Dispensing Bag with Longitudinal Split

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

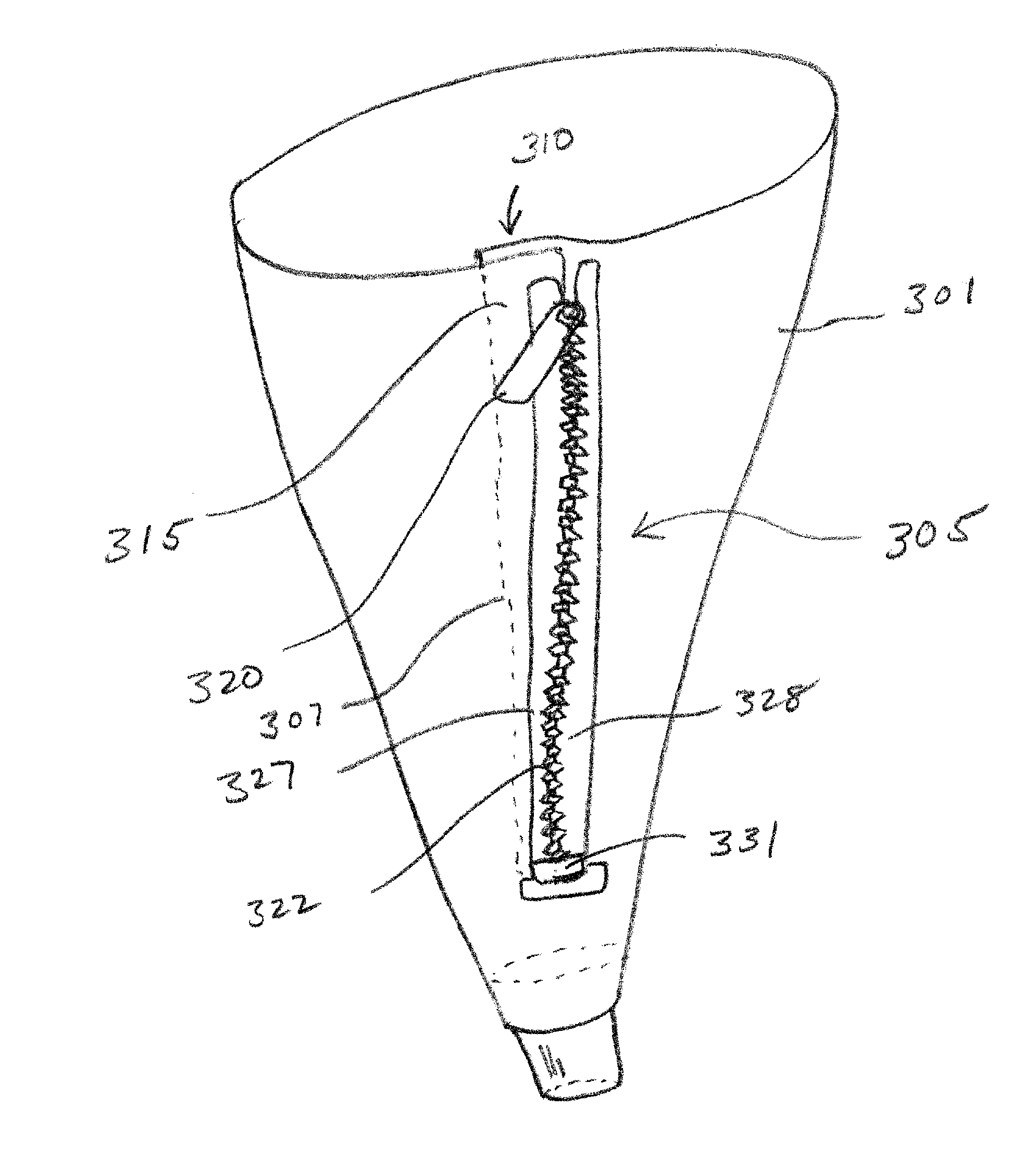

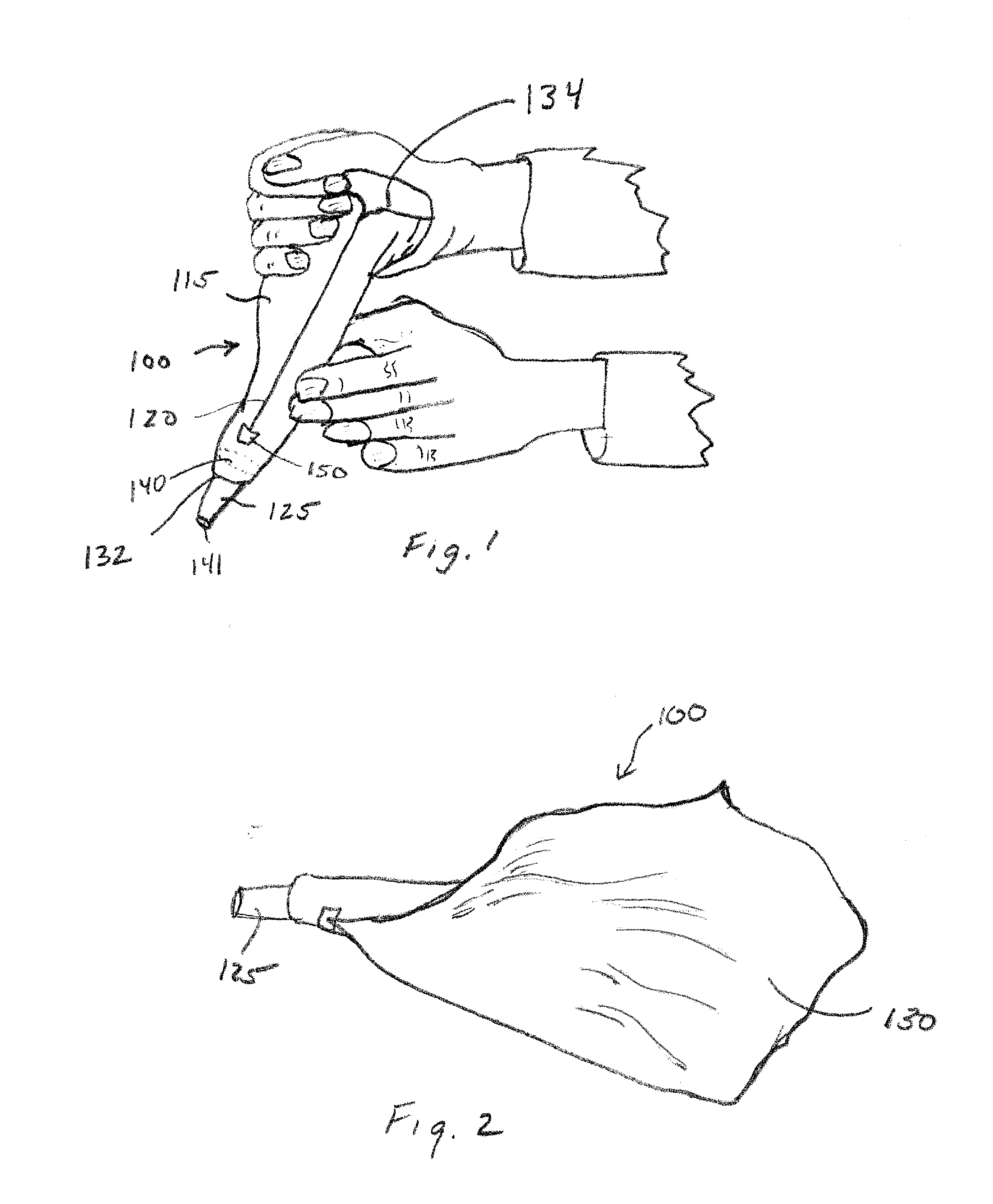

[0023]Now referring to FIG. 1 a dispenser bag 100 according to the invention is disclosed that includes a flexible body 115 and a ridged tubular element 125 or tip installed within the bag 100 and extending therefrom. The bag depicted in FIG. 1 is intended to be used to dispense icing and is commonly referred to as a pastry bag. The tubular tip has a first opening 141 that is smaller than the round opening 132 at the bottom of the pastry bag and can be inserted through the opening 132 in the bag. The tubular element 125 extends through the opening in bag 132 until the outer sidewalls of the tip seat against the inner sidewalls of the bag 115. The edge of the larger opening 140 is thereby seated within bag 115. The tubular element 125 imposes itself within the bag and will restrict the flow of icing or other viscous materials placed within the bag during use. The bag 115 is flexible and conical-shaped which is generally achieved by truncation of the bag at its small opening 132. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com