Low-pressure turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

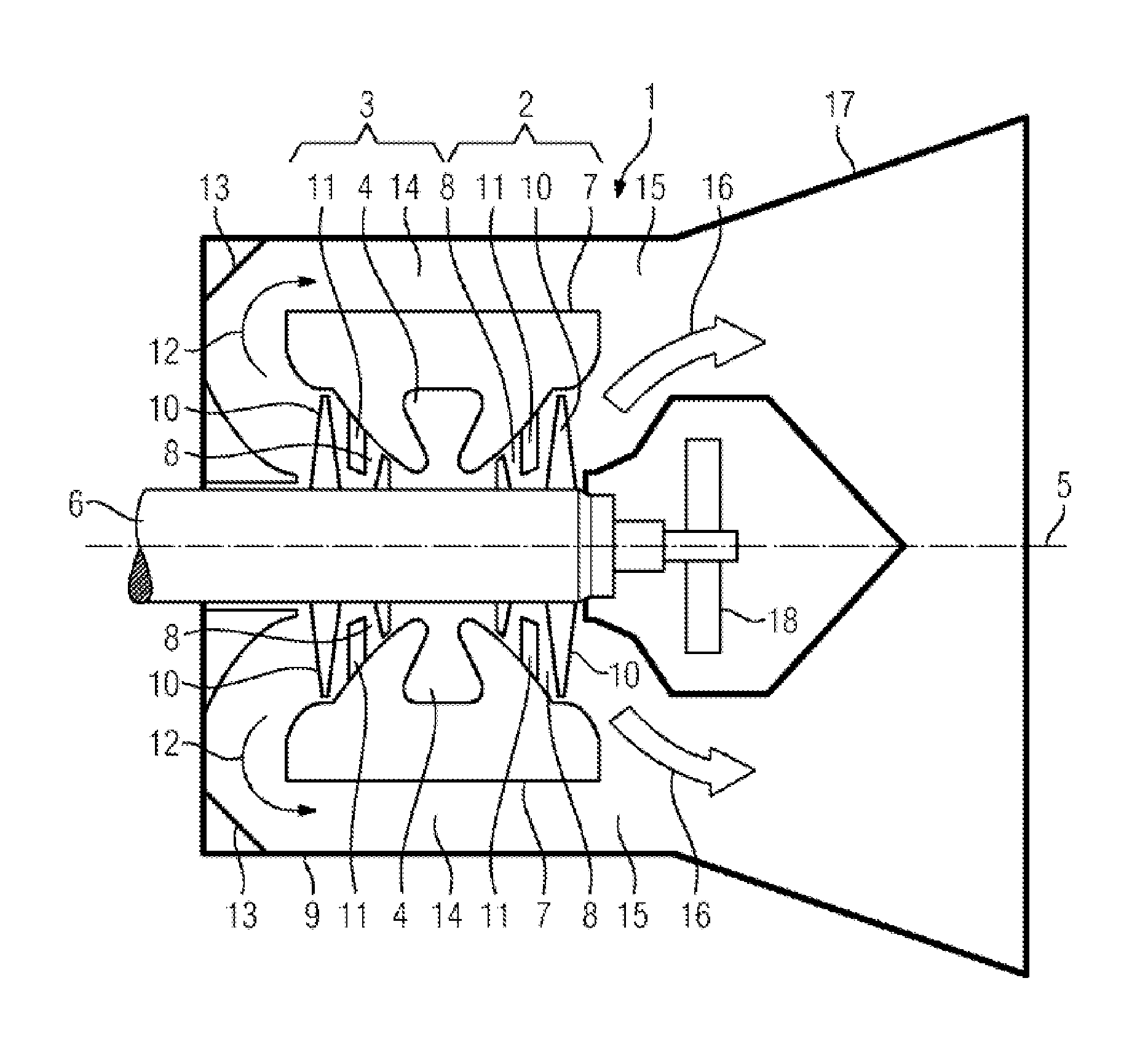

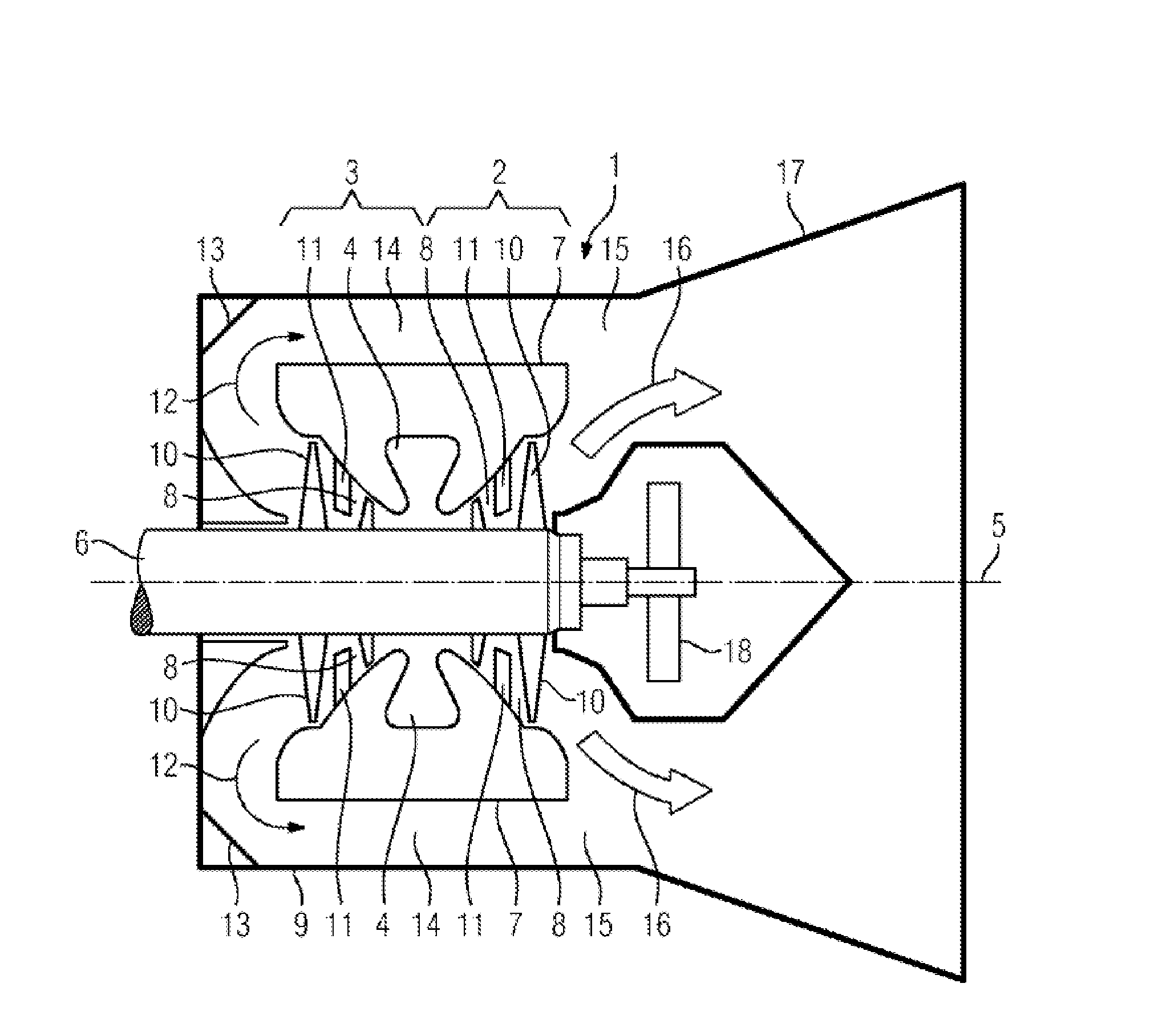

[0014]The FIGURE shows a low-pressure partial turbine 1, which has a two-flow configuration. This means that the low-pressure partial turbine 1 has a first flow 2 and a second flow 3. Live steam flows into the low-pressure partial turbine 1 via an admission connector 4. A flow path 8 is formed between a rotor 6 mounted rotatably about an axis of rotation 5 and an inner housing 7 arranged around the rotor 6.

[0015]An outer housing 9 is arranged around the inner housing 7. The rotor 6 is formed with individual rotor blades 10. For the sake of clarity, only one rotor blade is provided with the reference sign 10. Guide vanes 11 arranged on the inner housing 7 are arranged between the individual rotor blade stages. For reasons of clarity, only one guide vane is provided with the reference sign 11.

[0016]Live steam flows in via the admission connector 4 and is expanded in the first flow 2 to the right, as seen in the plane of the drawing, and in the second flow 3 to the left, as seen in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com