Field cultivator sweep

a cultivator and field technology, applied in the field of cultivator sweep, can solve the problems of difficult for the roots of the crop to grow into or below the compressed soil, and achieve the effect of enhancing plant root growth and minimizing soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

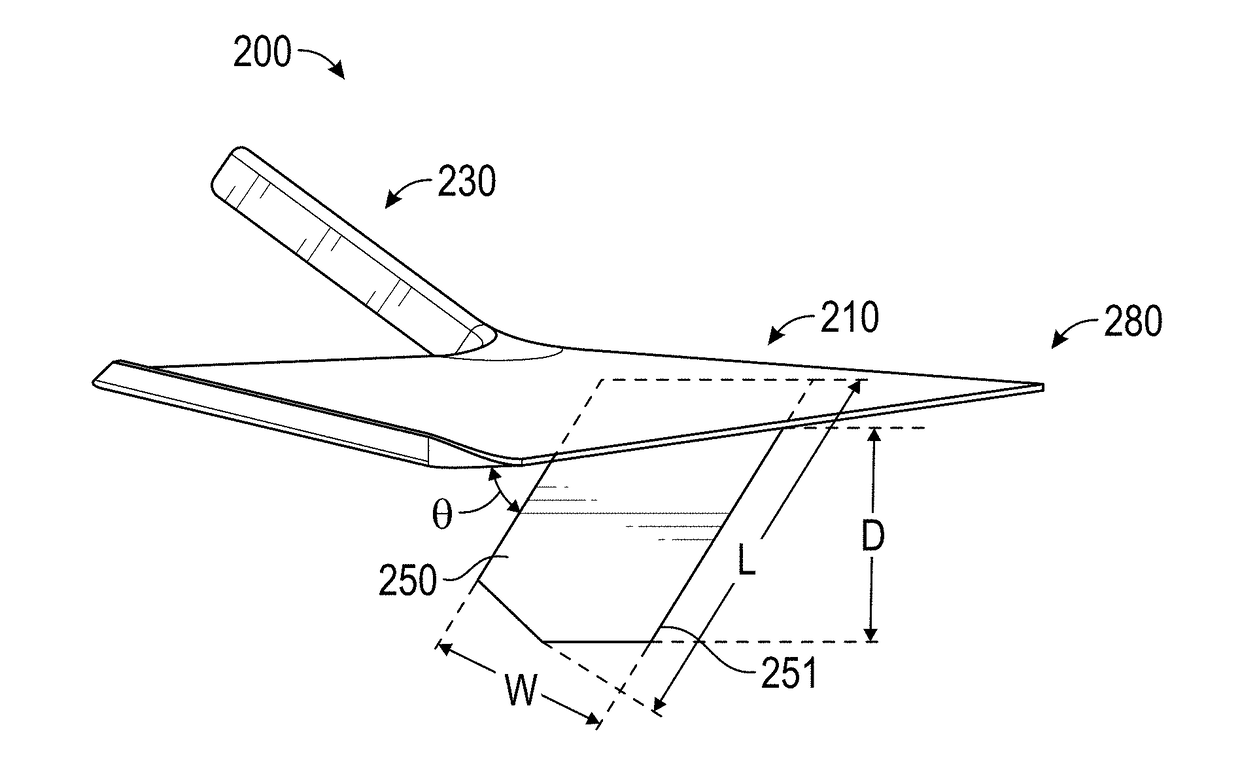

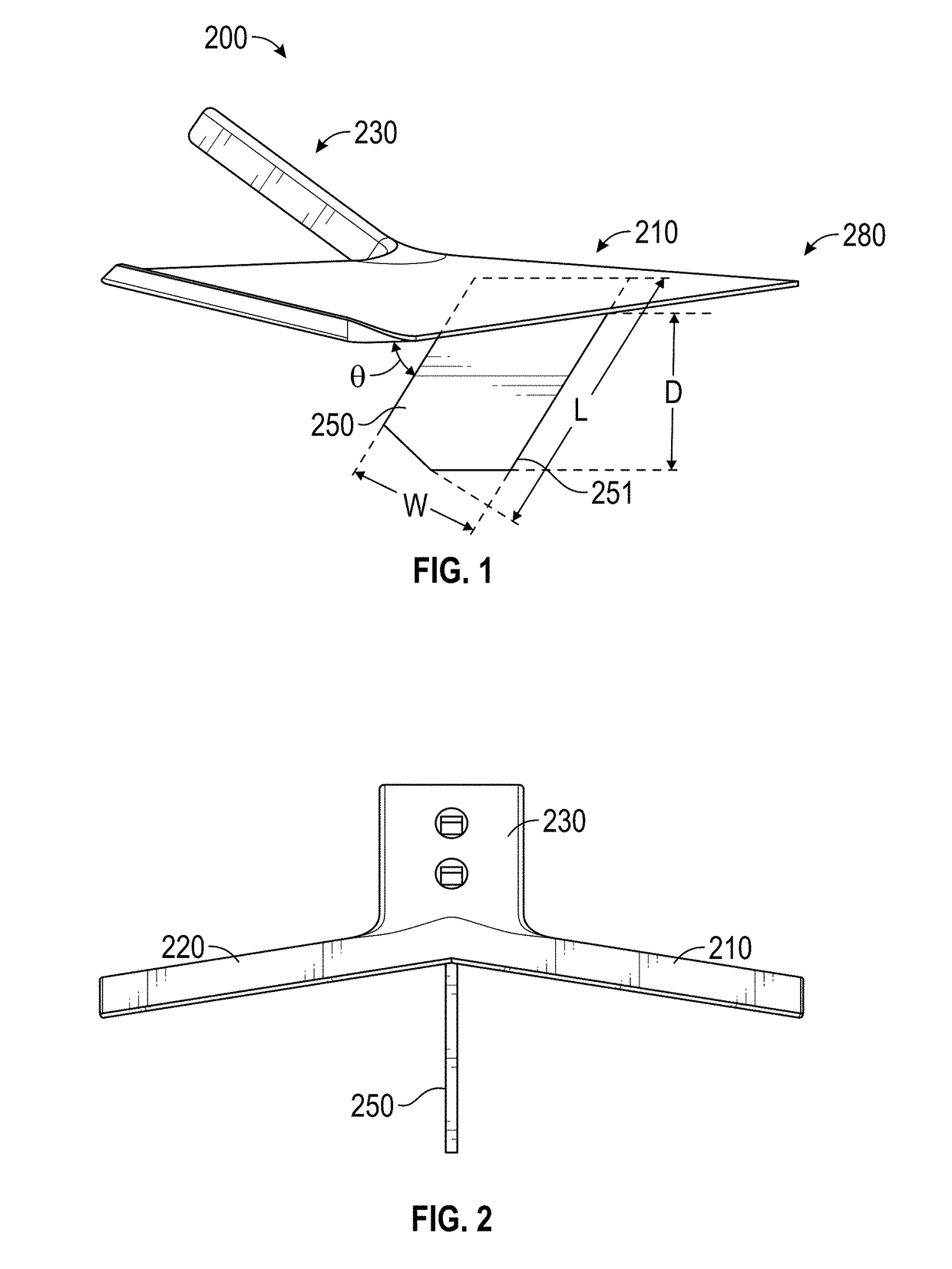

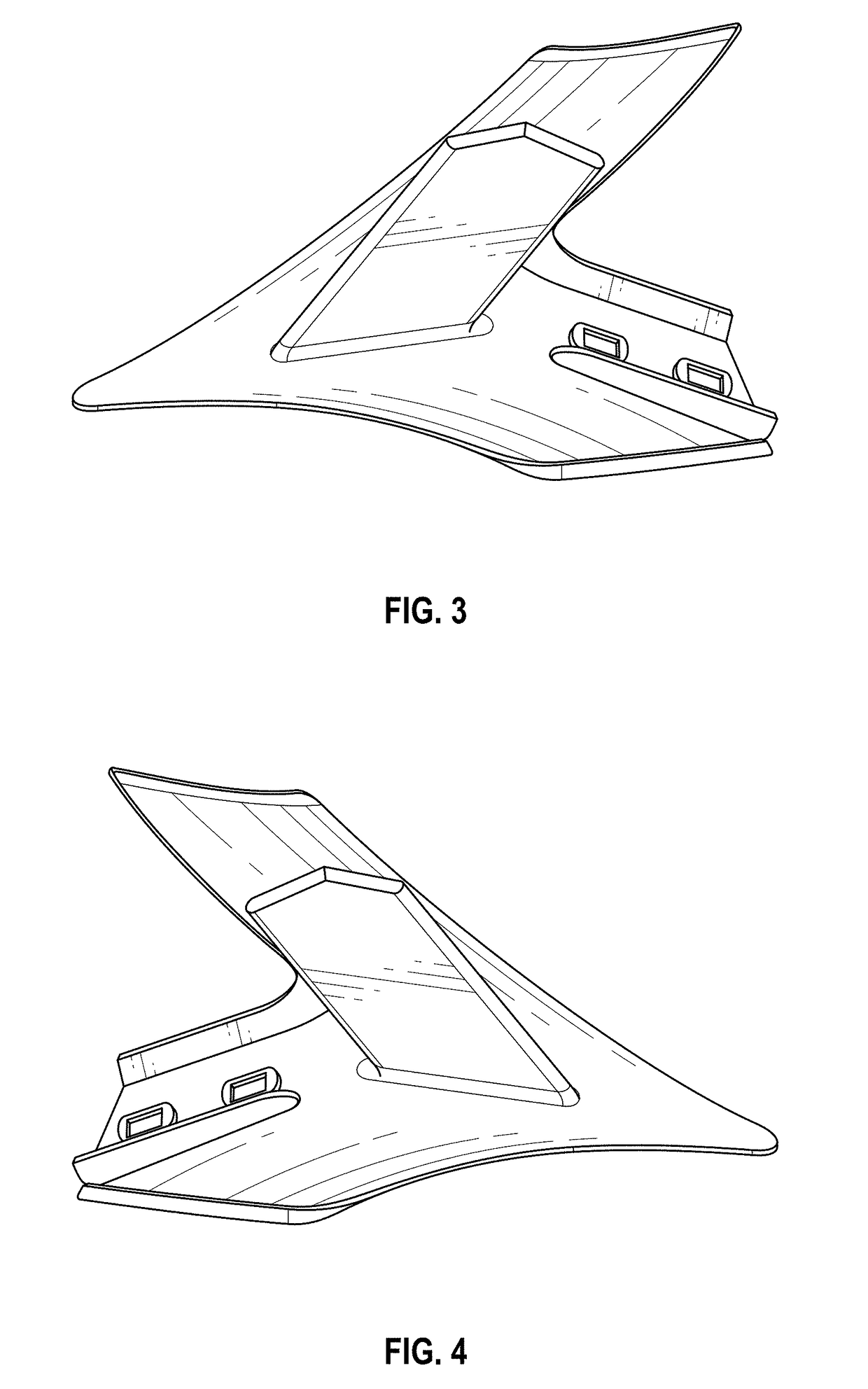

[0032]FIGS. 1-4 show a preferred embodiment of a field cultivator sweep 200 in accordance with the present invention. The field cultivator sweep 200 includes a first wing 210 and second wing 220, together forming a wing body, and an upstanding neck 230 at the rear of the body. The neck 230 is configured to attach to a shank of a cultivator. To this end, the neck 230 may include a plurality of apertures to connect the cultivator sweep 200 to the shank. For example, in FIG. 2 the field cultivator sweep 200 is illustrated as having two apertures 232 and 234 to allow the field cultivator sweep 200 to connect to the shank by a pair of bolts. It is understood the above connecting method is merely exemplary as the field cultivator sweep 200 may be attached to the shank by a different method, for example, by clamps, pins, screws, and welding. Furthermore, the number of apertures illustrated in FIG. 2 is not meant to be a limiting feature since some embodiments of the cultivator sweep 200 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com