Cast-in-place apparatuses for coupling objects to substrates and allowing movement of anchor members relative to substrates

a technology of substrates and casting apparatuses, which is applied in the direction of threaded fasteners, mechanical apparatus, nuts, etc., can solve the problems of large quantity of time, high cost, and inconvenient operation of conventional processes, and achieve the effect of facilitating the movement of an anchor member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

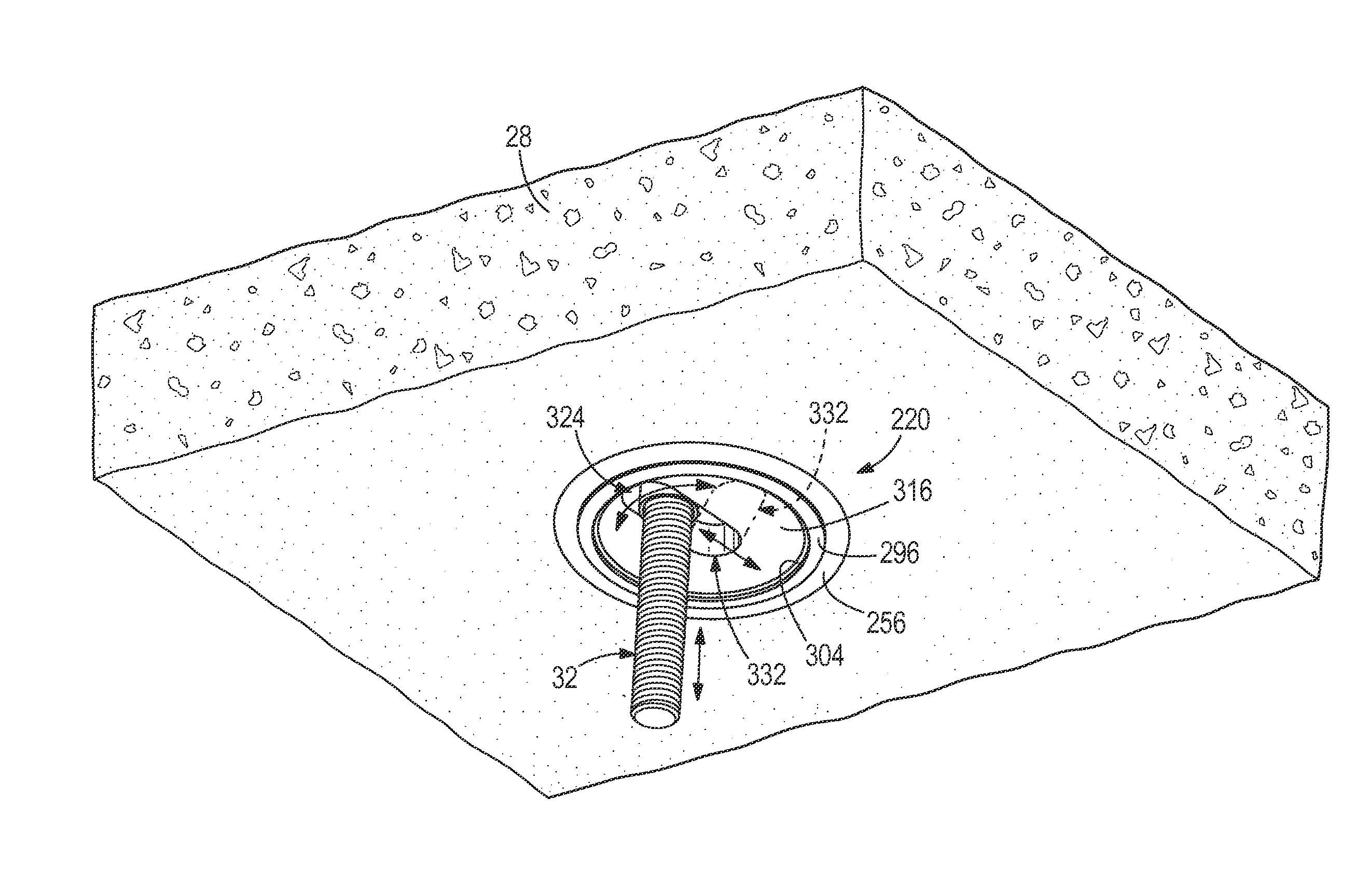

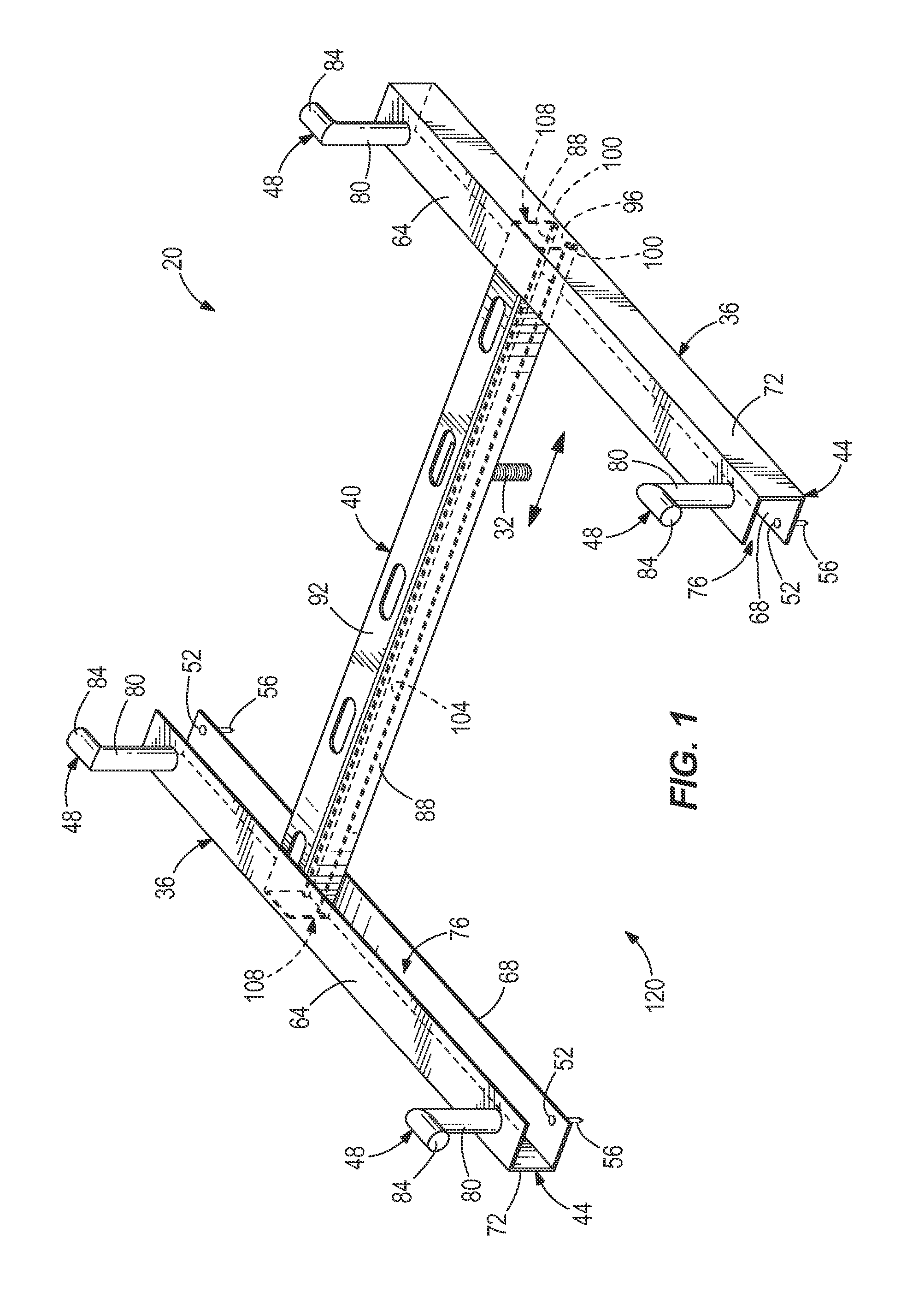

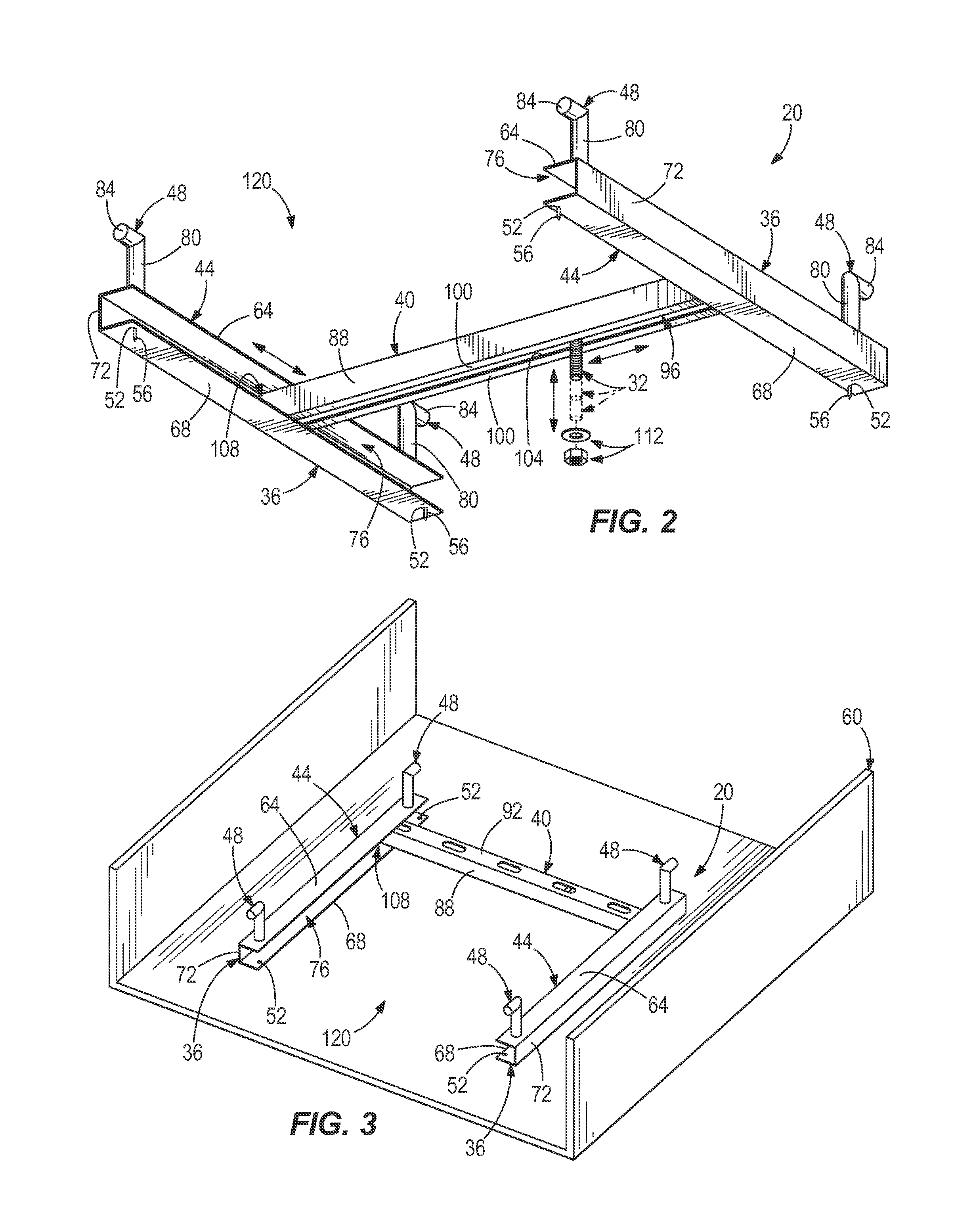

[0045]With reference to FIGS. 1-7, one example of an apparatus 20 for coupling an object 24 to a substrate 28 is illustrated. The apparatus 20 is configured to couple a wide variety of objects 24 to a wide variety of substrates 28. Examples of objects 24 include, but are not limited to, a duct, a conduit, electrical boxes or equipment, support members (e.g., pipe supports, etc.), rack structures, heavy equipment, secondary structural members, architectural members, among others. Examples of substrates 28 include, but are not limited to, concrete, asphalt, plastic, or other flowable materials capable of curing to a hard or rigid condition.

[0046]The apparatus 20 is capable of allowing movement or adjustability of an anchor member 32 in multiple directions or along multiple axes. In one example, the apparatus 20 allows movement of the anchor member 32 in two directions or along two axes (i.e., along any two of the x-axis, the y-axis and the z-axis in a three dimensional coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com