Tool holder compatible with molle/pals attachment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

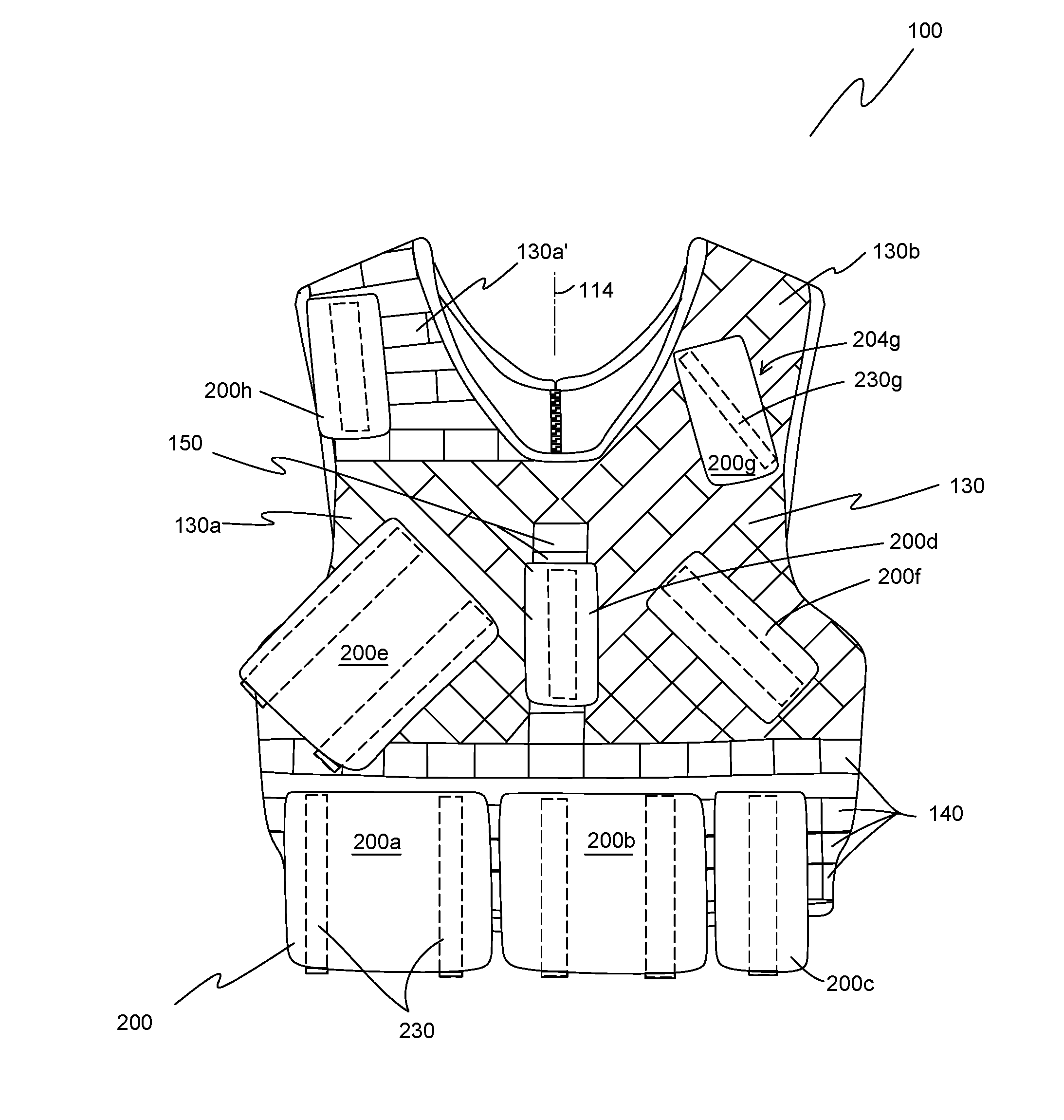

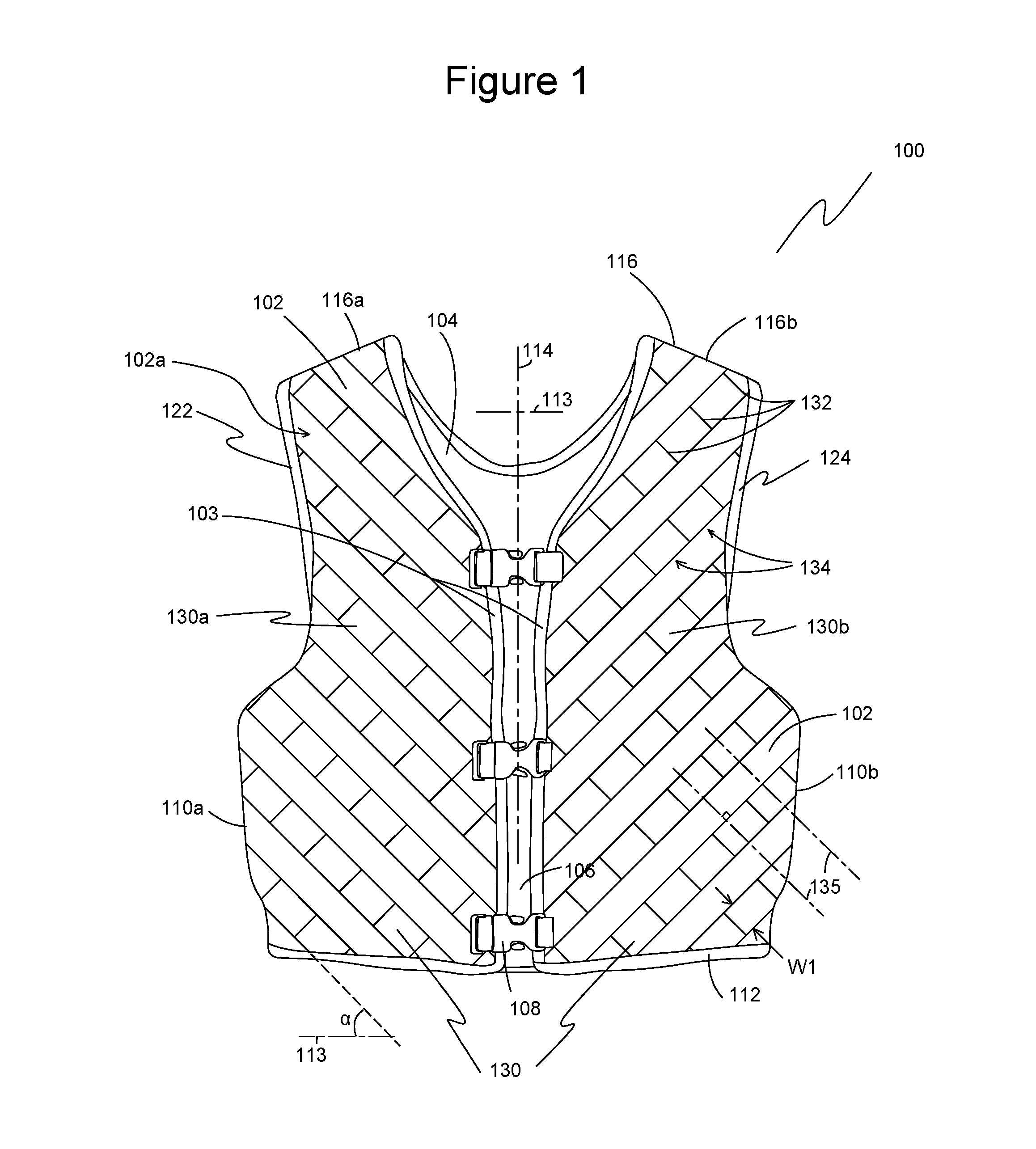

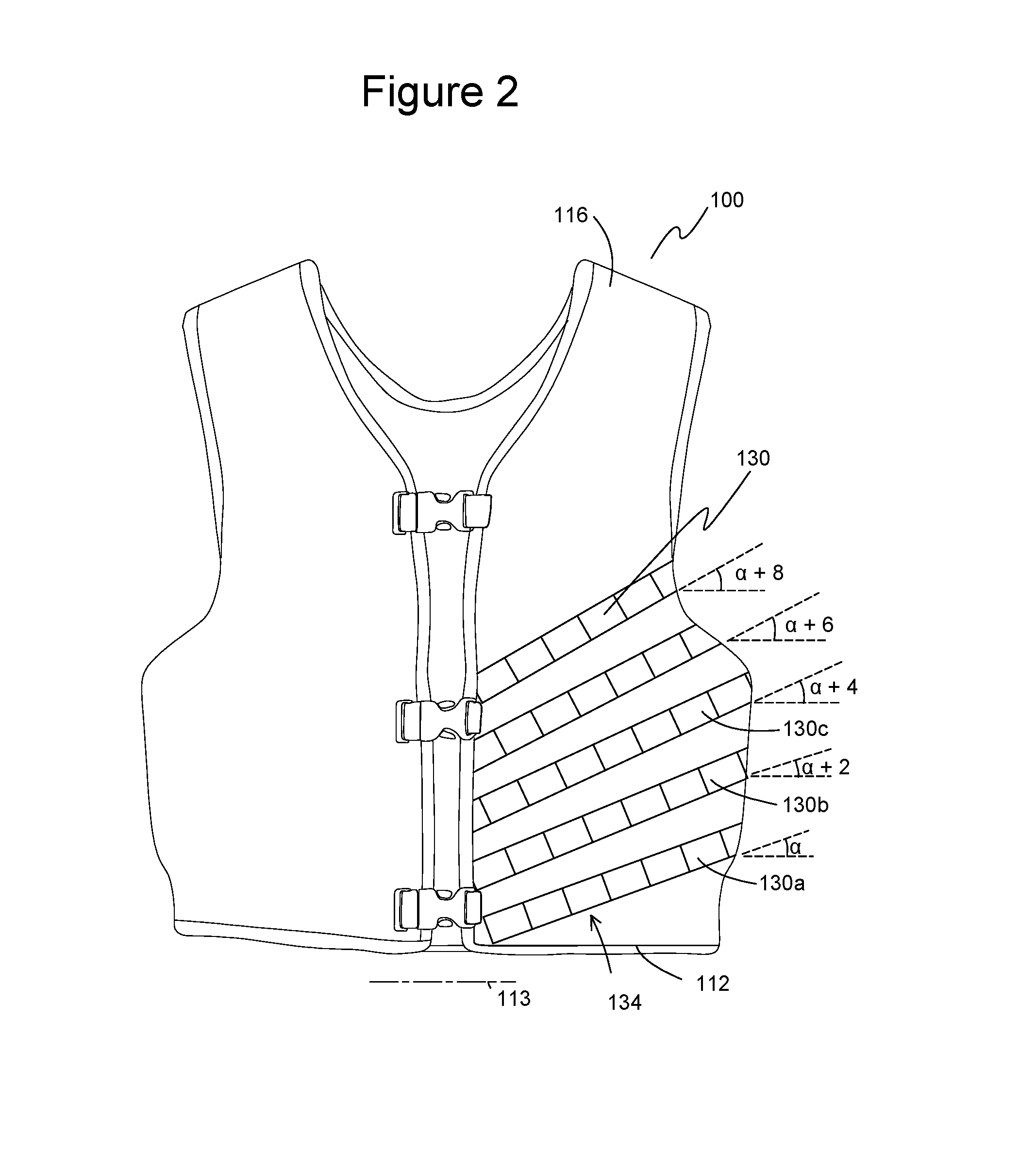

[0047]The preferred embodiment(s) of the present invention is illustrated in FIGS. 1-16. FIG. 1 shows a front view of one embodiment of a wearable garment 100 of the present invention. As shown, garment 100 is a vest with a front panel 102 and a back panel 104. A sternal region 103 extends vertically along the middle of front panel 102 and generally divides front panel 102 into a right half 122 and a left half 124. A central longitudinal garment axis 114 extending along sternal region 103. In one embodiment, right half 122 and left half 124 are generally symmetrical. In one embodiment, front panel 102 and back panel 104 are made of a breathable polyester mesh, but other fabrics, cloths, and materials are acceptable.

[0048]In one embodiment, garment 100 has an opening 106 to permit the user to don and take off garment 100. In other embodiments, garment 100 is configured as a pull-over shirt or vest that has adjustable straps to tighten garment 100 on the user after donning. Opening 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com