Drum brake which can be operated by an electric motor

a technology of electric motors and drum brakes, applied in the direction of brake systems, mechanical devices, transportation and packaging, etc., can solve the problems of increasing the complexity of manufacturing in that area, unable to permit simple variations in the context of mass production, and problems, etc., to achieve simple and efficient adaptation of drum brake modules and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

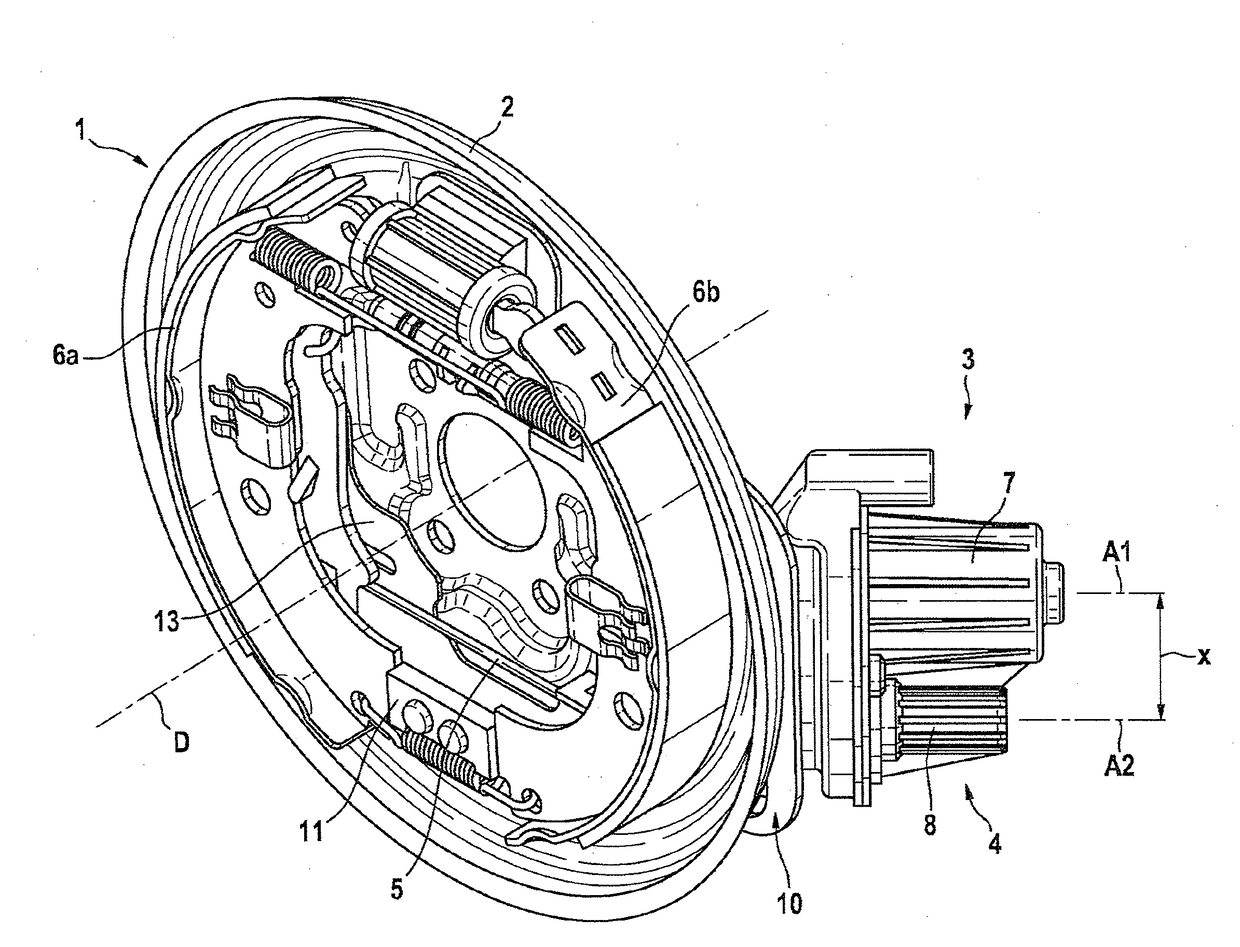

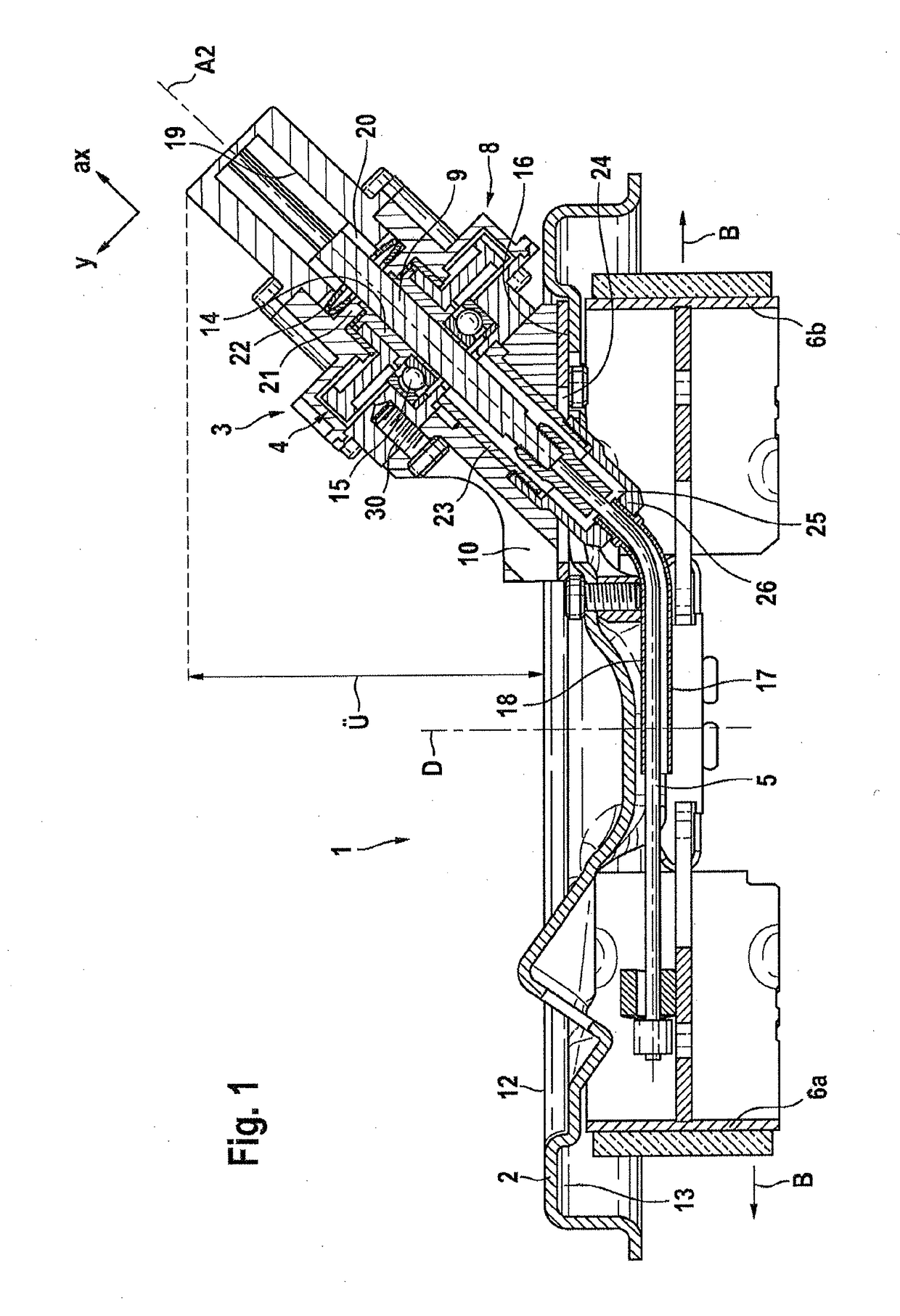

[0021]A known electromotively actuable drum brake module 1 for arrangement on axle components of a motor vehicle comprises, as per FIG. 1, an anchor plate 2 with brake pads 6a,b mounted thereon, which brake pads are provided within a brake drum (not shown).

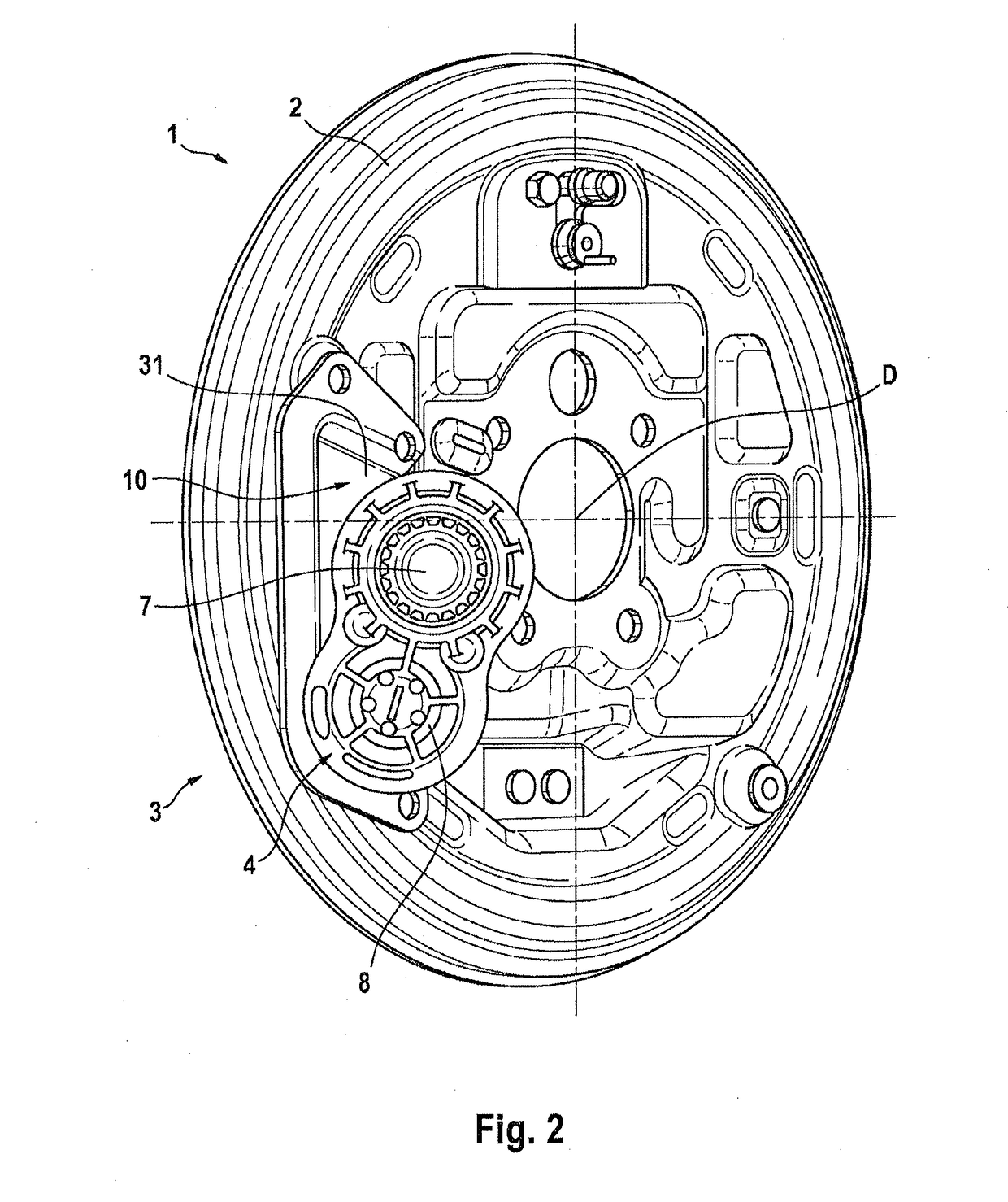

[0022]Fastened to an opposite side of the anchor plate 2 is an electromotively driven cable pull actuator 3 which, by way of a gearing 4 and a cable pull 5 connected downstream, engages on one or more of the brake pads 6a,b such that said brake pad(s) 6a,b can perform an actuation movement B in the direction toward the brake drum in order to realize a service brake and / or parking brake function. A support device 11 may be provided between the brake pads 6a,b.

[0023]The gearing 4 comprises a gearing housing 8 which accommodates or at least bears the motor 7. The motor 7 consumes direct-current voltage, is mechanically or electronically commutated, and is of a standard type that is available at low cost.

[0024]FIG. 1 illustrates, at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com