A Roller Guide and a Method for Guiding Stock

a technology of roller guides and guides, applied in auxillary arrangements, measuring devices, manufacturing tools, etc., can solve the problems of heavy wear of guide rollers, and achieve the effect of increasing the lateral distance between guide rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

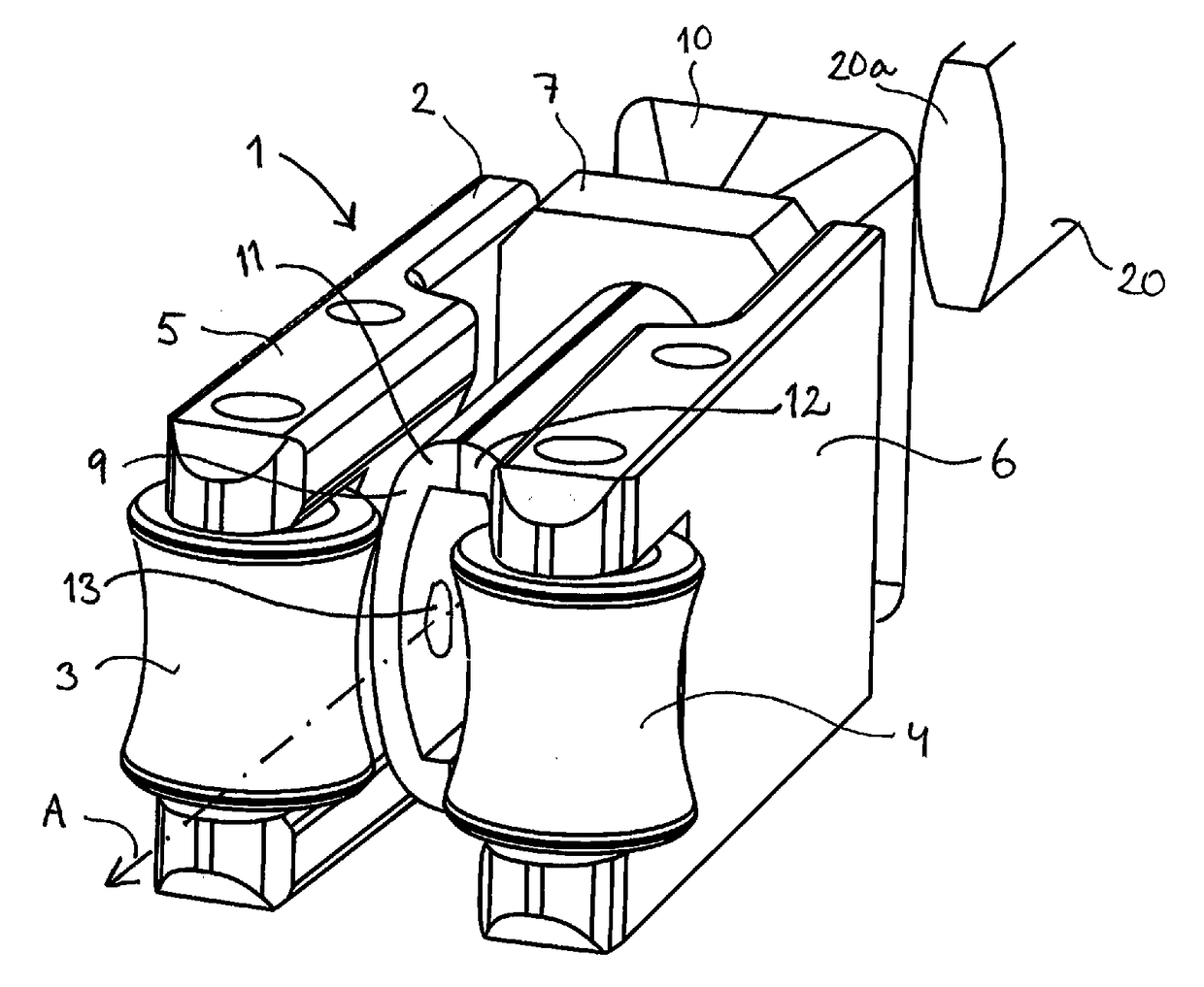

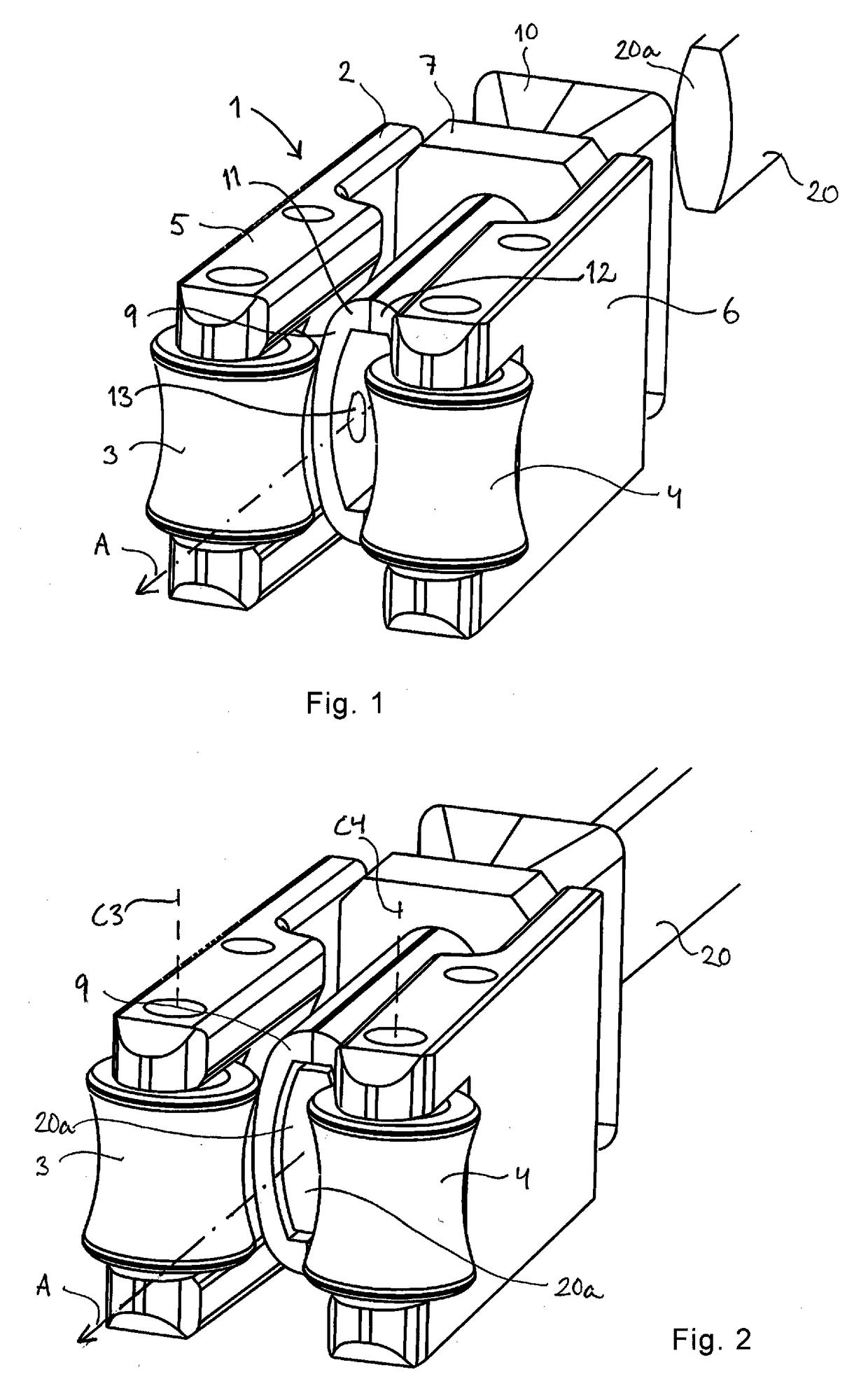

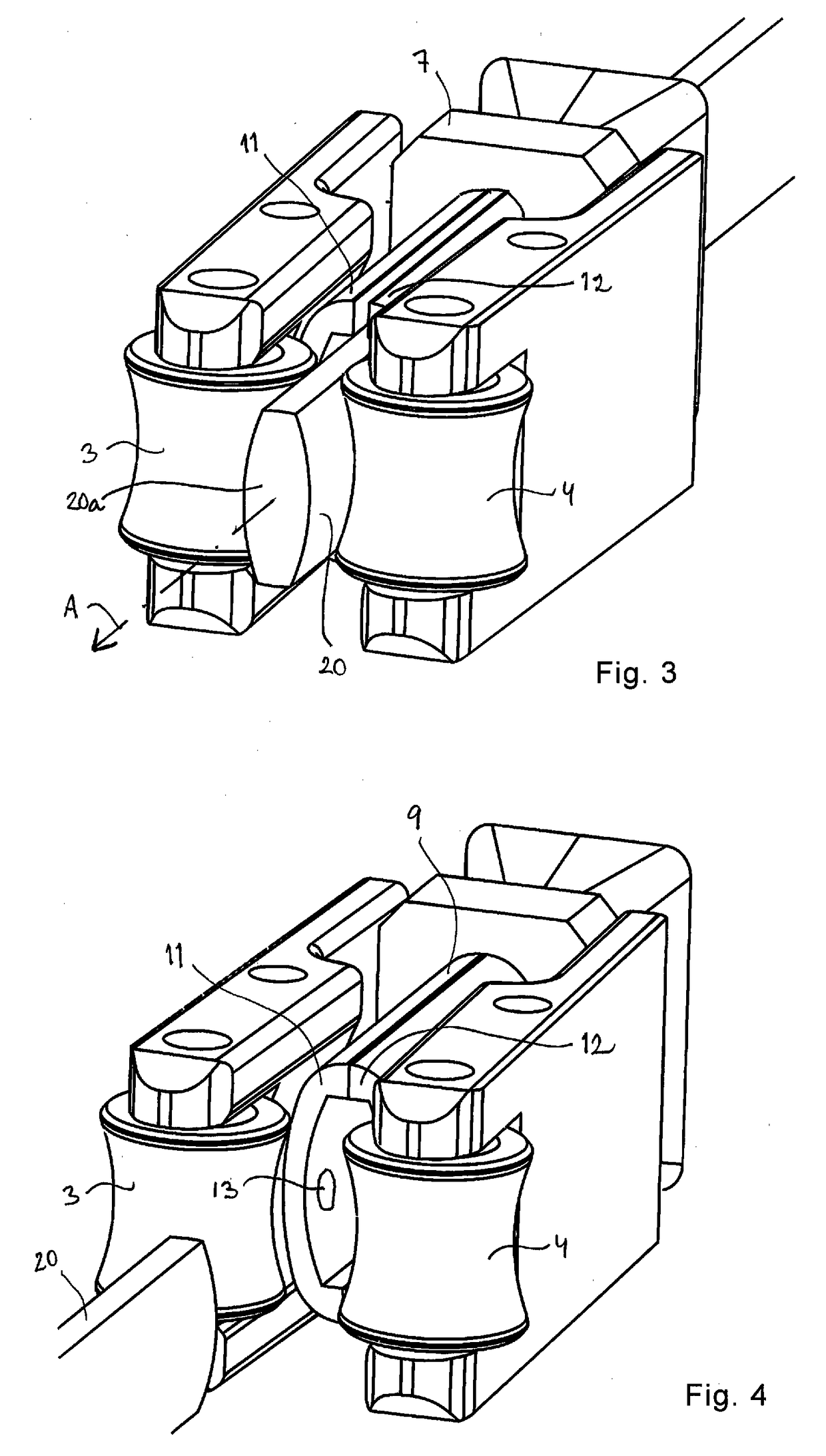

[0033]A schematic illustration of a roller guide 1 according to an embodiment of the present invention is shown in FIG. 1-4. The roller guide 1 is intended for guiding stock in a longitudinal feeding direction A in a rolling mill, primarily toward a pair of rolls for shaping the stock. The roller guide 1 comprises a frame arrangement 2 and a pair of guide rollers 3, 4, each guide roller 3, 4 being mounted on an arm 5, 6 of the frame arrangement 2. The arms 5, 6 are pivotable and movable such that a lateral distance, i.e. in a direction perpendicular to the feeding direction A, between the guide rollers 3, 4 can be adjusted. The guide rollers 3, 4 are rotatable about parallel axes of rotation C3, C4 perpendicular to the longitudinal feeding direction A and to the lateral direction. The roller guide 1 further comprises a control unit 7 in which positioning means for adjusting the lateral distance between the guide rollers 3, 4 by means of moving and pivoting the arms 5, 6 is comprised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lateral distance | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com