Method For Producing A Container Body

a container and body technology, applied in the field of container body production, can solve the problems of long-standing problems and errors in response, and achieve the effect of avoiding or avoiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

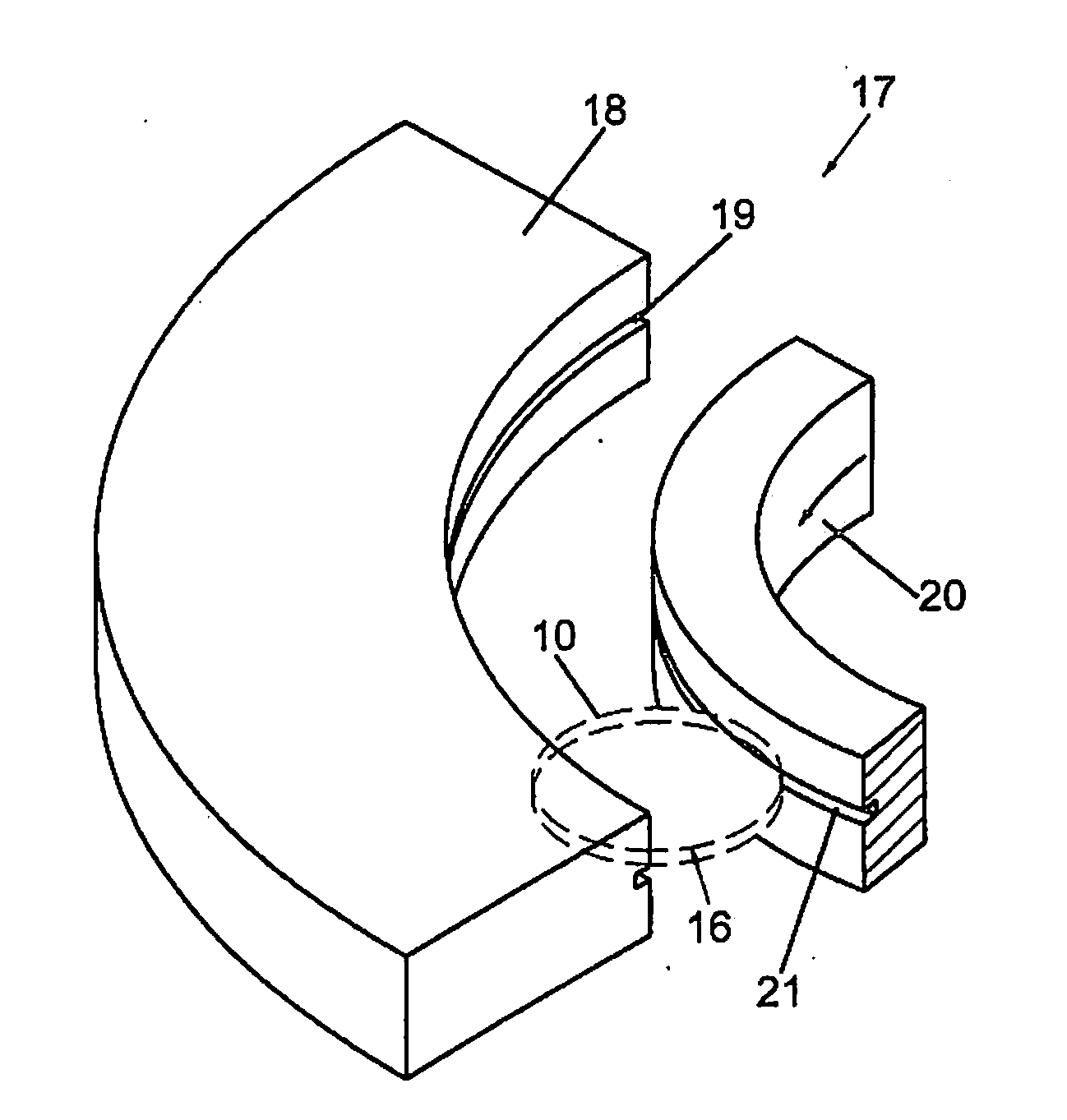

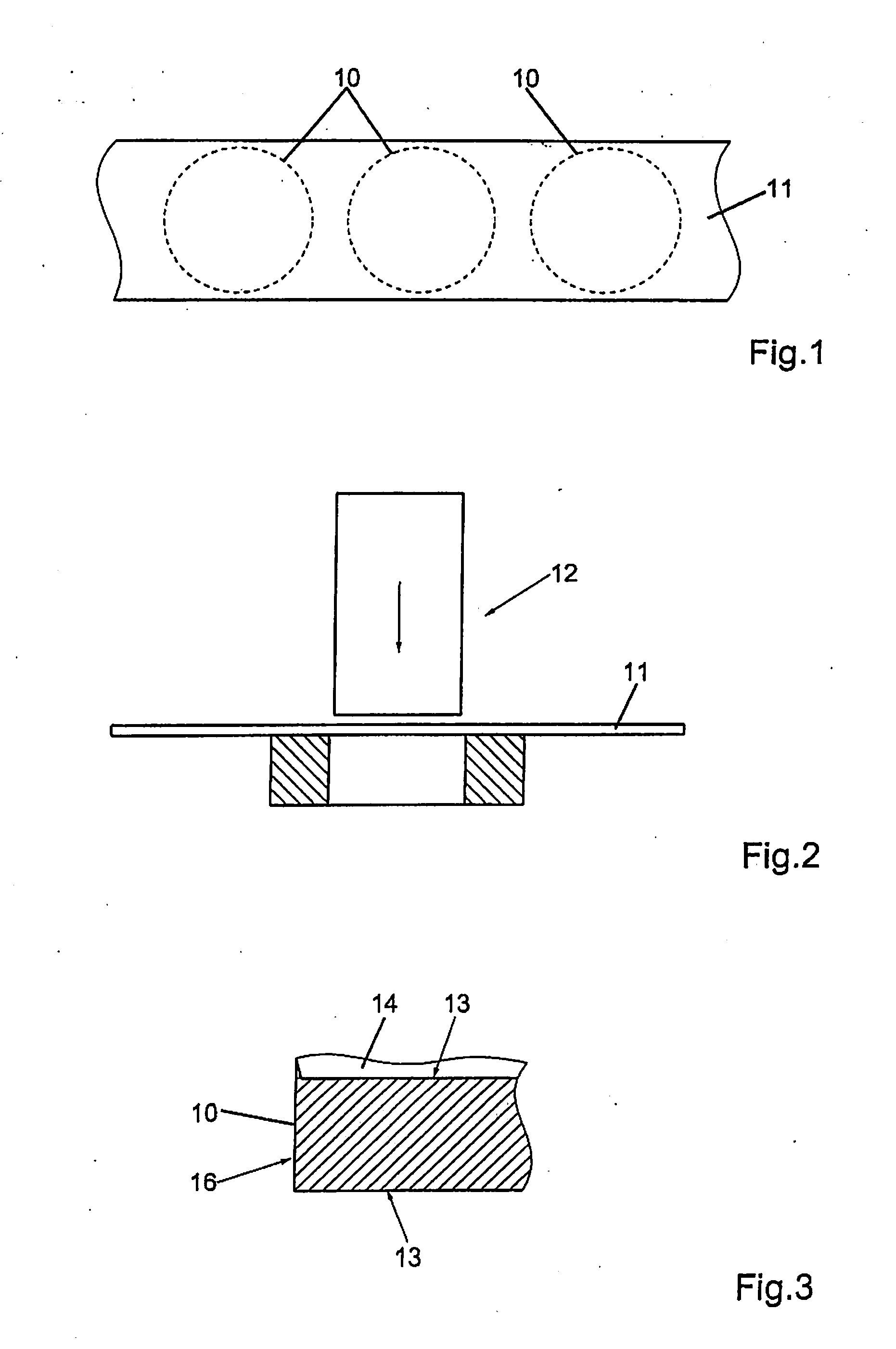

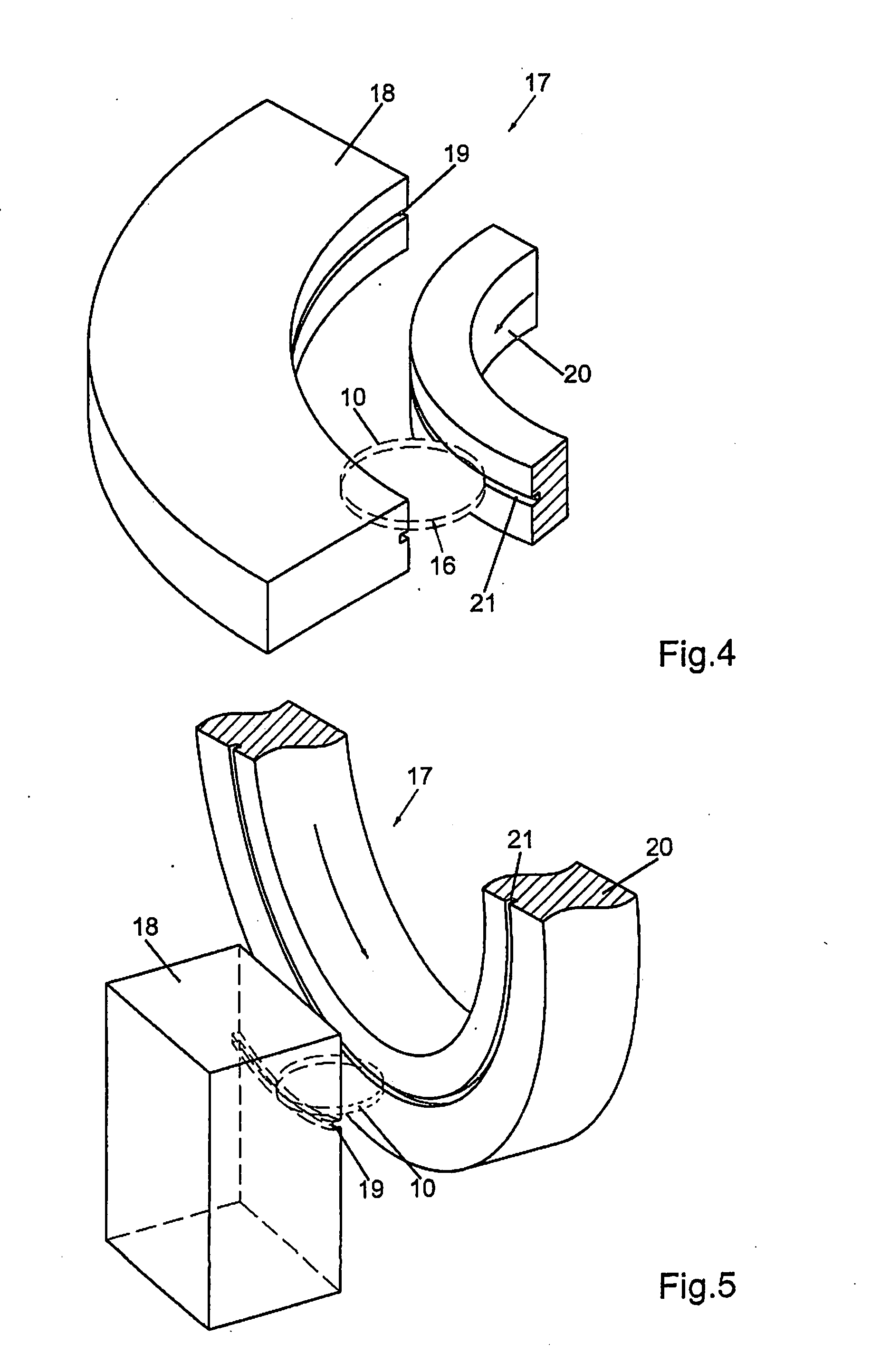

[0022]The invention relates to a method for producing a container body comprising a hollow-cylindrical shape, for example, which, in the case of the preferred exemplary embodiment, is open at an axial end and which, at the other axial end, merges in a seam and joint-free manner into a container part, which closes the container body. As an alternative, a container body, which is open at both axial ends, can also be produced by means of impact extrusion. The container body is produced from a disc-shaped, cylindrical blank 10. In the case of the instant method, the blank has a circular contour and will thus be identified hereinbelow as round blank 10.

[0023]In a first method step, the round blanks 10 are punched out of a metal sheet 11, which, according to the example, consists of aluminum. The metal sheet 11 can be unwound from a roll as strip-shaped material and can be punched out with the help of a punching tool 12, as it is illustrated schematically in FIG. 2.

[0024]After the punchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| symmetrical shape | aaaaa | aaaaa |

| soft | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com