Method and Criteria for Trajectory Control

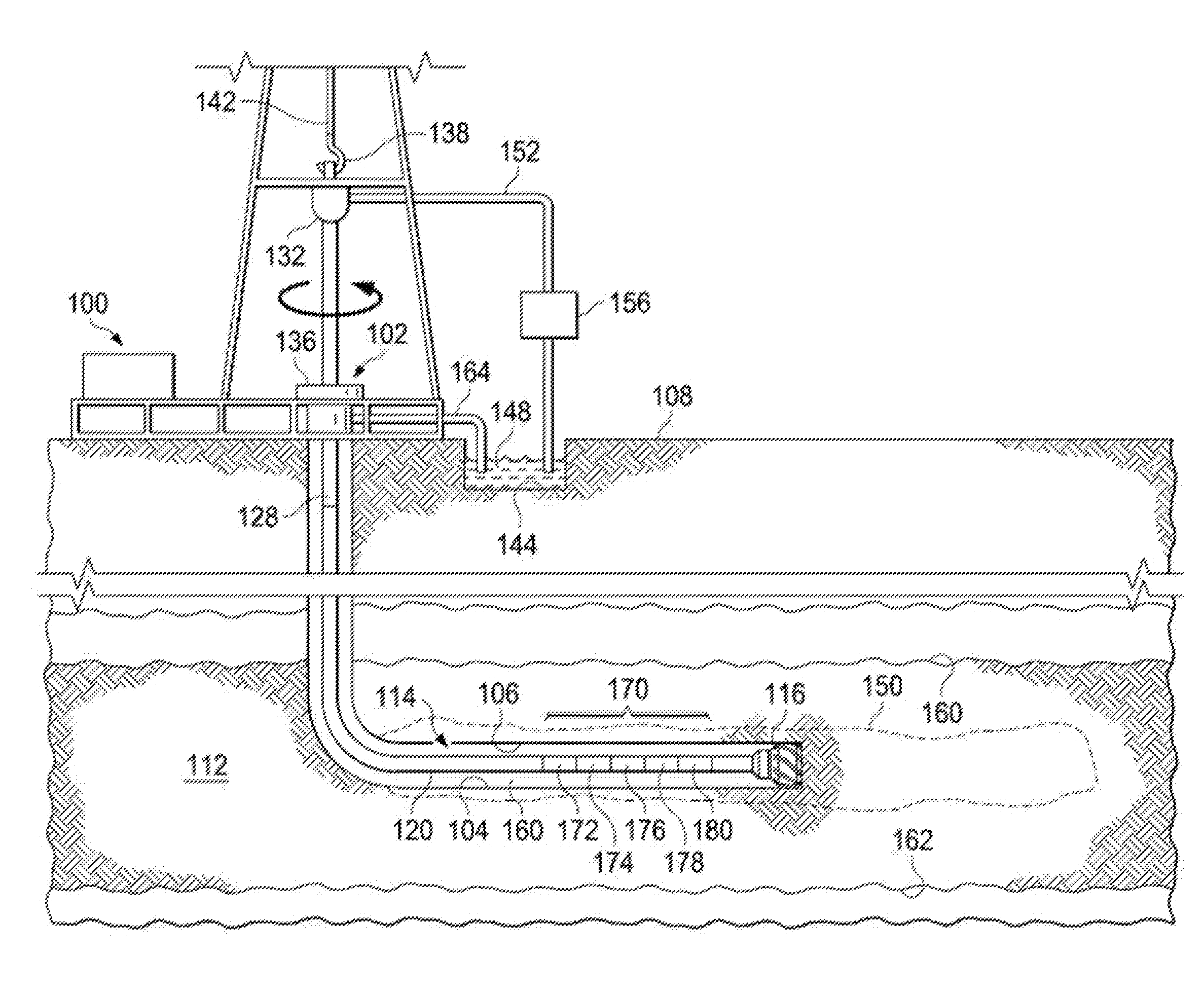

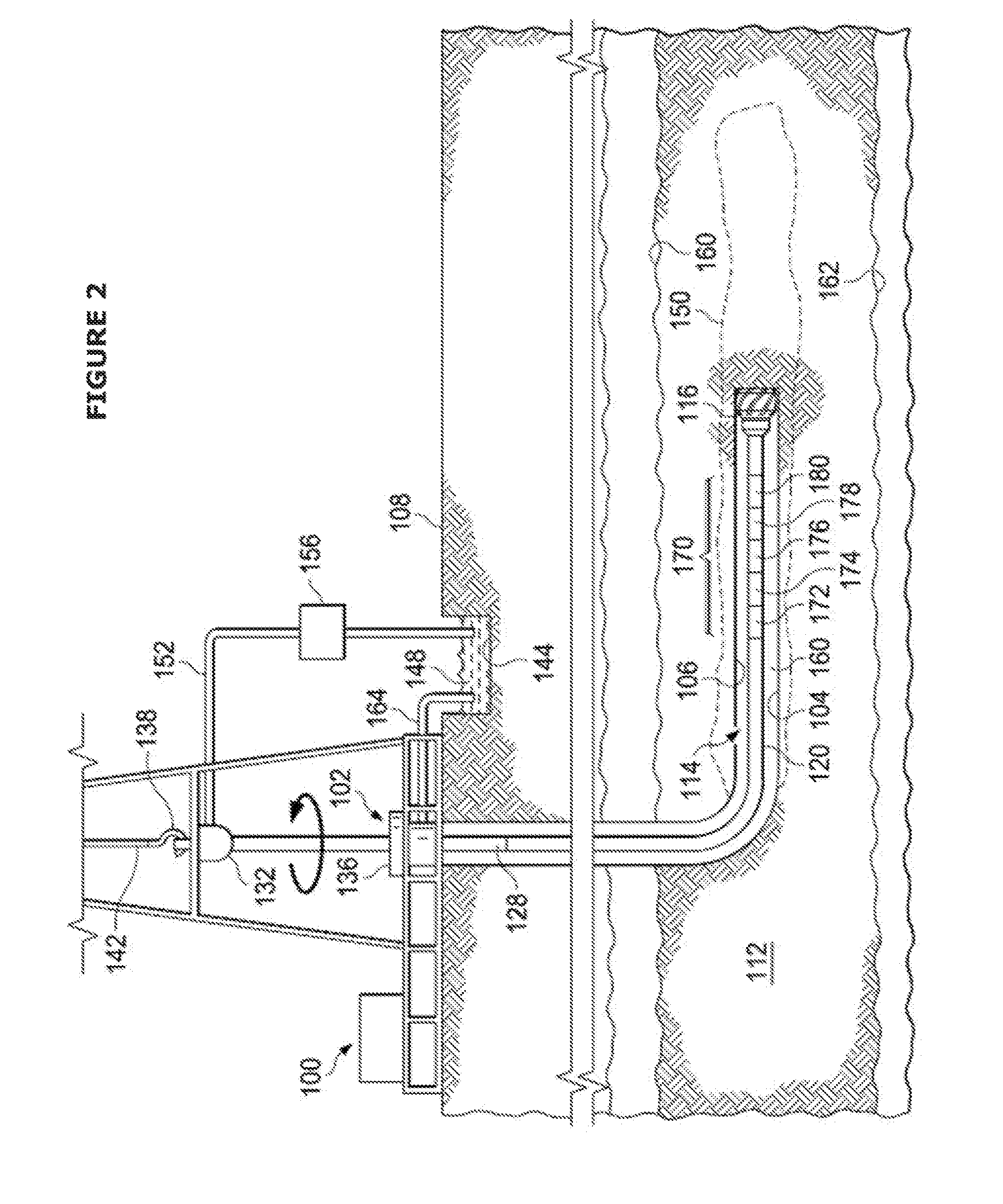

a trajectory control and trajectory technology, applied in the direction of electric controllers, surveyors, borehole/well accessories, etc., can solve the problem that the actual wellbore trajectory deviates from the design well path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

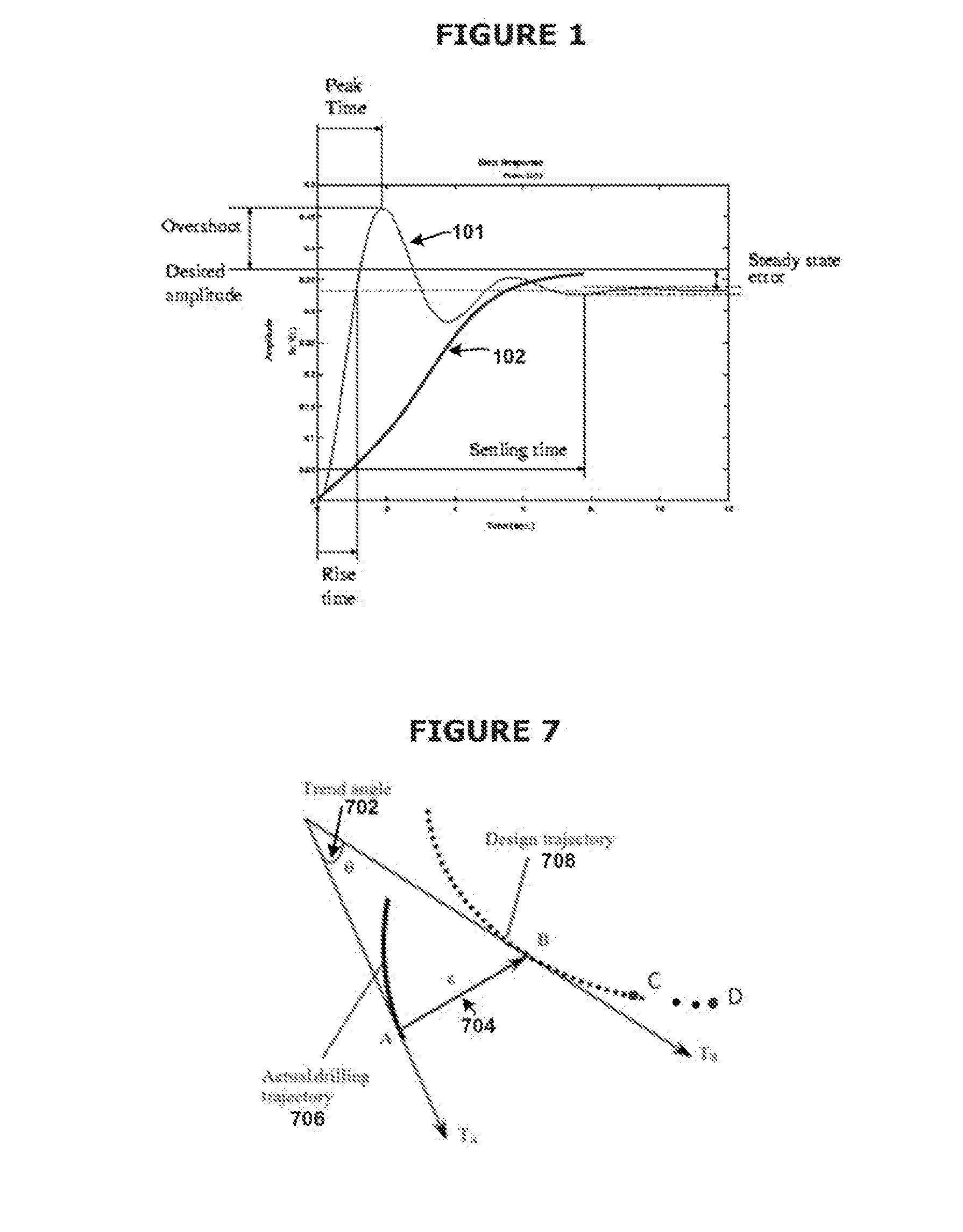

[0092]A computer-implemented method for performing automated downhole wellbore trajectory control for correcting between an actual wellbore trajectory path and a planned wellbore trajectory path, the method comprising: receiving real-time path data for determining the actual wellbore trajectory path; receiving parameters for the planned wellbore trajectory path; determining whether the actual wellbore trajectory path deviates from the planned wellbore trajectory path; responsive to a determination that the actual wellbore trajectory path deviates from the planned wellbore trajectory path, determining whether the actual wellbore trajectory path deviates from a correction path; responsive to a determination that the actual wellbore trajectory path deviates from the correction path; determining a target point along the planned wellbore trajectory path for modifying the correction path; determining trajectory correction parameters using a minimum incremental wellbore energy method; and ...

example two

[0093]A computer-implemented method for performing automated downhole wellbore trajectory control for correcting between an actual wellbore trajectory path and a planned wellbore trajectory path, the method comprising: receiving real-time path data for determining the actual wellbore trajectory path; receiving parameters for the planned wellbore trajectory path; determining a trend angle and a deviation vector length between the actual wellbore trajectory path and the planned wellbore trajectory path; determining whether the actual wellbore trajectory path deviates from the planned wellbore trajectory path; responsive to a determination that the actual wellbore trajectory path deviates from the planned wellbore trajectory path, determining whether the actual wellbore trajectory path deviates from a correction path; responsive to a determination that the actual wellbore trajectory path deviates from the correction path; determining a target point along the planned wellbore trajectory...

example three

[0094]A computer-implemented method for performing automated downhole wellbore trajectory control for correcting between an actual wellbore trajectory path and a planned wellbore trajectory path, the method comprising: receiving real-time path data for determining the actual wellbore trajectory path; receiving parameters for the planned wellbore trajectory path; determining whether the actual wellbore trajectory path deviates from the planned wellbore trajectory path; responsive to a determination that the actual wellbore trajectory path deviates from the planned wellbore trajectory path, determining whether the actual wellbore trajectory path deviates from a correction path; responsive to a determination that the actual wellbore trajectory path deviates from the correction path; determining a target point along the planned wellbore trajectory path for modifying the correction path; determining trajectory correction parameters using a minimum incremental wellbore energy method; dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com