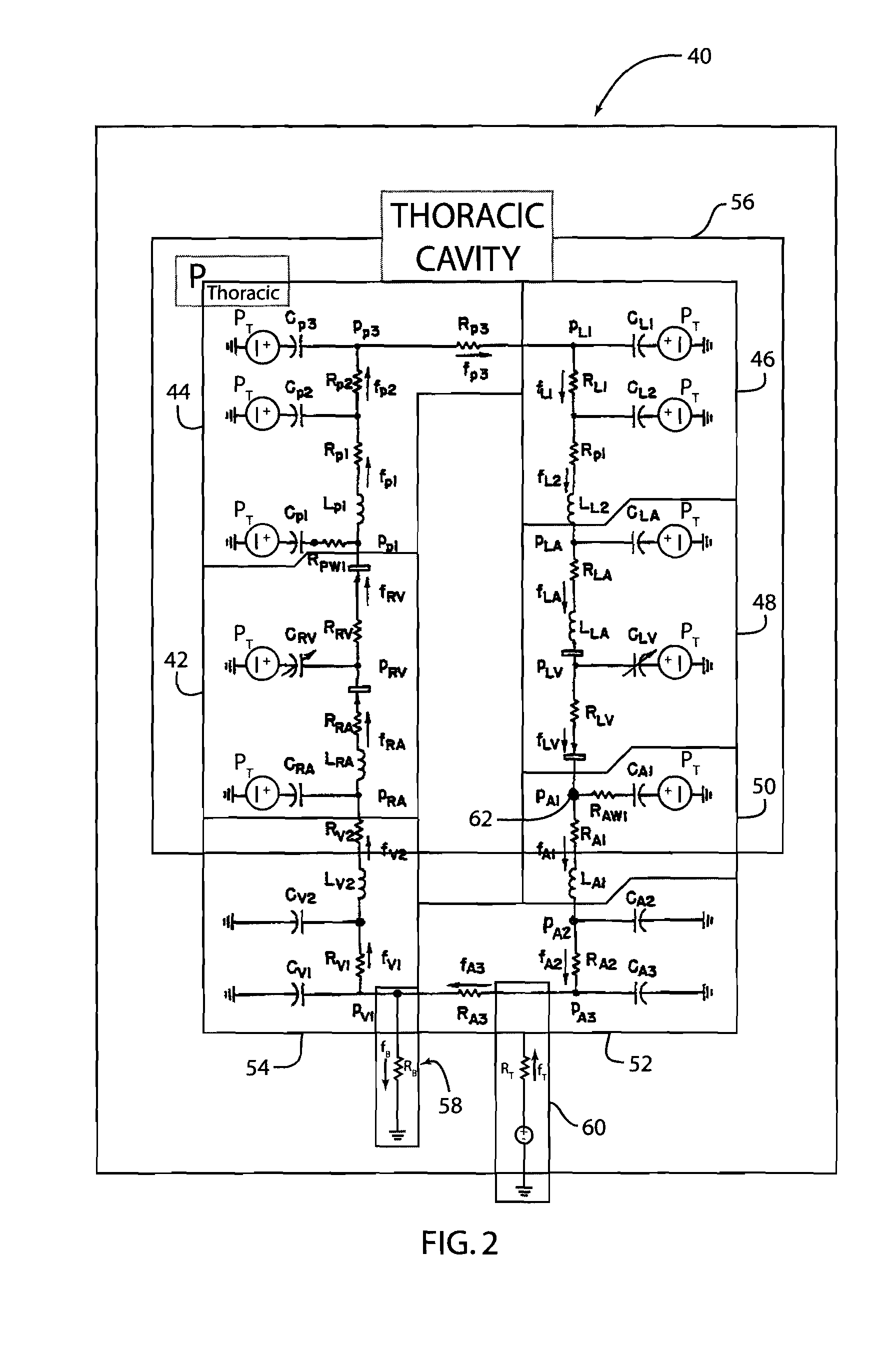

Configurable bio-transport system simulator

InactiveUS6381562B2Easy to customizeSave effortNanoinformaticsAnalogue computers for chemical processesComputational scienceBiological body

A method of simulating a bio-transport system comprising: (a) characterizing one or more elements to represent a bio-transport system of an organism or a portion thereof; (b) constructing one or more mathematical representations that model one or more bio-transport dynamics for each element based on the characterization of the elements to form a configured simulation model; (c) initializing the configured simulation model; (d) executing the configured simulation model to obtain bio-transport dynamics data for one or more elements; and (e) outputting information to a user based on at least a portion of the bio-transport dynamics data.

Owner:KEANE JOHN A

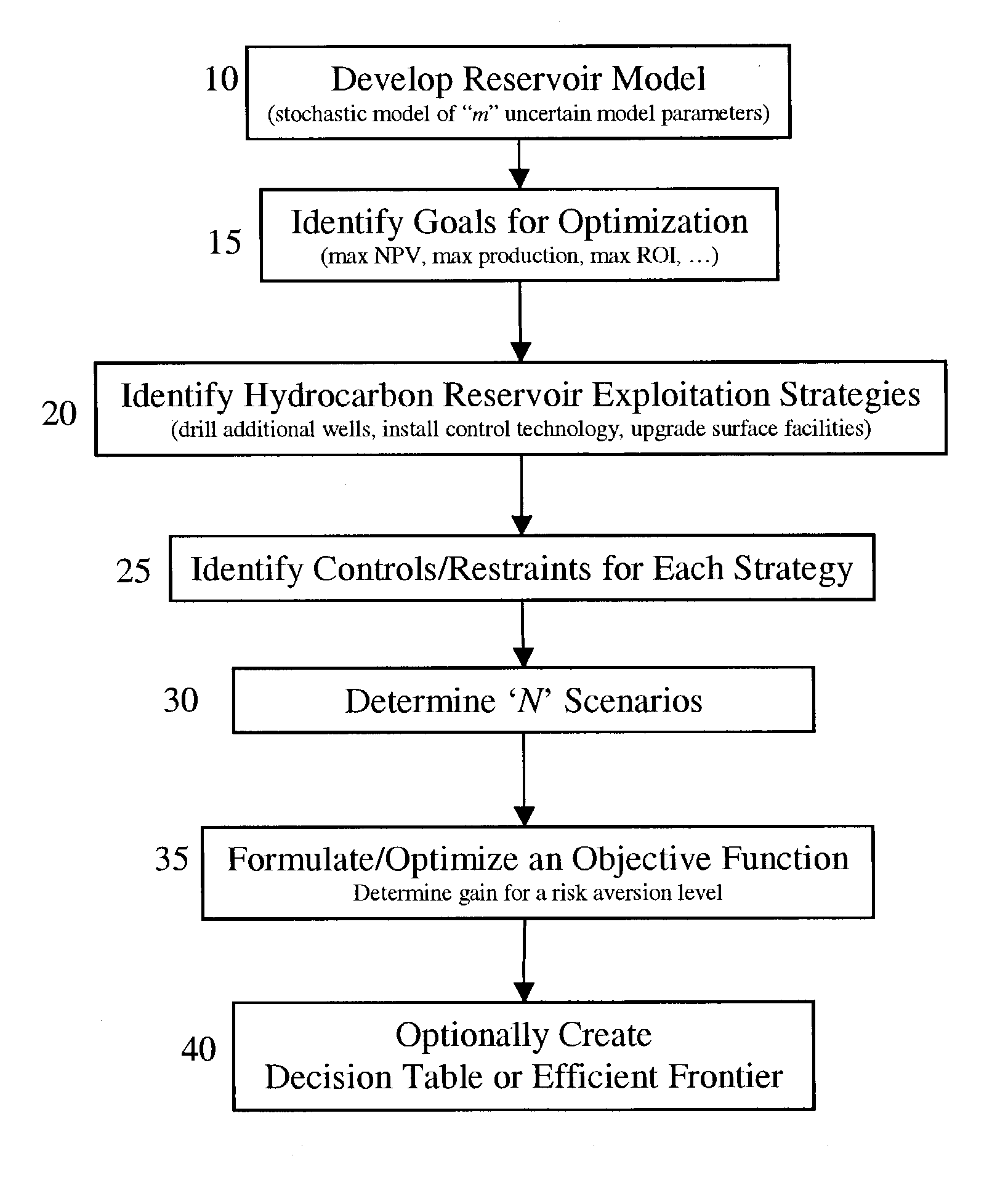

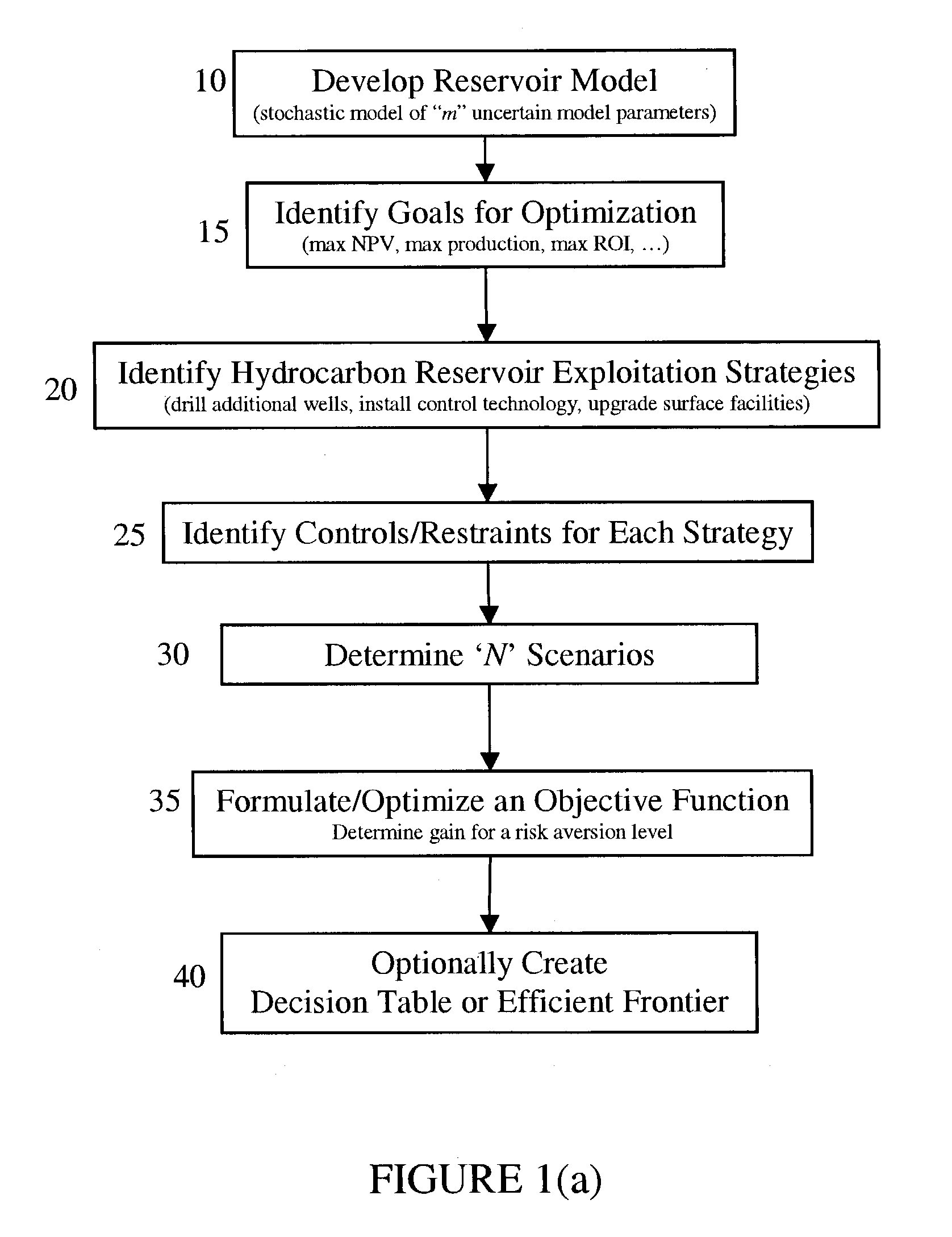

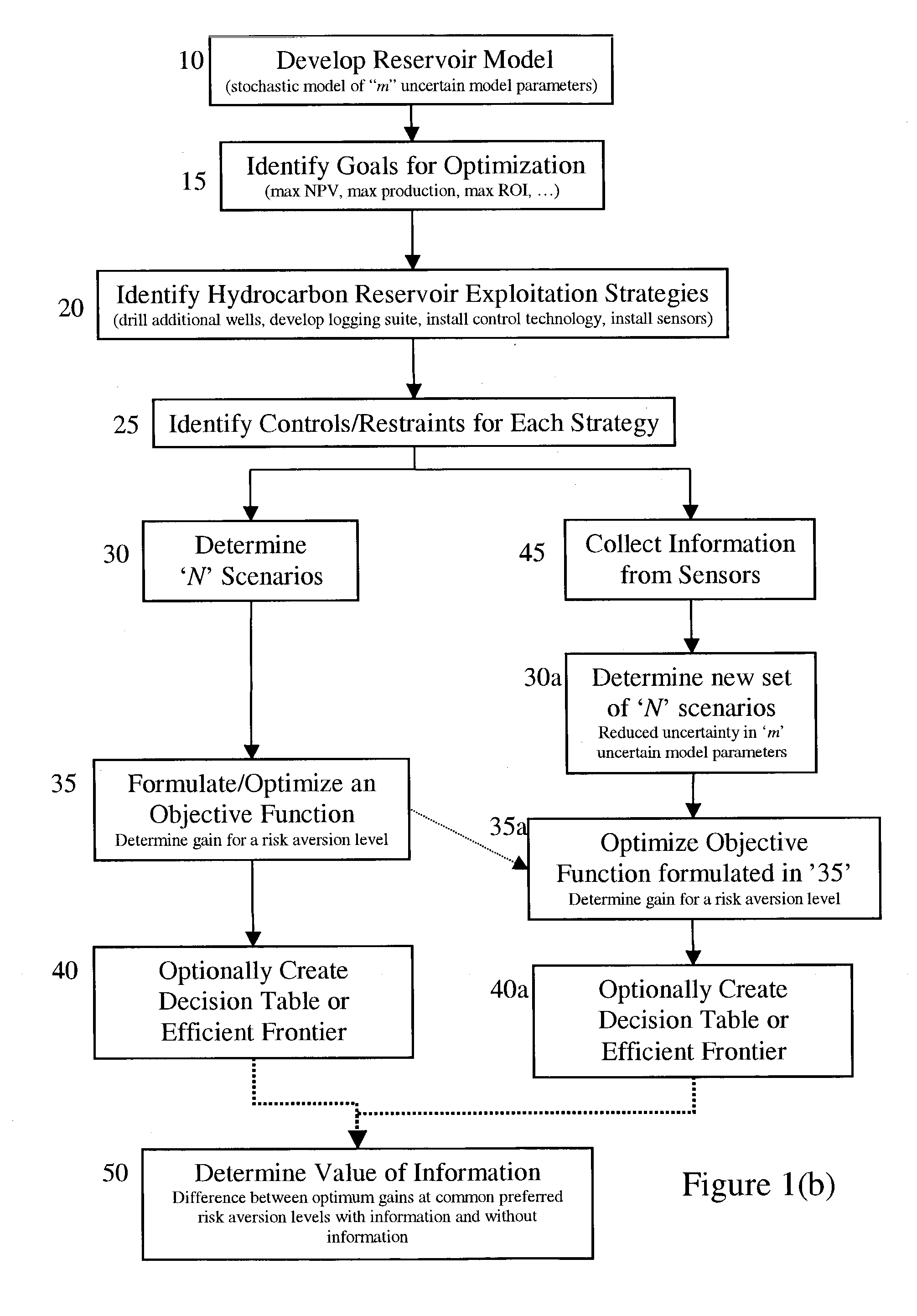

Tools for decision-making in reservoir risk management

ActiveUS20030225606A1FinanceComputation using non-denominational number representationEngineeringStochastic calculus

The present invention discloses a method for performing a stochastic analysis of one or more hydrocarbon reservoir exploitation strategies taking into consideration one or more uncertain parameters. The method optimizes an objective function that considers the gain in value of a reservoir management goal attributable to these exploitation strategies. The methodology may be used to decide whether or not to implement a strategy. Alternatively, it may be used to decide which competing strategy will yield the maximum benefit. In another embodiment of the present invention, the value of information obtained from the installation of additional sensors or new measurements is also considered.

Owner:SCHLUMBERGER TECH CORP

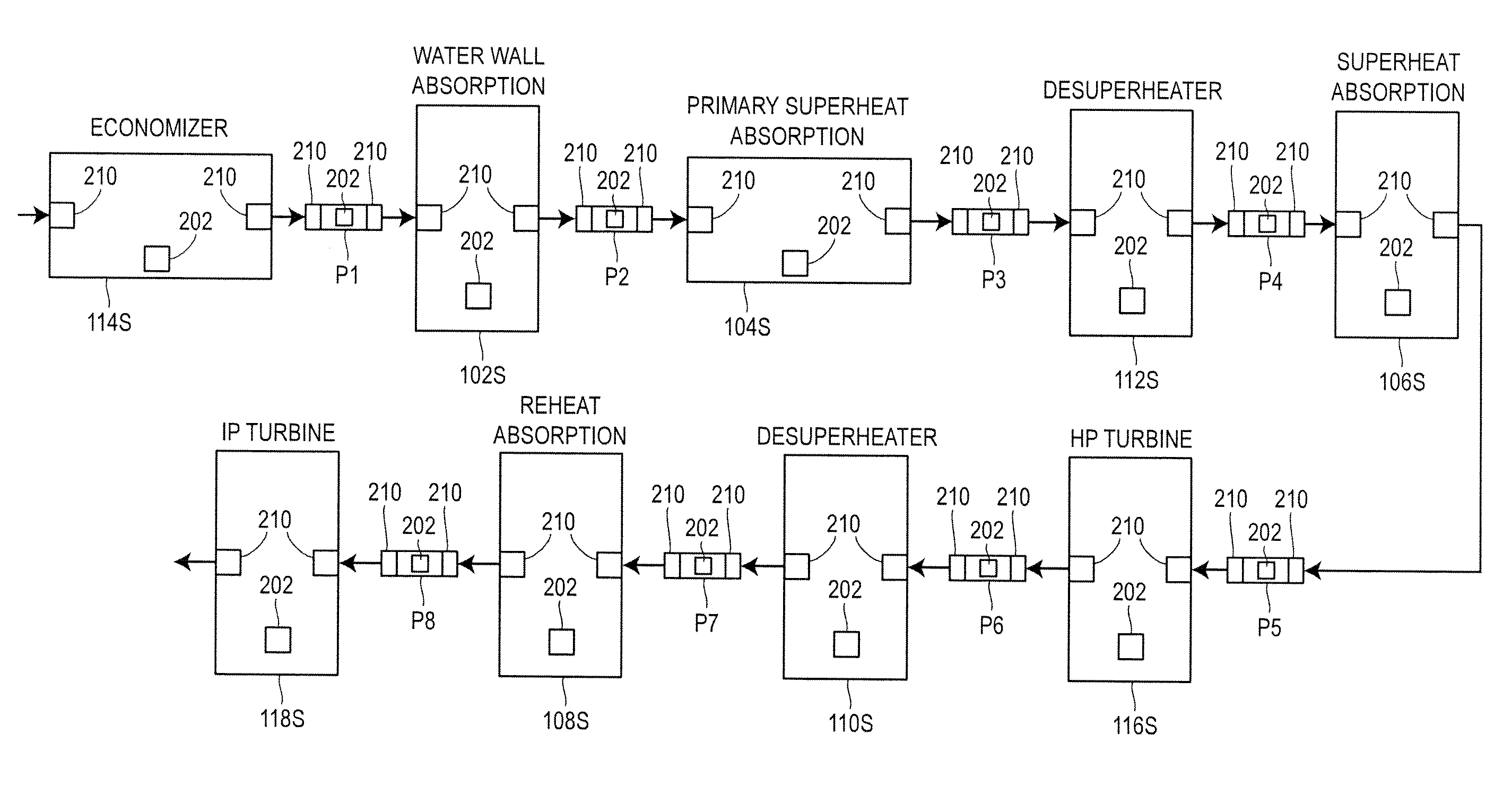

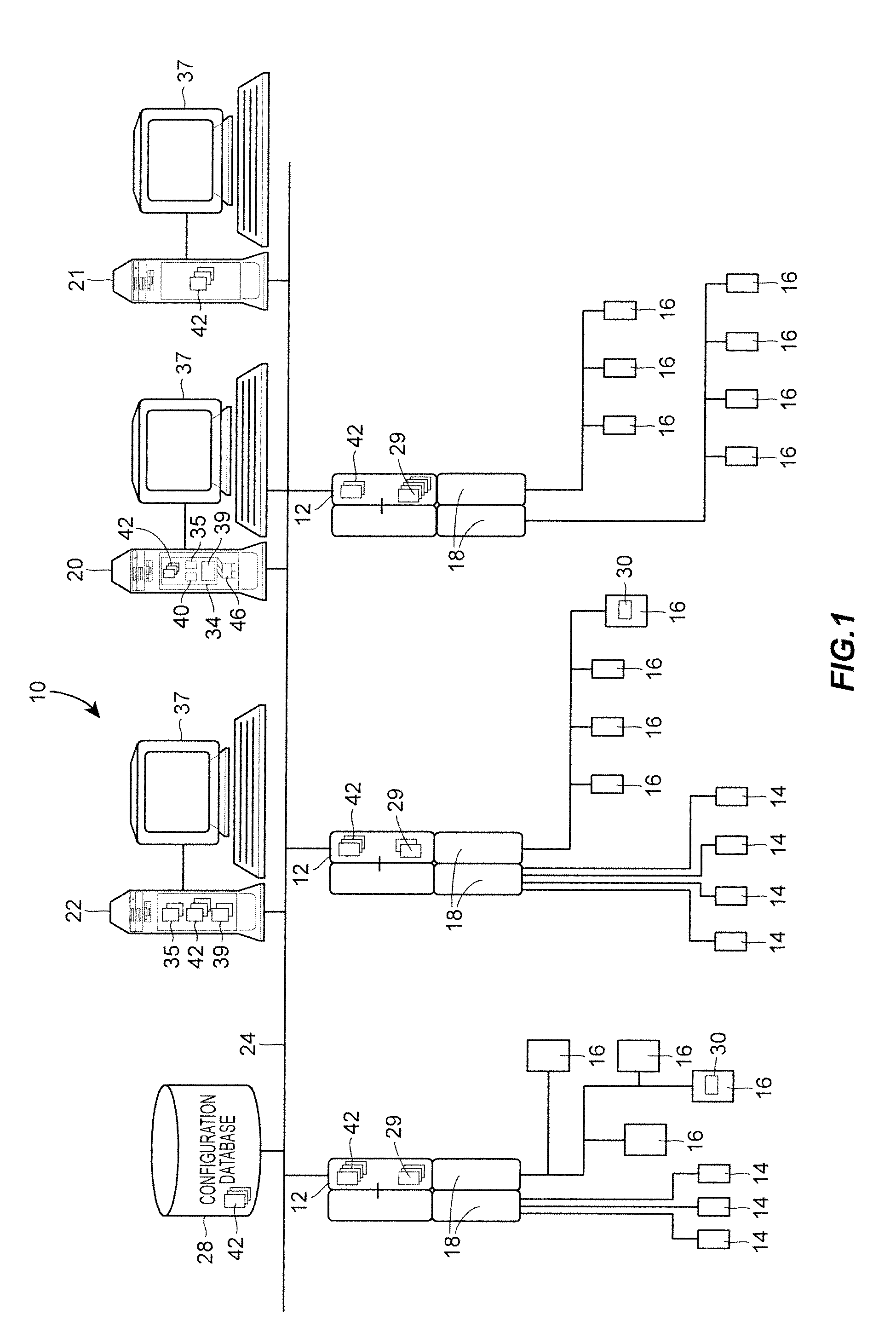

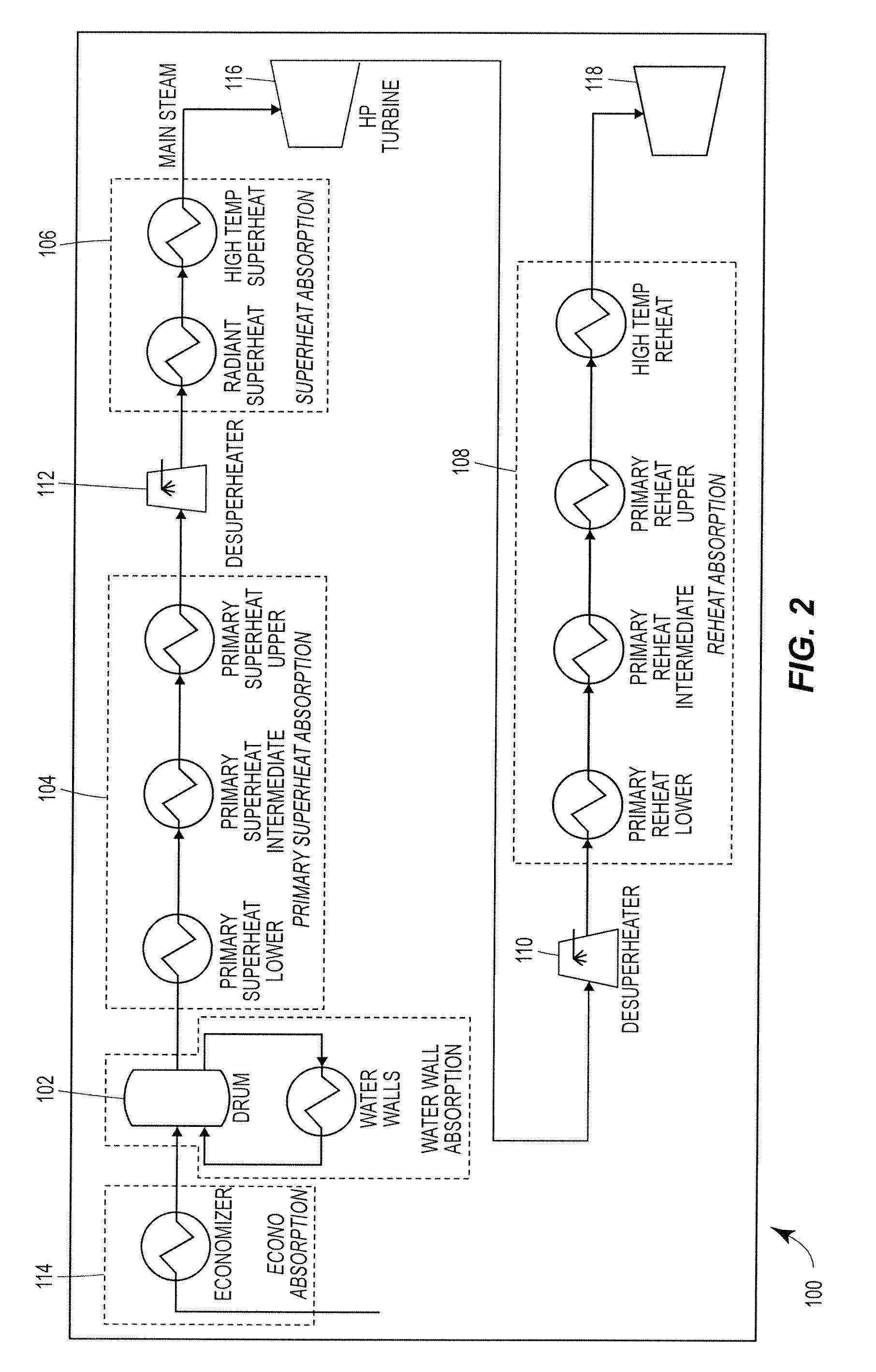

Decentralized industrial process simulation system

ActiveUS20110131017A1Accurately solves massAccurately flow balanceProgramme controlAnalogue computers for control systemsMass storageParallel computing

A high fidelity distributed plant simulation technique includes a plurality of separate simulation modules that may be stored and executed separately in different drops or computing devices. The simulation modules communicate directly with one another to perform accurate simulation of a plant, without requiring a centralized coordinator to coordinate the operation of the simulation system. In particular, numerous simulation modules are created, with each simulation module including a model of an associated plant element and these simulation modules are stored in different drops of a computer network to perform distributed simulation of a plant or a portion of a plant. At least some of the simulation modules, when executing, perform mass flow balances taking into account process variables associated with adjacent simulation modules to thereby assure pressure, temperature and flow balancing (i.e., conservation of mass flow) through the entire simulation system. In a dynamic situation, a transient mass storage relay technique is used to account for transient changes in mass flow through any non-storage devices being simulated by the simulation modules. Moreover, adjacent simulation modules located in different drops communicate directly with one another using a background processing task, which simplifies communications between adjacent simulation modules without the need for a central coordinator.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

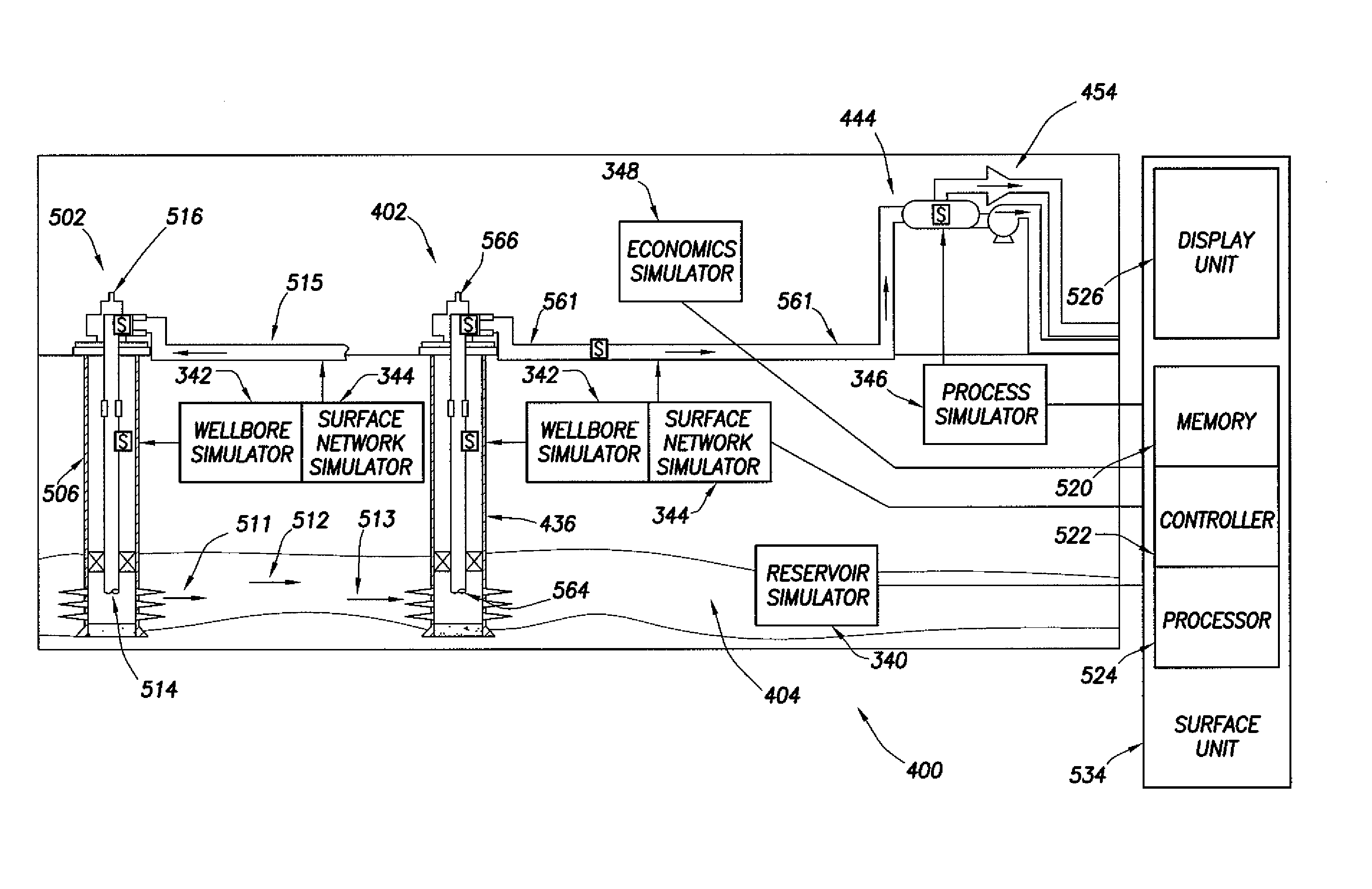

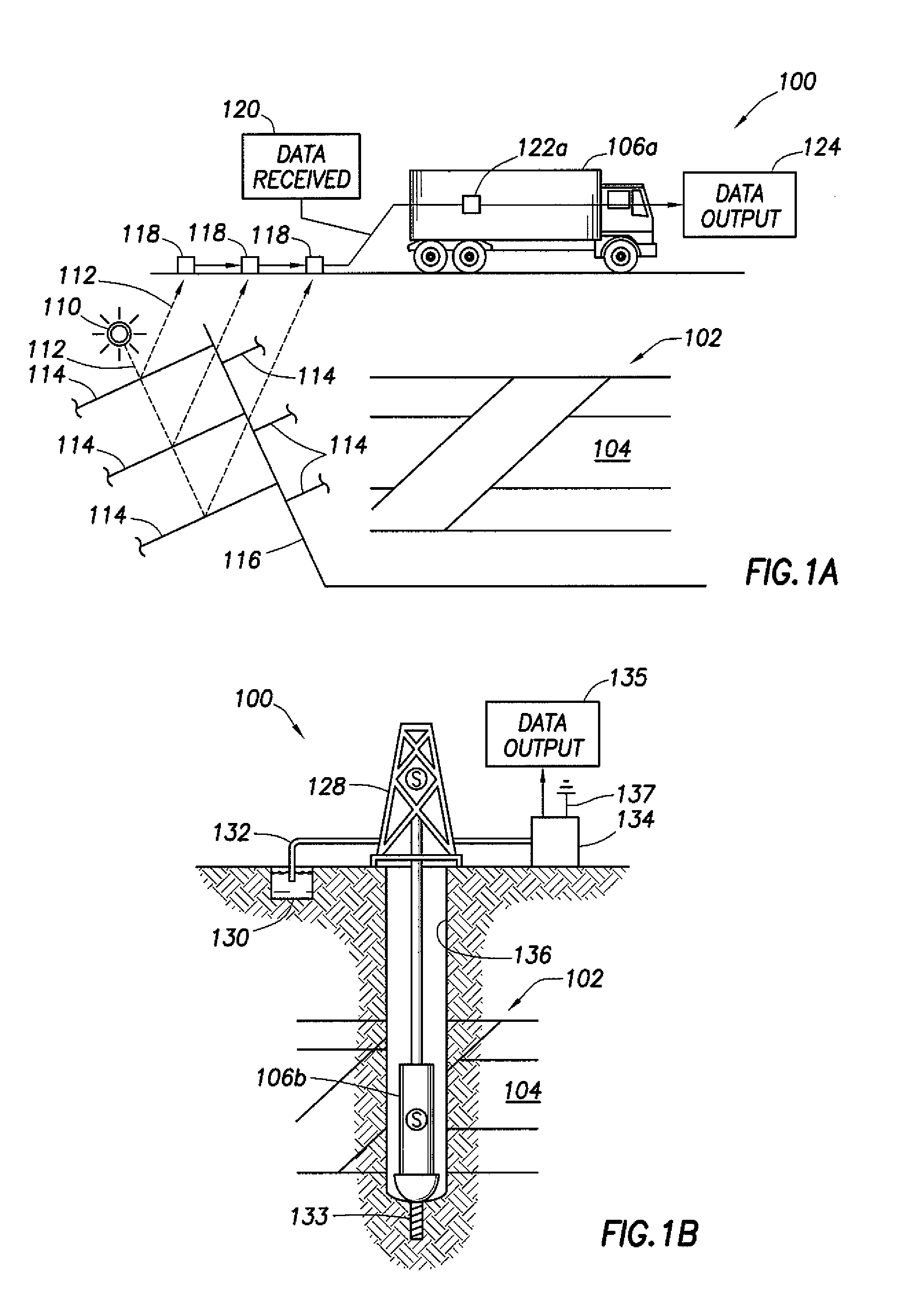

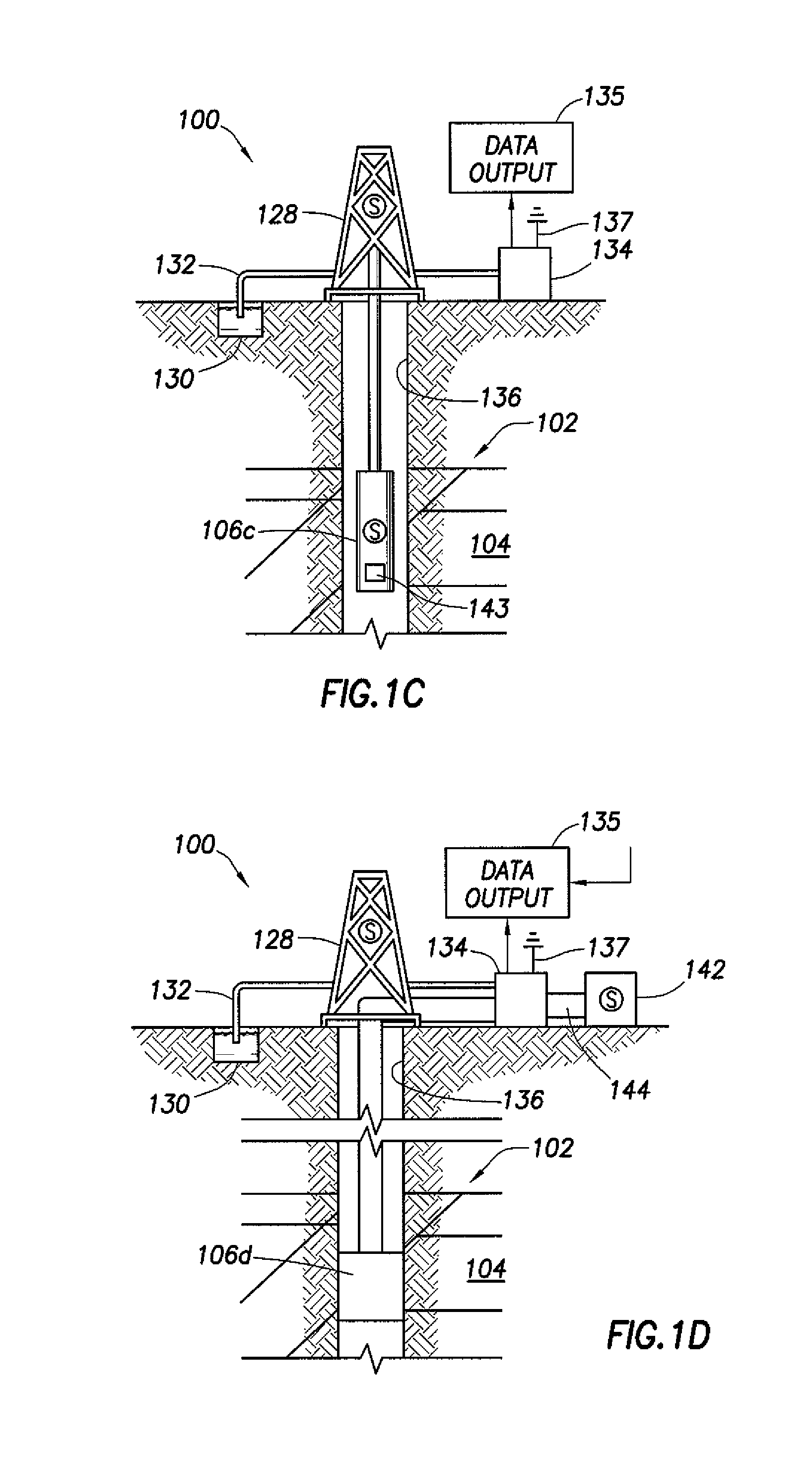

System and method for performing oilfield simulation operations

The invention relates to a method for performing operations of an oilfield having at least one process facilities and at least one wellsite operatively connected thereto, each at least one wellsite having a wellbore penetrating a subterranean formation for extracting fluid from or injecting fluid to an underground reservoir therein. The method involves selectively coupling a plurality of oilfield simulators according to a predefined configuration, each oilfield simulator modeling at least a portion of the oilfield, a first oilfield simulator of the plurality of oilfield simulators receives an oilfield control parameter as an input, identifying an uncertainty parameter associated with a plurality of probable values each corresponding to a weighted probability, a second oilfield simulator of the plurality of oilfield simulators receives the uncertainty parameter as an input, modeling the operations of the oilfield to generate an estimated performance by selectively communicating between the plurality of oilfield simulators, the operations of the oilfield is modeled with a predetermined value of the oilfield control parameter and at least one of the plurality of probable values of the uncertainty parameter; and identifying an optimal value of the oilfield control parameter based on the estimated performance.

Owner:SCHLUMBERGER TECH CORP

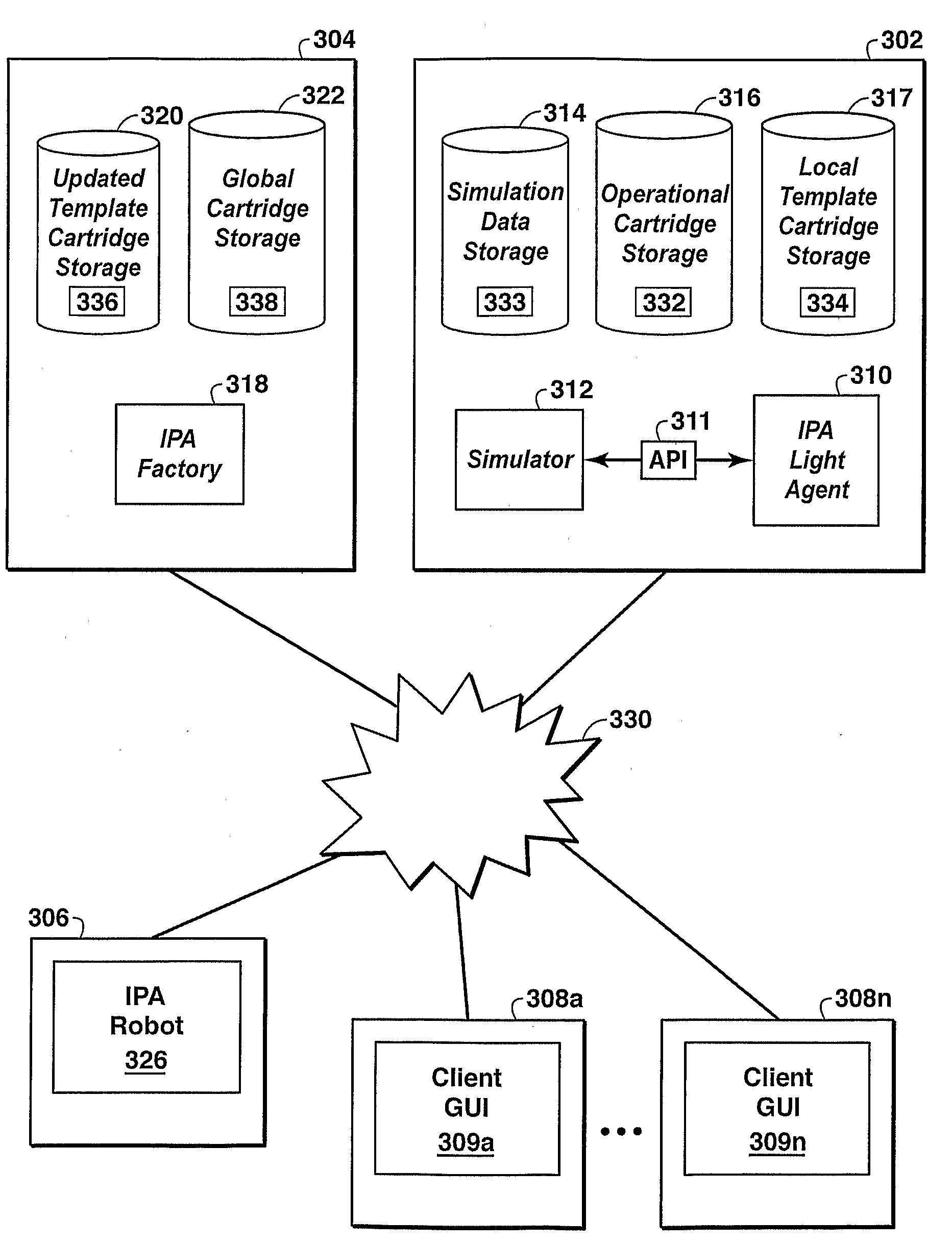

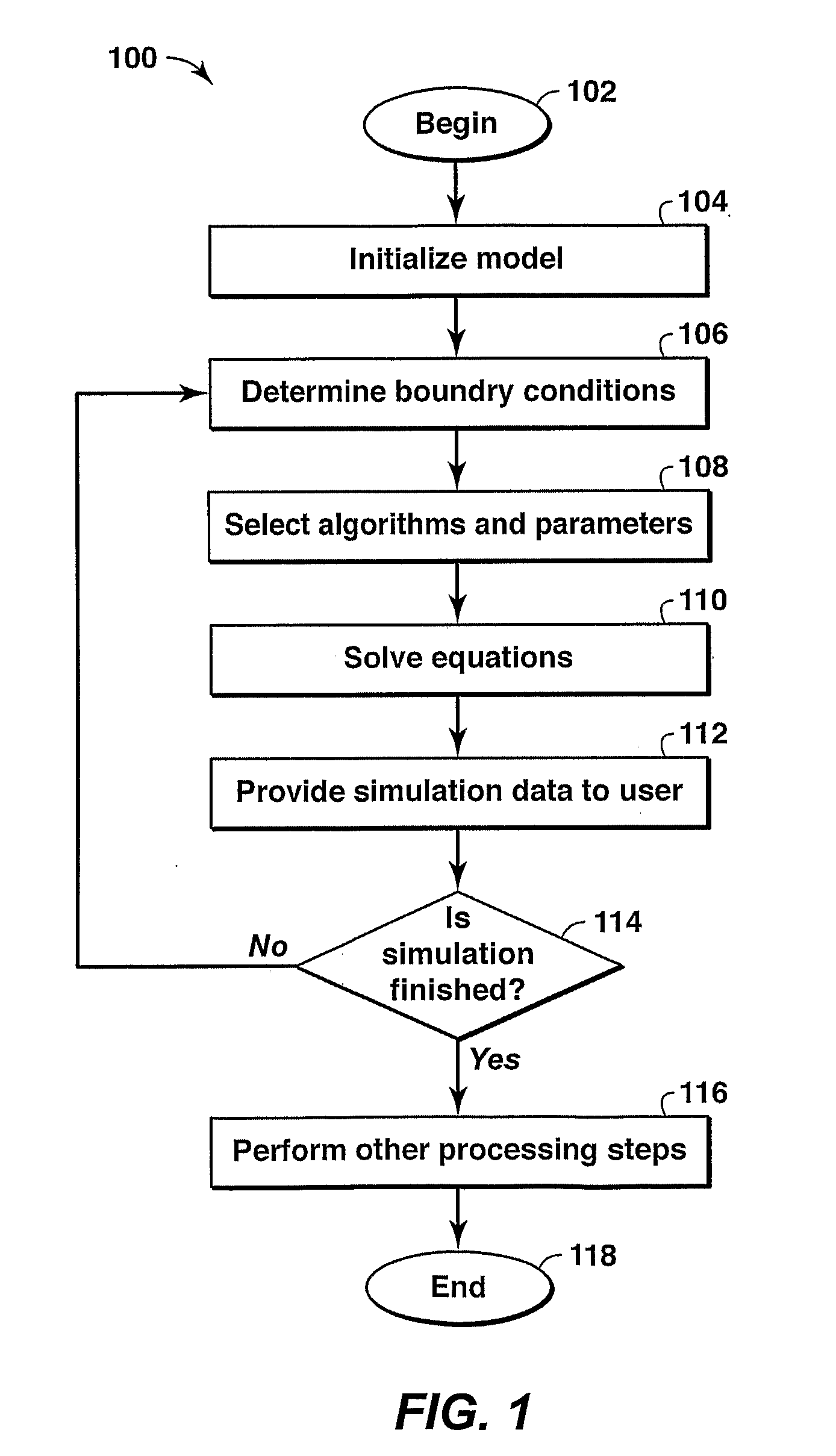

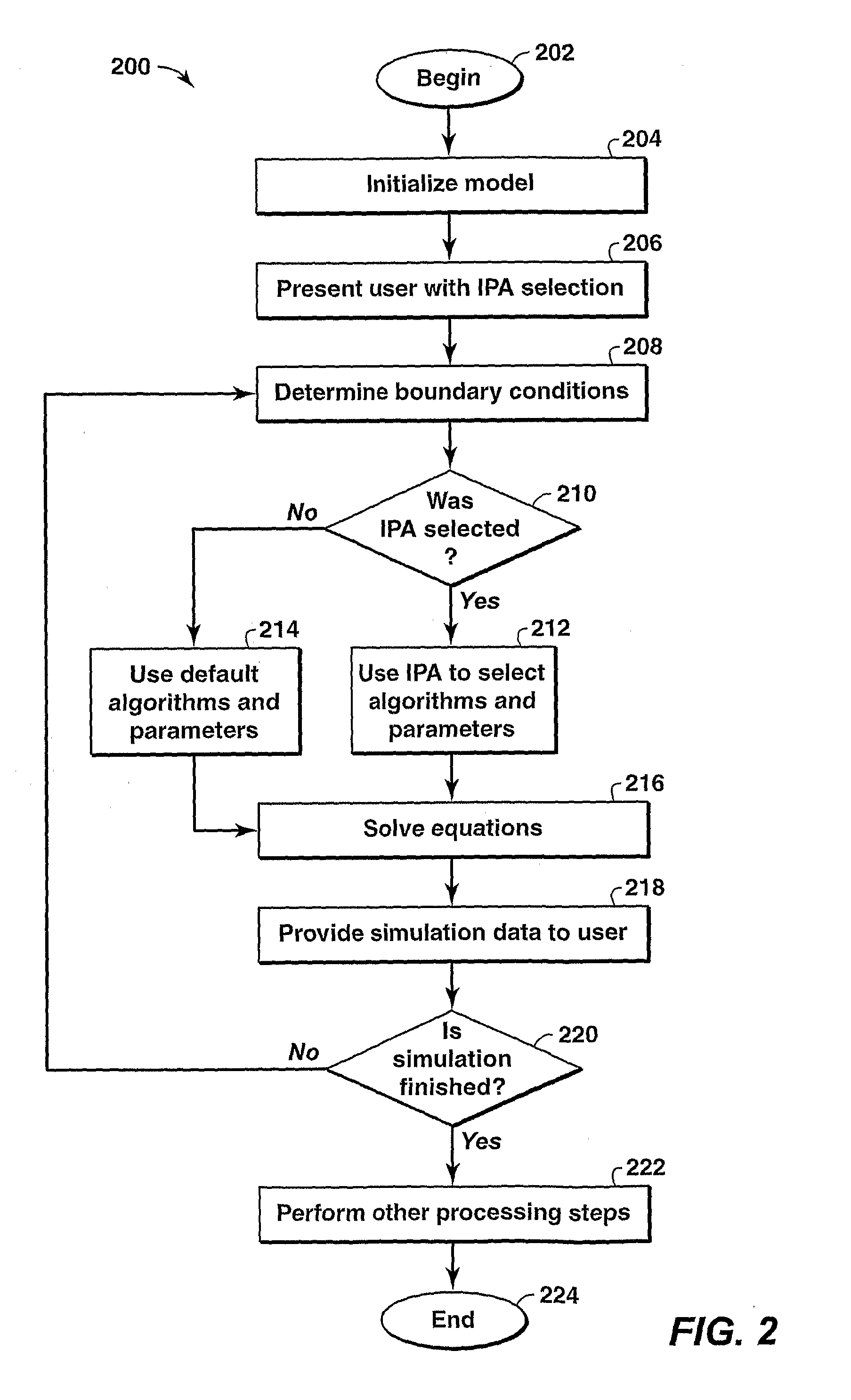

Simulation System and Method

InactiveUS20100082142A1Enhance run-time performanceImprove running stabilityComputation using non-denominational number representationDesign optimisation/simulationPorous mediumComputational simulation

A method and system are described that enhance the computational simulation, such as a fluid flowing through a porous media, under the present techniques. In particular, a computer implemented simulation method is described that includes initializing a simulator and utilizing an intelligent performance assistant to select a set of parameters and algorithms for the simulator. Then, equations are solved with the set of parameters and algorithms and the solution to the equations is then obtained.

Owner:USADI ADAM K +6

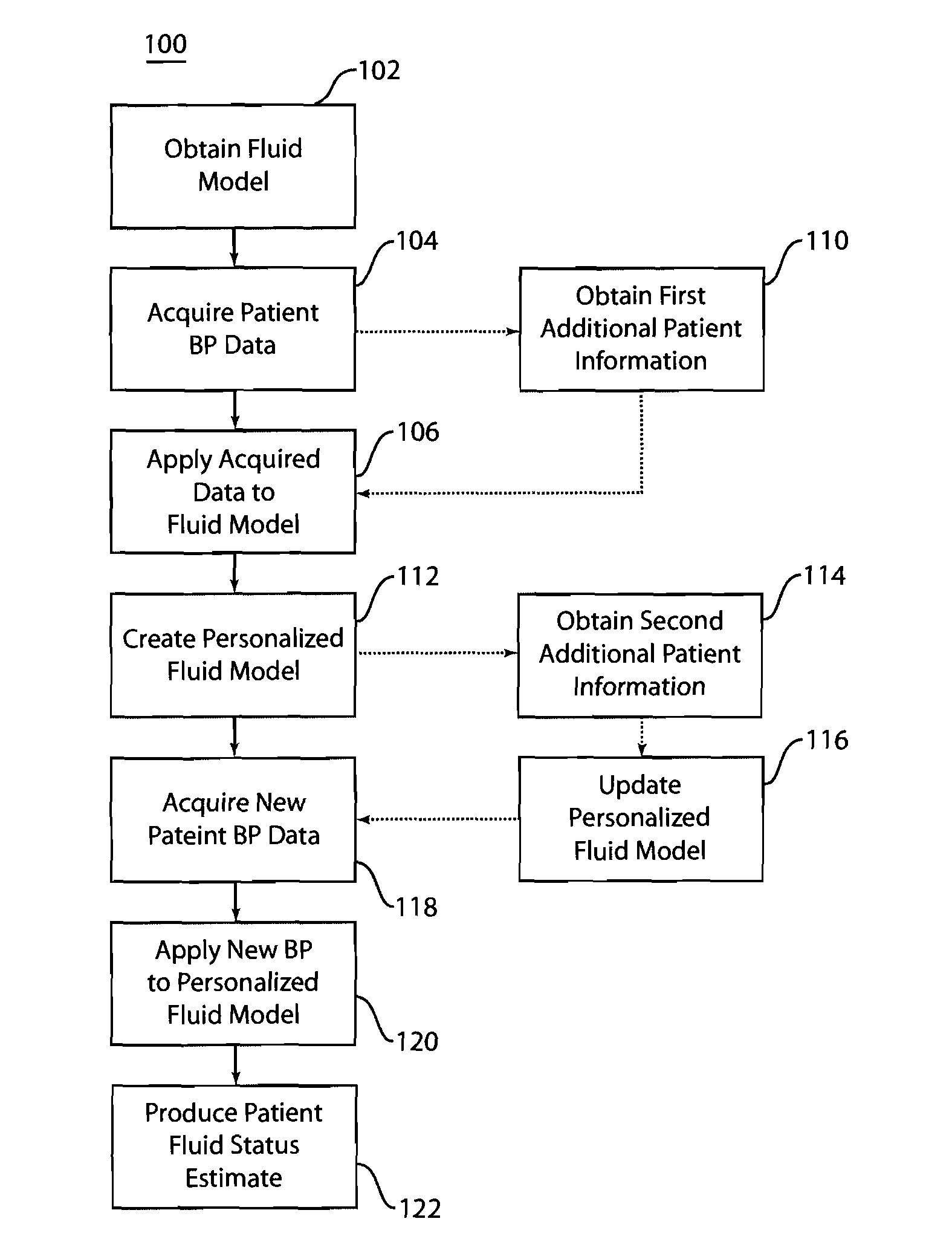

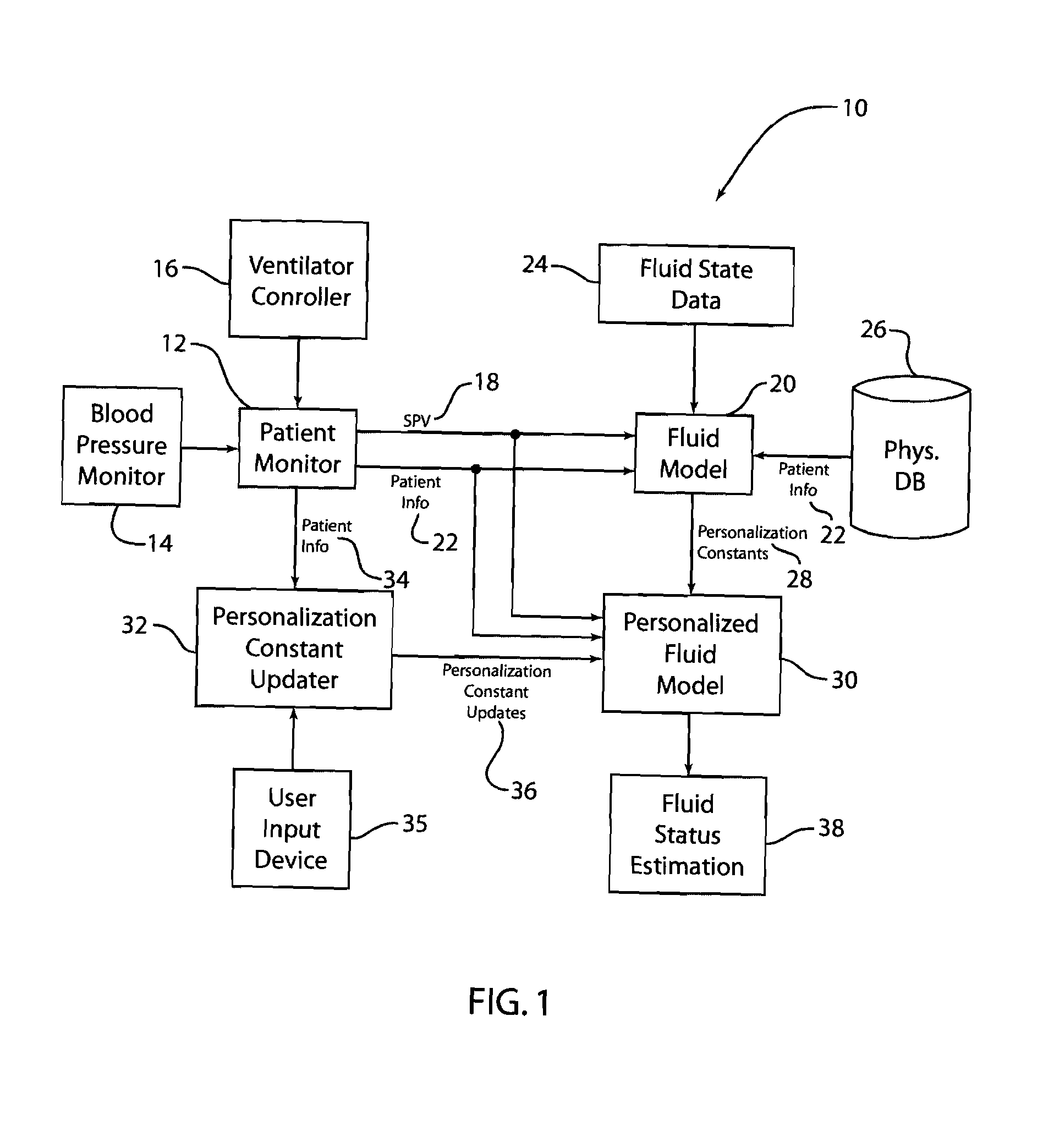

Personalized fluid assessment

A system and method of monitoring the fluid status of a patient. The system may include a patient monitor that receives blood pressure data. A first fluid model receives the blood pressure data, and a personalized fluid model is derived from the application of the blood pressure data to the first fluid model. An estimation of the patient's fluid status may be derived from the personalized fluid model. The method may include the steps of measuring a first blood pressure value, creating a personalized fluid model, measuring a second blood pressure value, applying the second blood pressure value to the personalized fluid model; and deriving an estimation of the fluid status of the patient.

Owner:GENERAL ELECTRIC CO

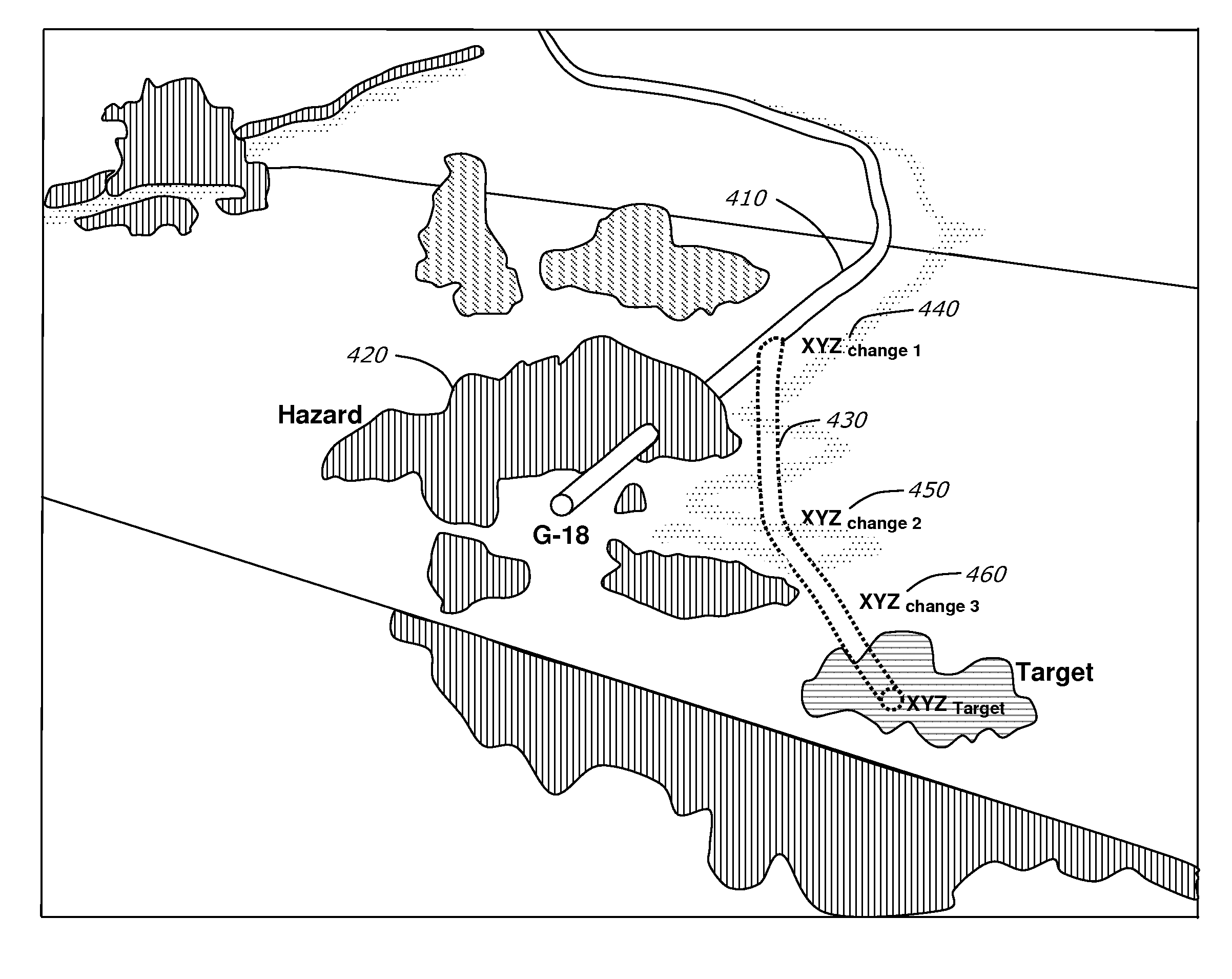

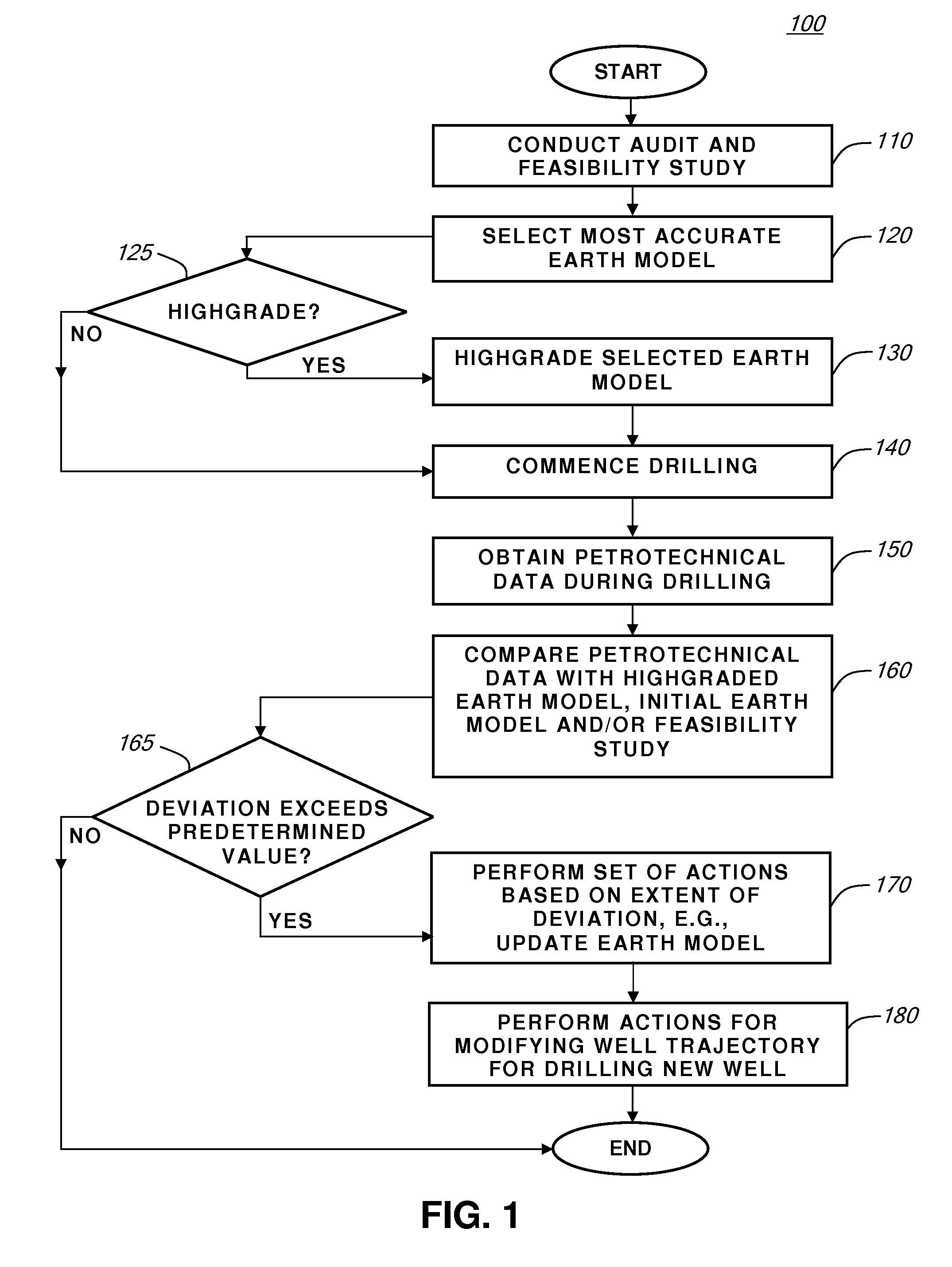

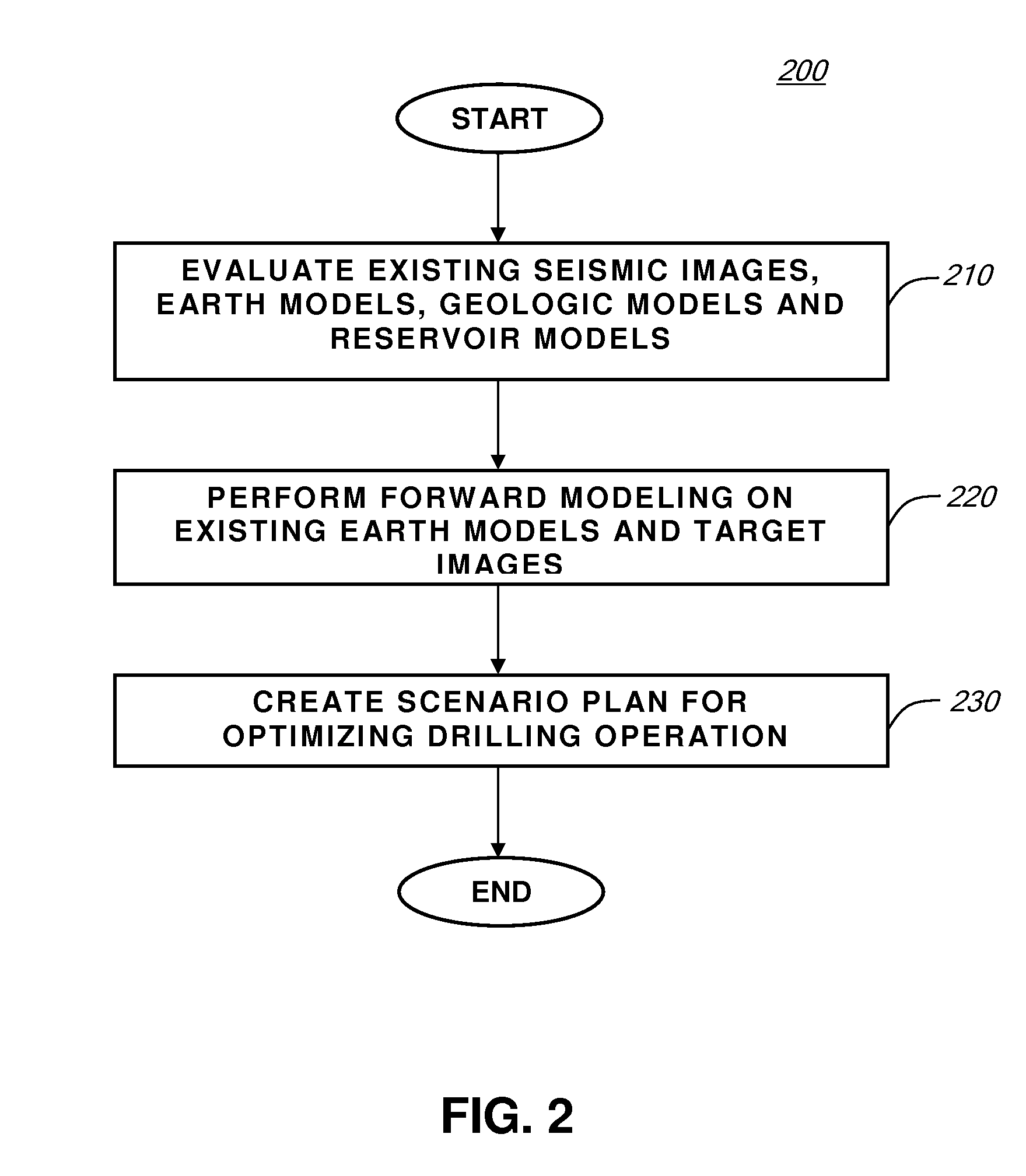

Optimizing Drilling Operations Using Petrotechnical Data

ActiveUS20090157367A1High resolutionEasy CalibrationDirectional drillingGeomodellingWell drillingEarth model

A method for optimizing drilling operations. The method includes providing an earth model of a volume having a well, obtaining petrotechnical data about the volume while drilling the well, comparing the petrotechnical data with the earth model, updating the earth model with the petrotechnical data based on the comparison, and modifying a drilling plan of the well using the updated earth model.

Owner:WESTERNGECO LLC

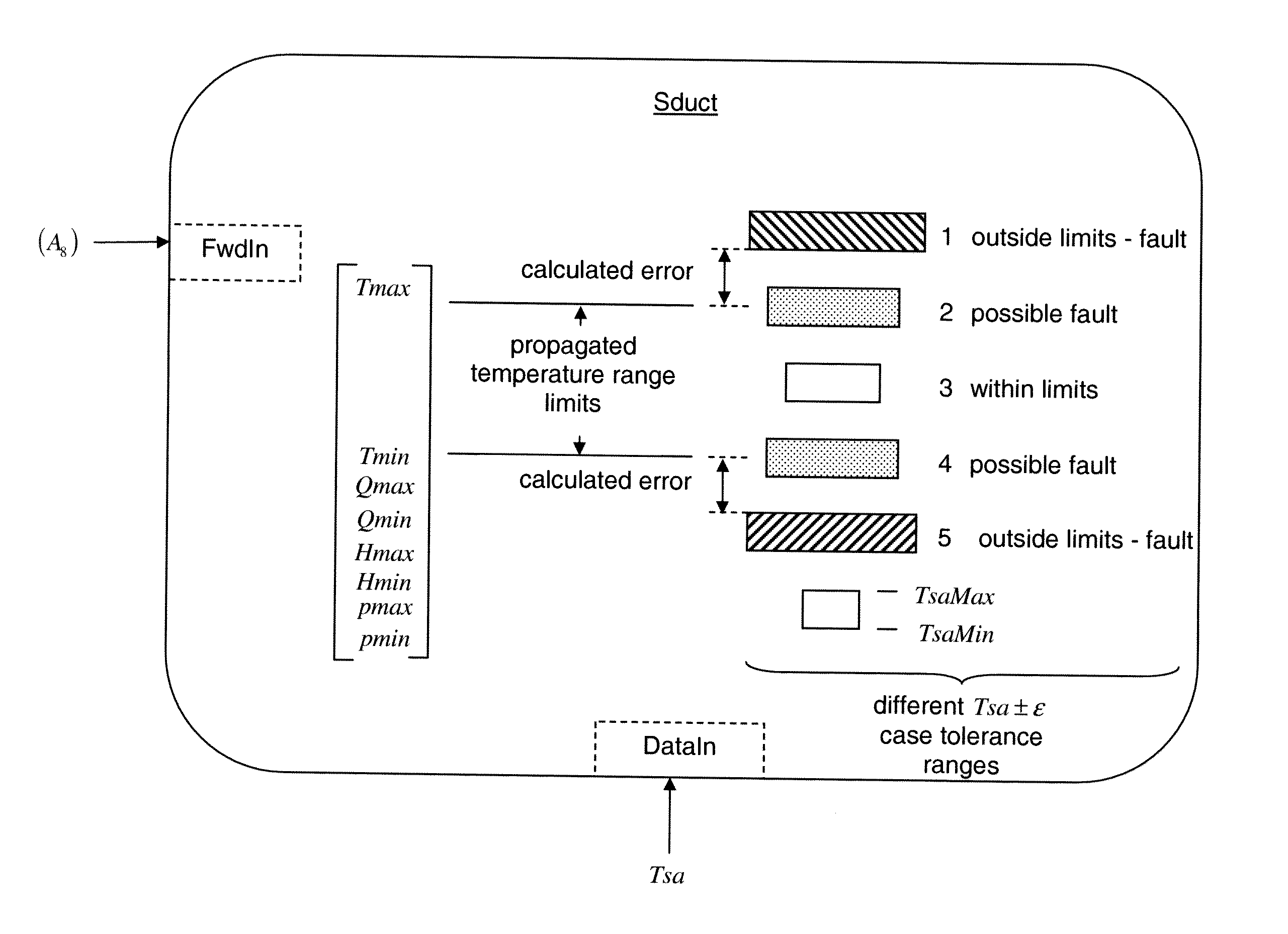

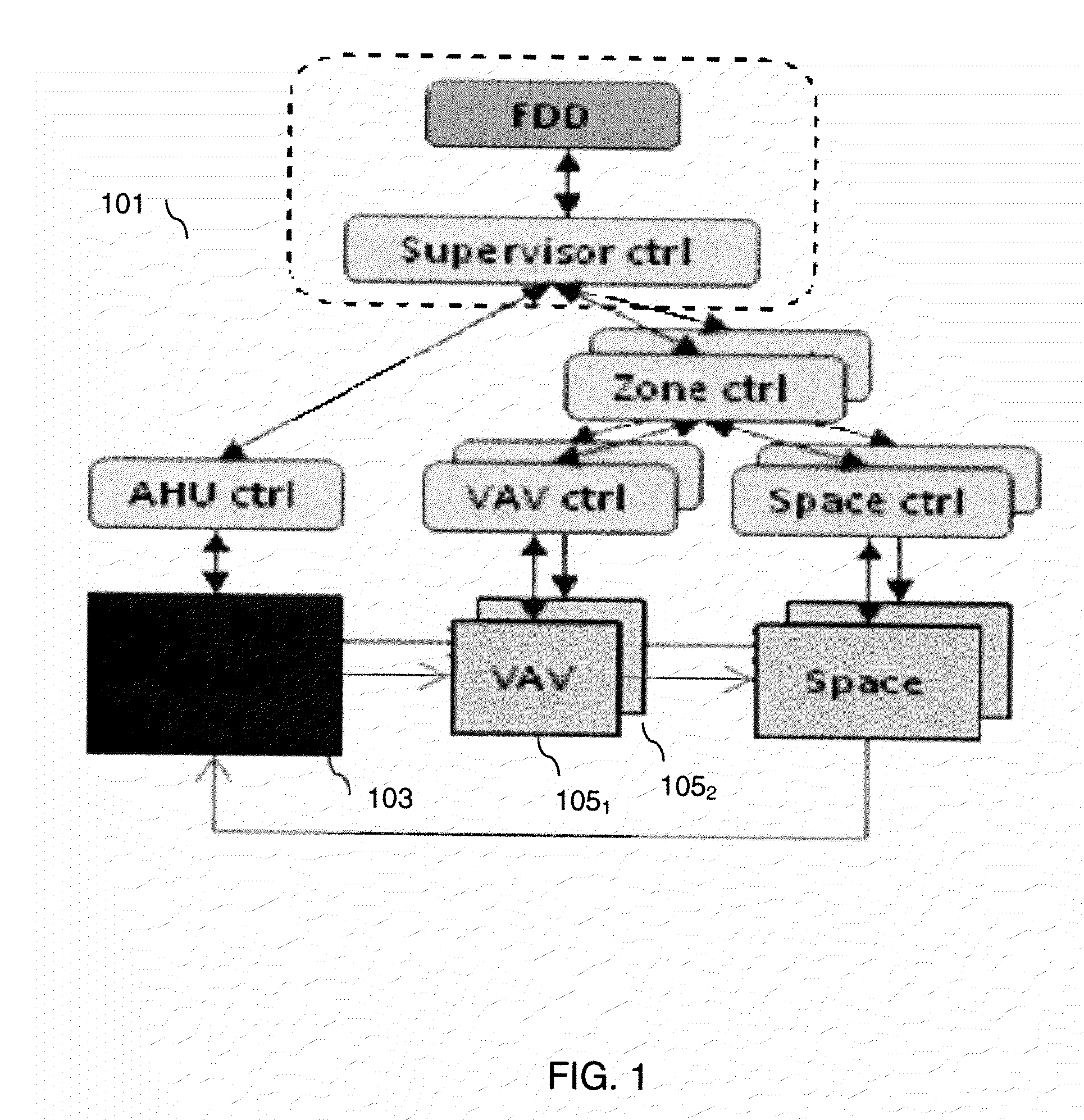

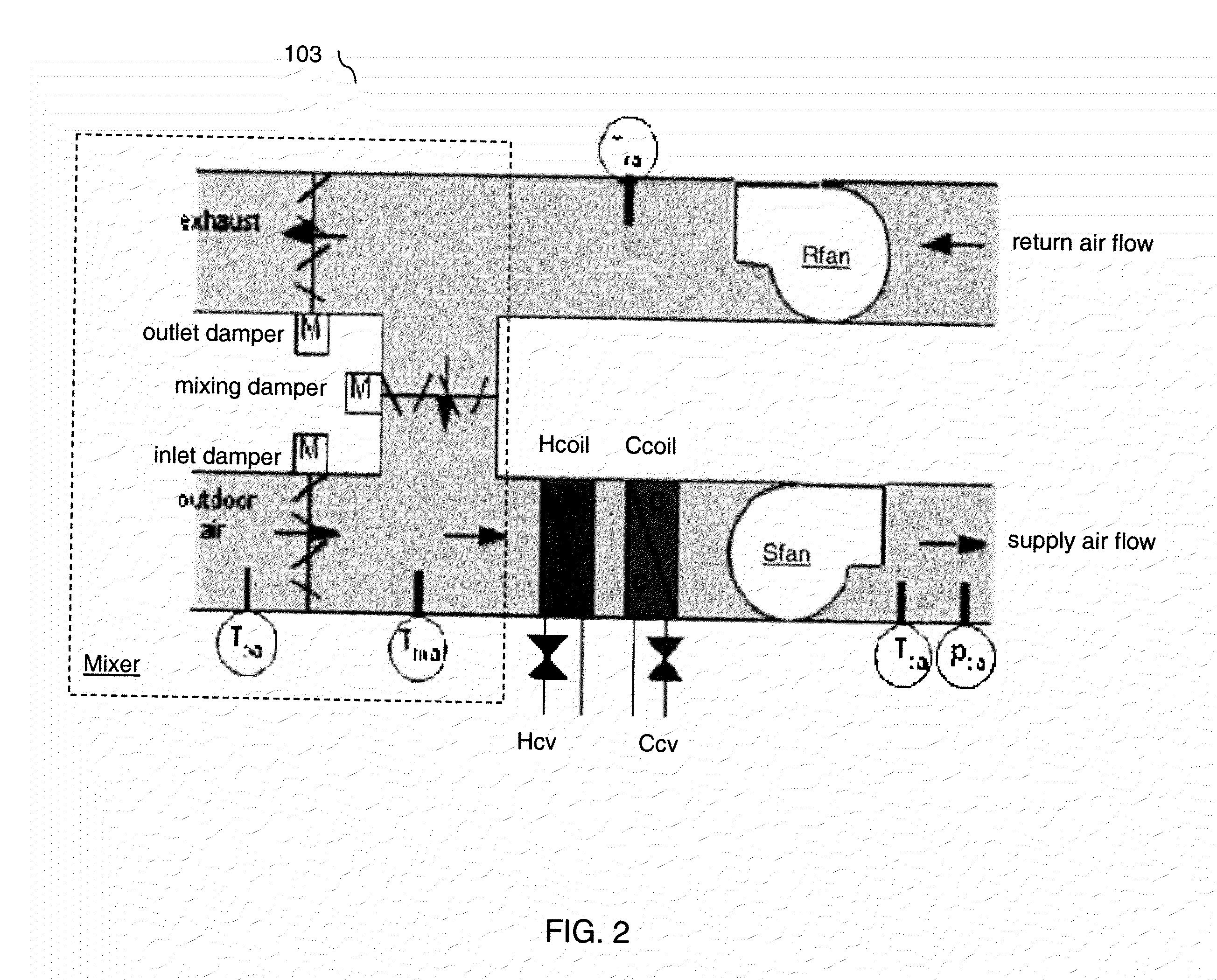

Heat Flow Model for Building Fault Detection and Diagnosis

ActiveUS20110093424A1Lighting and heating apparatusStatic/dynamic balance measurementReal-time dataHeat flow

Systems and methods are described that provide a Heat Flow Model (HFM) graph modeling methodology. Embodiments automatically translate formal HVAC system descriptions from a Building Information Model (BIM) into HFM graphs, and compile the graphs into executable FDD systems. During an engineering phase, a user interface is used to enter parameters, conditions, and switches not found in the BIM. During a runtime phase, real-time data from an HVAC control system is input to the generated FDD system (HFM graph) for fault detection and diagnosis.

Owner:SIEMENS AG

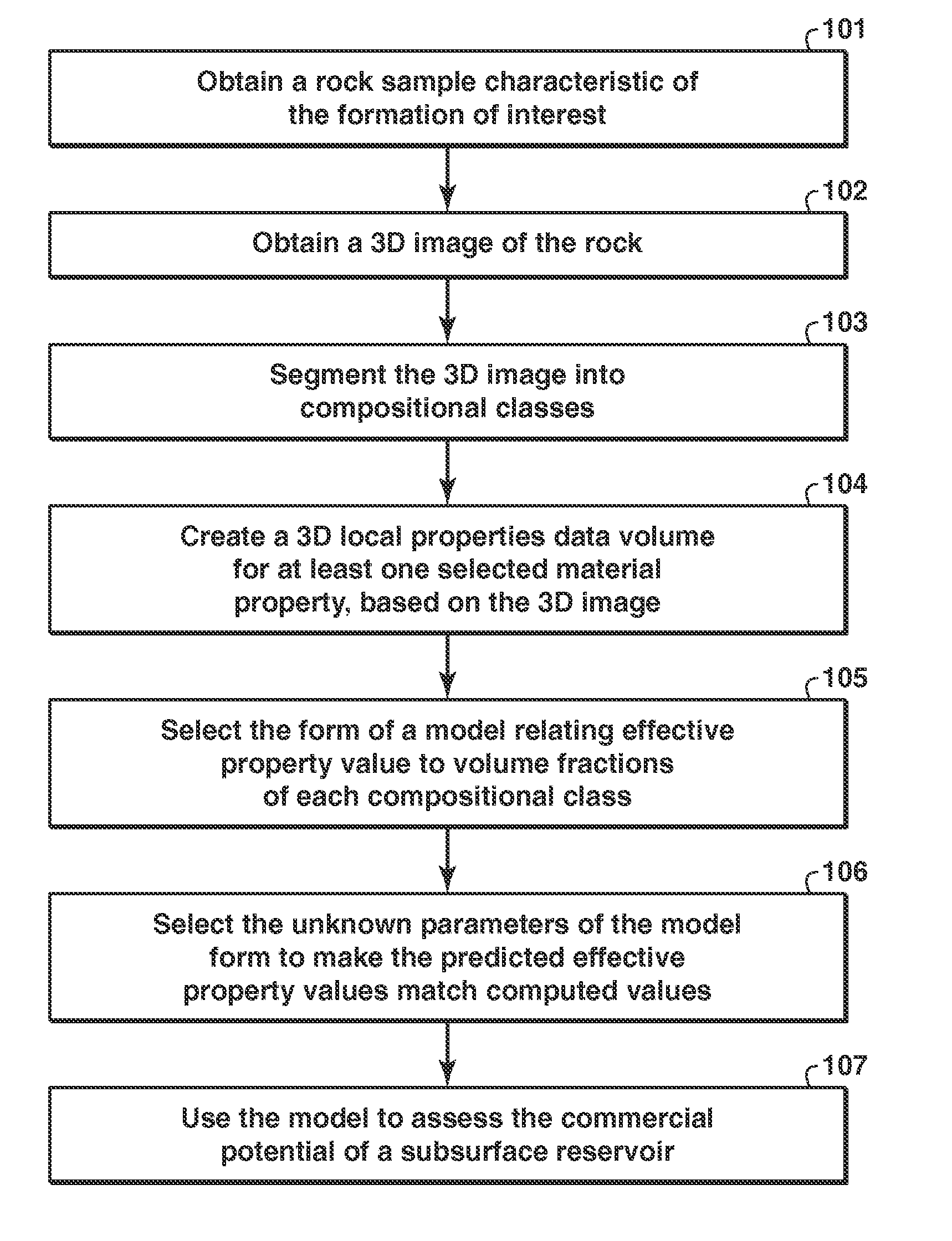

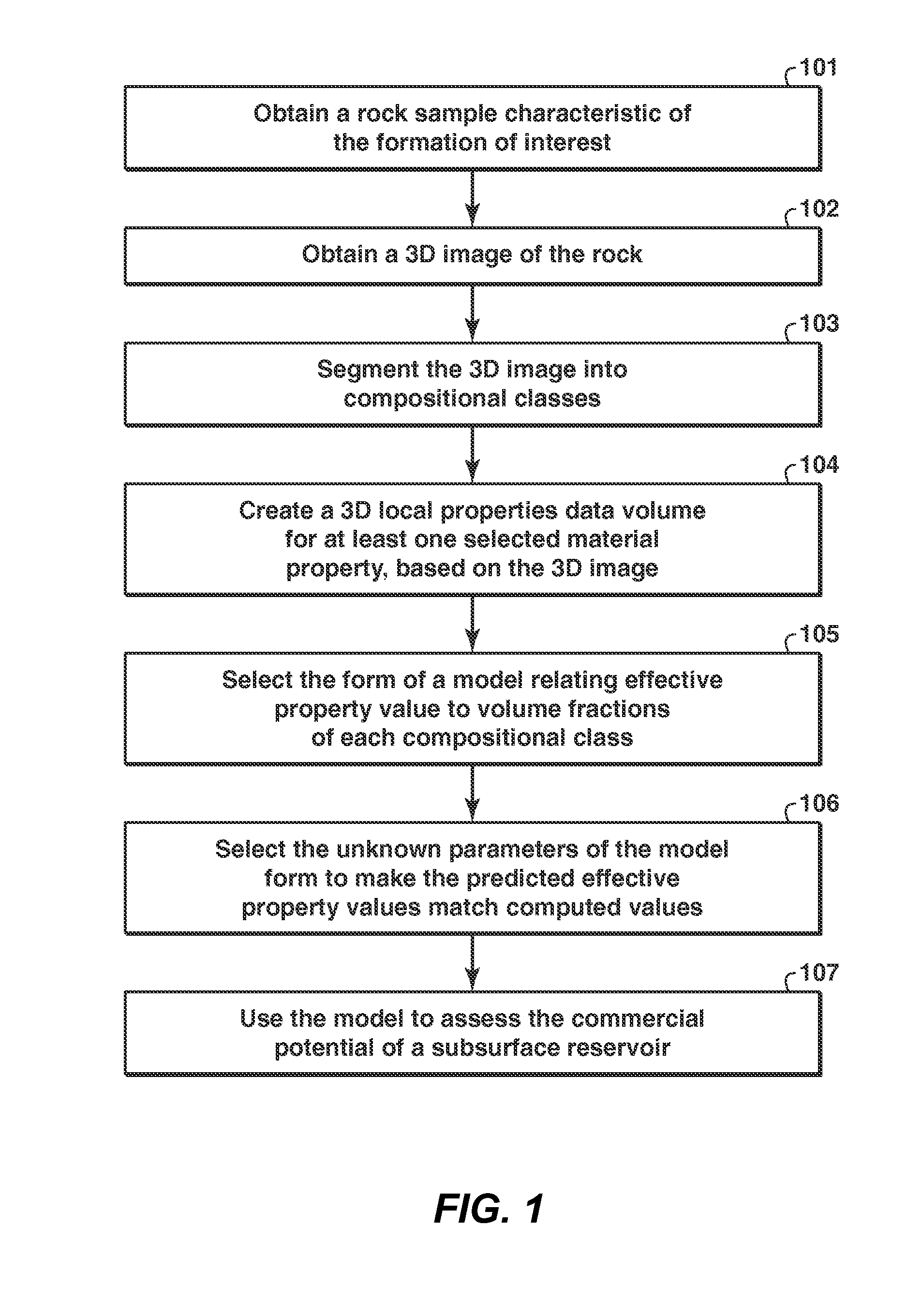

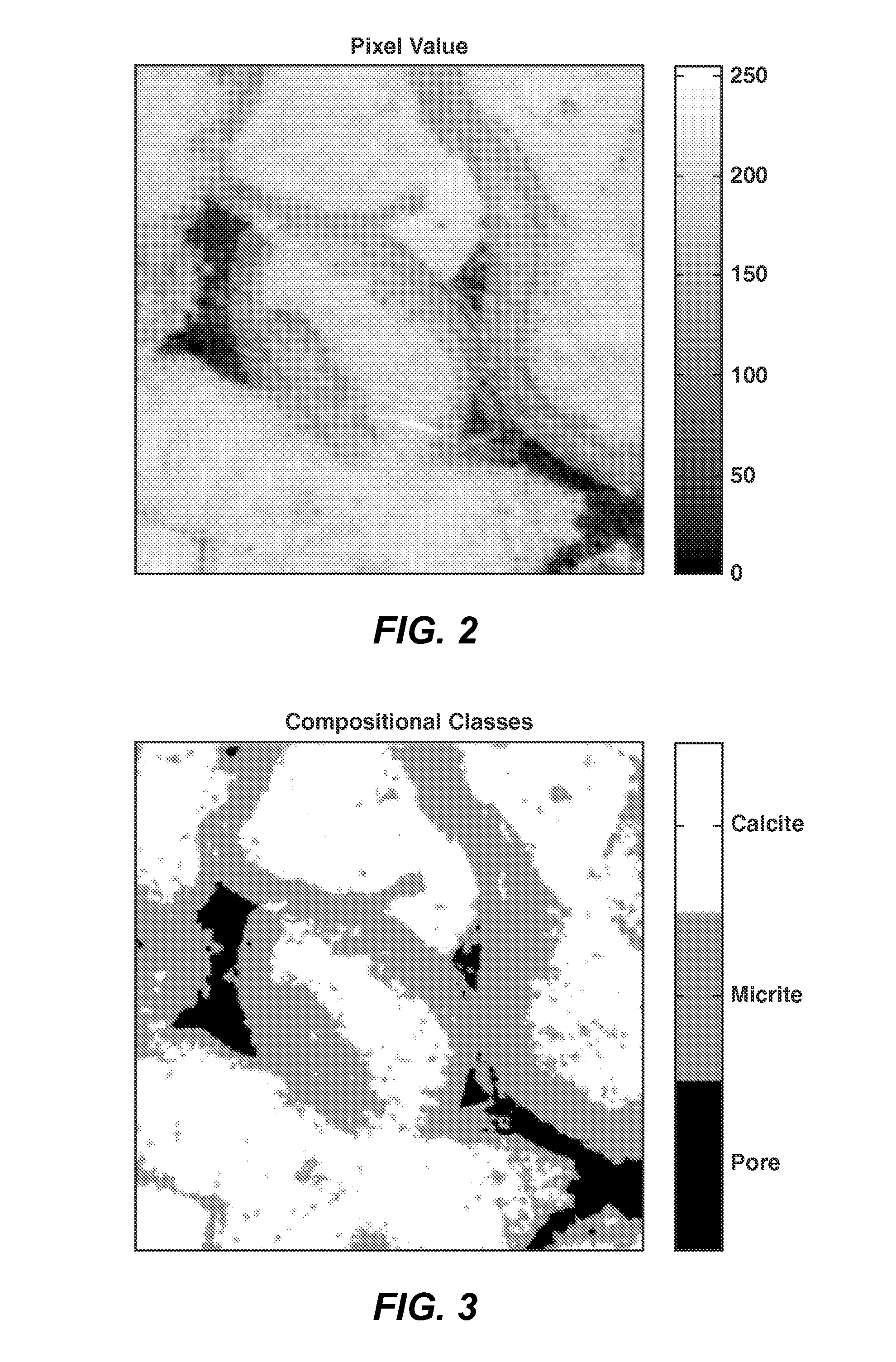

Method for determining the properties of hydrocarbon reservoirs from geophysical data

ActiveUS20100198638A1Sustainable waste treatmentMaterial analysis using wave/particle radiation3d imageRock sample

A hydrocarbon exploration method is disclosed for developing a model of at least one effective material property of a subsurface reservoir as a function of the composition and structure of the reservoir rock. In one embodiment, the method comprises: obtaining a 3D image (102) of a rock sample characteristic of a reservoir of interest (101); segmenting the 3D image into compositional classes (103) based on similarities in mineralogy, structure and spatial distribution; selecting a model (105) that relates an effective material property of interest to the volume fractions of each compositional class; and determining the parameters of the model (106). The model may be used to assess the commercial potential of the subsurface reservoir (107).

Owner:EXXONMOBIL UPSTREAM RES CO

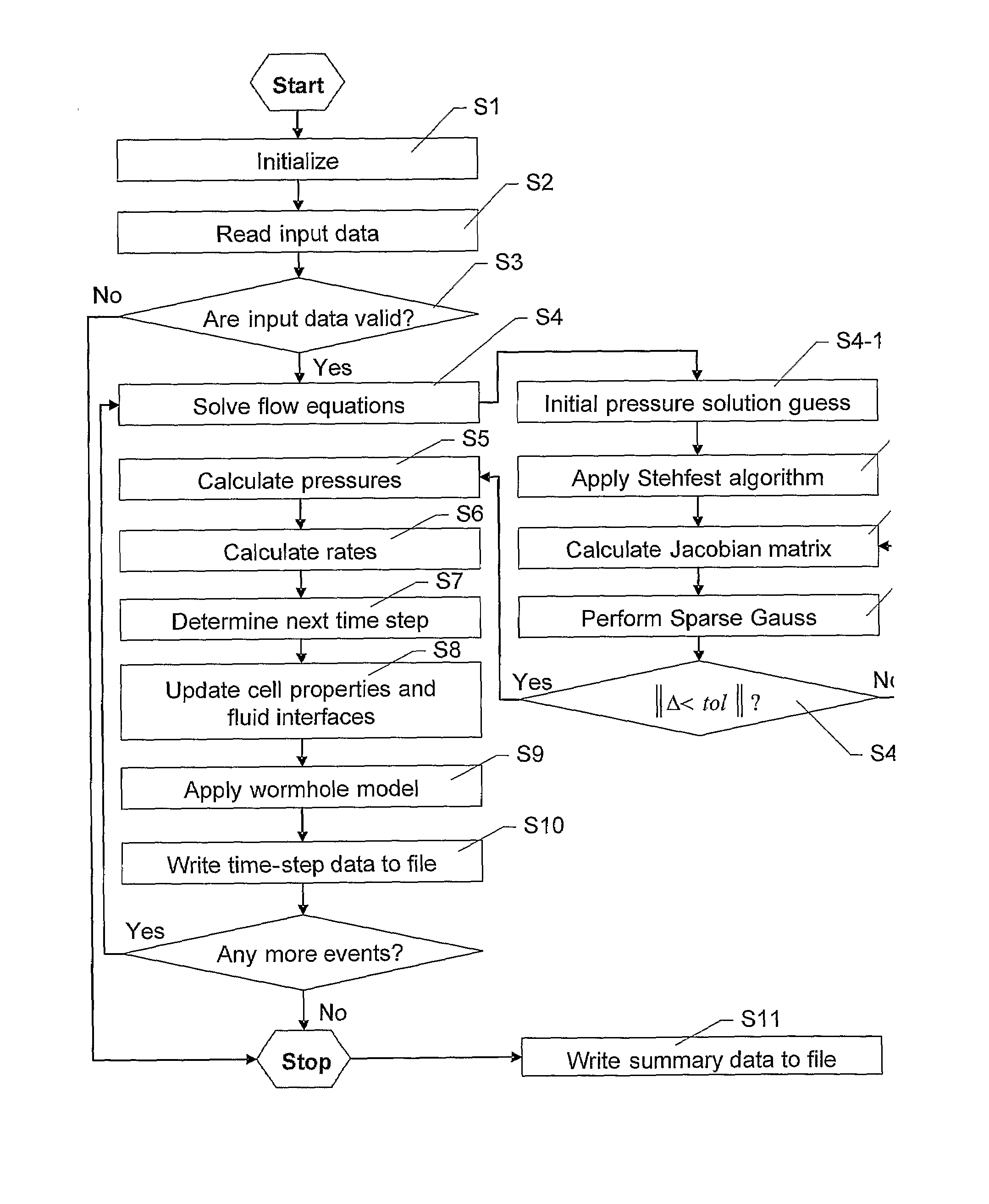

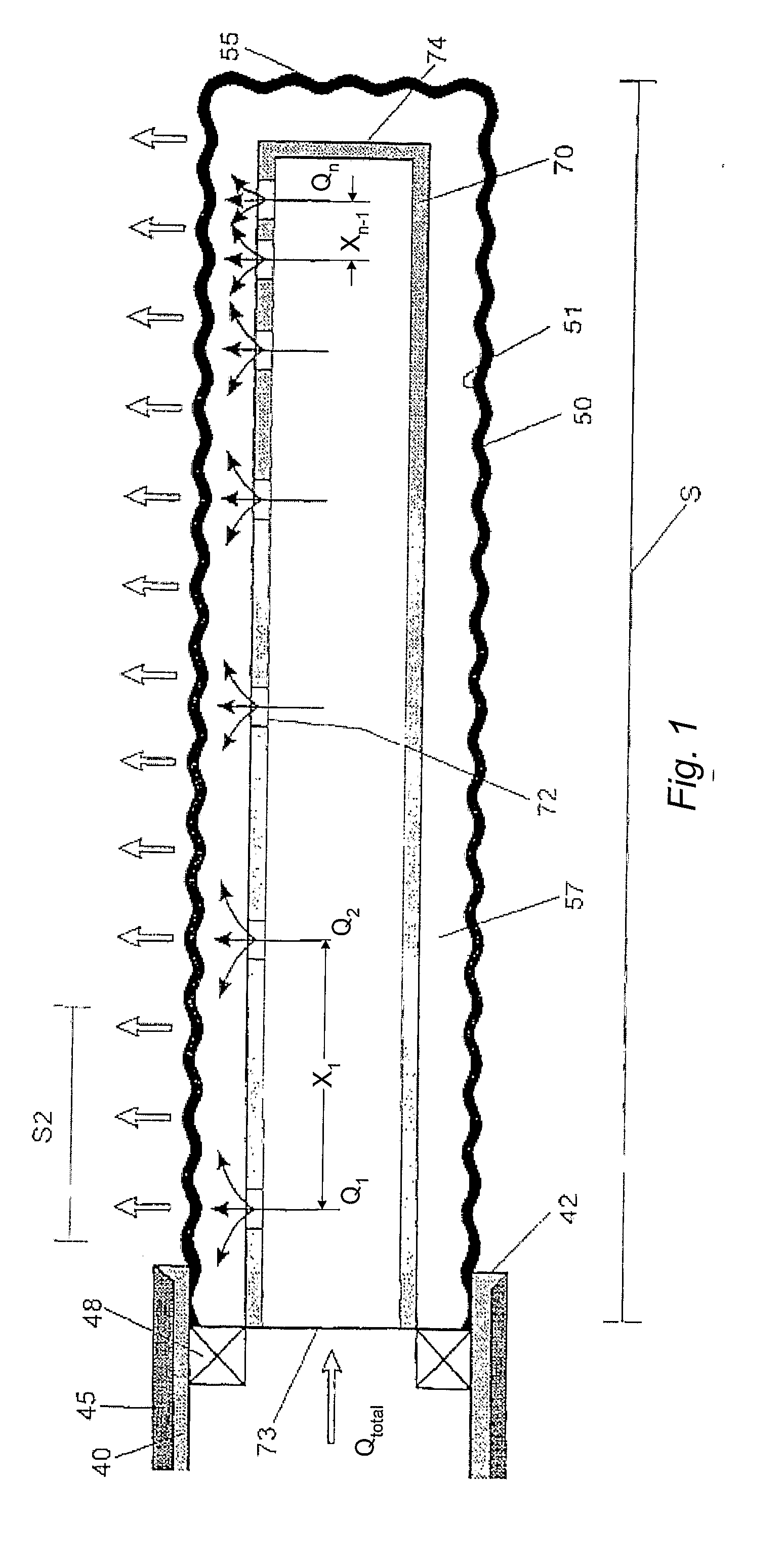

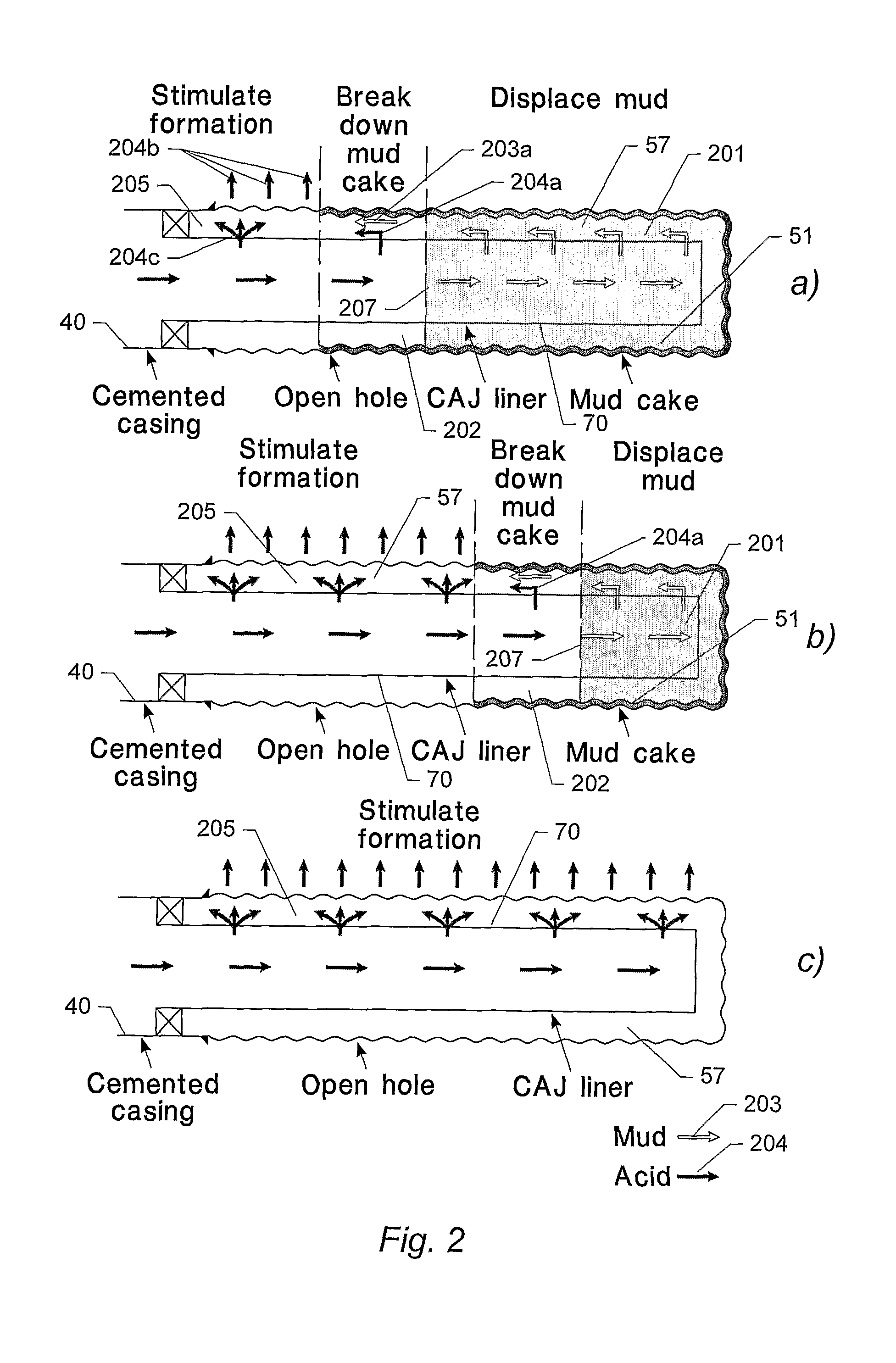

Flow simulation in a well or pipe

ActiveUS20090294122A1Accurate and efficient numerical solutionImprove modeling accuracySurveyFluid removalFluid transportEngineering

A method of simulating fluid transport in a system for stimulating a well in a material formation of a resource reservoir, the system comprising a conduit element arranged in said well, the conduit element comprising a conduit wall including one or more openings for discharging a fluid into the material formation surrounding the conduit element; the method comprising establishing and numerically processing a transport model of fluid transport inside the conduit element. The transport model further includes a model of fluid transport in a predetermined space around said conduit element.

Owner:TOTAL E&P DANMARK AS

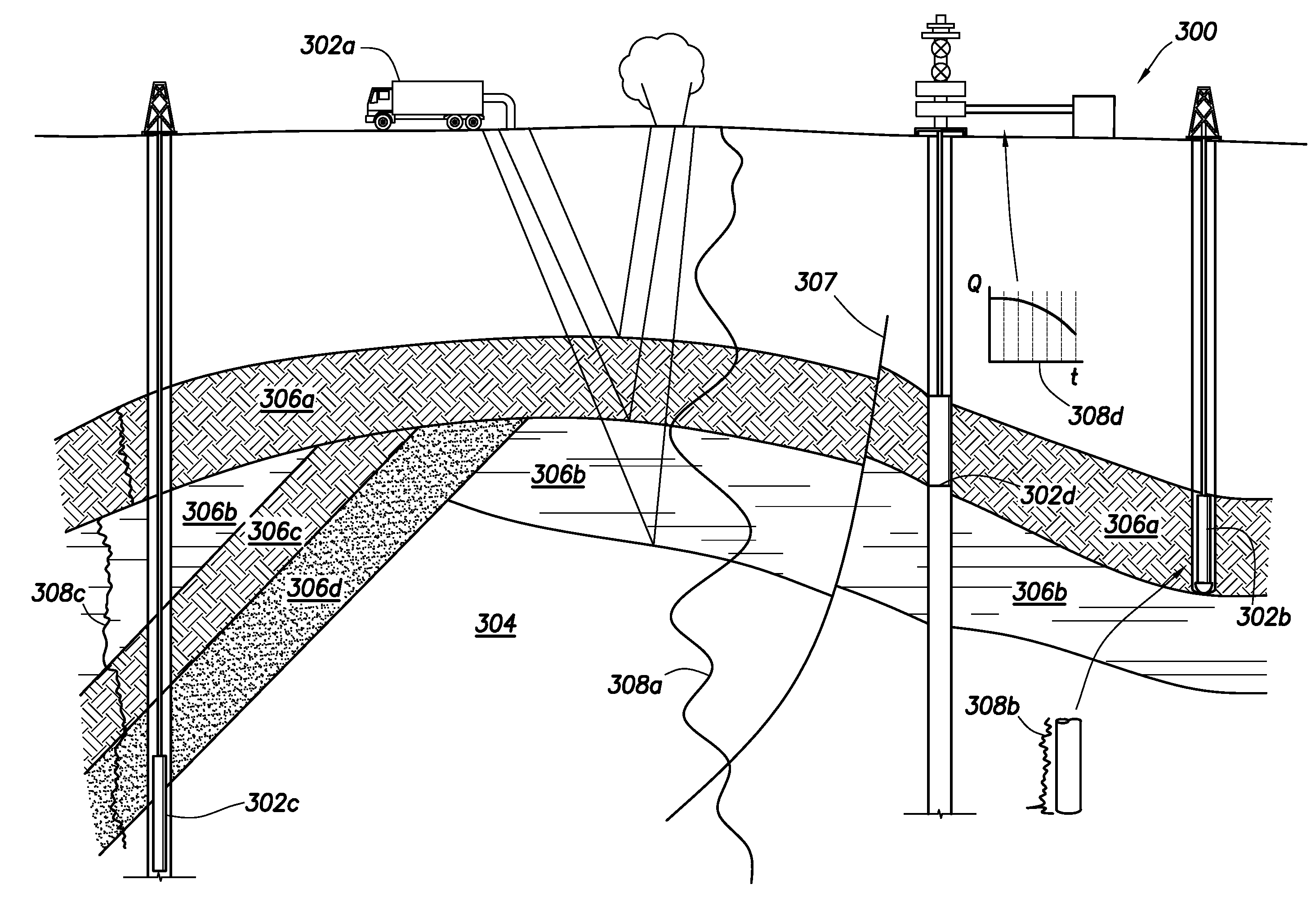

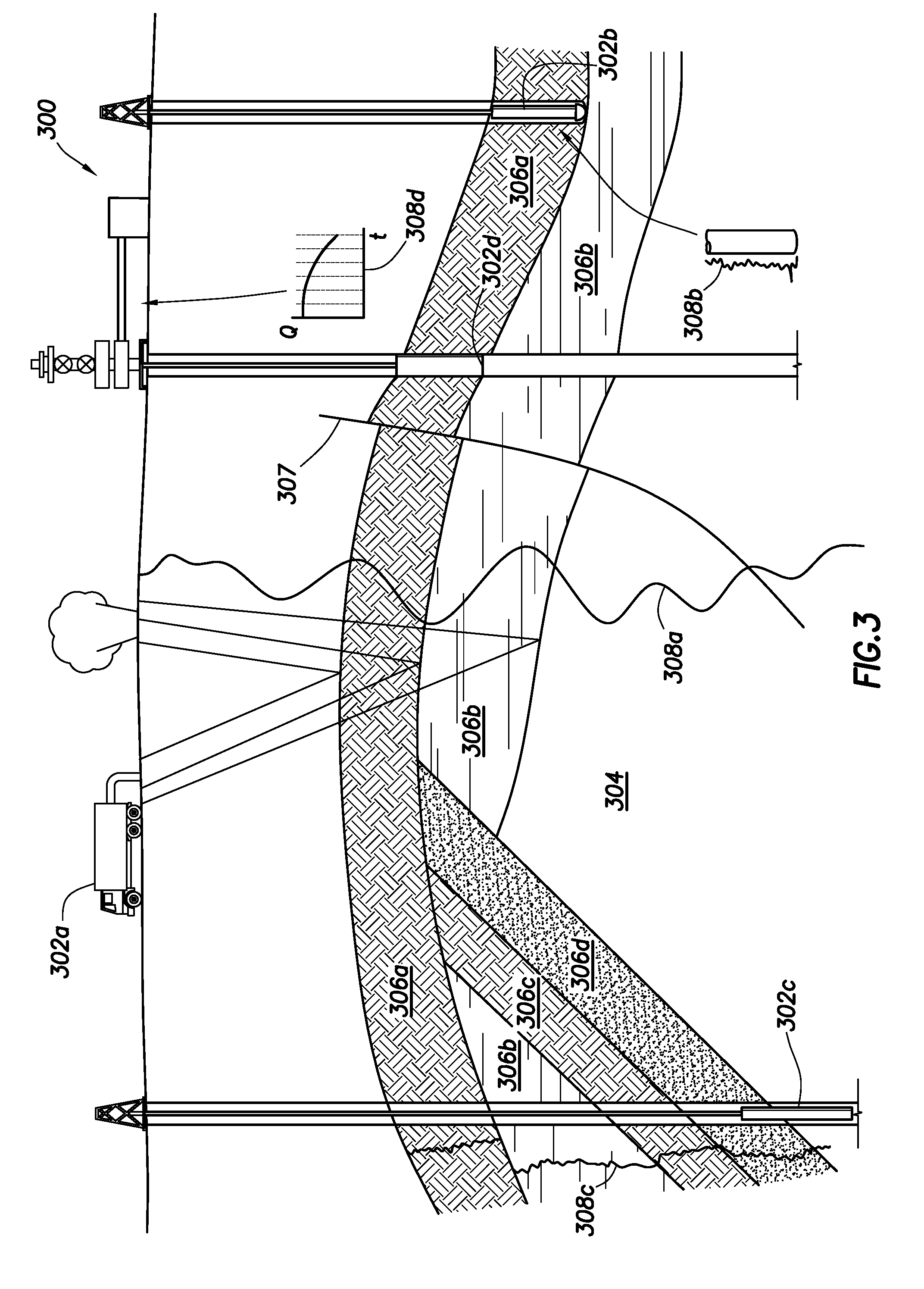

Method for managing production from a hydrocarbon producing reservoir in real-time

ActiveUS20090084545A1Electric/magnetic detection for well-loggingSurveyReal-time simulationStreamflow

The invention relates to a method of performing an oilfield operation of an oilfield having at least one wellsite, each wellsite having a wellbore penetrating a subterranean formation for extracting fluid from an underground reservoir therein. The method steps include obtaining a plurality of real-time parameters from a plurality of sensors disposed about the oilfield, wherein the plurality of real-time parameters comprise at least one selected from a group consisting of real-time flow rate data and real-time pressure data of the wellbore, configuring a gridless analytical simulator for simulating the underground reservoir based on the plurality of real-time parameters, generating real-time simulation results of the underground reservoir and the at least one wellsite in real-time using the gridless analytical simulator, and performing the oilfield operation based on the real-time simulation results

Owner:SCHLUMBERGER TECH CORP

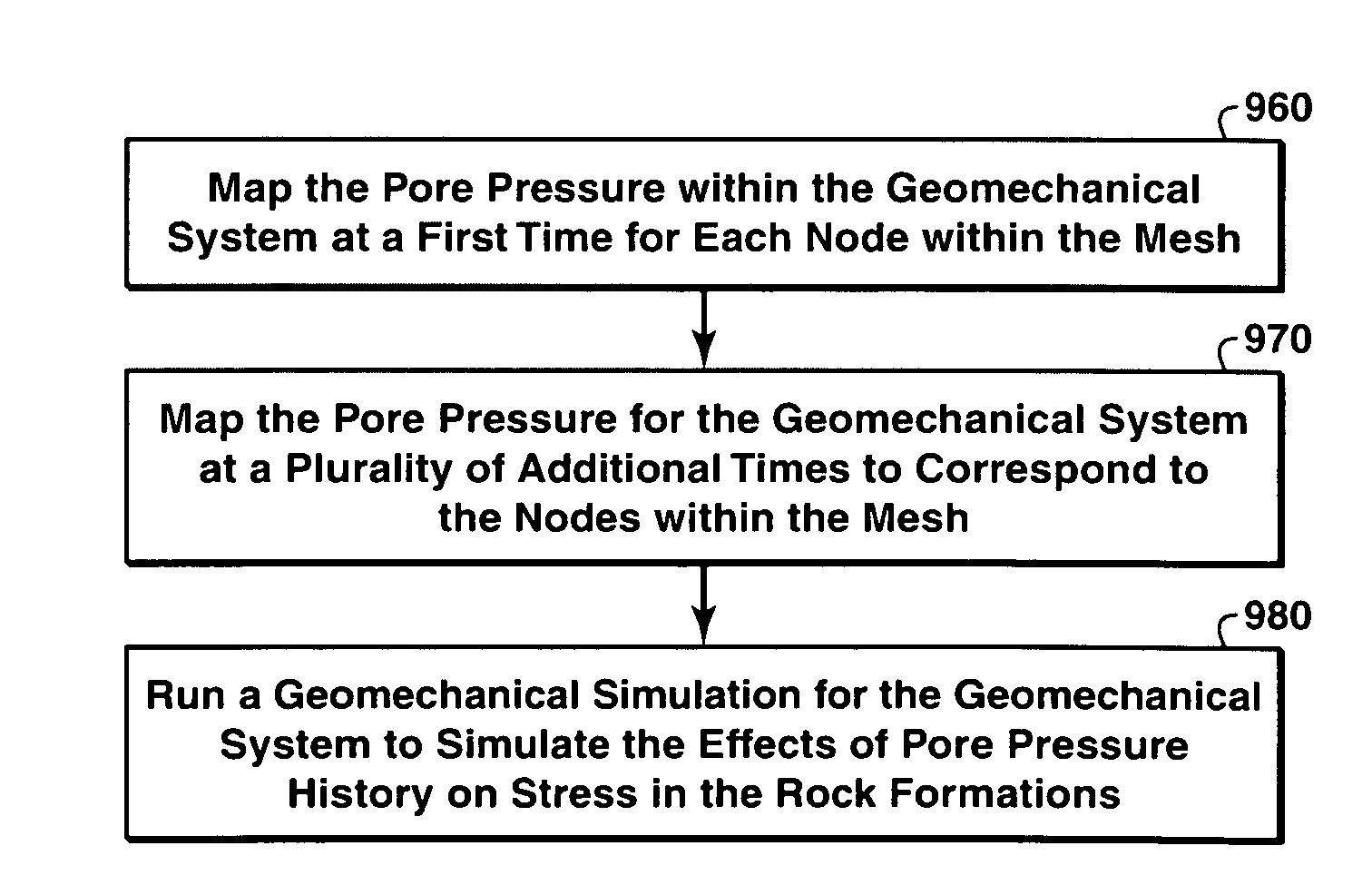

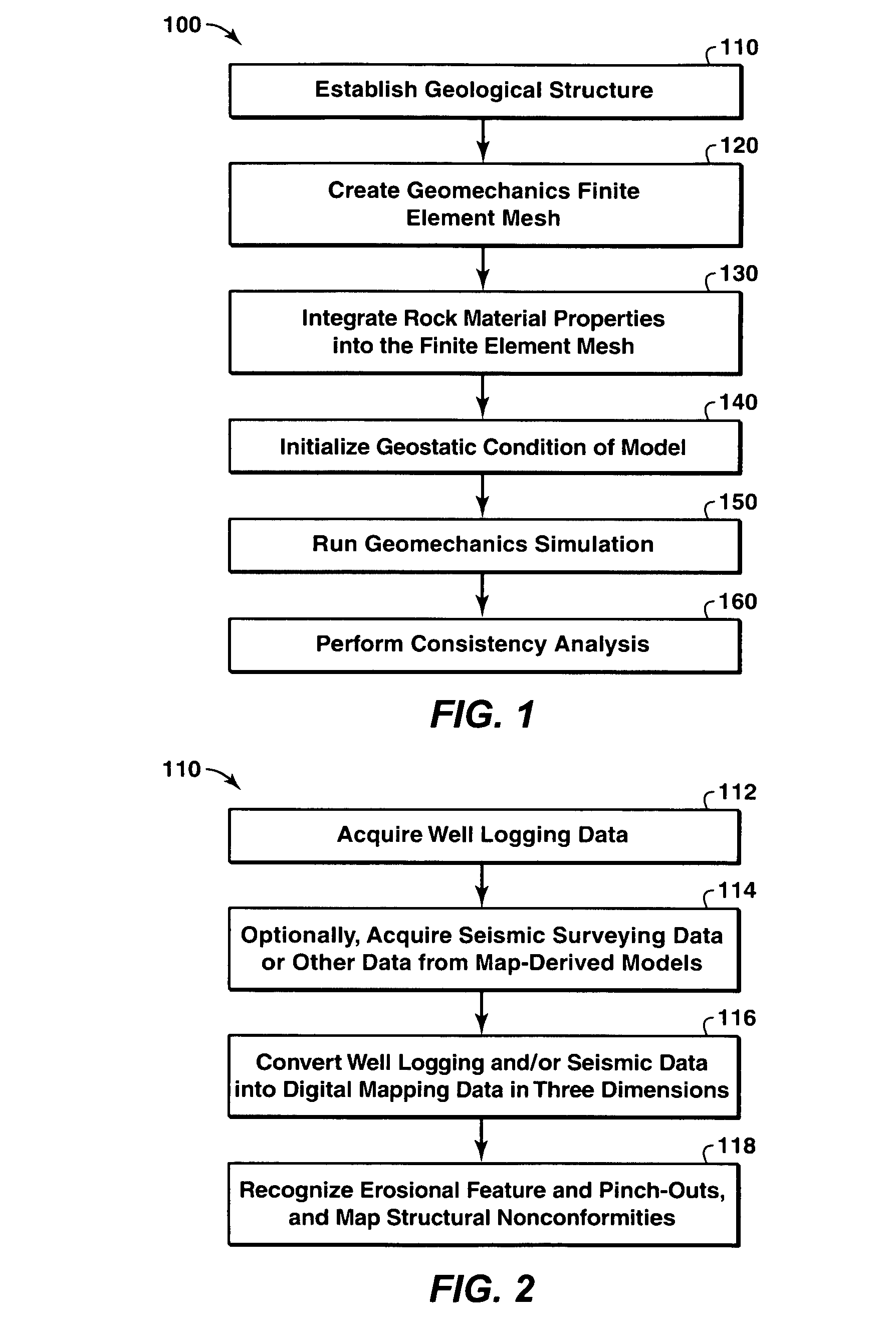

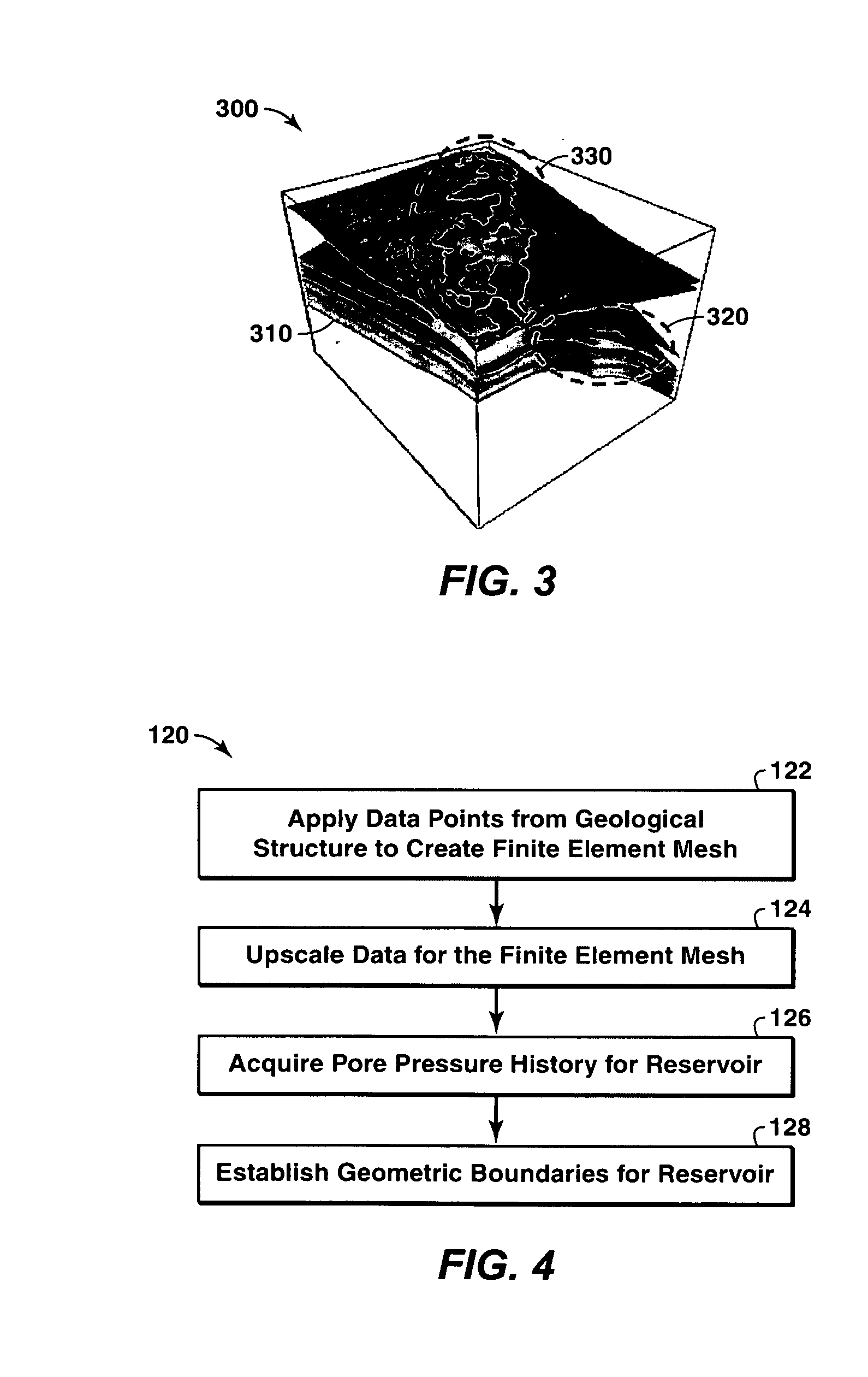

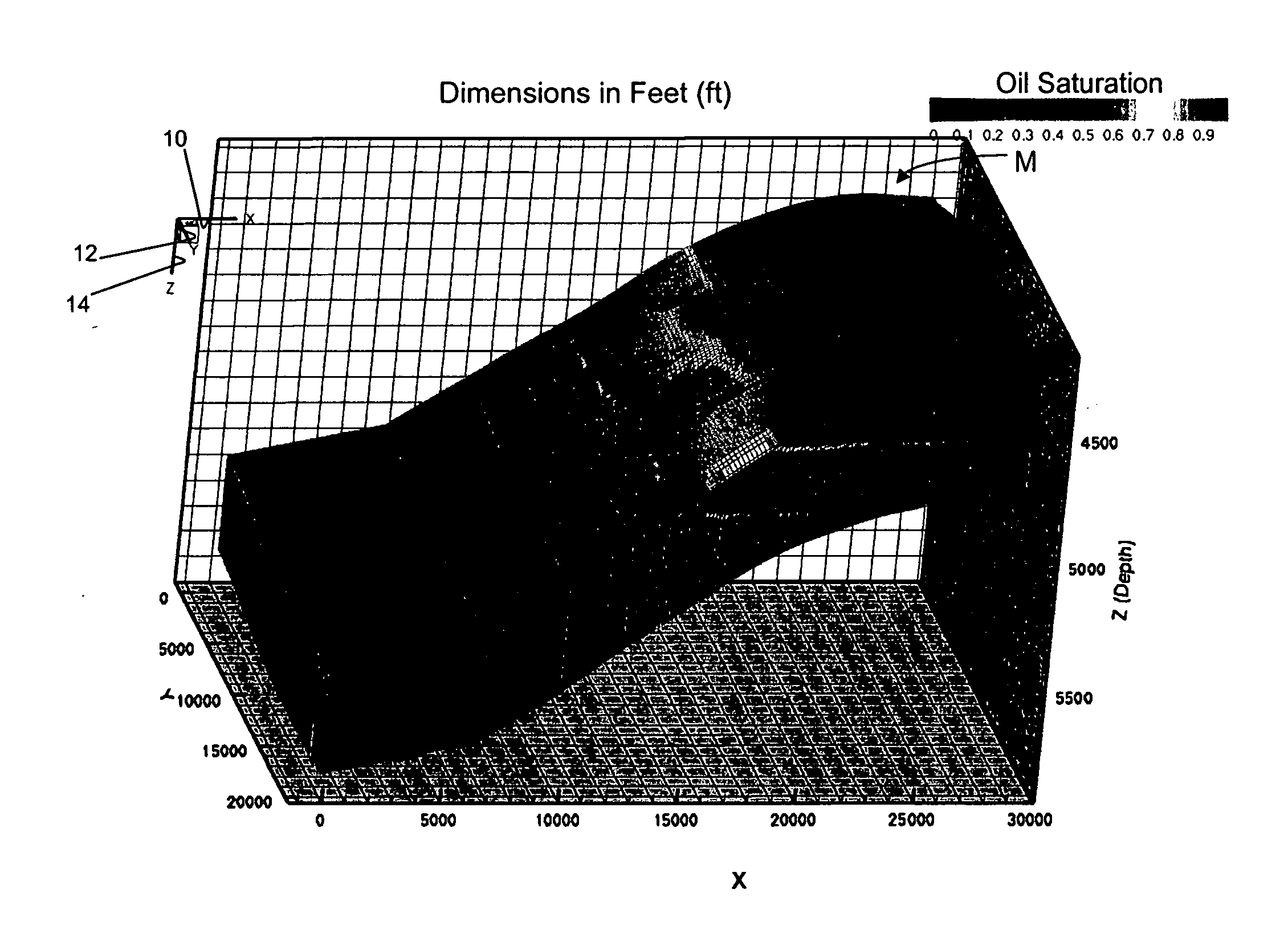

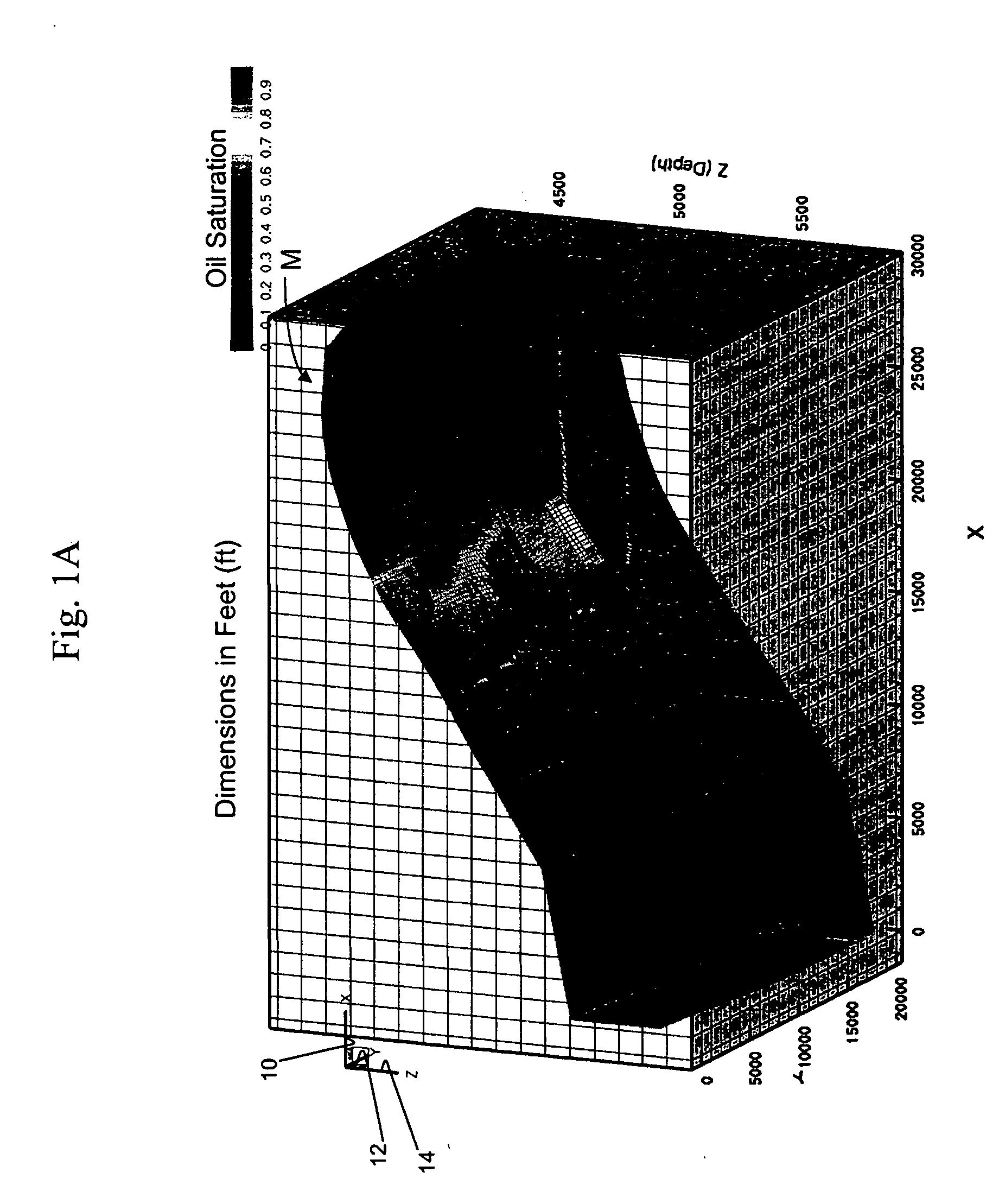

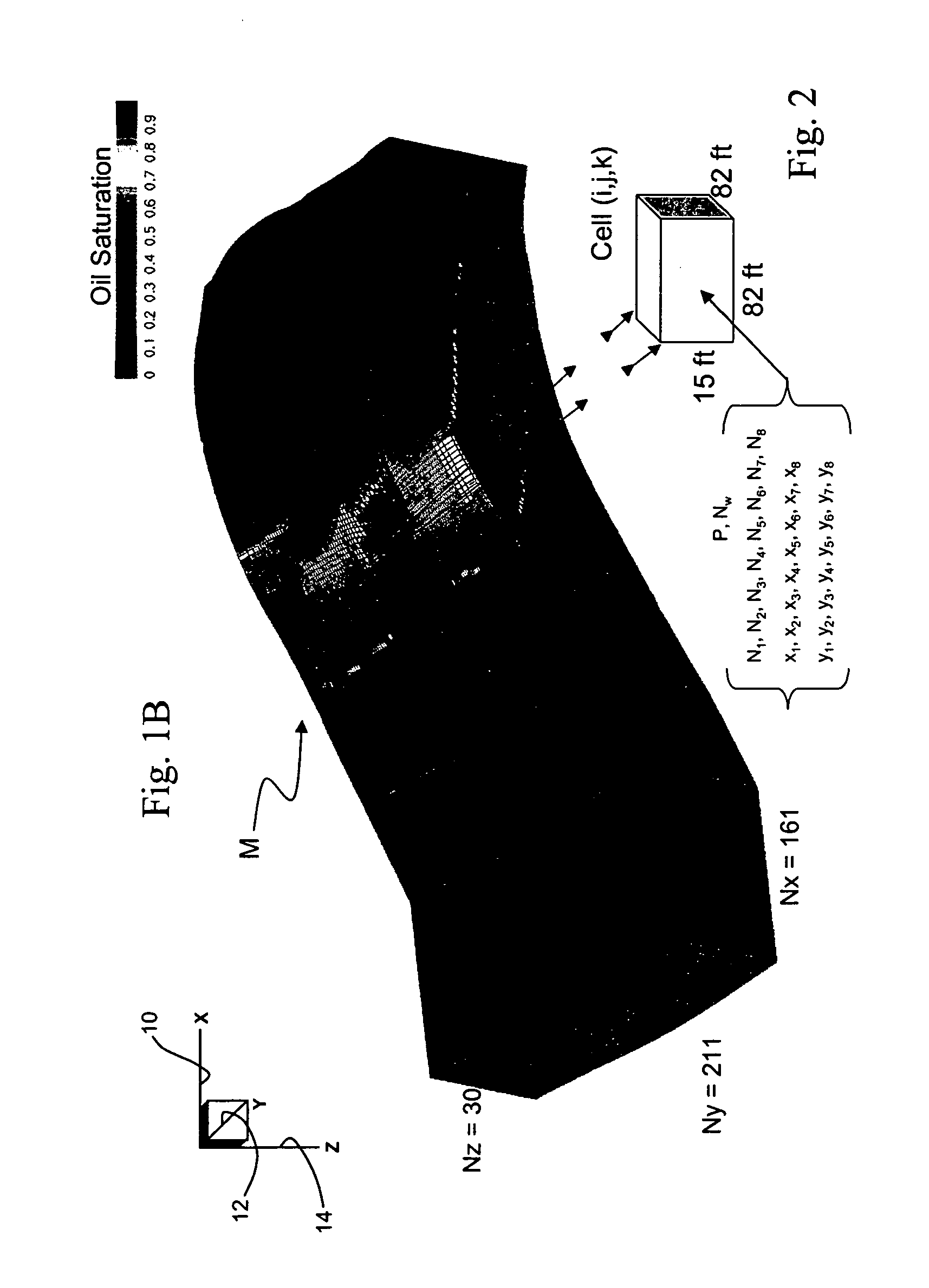

Method For Multi-Scale Geomechanical Model Analysis By Computer Simulation

A method of predicting earth stresses in response to changes in a hydrocarbon-bearing reservoir within a geomechanical system includes establishing physical boundaries for the geomechanical system, acquiring logging data from wells drilled, and acquiring seismic data for one or more rock layers. The well and seismic data are automatically converted into a three-dimensional digital representation of one or more rock layers within the geomechanical system, thereby creating data points defining a three-dimensional geological structure. The method also includes (a) applying the data points from the geological structure to derive a finite element-based geomechanical model, and (b) initializing a geostatic condition in the geomechanical model, and then running a geomechanics simulation in order to determine changes in earth stresses associated with changes in pore pressure or other reservoir characteristics within the one or more rock layers.

Owner:EXXONMOBIL UPSTREAM RES CO

Highly-parallel, implicit compositional reservoir simulator for multi-million-cell models

ActiveUS20060036418A1Reducing computer processing timeReduce processing timeElectric/magnetic detection for well-loggingPermeability/surface area analysisSupercomputerDistributed memory

A fully-parallelized, highly-efficient compositional implicit hydrocarbon reservoir simulator is provided. The simulator is capable of solving giant reservoir models, of the type frequently encountered in the Middle East and elsewhere in the world, with fast turnaround time. The simulator may be implemented in a variety of computer platforms ranging from shared-memory and distributed-memory supercomputers to commercial and self-made clusters of personal computers. The performance capabilities enable analysis of reservoir models in full detail, using both fine geological characterization and detailed individual definition of the hydrocarbon components present in the reservoir fluids.

Owner:SAUDI ARABIAN OIL CO

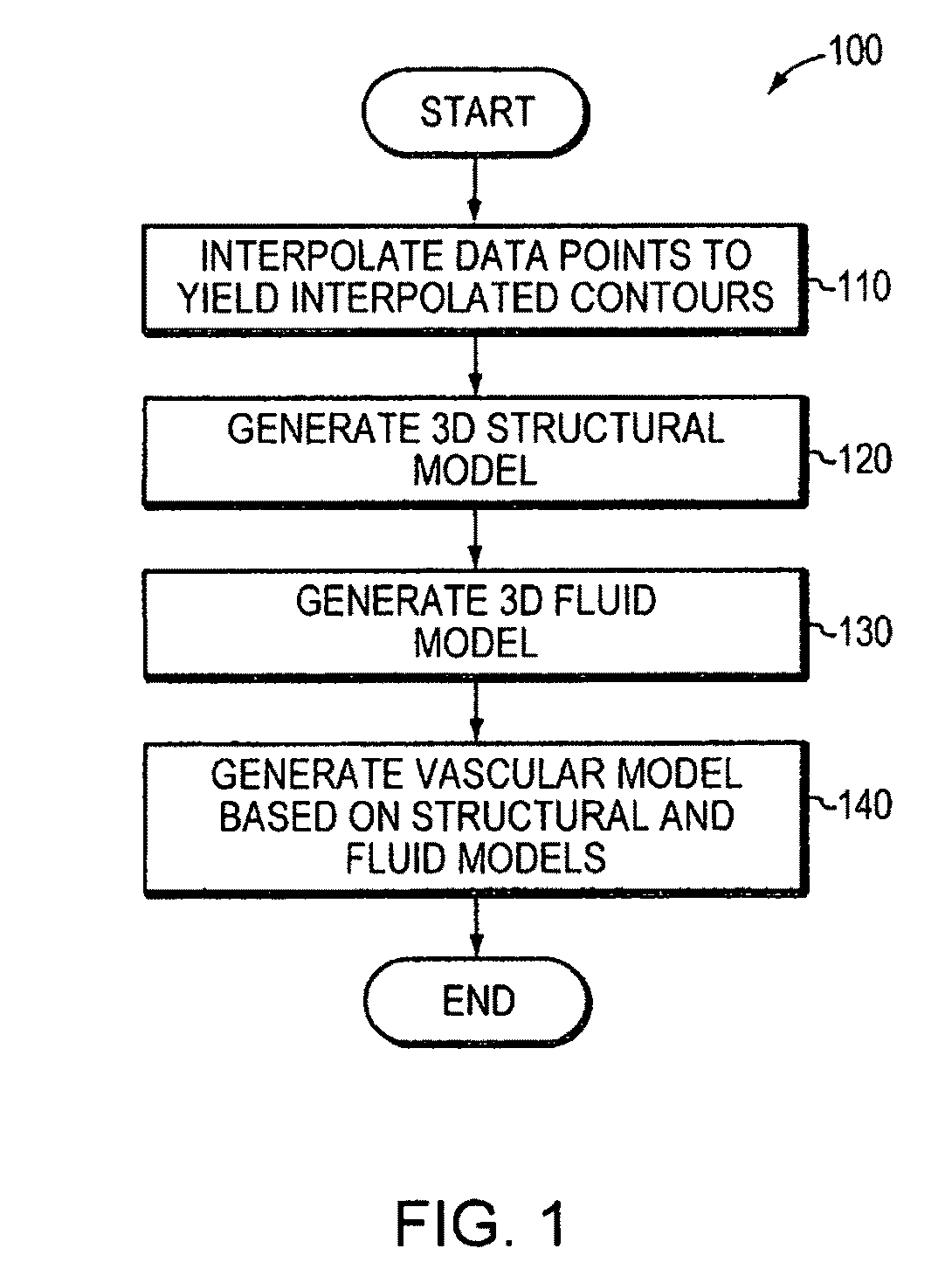

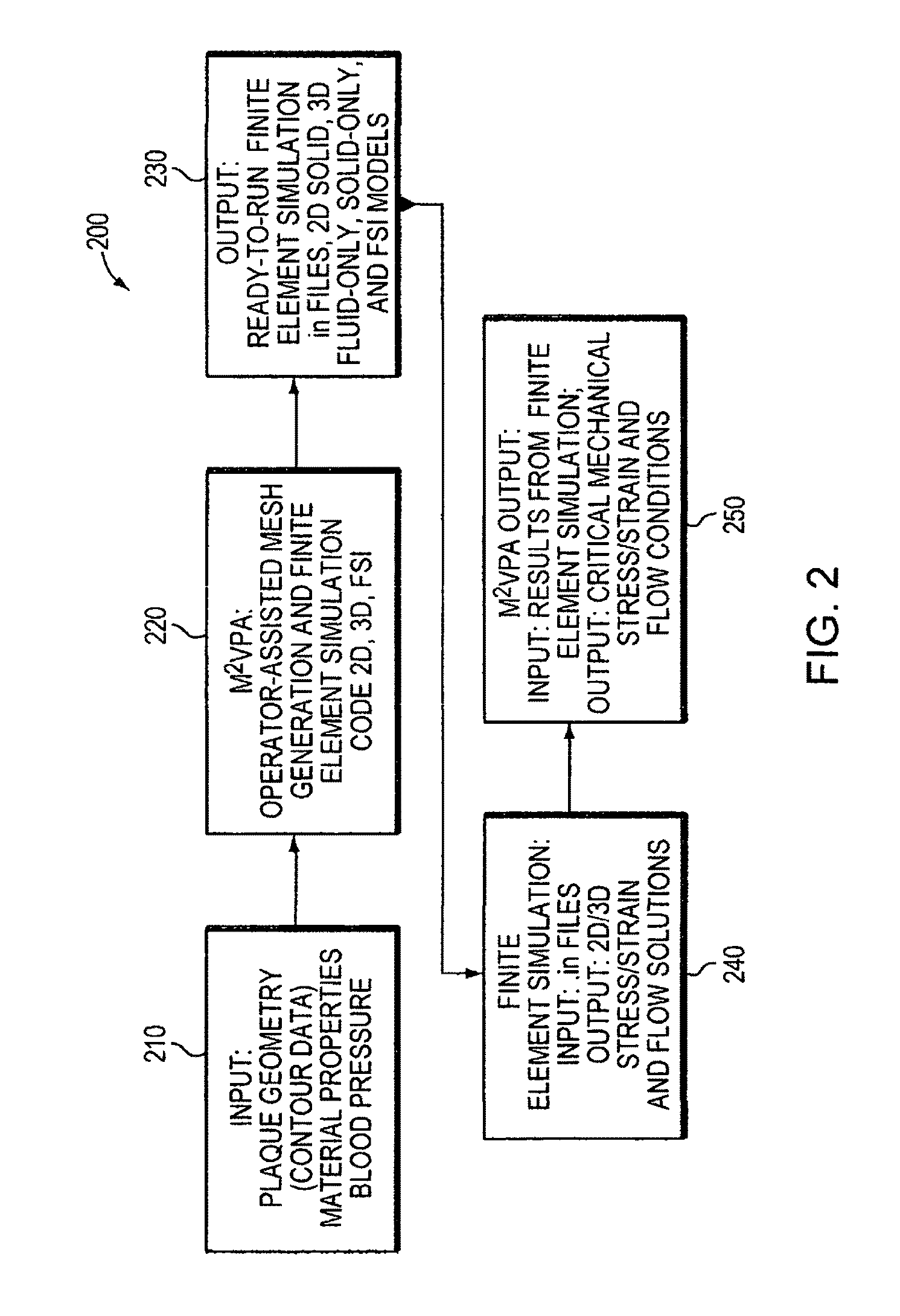

Automatic vascular model generation based on fluid-structure interactions (FSI)

ActiveUS8554490B2Automatically and accurately modelCatheterCharacter and pattern recognitionRadiologyComputerized system

A computer system and method are disclosed for automatically generating a vascular model of a blood vessel to support, for example, identification of mechanical factors corresponding to the blood vessel. The method includes interpolating data points corresponding to a contour of the blood vessel; generating a structural model representing three-dimensional structural characteristics of the blood vessel based on interpolated contours; generating a fluid model representing three-dimensional characteristics of fluid flow within the vessel; and generating a vascular model based on the structural model and the fluid model. The method may also include performing a mechanical analysis of the vascular model to identify a mechanical factor associated with the vessel, for example, a factor associated with a potential plaque rupture within the vessel. Embodiments of the invention are applicable to the diagnosis, assessment, or treatment of cardiovascular diseases.

Owner:WORCESTER POLYTECHNIC INSTITUTE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com