Mobile Home Anchoring System

a mobile home and anchoring technology, applied in the field of mobile home anchoring system, can solve the problems of inability to use conventional foundation devices and constructions, inability to secure ground connection, and inability to meet the needs of mobile home anchoring, etc., and achieve the effect of improving lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

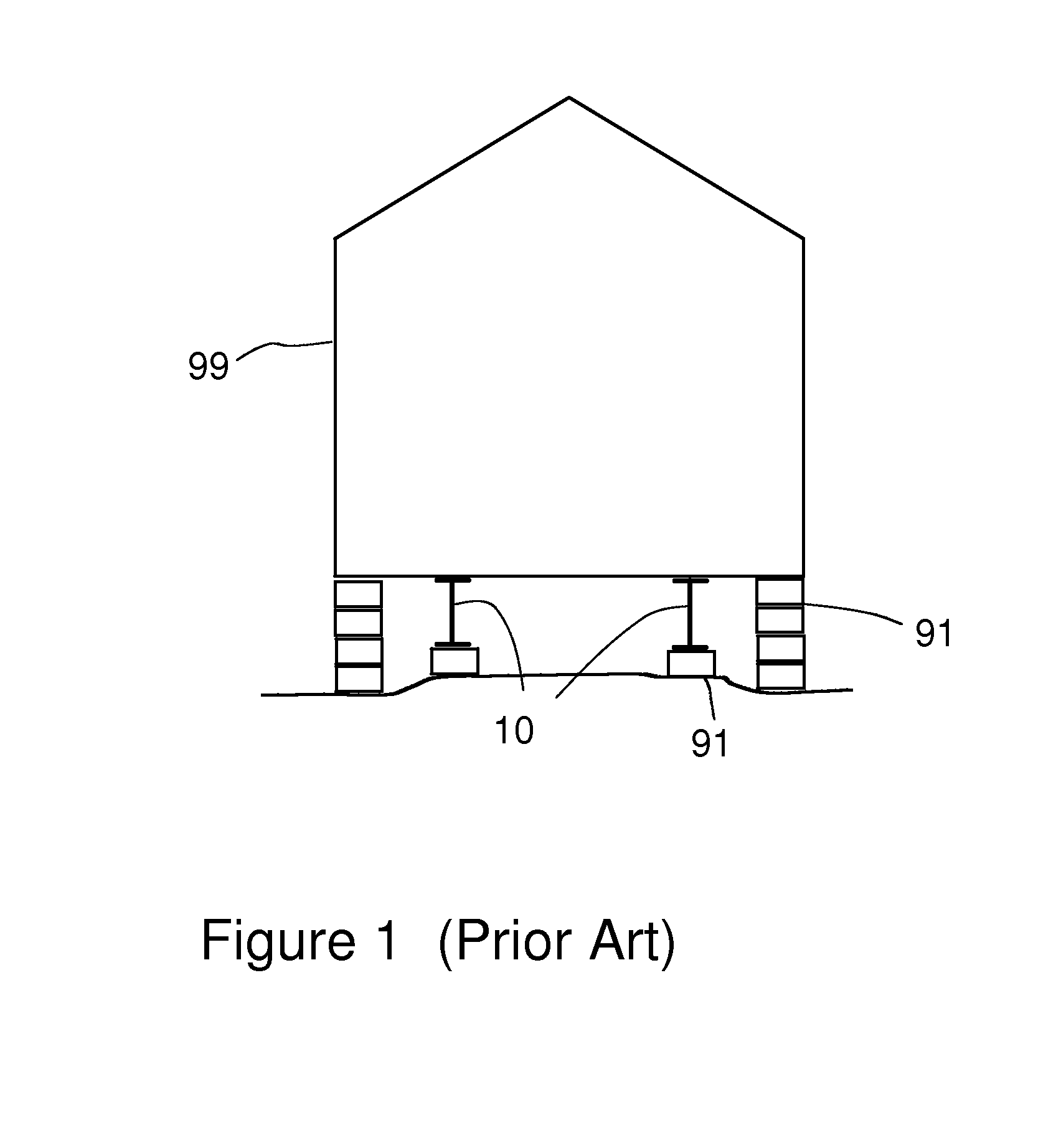

[0011]FIG. 1 is an end view of a conventional mobile home supported in conventional manner on rigid blocks. The prefabricated residential structure 99 is supported on two beams 10 which are in turn supported on rigid masonry blocks 91. Blocks are similarly used to provide vertical support to the overhanging wall edges of the structure as shown. Often, vertical straps (not shown) are used to tie the beams 10 and structure 99 to anchors buried in the supporting ground.

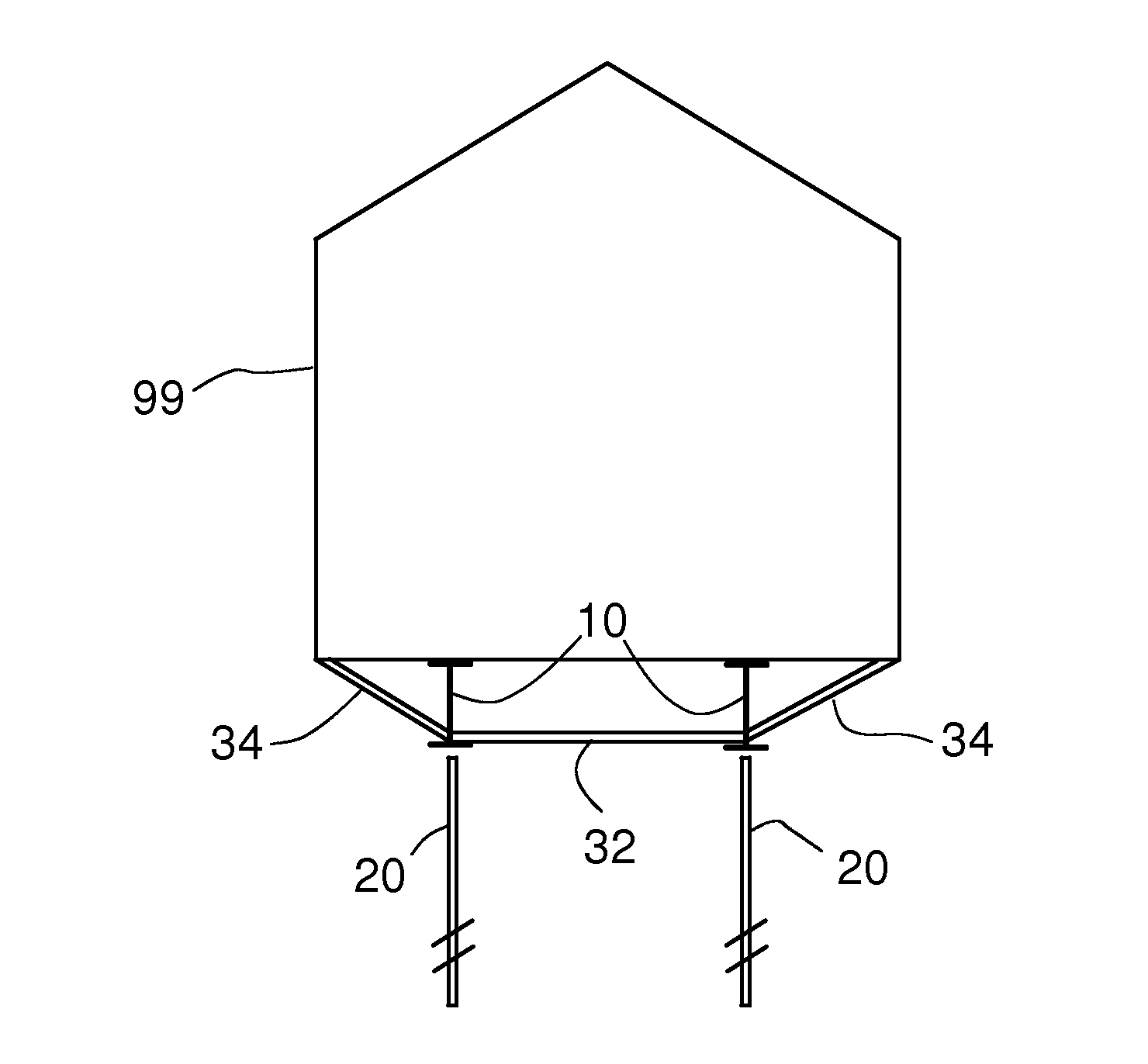

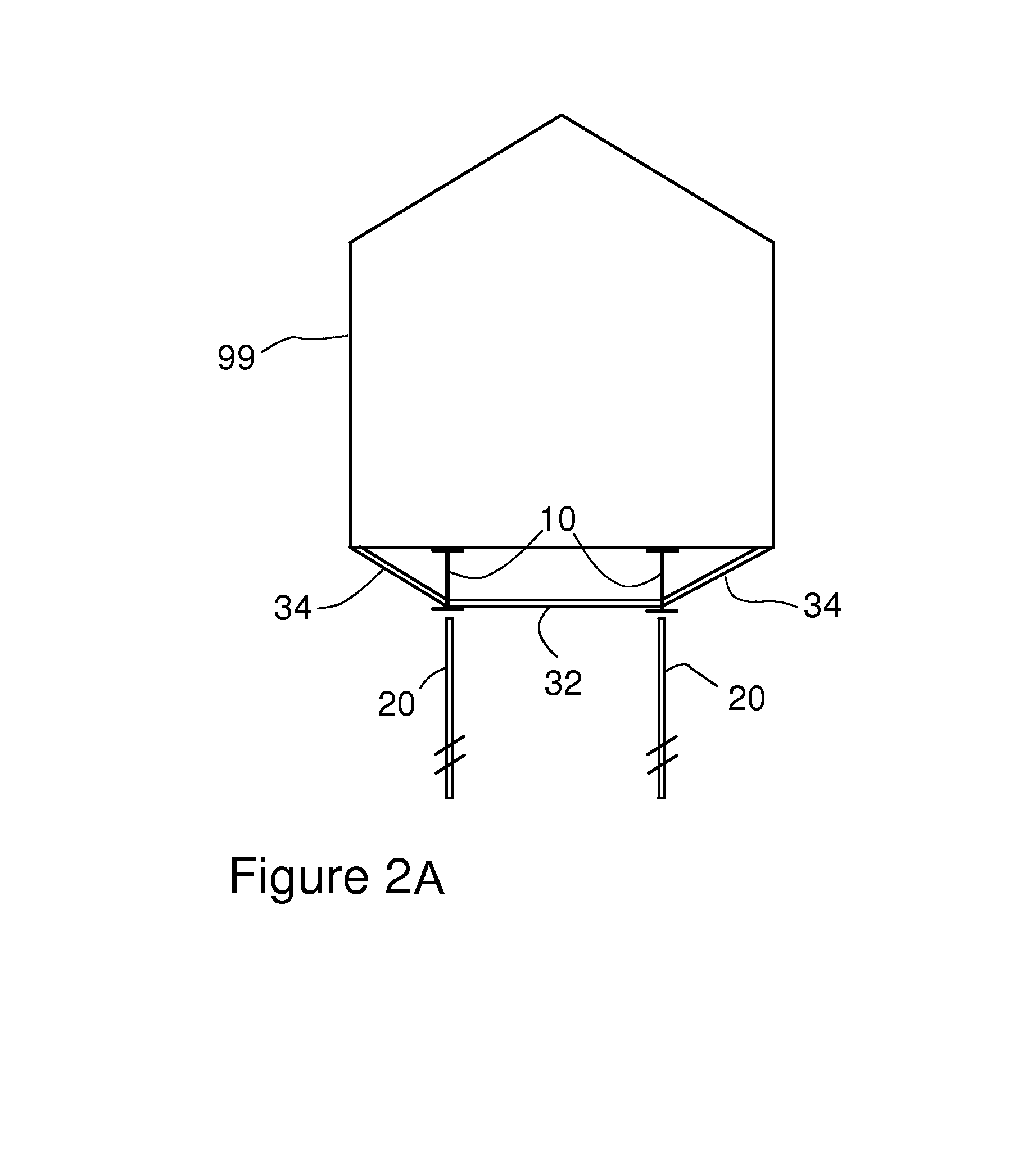

[0012]FIG. 2A is a two-dimensional side view of one embodiment of the invention. A prefabricated residential structure 99 is supported on two parallel beams 10 having a conventional “I” beam configuration. The length aspect of the beams is not shown but will be understood to be continuous and similar over the extent of each of the beams 10. The beams are substantially horizontal and parallel and designed to support and secure the weight and distribution of the structure 99 in conventional manner and extend substantially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com