Work vehicles with cylinder cushioning arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

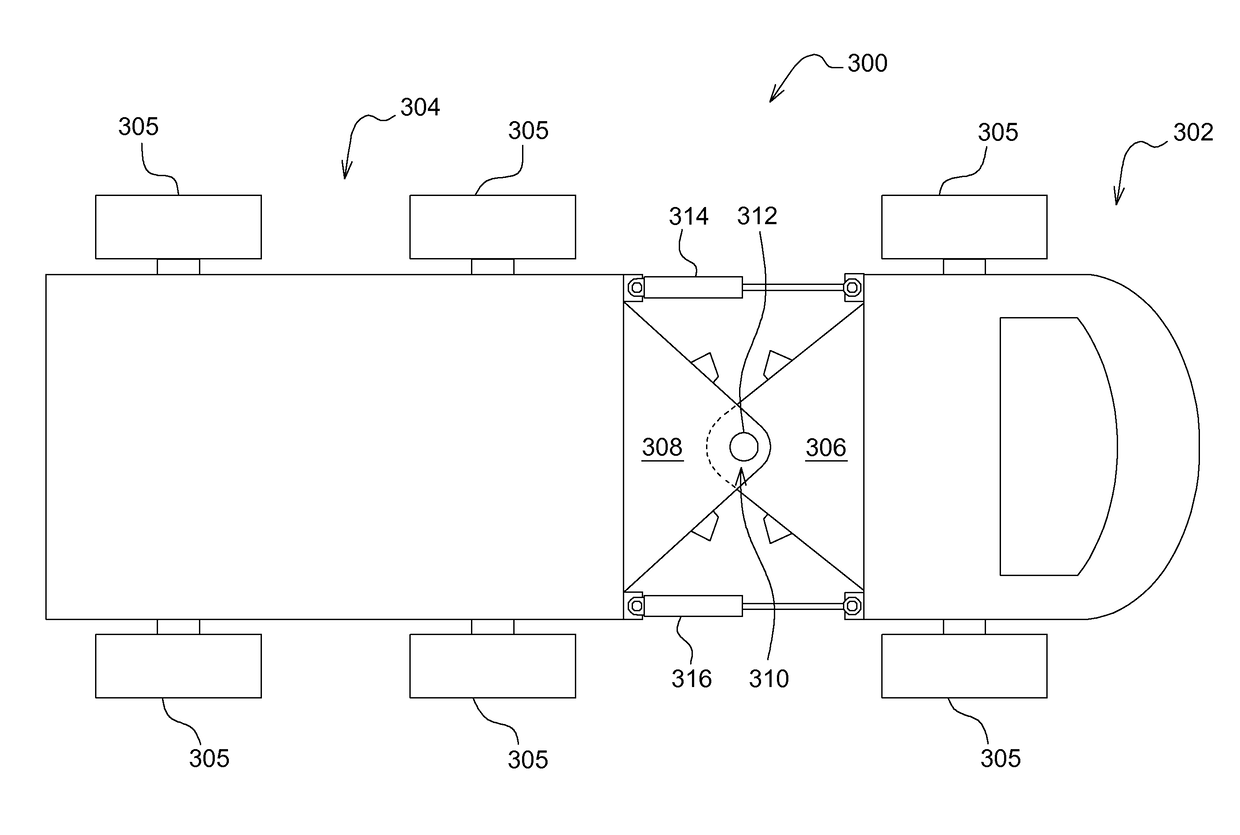

[0032]Referring to FIG. 1, a hydraulic cylinder 100 comprises a piston rod 102, a piston 104 mounted on the piston rod 102, a rod end port 106 formed in the rod end of the hydraulic cylinder 100, a cylinder end port 108 and a throttled cylinder end port 110 formed in the cylinder end of the hydraulic cylinder 100, and an internal damper 112 that throttles hydraulic fluid flow through the throttled cylinder end port 110.

[0033]The internal damper 112 comprises an aperture 114 formed in the cylinder end of the hydraulic cylinder 100, and a rod 116 supported on the end of the piston 104.

[0034]As the piston 104 moves to the left in FIG. 1, hydraulic fluid flows out of the cylinder end port 108 and the throttled cylinder end port 110. Likewise, hydraulic fluid flows into the rod end port 106. When the piston 104 moves to the right in FIG. 1, the hydraulic fluid flows are reversed.

[0035]Eventually, as the piston moves to the left in FIG. 1, the rod 116 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com