Healthcare Footwear Article with Silicon Rubber Sole Body and Its Manufacturing Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The following detailed description of the preferred embodiment is the preferred mode of carrying out the invention. The description is not to be taken in any limiting sense. It is presented for the purpose of illustrating the general principles of the present invention. Each of the inventive features described below can be used independently of one another or in combination with other features.

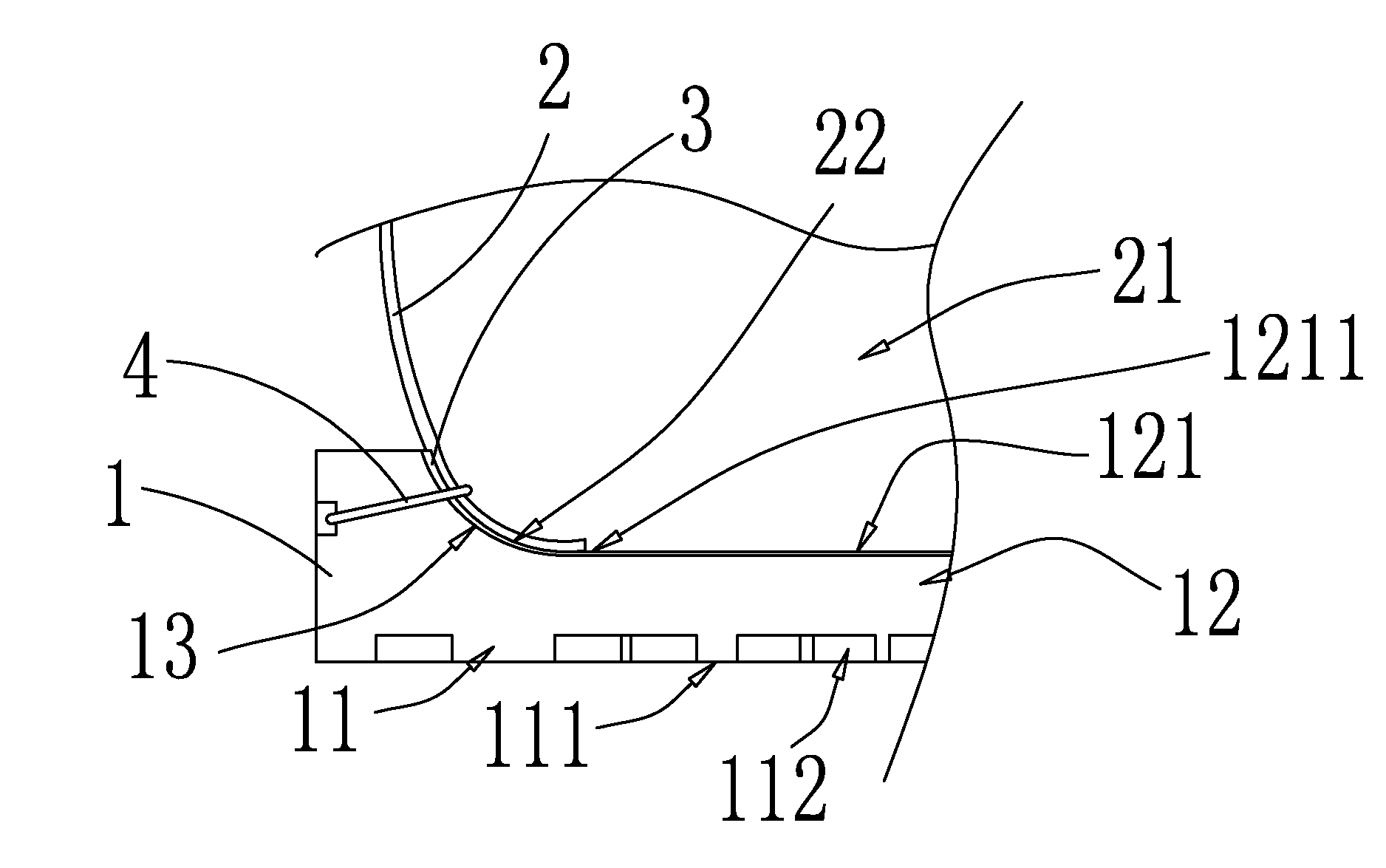

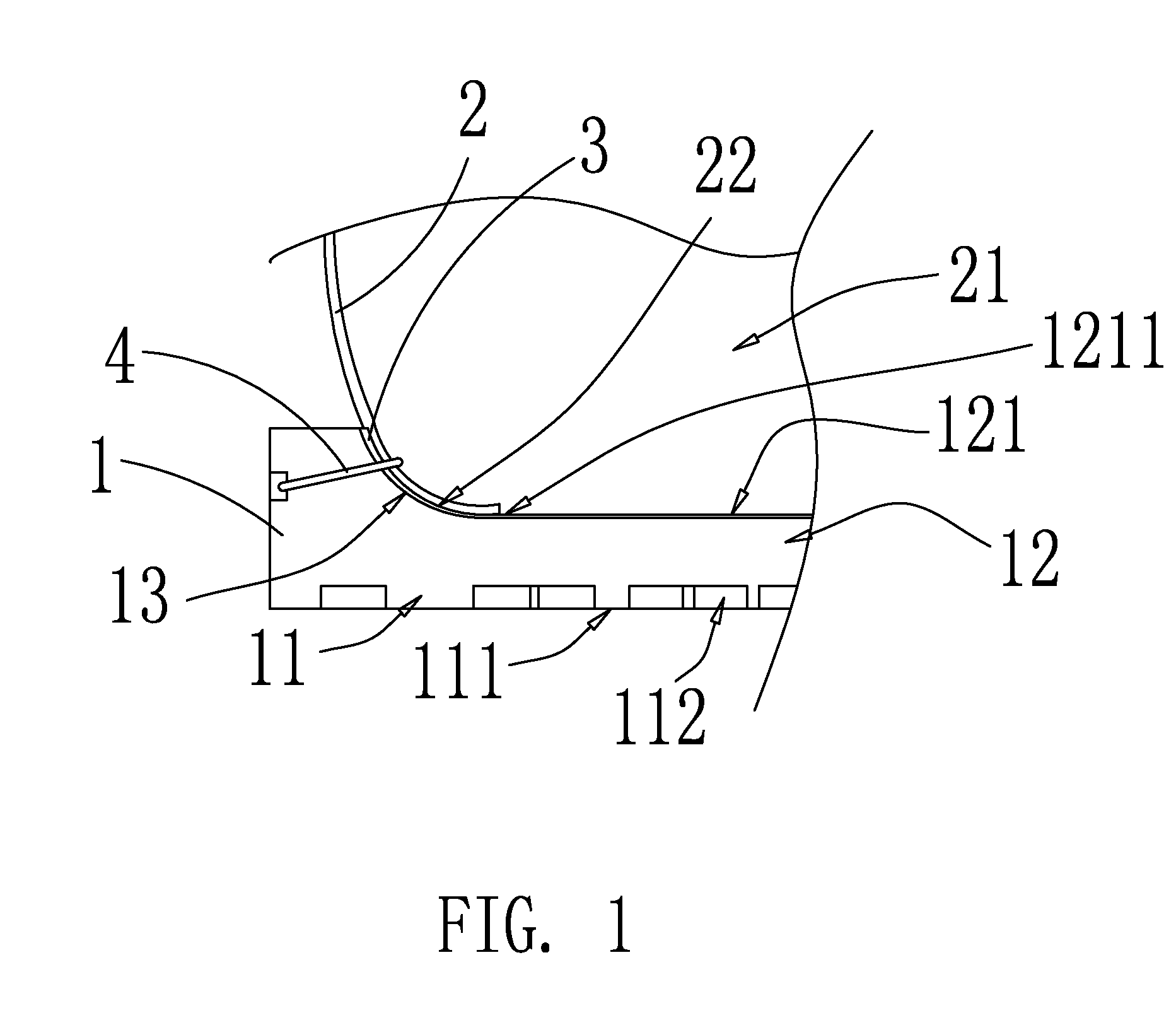

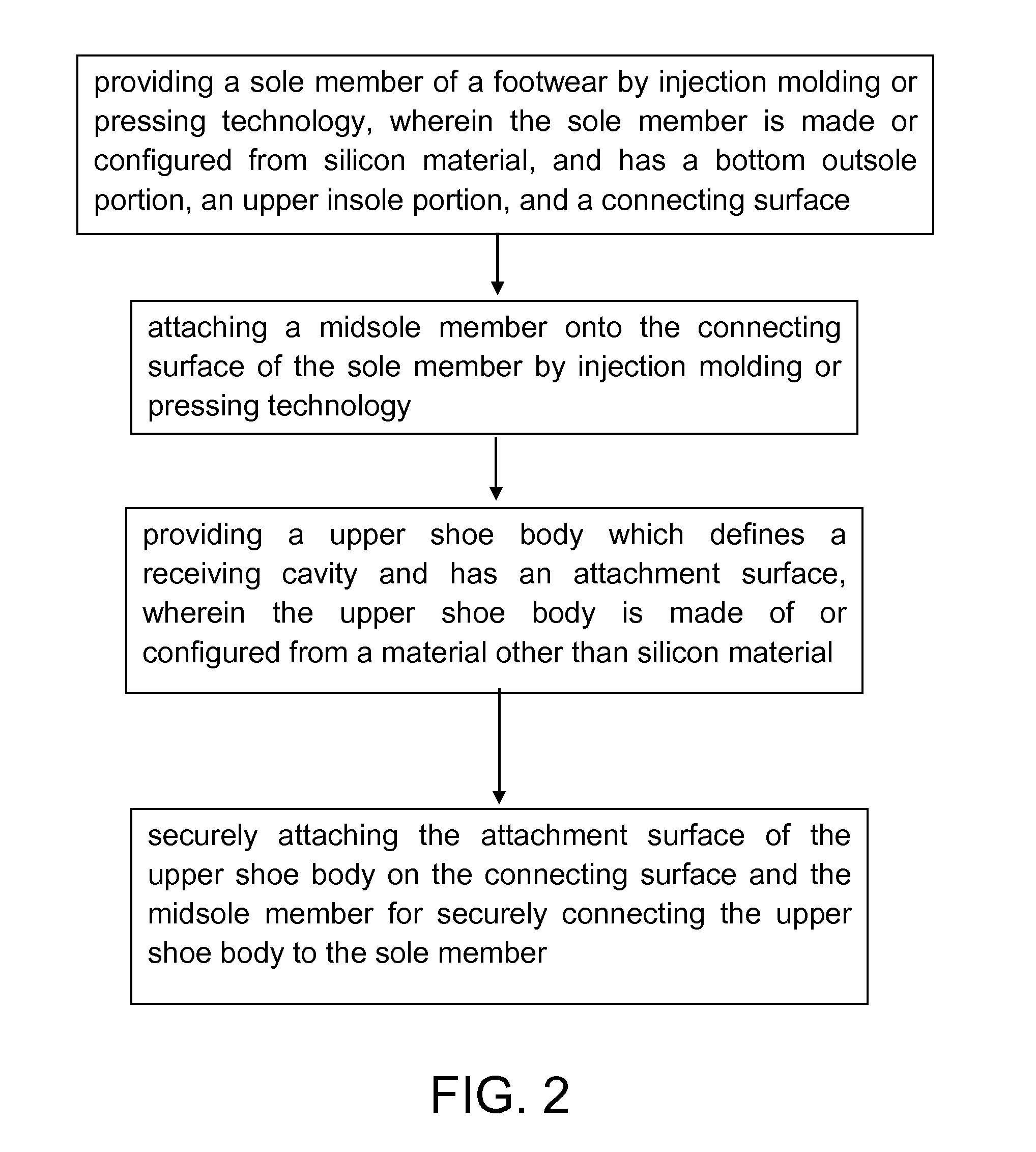

[0021]Referring to FIG. 1 of the drawings, a healthcare footwear article, such as a healthcare shoe, according to a preferred embodiment of the present invention is illustrated. The healthcare footwear article comprises a healthcare sole member 1, an upper shoe body 2, and a midsole member 3.

[0022]The upper shoe body 2 defines a receiving cavity 21 and has an attachment surface 22. The healthcare sole member 1 is provided underneath the upper shoe body 2, and has a bottom outsole portion 11, an upper insole portion 12, and a connecting surface 13, wherein the healthcare sole member 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com