Shoe with improved structure

a technology of shoe and structure, applied in the direction of uppers, bootlegs, stiffners, etc., can solve the problems of uneven transmission of sensory information, impact, and other stresses, uneven rolling movement of the shoe, and uneven rolling movement of the foot, so as to reduce the amount of material, maintain a certain resistance to compression, and be more deformable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0042]The first embodiment to be described relates, for example, to a shoe for walking or running on level, hilly, or mountainous terrain. However, the invention is applicable to other disciplines such as those mentioned above. The term “shoe” is used here for convenience, but is not intended to limit the scope of the invention from what would be encompassed by the use of the term “footwear” or “article of footwear.”

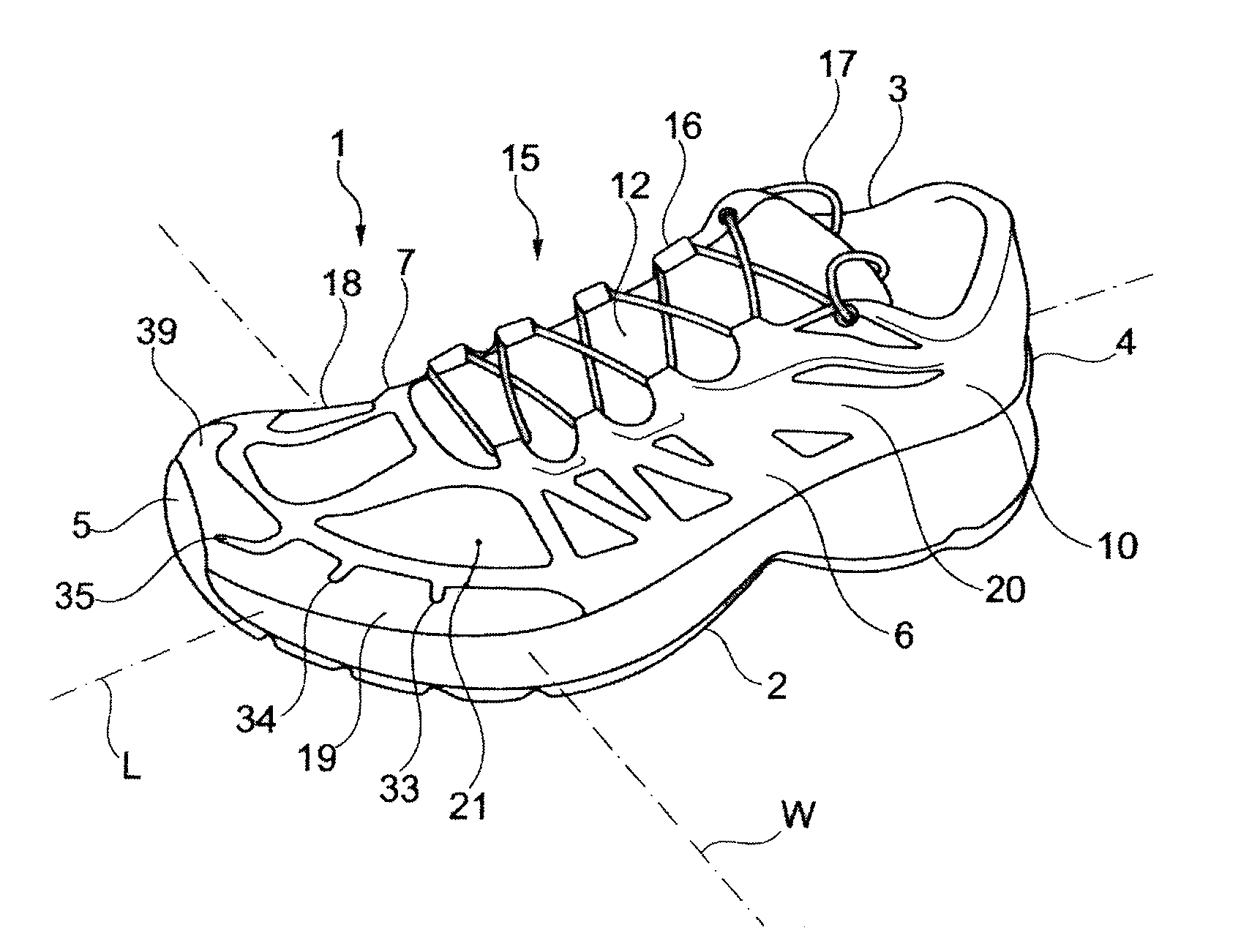

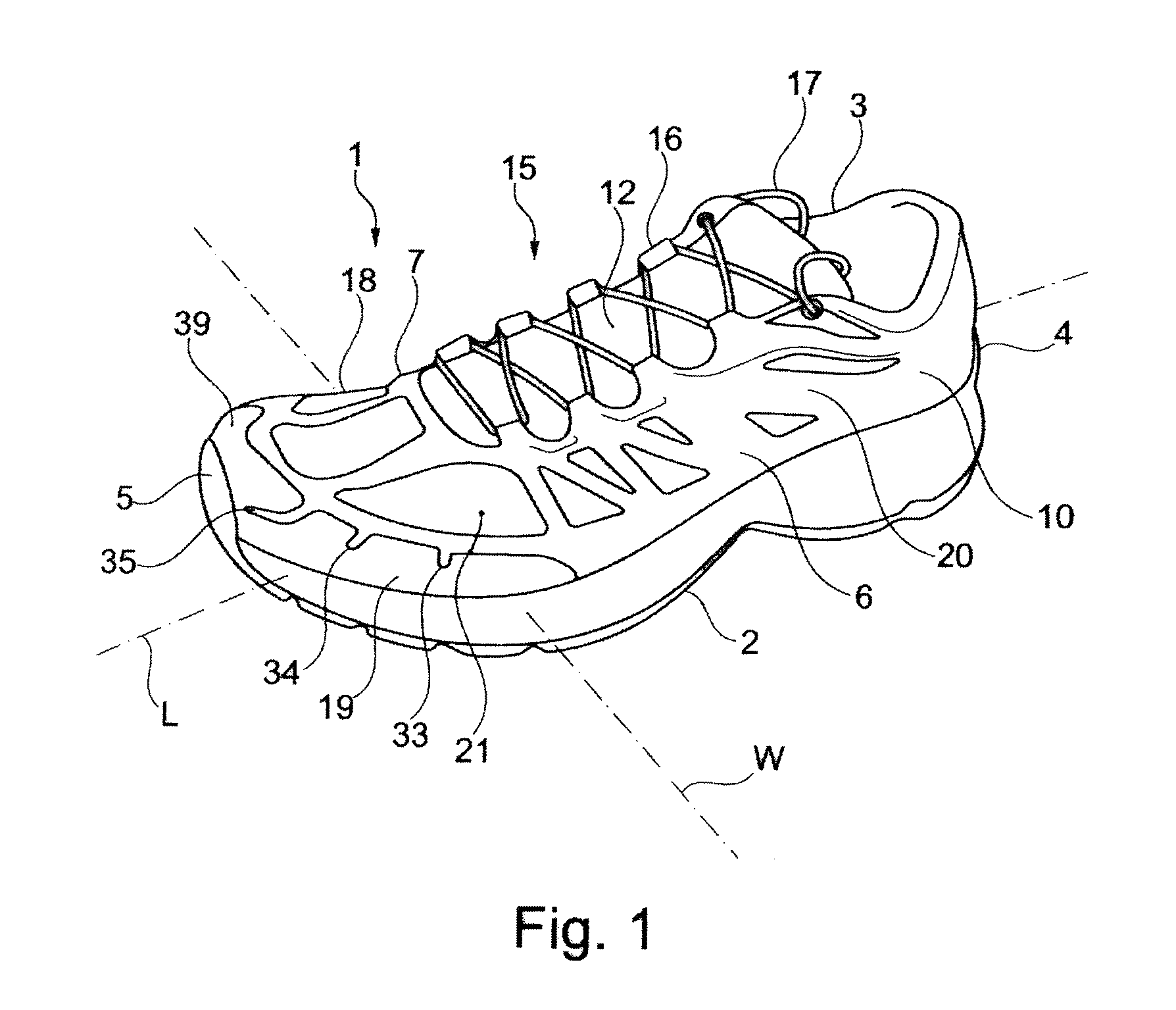

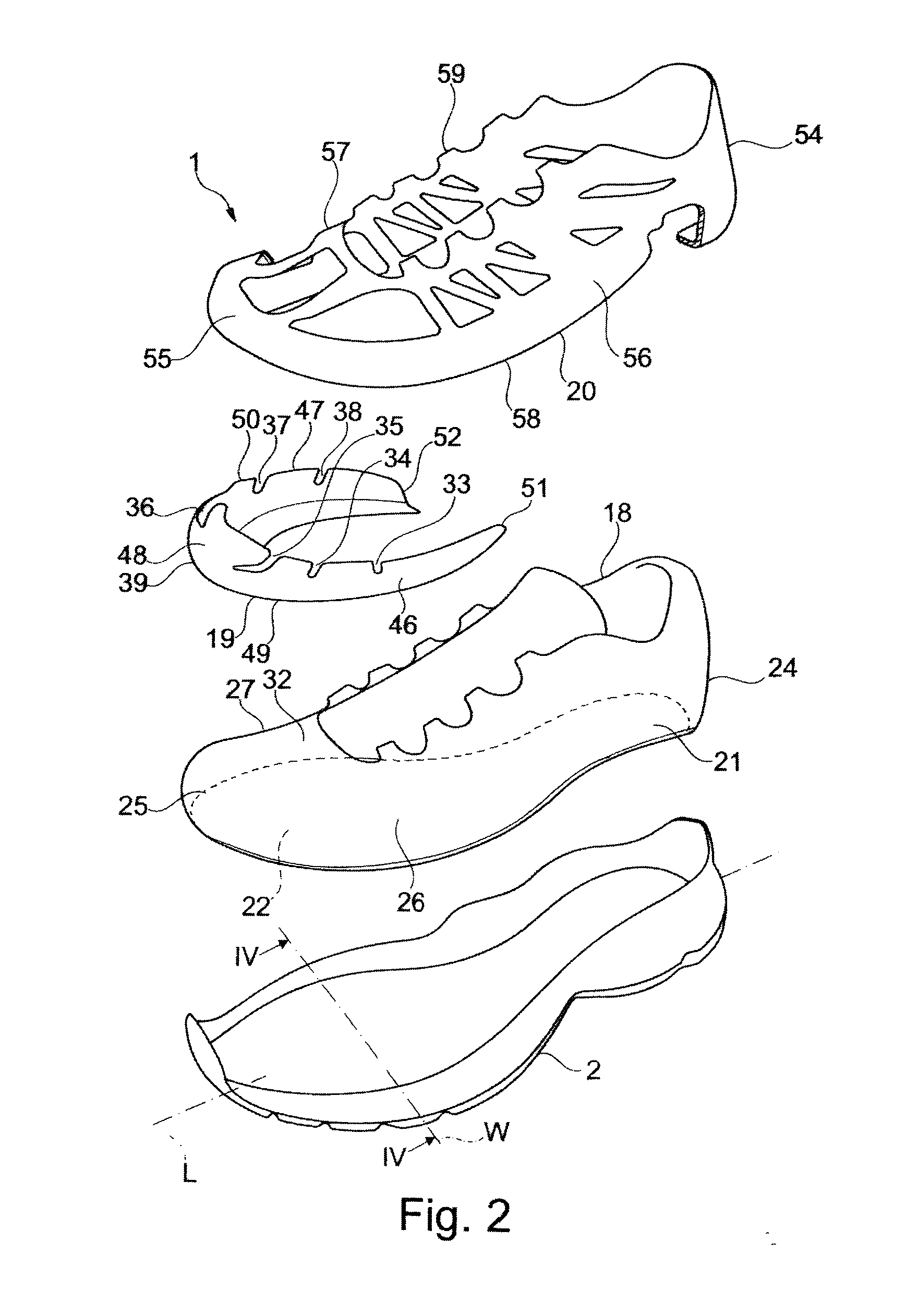

[0043]The first embodiment is described below with reference to FIGS. 1 to 6.

[0044]As shown in FIG. 1, a walking or running shoe 1 is provided to receive the foot of the user. The shoe 1 comprises an outer sole assembly 2 and an upper 3 arranged on the sole assembly. The shoe extends lengthwise along a longitudinal direction L, between a rear end or heel 4 and a front end or tip 5, and widthwise along a transverse direction W, between a lateral side 6 and a medial side 7.

[0045]As shown, the upper 3 includes a lower portion 10 configured to surround the foot. Alternativel...

second embodiment

[0071]The second embodiment according to FIG. 7 features a shoe 1, including an outer sole assembly 2 and an upper 3, which comprises a first shell 21, a first reinforcing structure 19, and a fitting 20. Here again, the reinforcing structure 19 is an arc-shaped toe cap 39 with a lateral arm 46, a medial arm 47 not visible in FIG. 7, and a front bridge 48. The toe cap 39 extends height-wise between a lower edge 49 and an upper edge 50.

[0072]Specific to the second embodiment of the invention, shown in FIG. 7, is the distribution of holes arranged in the reinforcement 19, or reinforcing structure. In a non-limiting manner, at least some of the holes are slits 71, 72, 73, 74 arranged away from the contour of the toe cap 39. This means that these slits do not open out in the area of the contour of the toe cap, by remaining separated from the lower edge 49 and upper edge 50. The slits here have different sizes, in particular different lengths. This makes it possible to provide flexibility...

third embodiment

[0073]The third embodiment according to FIGS. 8 to 10 also features a shoe 1, including an outer sole assembly 2 and an upper 3 that includes a first shell 21, a first reinforcing structure 19, and a fitting 20.

[0074]Specific to the third embodiment is that which relates in particular to the reinforcement 19, or reinforcing structure. In general, the reinforcing structure 19 includes a lateral wall 86 and a medial wall 87. In a non-limiting manner, each wall 86, 87 covers the first shell, in the sense that it is arranged outside of the latter. Here again, an alternative construction is that for which each wall is arranged within the first shell, but the external arrangement brings more comfort.

[0075]Similar to what has been shown for the toe cap 39, the lateral wall 86 has holes 88, and the medial wall has holes 89. This is also designed to modify the flexibility of the walls, and therefore the flexibility of the lateral 6 and medial 7 sides of the upper 3 of the shoe. The holes hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com