Tube expander with positioning structure

a technology of positioning structure and tube expander, which is applied in the direction of positioning device, metal-working feeding device, manufacturing tool, etc., can solve the problems of increased manpower and time cost, easy damage to tube members, and inability to provide positioning structure, so as to achieve rapid and accurate movement and save time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The aforementioned and further advantages and features of the present invention will be understood by reference to the description of the preferred embodiment in conjunction with the accompanying drawings.

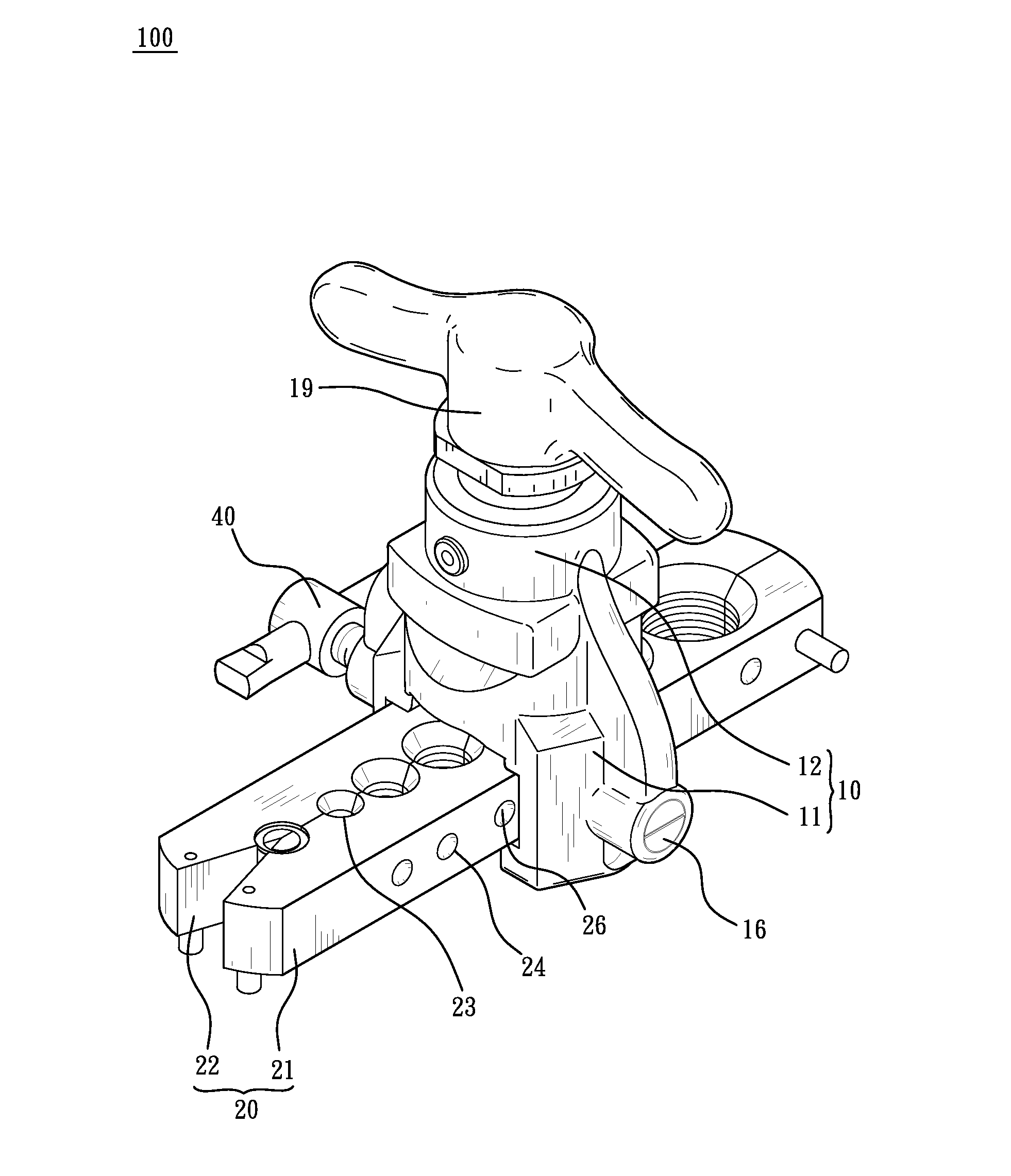

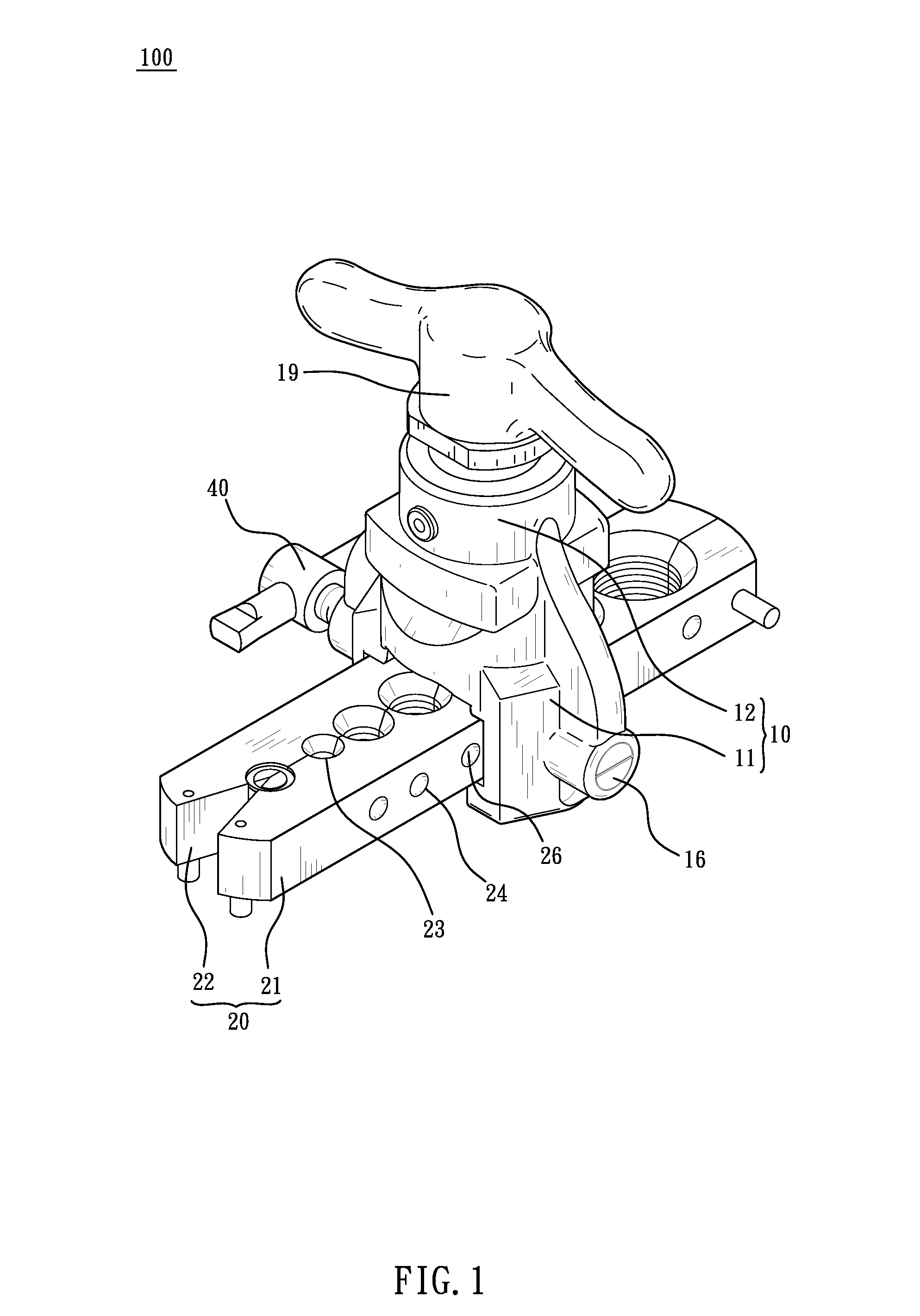

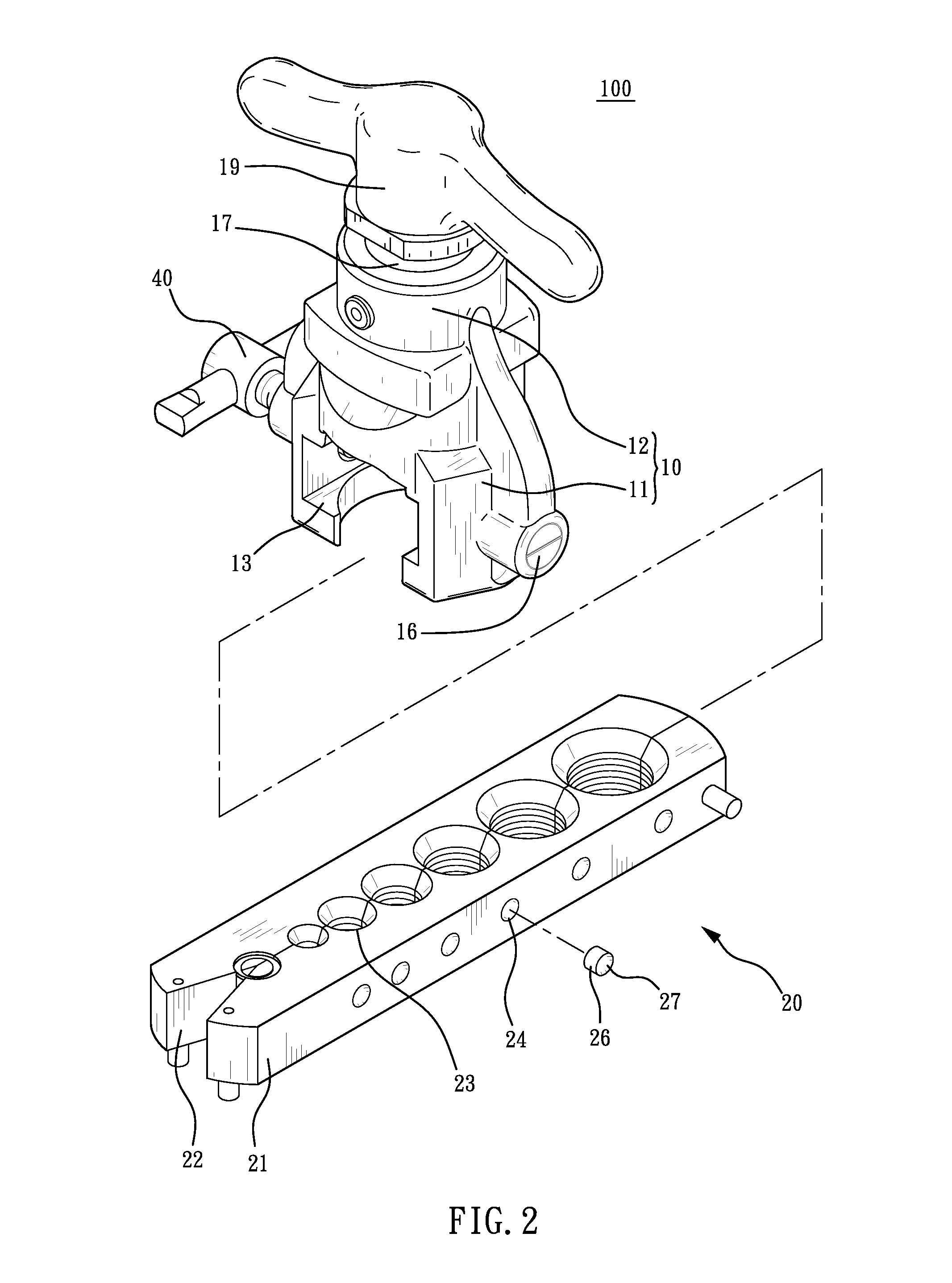

[0021]Referring FIG. 1 to FIG. 5, the present invention provides a tube expander 100 with positioning structure, comprising a base 10, a tube clamp 20, a positioning device 30, and an adjusting thread rod 40.

[0022]The base 10 is made of aluminum, provided with a body 11 and connected to a neck 12 on the top end of the body 11. A guiding groove 13 is transversely disposed on the body 11. A positioning bore 14 is disposed on the wall of the body 11 and at the same time disposed on one side of the guiding groove 13, wherein the positioning bore 14 is connected to the outer face of the body 11 and the guiding groove 13, respectively. An inner thread 15 is disposed on one end of the positioning bore 14 connected with the outer face of the body 11 for receiving a nut 16. A rotating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com