Mask Structure Without an Inner Waterproof Ring

a mask and waterproof technology, applied in the field of mask structures, can solve the problems of large mold cost, large mold size, and inability to manufacture masks, and achieve the effects of improving production efficiency, good waterproof effect and wearing comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

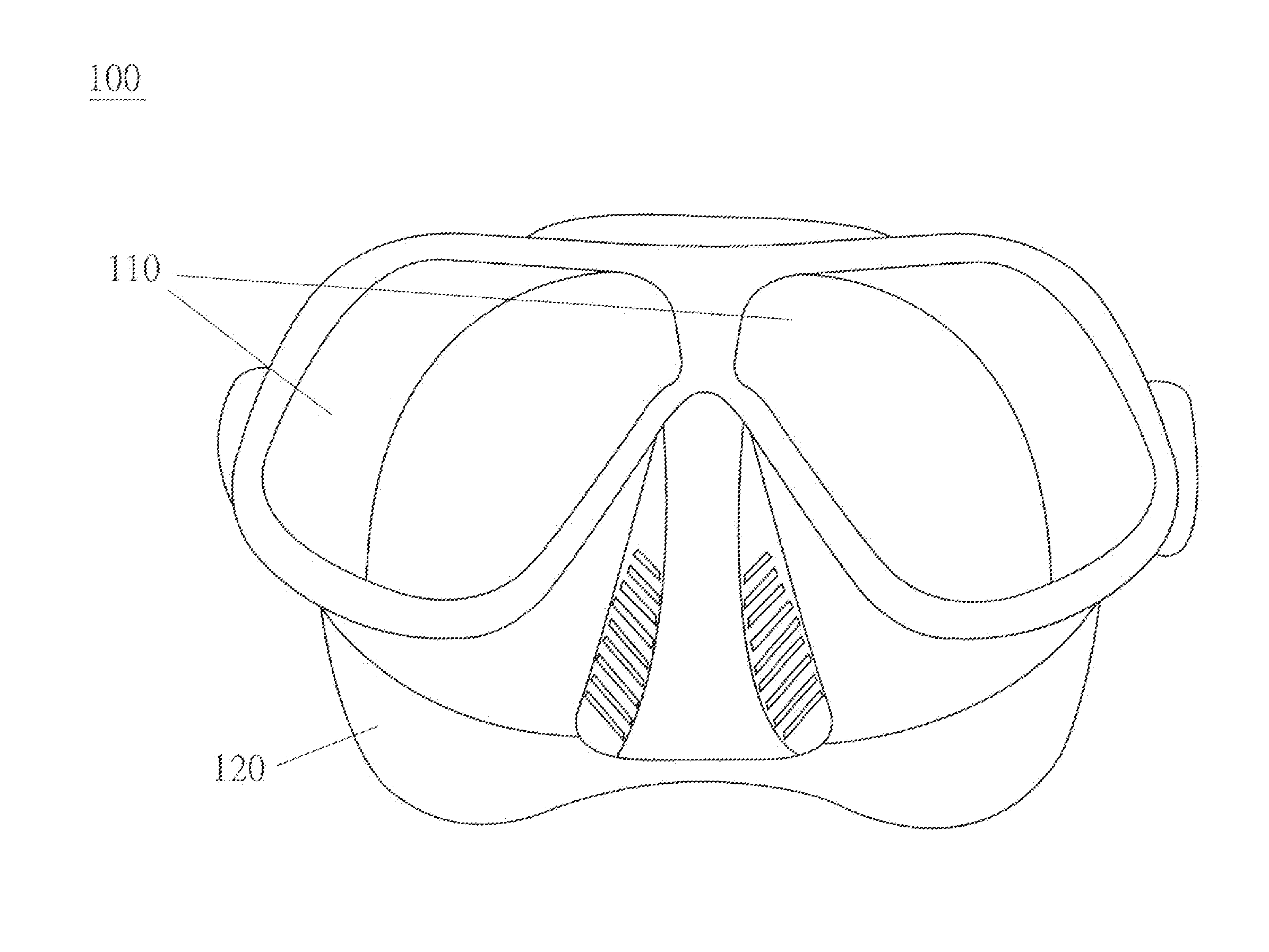

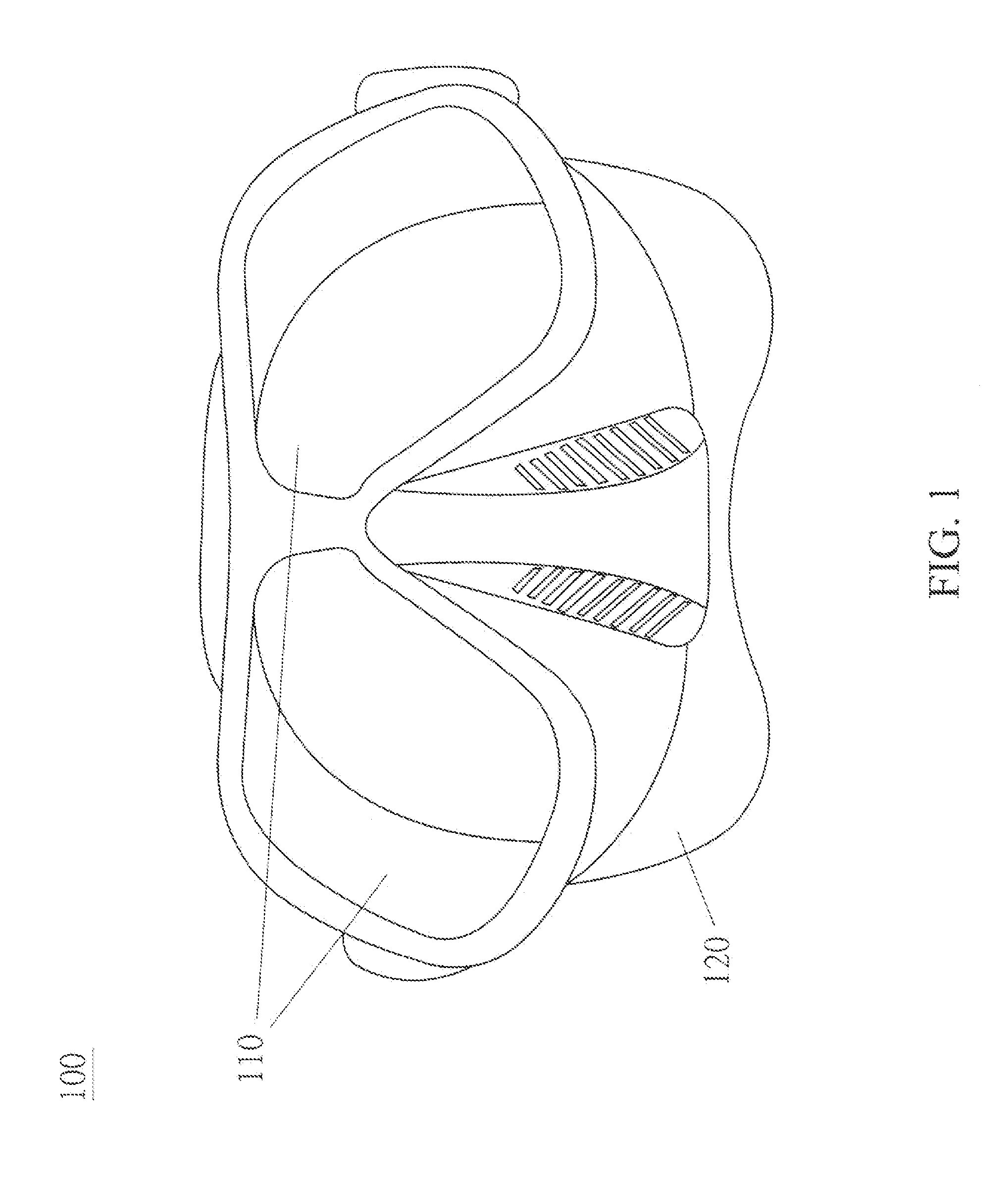

Image

Examples

first embodiment

[0036]In detail, the lens assembly 212 has two lens assemblies 212 in the first embodiment shown in FIGS. 4 to 6. The mask structure 200 without an inner waterproof ring of the present invention may further comprise two buckling members 214 that are formed integrally with the outer edge of the two lens assemblies 212.

second embodiment

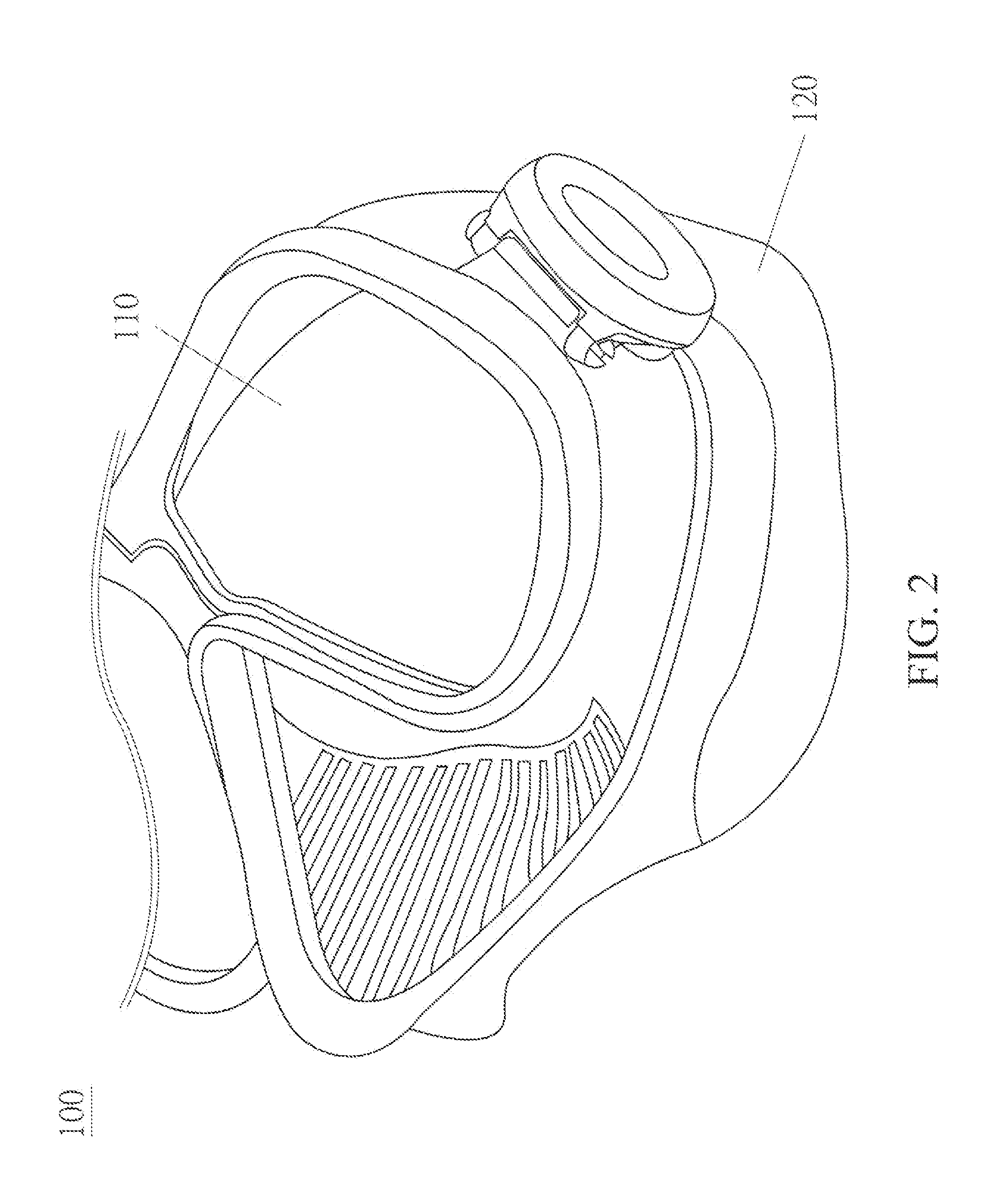

[0037]As shown in FIGS. 8 to 10, in the present invention, the mask structure 200 without an inner waterproof ring may further comprise a frame 240 for receiving the lens assembly 212 therein. Thereby, the mask structure 200 without an inner waterproof ring of the present invention can have an increased overall rigidity and preferable visual texture.

[0038]As shown in FIG. 11, the inner surface of the skirt portion 222 of the first injection molded component 220 is also a flat surface 224 without the inner waterproof ring.

[0039]To allow the user to wear the mask structure 200 without an inner waterproof ring of the present invention securely on the face, the mask structure 200 without an inner waterproof ring may further have a strap 230. The two ends of the strap 230 are adapted to connect the two buckling members 214 respectively to facilitate the adjustment of the tightness of the mask structure 200 by the user.

[0040]Thus, due to the arrangement of the aforesaid lens assembly 212 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com