Enhanced Charging Handle

a charging handle and handle technology, applied in the field of firearms, can solve the problems of improper operation, deficient ergonomics of the charging handle, etc., and achieve the effect of enhancing the charging handle, more surface area, and reliably operating the charging handl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

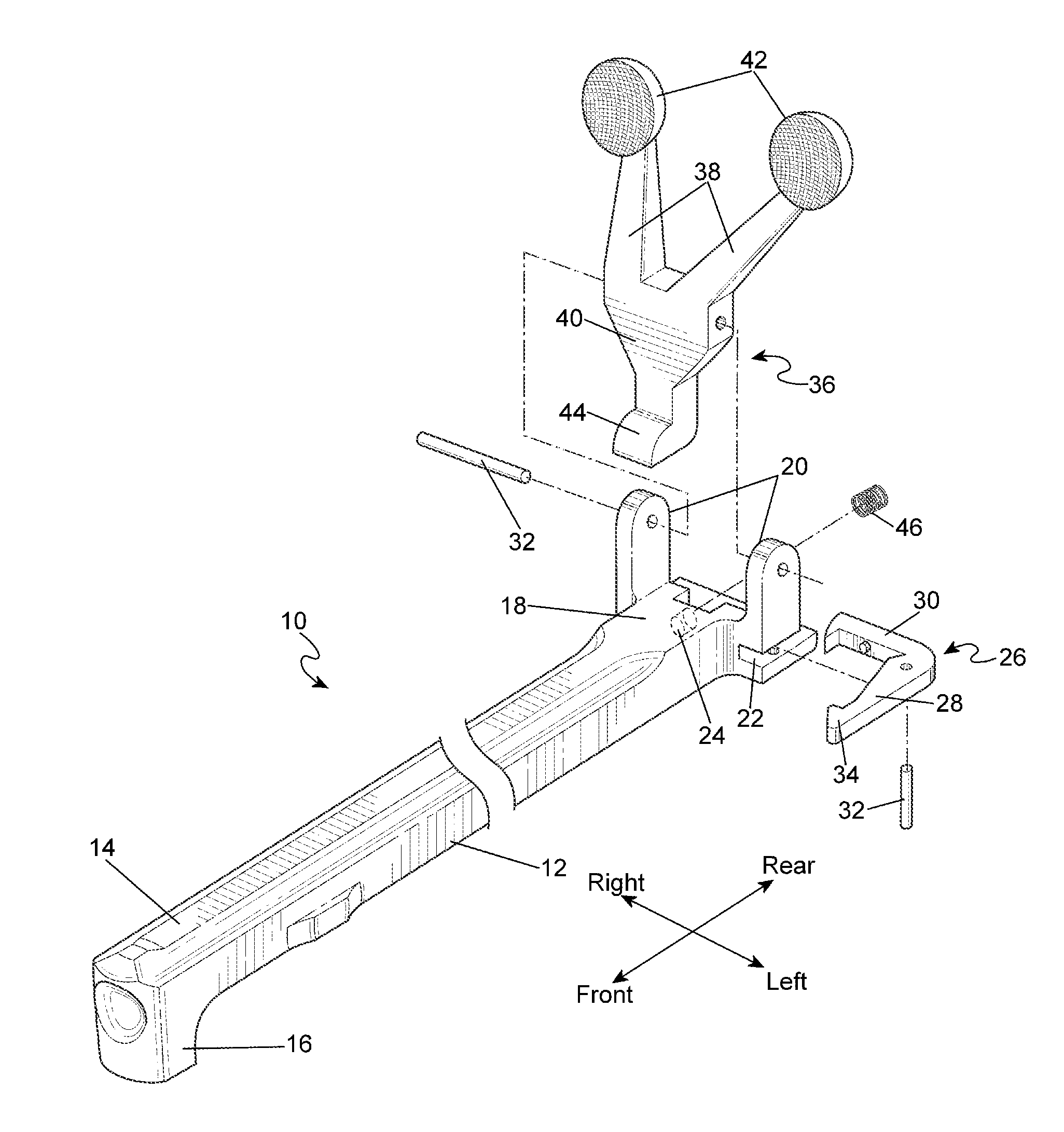

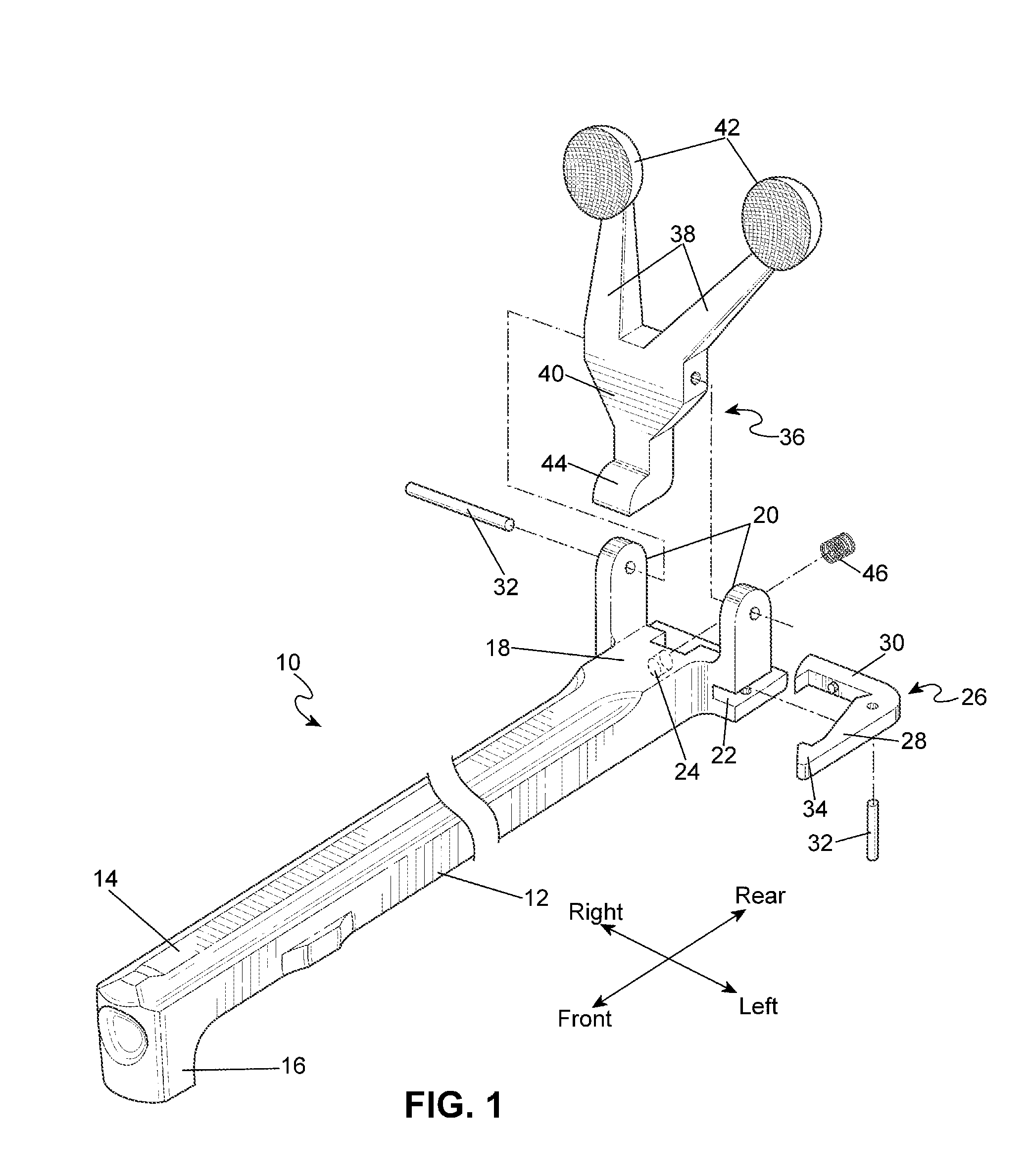

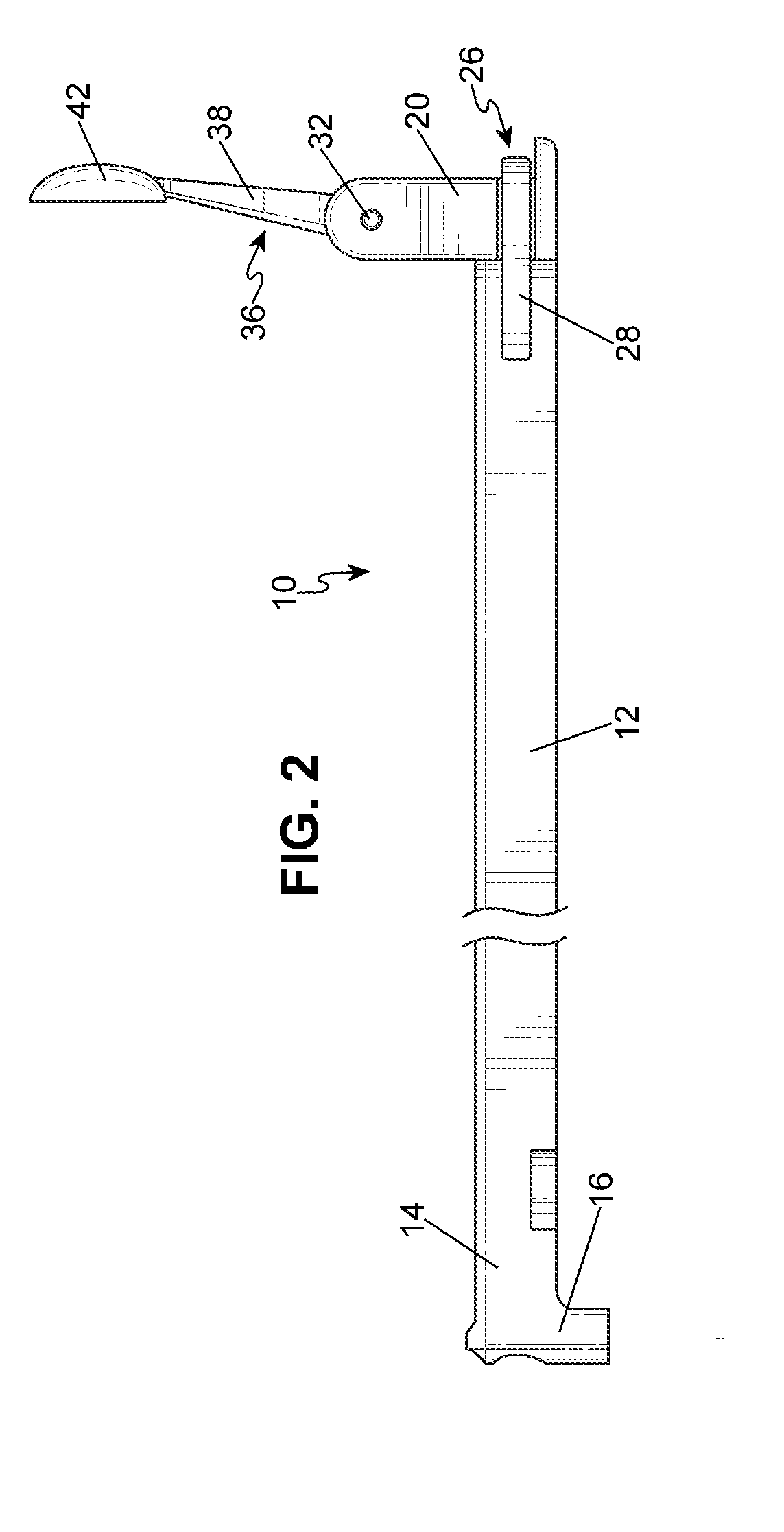

[0014]Referring to FIGS. 1, 2, and 5 the enhanced charging handle 10 has an elongated shaft 12 having a forward end 14 with a bolt hook 16 that engages the bolt carrier group (not shown). The charging handle 10 also has a rear end 18 having two parallel vertical arms 20 where one vertical arm 20 extends from the right side of the rear end 18 and the other vertical arm 20 extends from the left side of the rear end 18. The rear end 18 further has a longitudinal slot 22 on the left side and a rear-facing spring cavity 24 in the center.

[0015]Horizontally oriented within the slot 22 is an L-shaped latch 26 having a forward leg 28 and a rear leg 30. The latch 26 is pivotally attached to the rear end 18 by a vertically oriented roll pin 32 inserted through corresponding holes in the latch 26 and rear end 18. The forward leg 28 has an inward-facing tooth 34 at the distal end that can engage a lip on the upper receiver (not shown) thereby locking the charging handle 10 in the forward positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com