Safe igniting device applied to electronic igniting non-electric welding rod

A technology of non-electric welding rods and ignition devices, applied in auxiliary devices, welding media, welding equipment, etc., can solve the problems of no insurance circuit, operator danger, safety hazards, etc., to avoid safety hazards, reliable connection, reliable and stable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

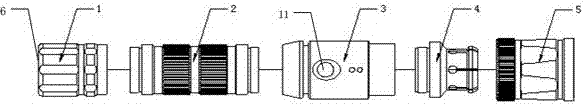

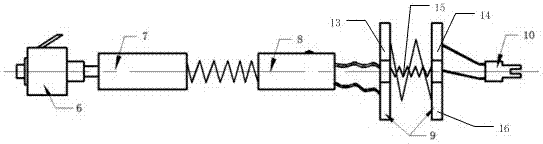

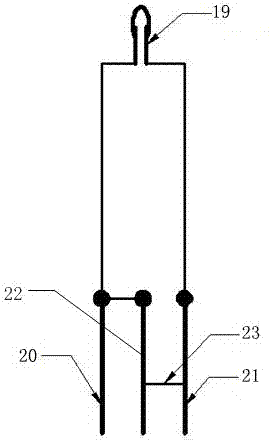

[0023] like Figure 1~Figure 3 As shown, a safety ignition device for electronic ignition without electric electrodes, which includes an external structure and an internal circuit structure, the external structure includes a rear seat 1, a battery cylinder 2, a middle switch part 3 and a locking part 5, The rear seat 1, the battery cartridge 2, the middle switch part 3 and the locking part 5 are installed in sequence with each other, and the locking part 5 is also installed in cooperation with the cartridge base 12 to lock or loosen the cartridge base 12, and the inside of the locking part 5 An intermediate connector 4 is provided, and the intermediate connector 4 is fitted in the locking part 4 and connected to the cartridge base 12; the internal circuit structure includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com