Ice maker with freezing aid

a technology of ice maker and ice maker, which is applied in the field of ice maker, can solve the problems of inconvenient use and significant acceleration of ice production, and achieve the effect of accelerating ice production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

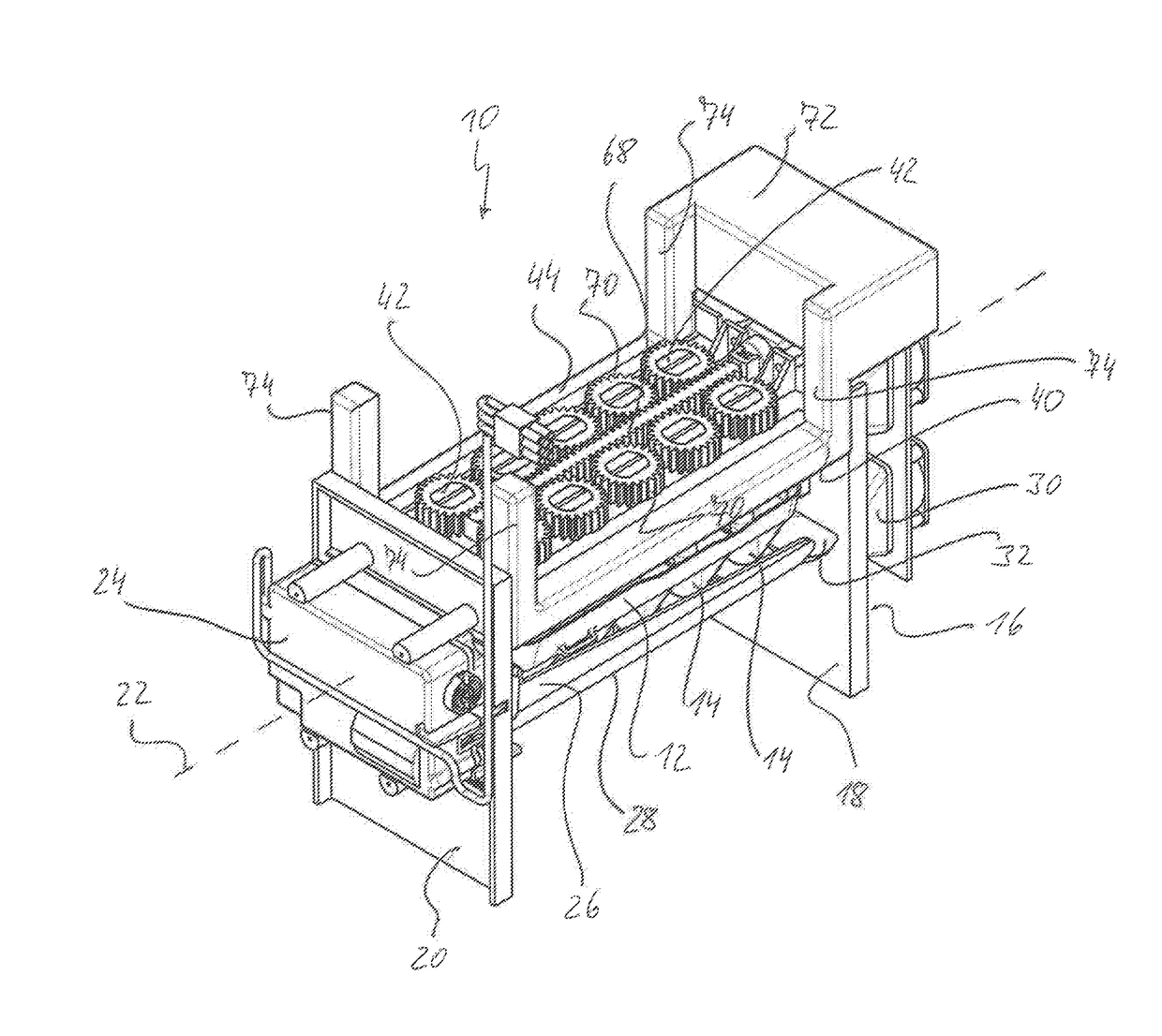

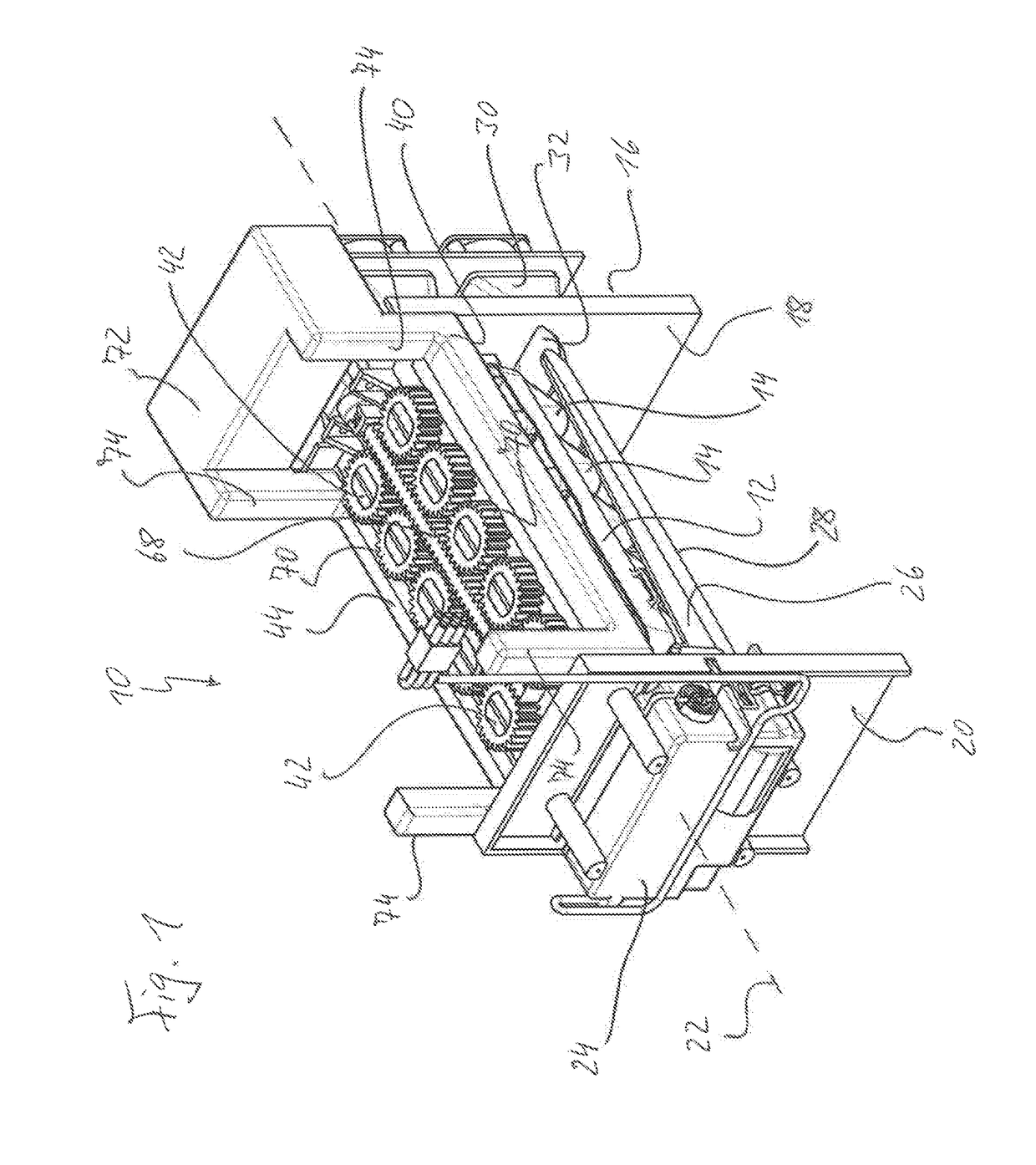

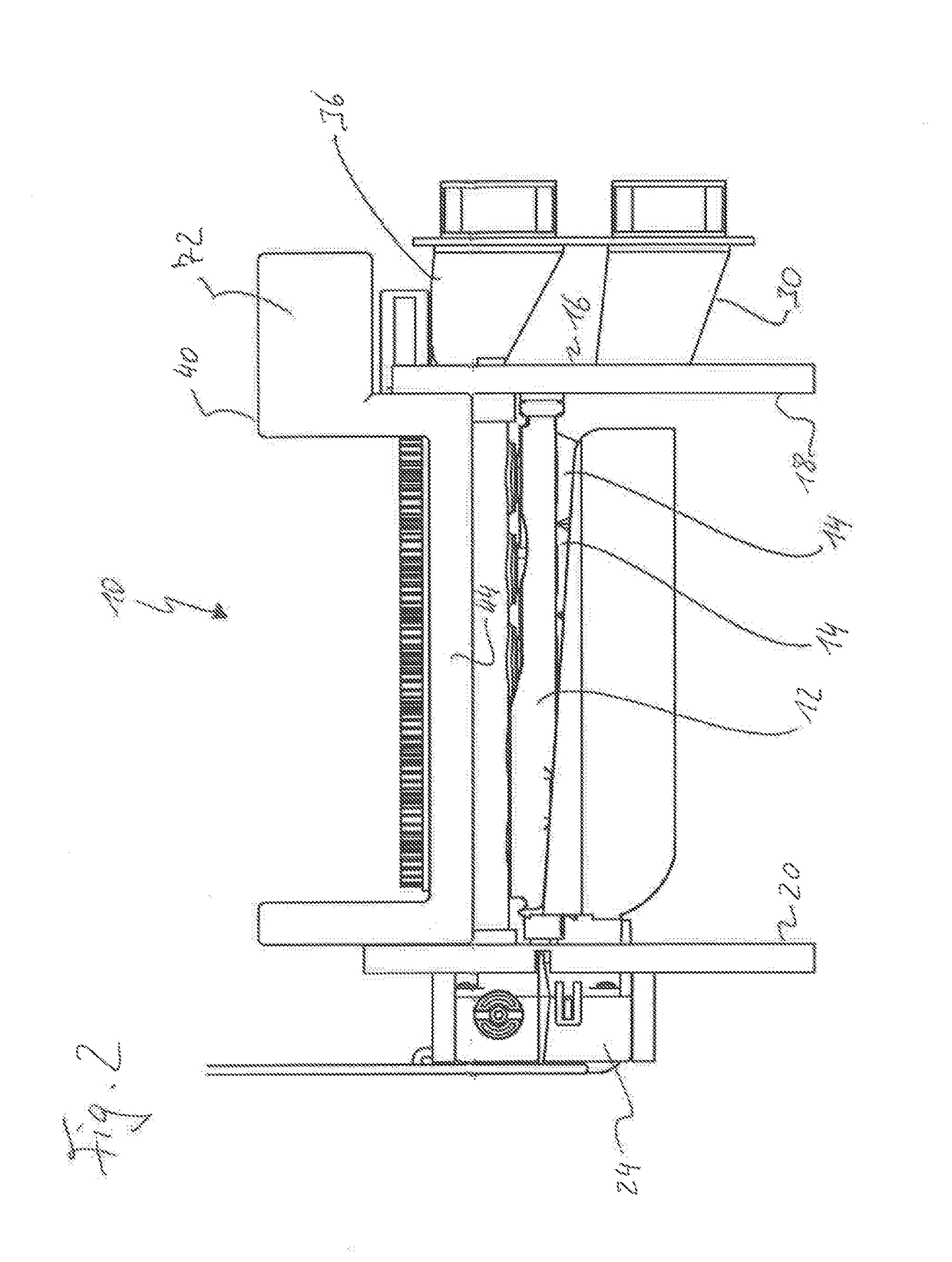

[0036]Reference is first made to FIGS. 1 and 2. The ice maker shown therein is generally designated 10. It comprises as the central component an ice-making tray 12 which serves to produce ice pieces. The ice-making tray 12 forms a plurality of ice-piece-producing cavities 14 which can be filled with fresh water by means of a water supply device (not shown). By the action of cold, the water in the ice-piece-producing cavities 14 freezes. The ice maker 10 works by the so-called twisted tray principle, according to which the ice-making tray 12 is twisted in order to release the frozen ice pieces from the cavity walls of the ice-piece-producing cavities 14. In an ice-ejecting rotational position of the ice-making tray 12, the finished ice pieces are then able to fall out of the ice-making tray 12 and be caught in a collecting container (not shown) situated beneath the ice maker 10.

[0037]The ice maker 10 comprises a base frame 16, which in the example shown comprises two frame plates 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com