Method for Obtaining a Cooking Vessel Having a Colored Hard-Anodized Outer Face

a technology of hard anodized outer face and cooking vessel, which is applied in the field of culinary appliances and utensils with cooking vessels, can solve the problems of difficult cleaning of the surface thus obtained, complex process implementation, and many steps, and achieve the effect of durable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

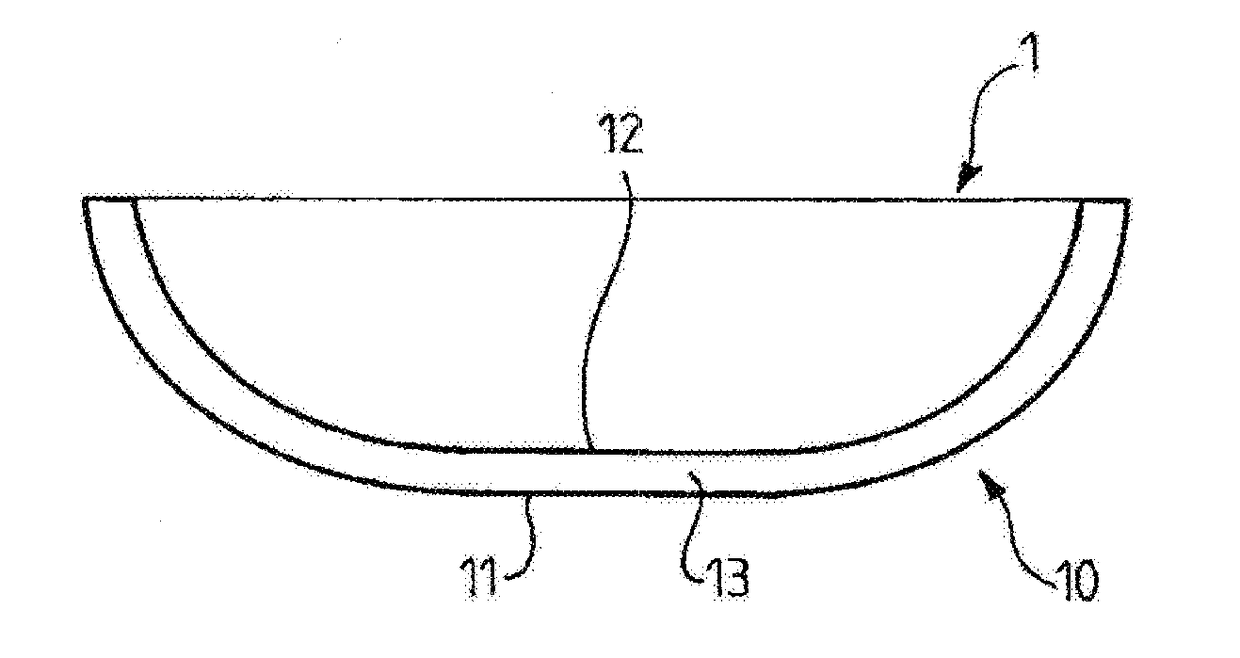

[0065]PTFE coating of the interior surface (12), hard anodization of the exterior surface (11), coloring of the hard anodized exterior surface (11).

example 2

[0066]Preliminary dual-surface hard anodization of the container (10) to obtain a hard base, PTFE coating of the interior surface (12), hard anodization of the exterior surface (11), coloring of the hard anodized exterior surface (11).

example 3

[0067]Dual-surface hard anodization of the container (10) to obtain a hard base, coloring of the hard anodized exterior surface (11) and the hard anodized interior surface (12).

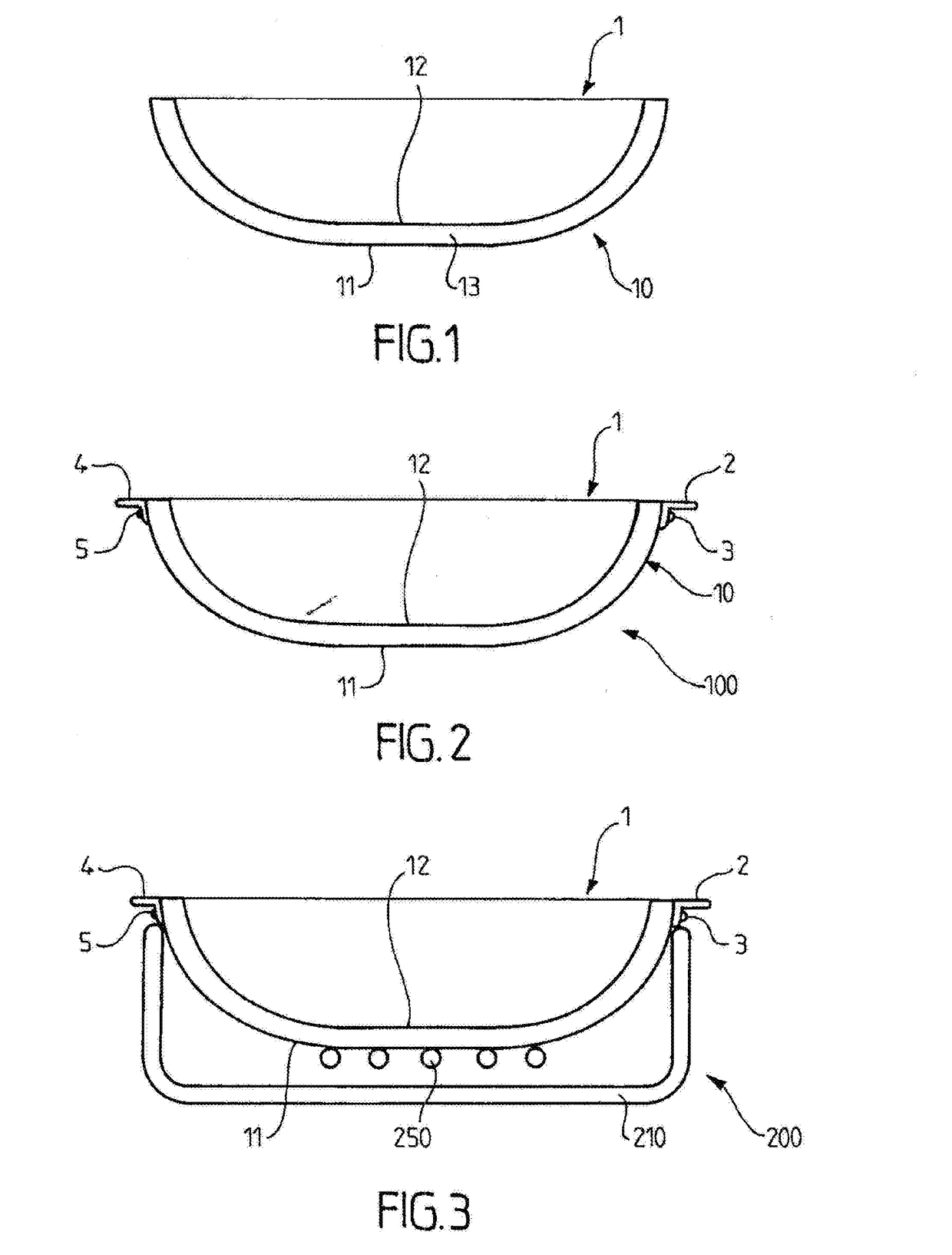

[0068]FIG. 2 depicts a culinary item (100) consisting of a cooking vessel (1) and a handling instrument (2) attached to said cooking vessel (1) by at least one rivet (3). To this end, the rivet (3) is assembled in a hole in the container (10) of the cooking vessel (1). If desired, multiple rivets (3) may be used to attach the handling instrument (2) to the cooking vessel (1). Preferably between two and four rivets (3) are used to attach the handling instrument (2) to the cooking vessel (1). Alternatively, the handling instrument (2) may be welded to said cooking vessel (1). If desired, another handling instrument (4) may be attached to said cooking vessel (1) by at least one other rivet (5) or by welding.

[0069]FIG. 3 depicts an electric cooking appliance (200), consisting of a cooking vessel (1) combined with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap