Rotor with magnet pattern

a magnet pattern and rotor technology, applied in the direction of magnetic circuit rotating parts, dynamo-electric machines, magnetic circuit shape/form/construction, etc., can solve the problems of difficult and expensive manufacturing of known designs, and achieve the effect of improving optimization, difficult and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

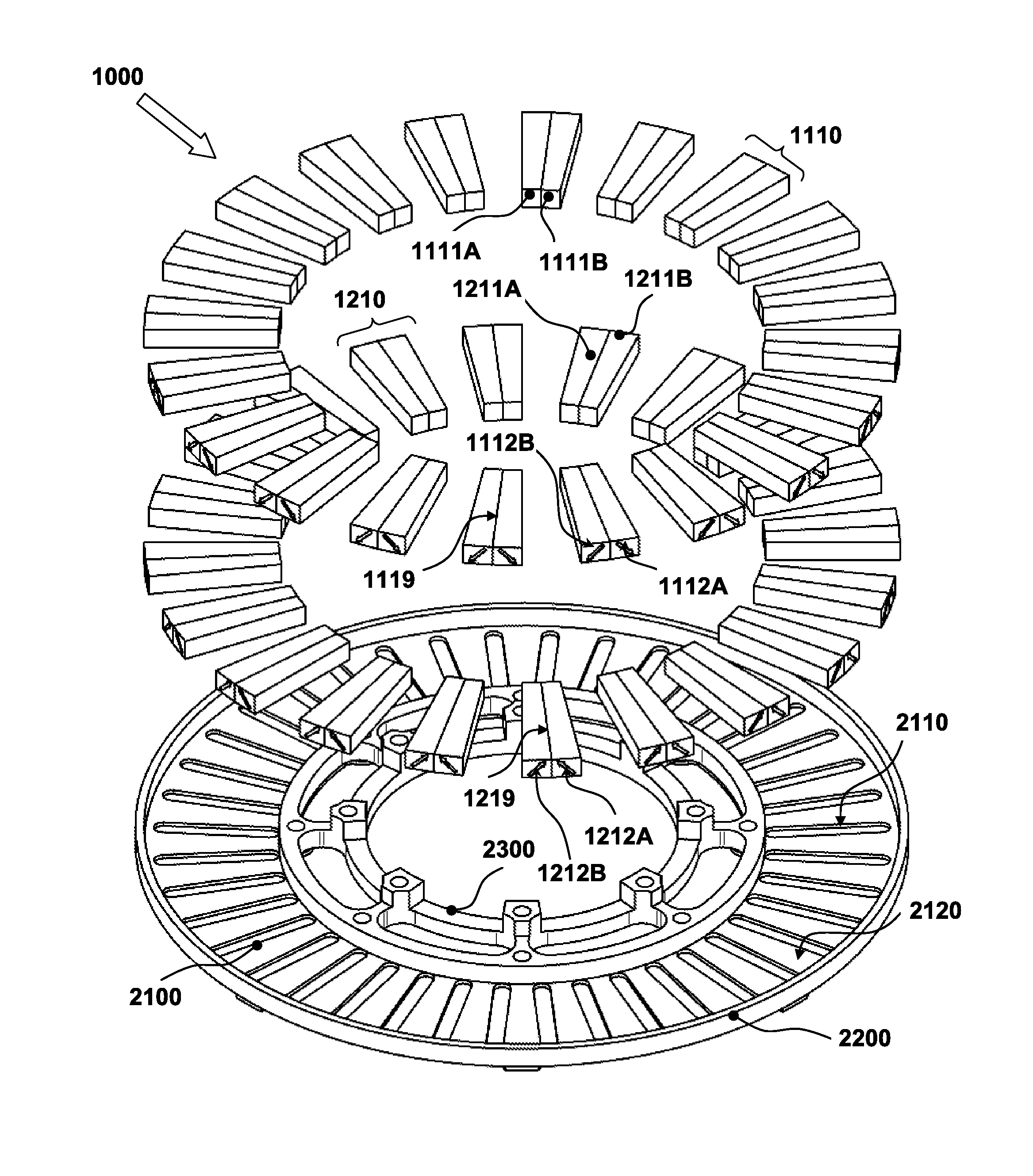

[0082]The present invention, in some embodiments thereof, relates to rotors for electric machines such as an electric motors and / or generators, and, more particularly, but not exclusively, to patterns for magnetic elements of planar rotors for axial air-gap electric machines.

[0083]As used throughout the present disclosure and in the claims below, the terms “machine” and “electrical machine” are to be understood to include both electric motors and electric generators.

Previously Known Designs

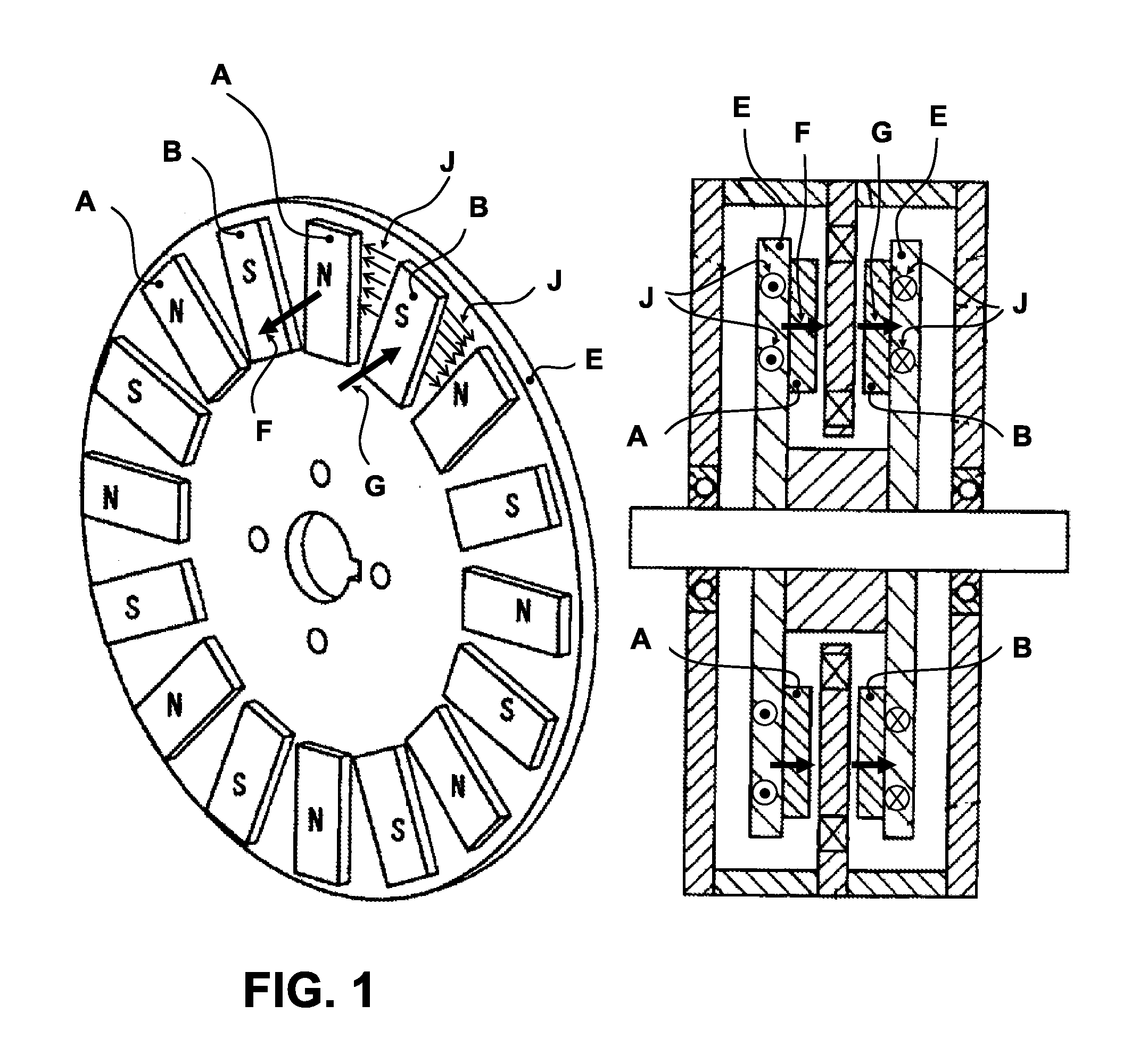

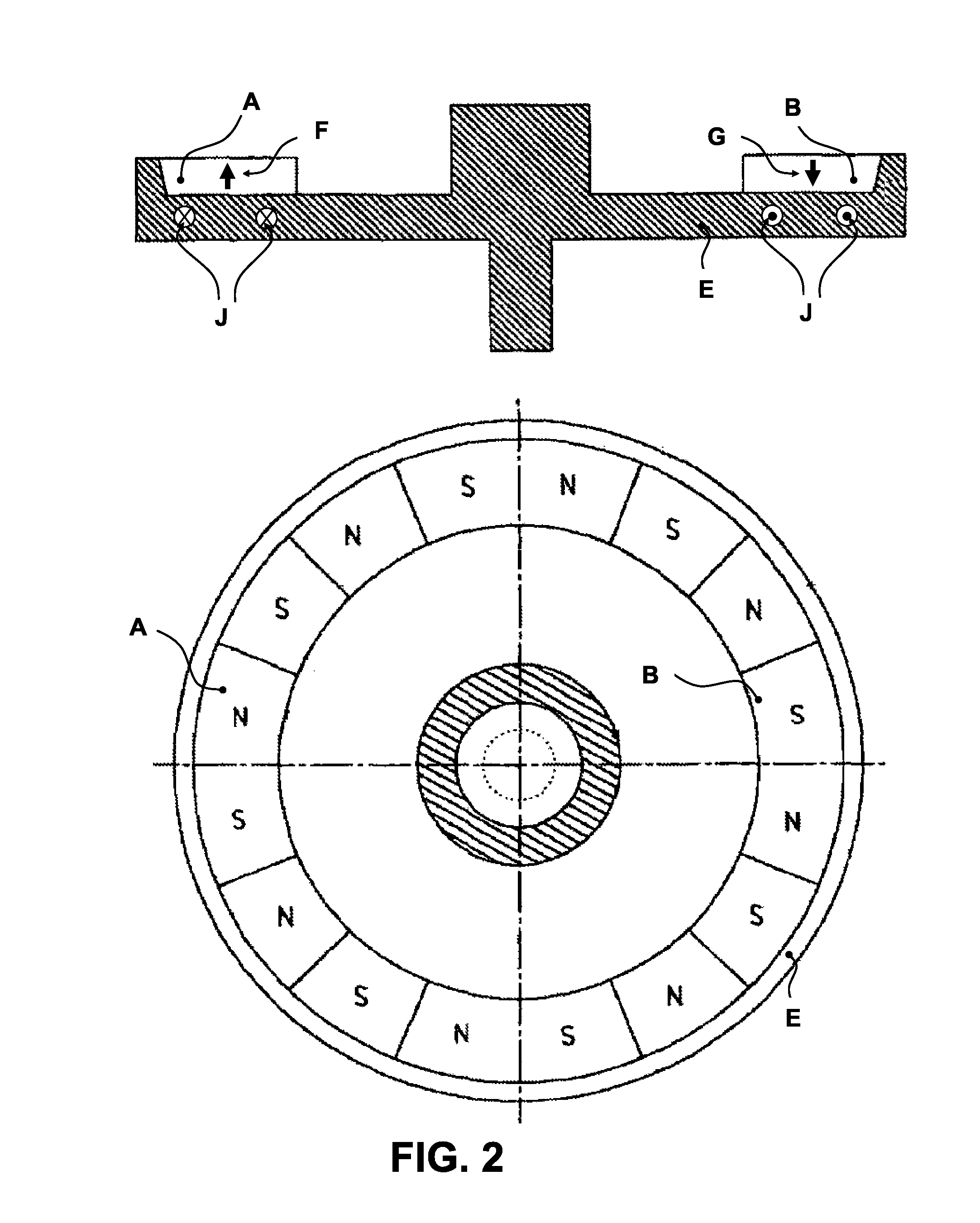

[0084]For purposes of better understanding some embodiments of the present invention, as illustrated in FIGS. 8-19 of the drawings, reference is first made to the construction and operation of several known designs for rotors, as illustrated in FIGS. 1-7.

[0085]Attention is first drawn to FIGS. 1 and 2, which show heteropolar magnet systems of axial flux rotors, according to methods of prior art. FIG. 1 is adapted from US patent application 2010 / 0253173 A1 of Koji Miyata et al. FIG. 2 is adapted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com