Damping force variable shock absorber

a shock absorber and variable technology, applied in shock absorbers, springs/dampers functional characteristics, cycle equipments, etc., can solve the problems of response delay or the like, the damping force is difficult to decrease or increase in any one stroke, and it is difficult to adjust one damping for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

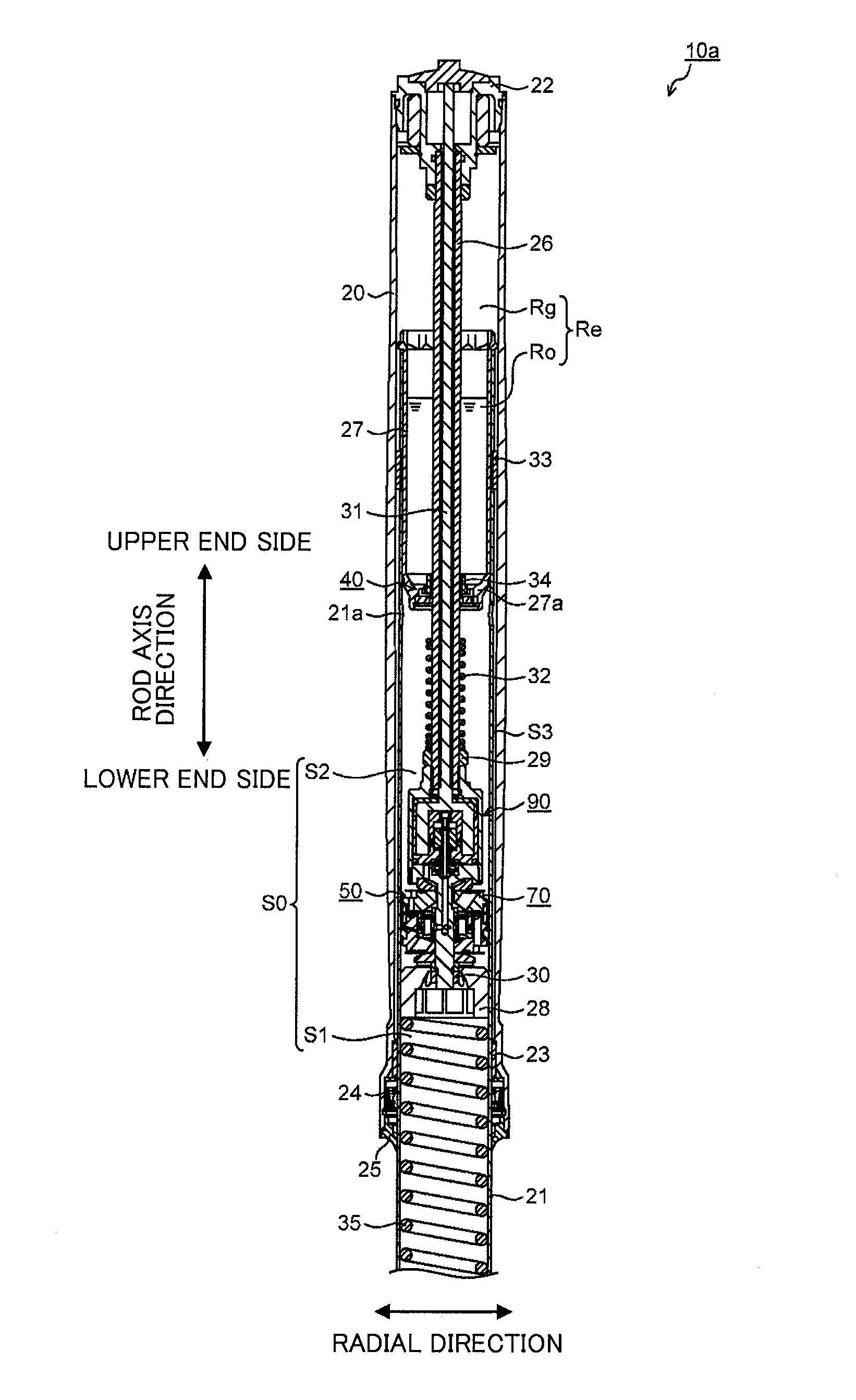

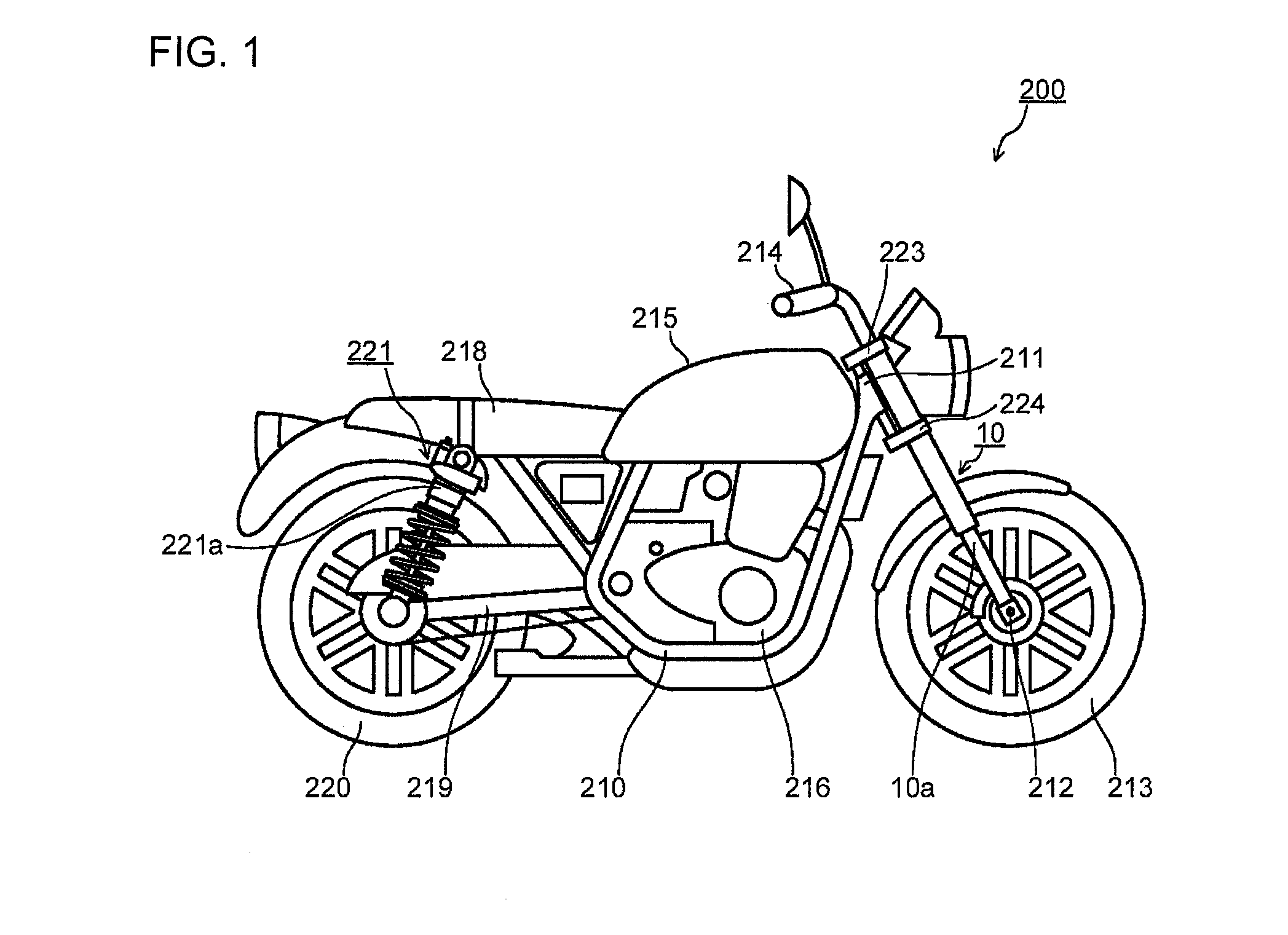

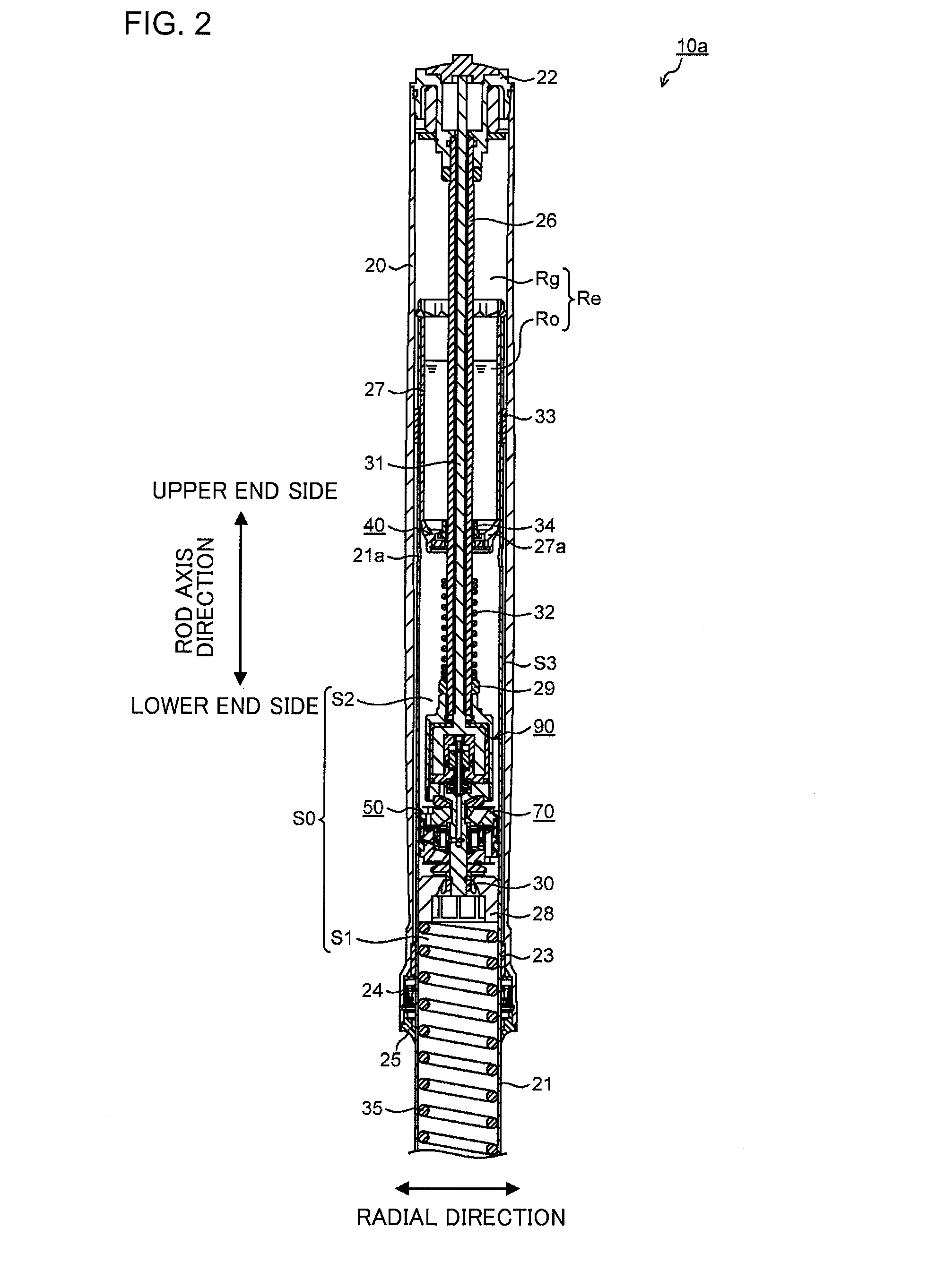

[0031]FIG. 1 is a schematic diagram of a two-wheeled motor vehicle 200 having a damping force variable shock absorber according to a first embodiment. In the present embodiment, a front fork 10 is illustrated as an example of a damping force variable shock absorber. That is, the front fork 10 functions as a damping force variable shock absorber.

[0032]As illustrated in FIG. 1, the two-wheeled motor vehicle 200 includes a vehicle body frame 210 that constitutes a part of a vehicle body, a head pipe 211 attached to a front end of the vehicle body frame 210, a front fork 10 provided on the head pipe 211, and a front wheel 213 attached to a lower end of the front fork 10 with an axle212 interposed.

[0033]The front fork 10 is disposed so as to sandwich the front wheel 213 from left and right sides. Specifically, the front fork 10 includes a first leg 10a and a second leg 10b (not illustrated). Only the first leg 10a disposed on the right side in a traveling direction is illustrated in FIG....

second embodiment

[0139]FIG. 8 is a drawing illustrating a longitudinal cross-section of a damping force variable device 51 of a first leg 10a of a front fork 10 which is a damping force variable shock absorber according to a second embodiment. FIG. 8 illustrates a portion of the inner tube 21 for the sake of convenience. Moreover, the same constituent elements as those of the first embodiment will be denoted by the same reference numerals and redundant description thereof will be omitted or simplified.

[0140]As illustrated in FIG. 8, the communication passage 72d of the damping force variable device 51 allows the pilot chamber 61 and the piston-side oil chamber S1 to communicate with each other. In this case, as illustrated in FIG. 8, one end of the communication passage 72d is open to a side surface of the lower piston member 72 below the sliding sealing member 73.

[0141]One end of the communication passage 72d is open to the gap 76 formed between the inner tube 21 and the piston 70 on the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com