Steam generation with carbon dioxide recycle

a technology of carbon dioxide and recycle, which is applied in the direction of fluid removal, earth-moving drilling, and wellbore/well accessories, etc., can solve the problem that dsg can only provide a narrow range of carbon dioxide concentrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

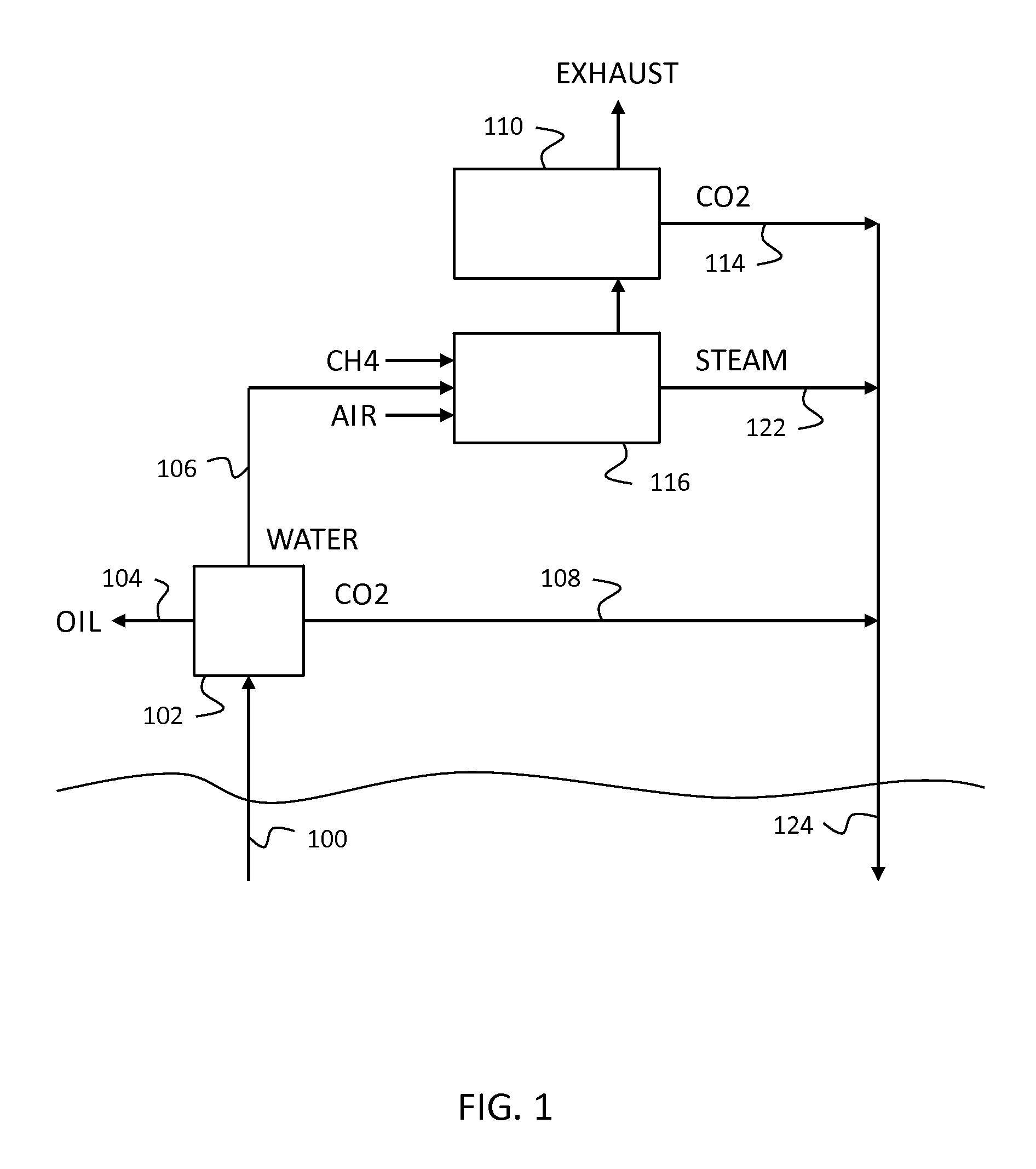

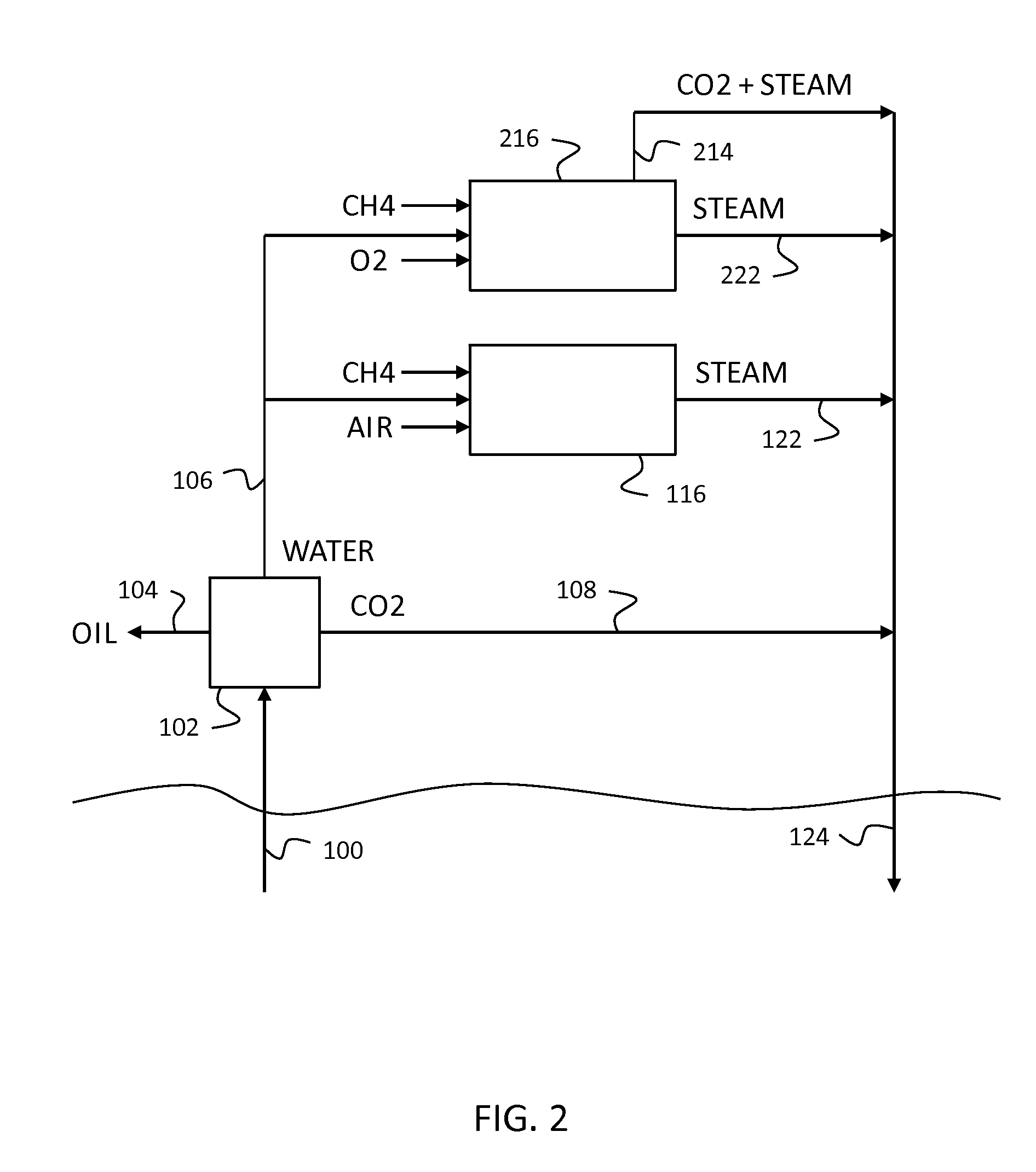

[0014]Embodiments of the invention relate to systems and methods of recovering hydrocarbons by injecting into a reservoir steam along with carbon dioxide recovered from flue gases produced while generating the steam and from separation of produced fluids. Due to benefits from the carbon dioxide injection, carbon dioxide capture rates from the flue gases selected below fifty percent in such combined recovery of the carbon dioxide enables lower fuel consumption even given that additional fuel is needed for the carbon dioxide capture versus steam only operations. As the capture rates from the flue gases increase above fifty percent like when employed for sequestration purposes, such approaches use more fuel than the steam only operations and may not be cost efficient. A carbon dioxide recovery unit coupled to an air-fired boiler or an auxiliary oxy-fired boiler may supply the carbon dioxide recovered from the flue gases.

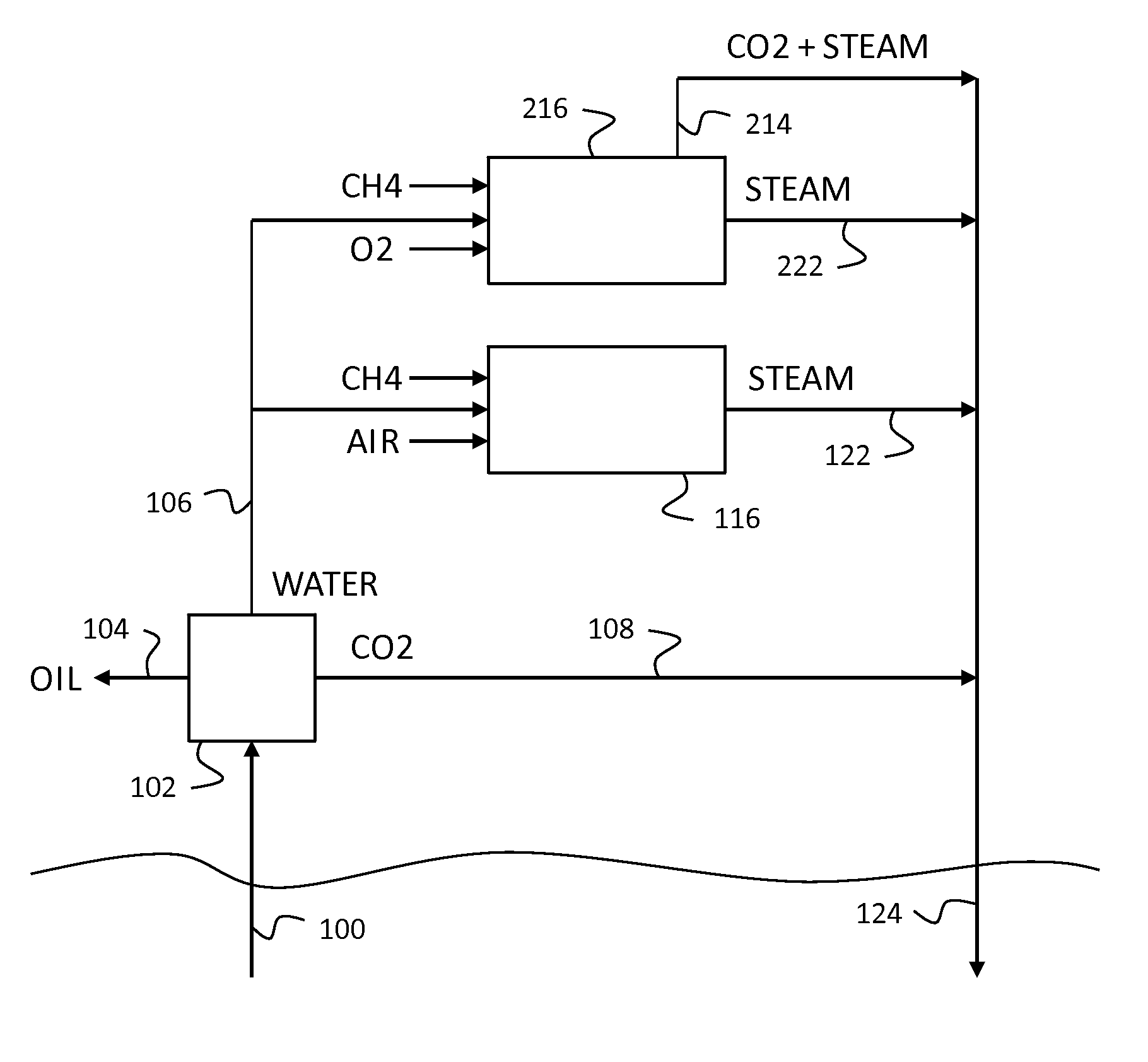

[0015]FIG. 1 illustrates a system for recovering hydrocarbons that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com