Pump System

a pump system and pump technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of reduced performance, loss of service life, and difficulty in economically producing hydrocarbons from low-permeability reservoir rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

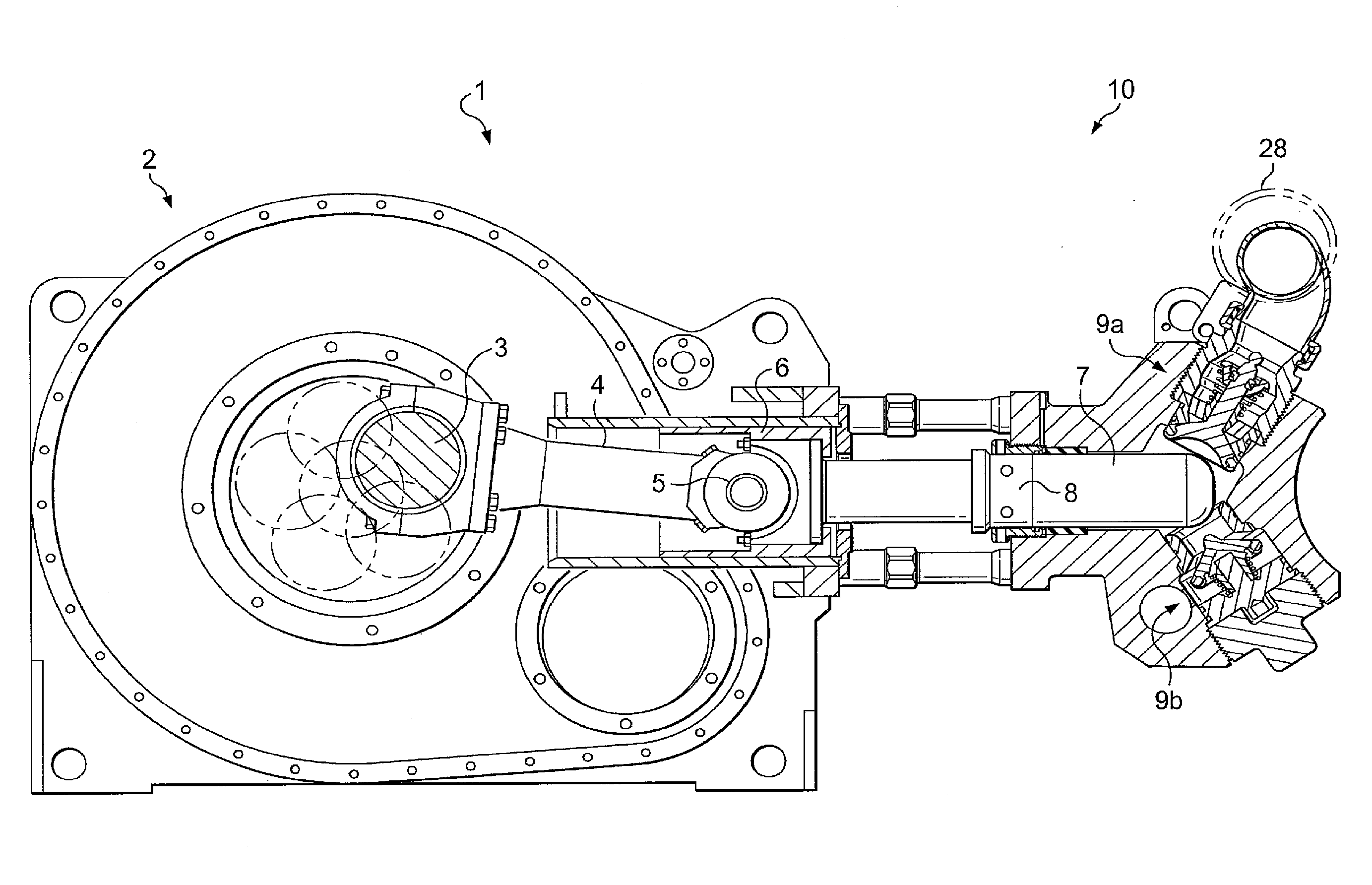

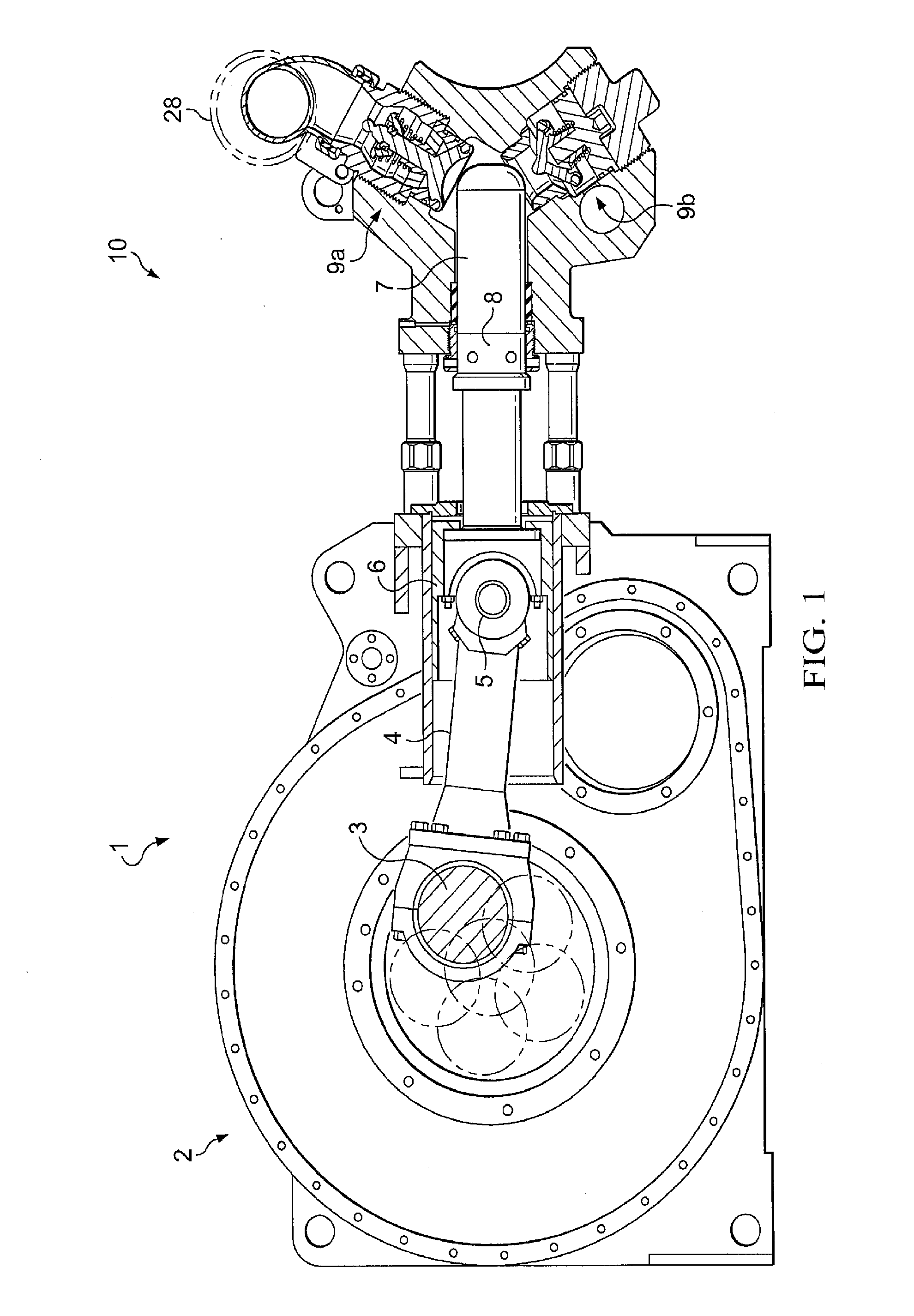

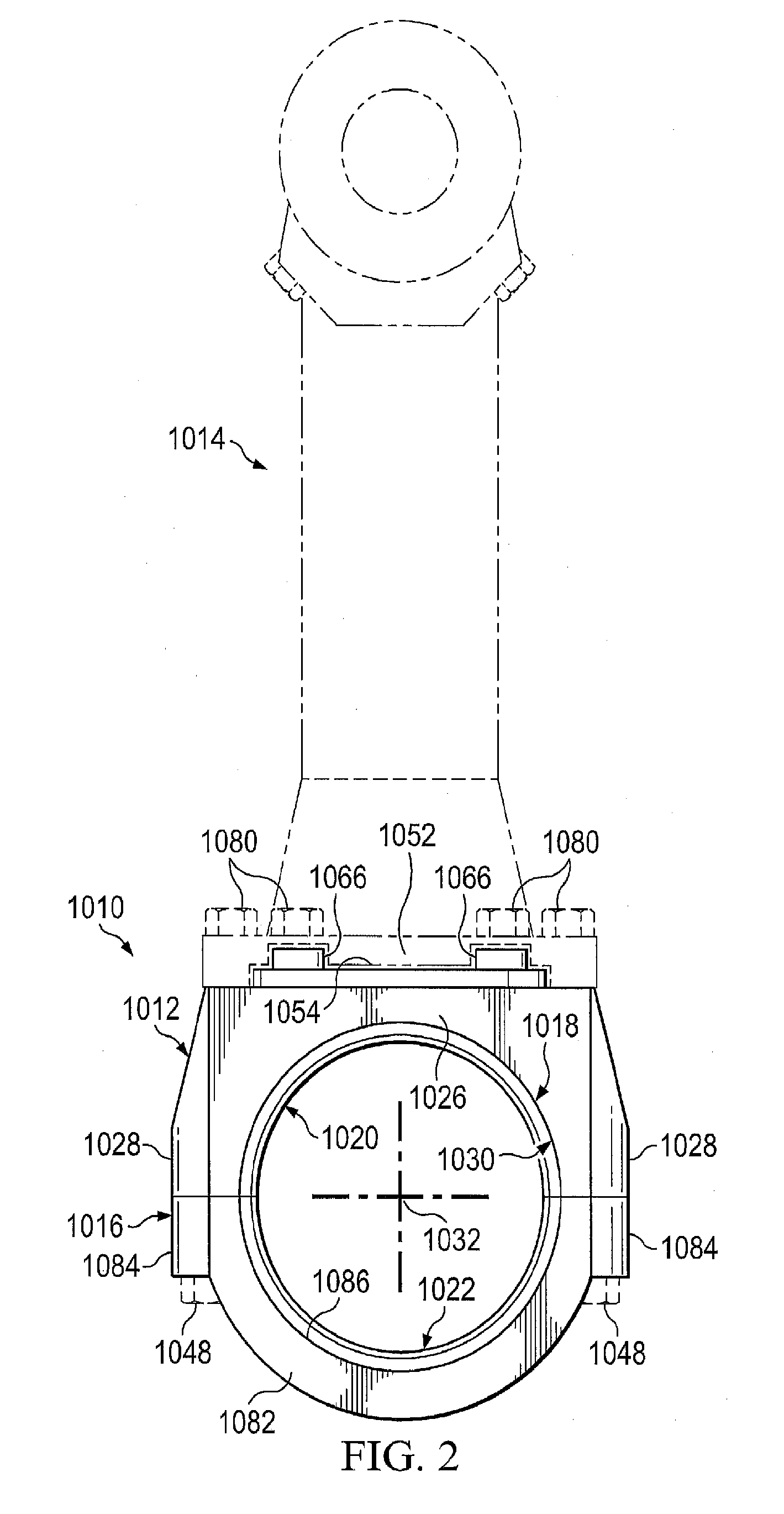

[0126]Referring now to FIGS. 11-14 in the drawings, a fluid end assembly 10 is illustrated according to the present application. Fluid assembly 10 shows a Y-shaped intersection between plunger 16, suction valve 24, and discharge valve 26. Fluid end 10 is configured to reduce metal fatigue in the fluid end and increase ease of maintenance. In particular to FIGS. 11 and 12 of the drawings, fluid end assembly 10 includes a pump housing 12 having a plunger bore 14 within which a plunger 16 reciprocates. At its inner end, plunger bore 14 terminates in a pumping chamber 18 that is supplied with fluid from above by a suction passage 20 in pump housing 12. Fluid pressurized by plunger 16 exits pumping chamber 18 downwardly through a discharge passage 22 in pump housing 12. A suction valve 24 in suction passage 20 establishes the one-way flow of fluid from a supply manifold 28 into pumping chamber 18. A discharge valve 26 in discharge passage 22 sets up the one-way flow of fluid from pumping...

second embodiment

[0144]Referring now to FIGS. 13 and 14 of the drawings, a fluid end assembly is shown at 410. Fluid end assembly 410 is substantially the same as fluid end assembly except that a suction valve 424 and a discharge valve 426, and the passages 420 and 422 for the valves 424 and 426, have been modified somewhat. These modifications are believed to further strengthen valves 424 and 424 and fluid end assembly 410.

[0145]Fluid end assembly 410 includes a pump housing 412 having a plunger bore 414 within which a plunger 416 reciprocates. At its inner end, plunger bore 414 terminates in a pumping chamber 418 that is supplied with fluid by a suction passage 420 in pump housing 412. Fluid pressurized by plunger 416 exits pumping chamber 418 through a discharge passage 422 in pump housing 412 located opposite suction passage 420. A suction valve 424 in suction passage 420 permits the one-way flow of fluid from a supply manifold 428 to pumping chamber 418. A discharge valve 426 in discharge passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com