Touch display device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

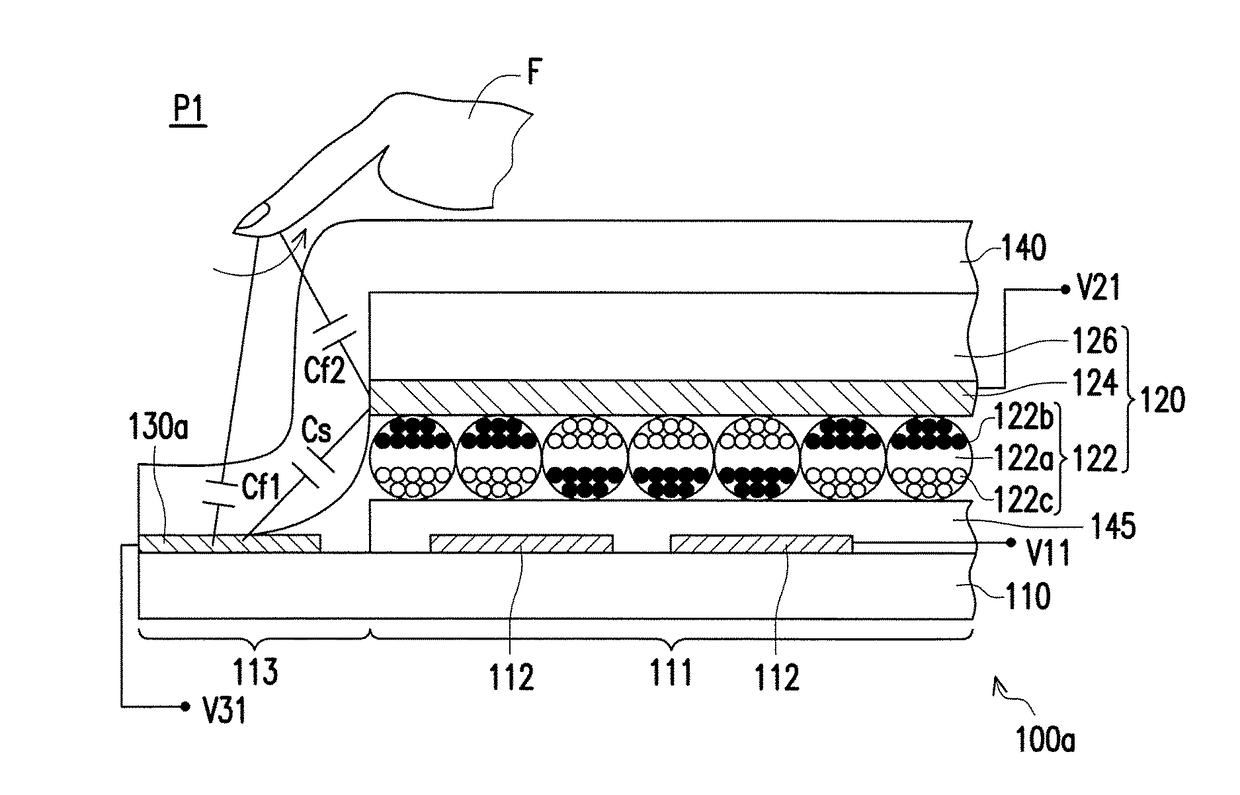

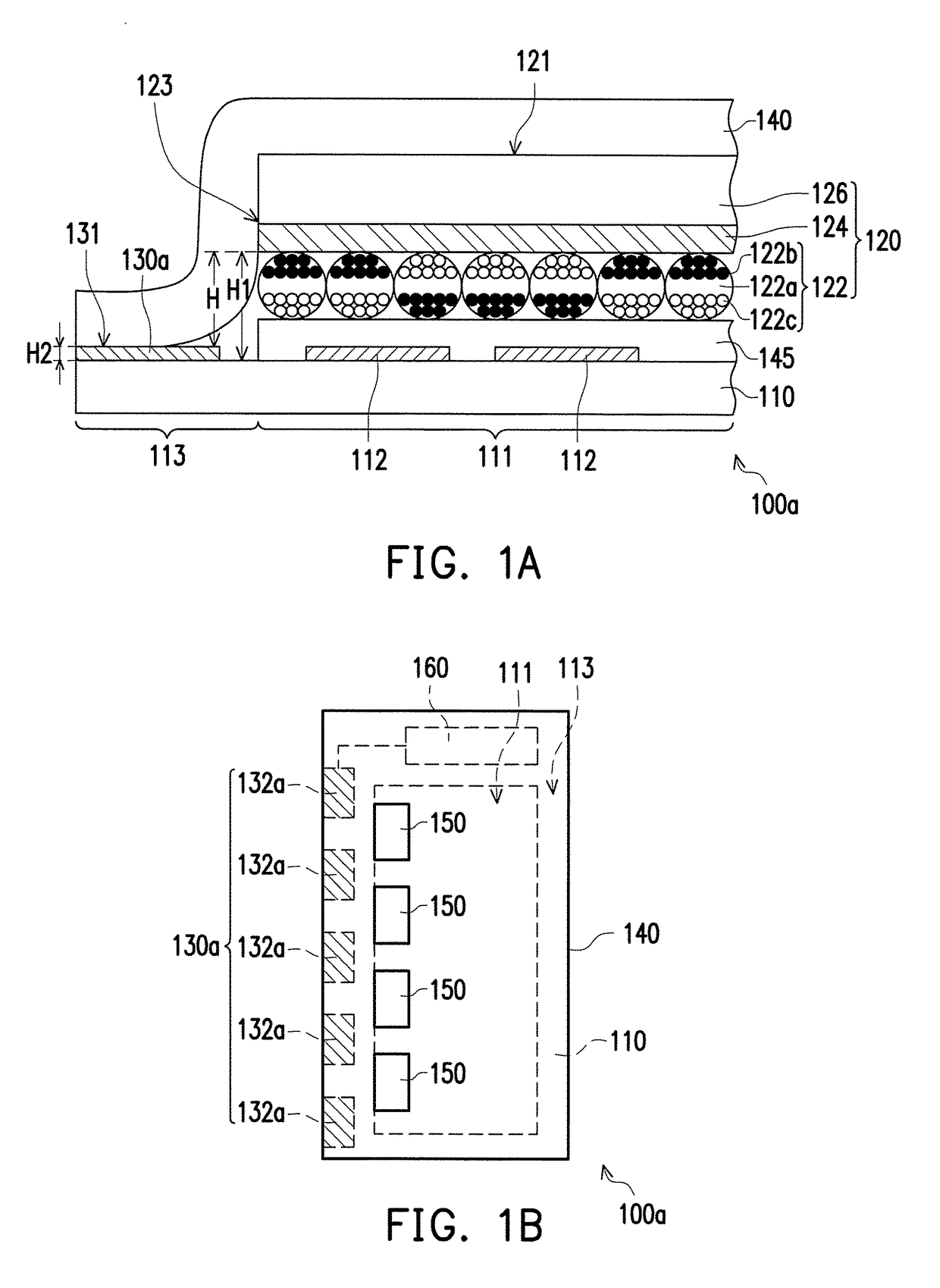

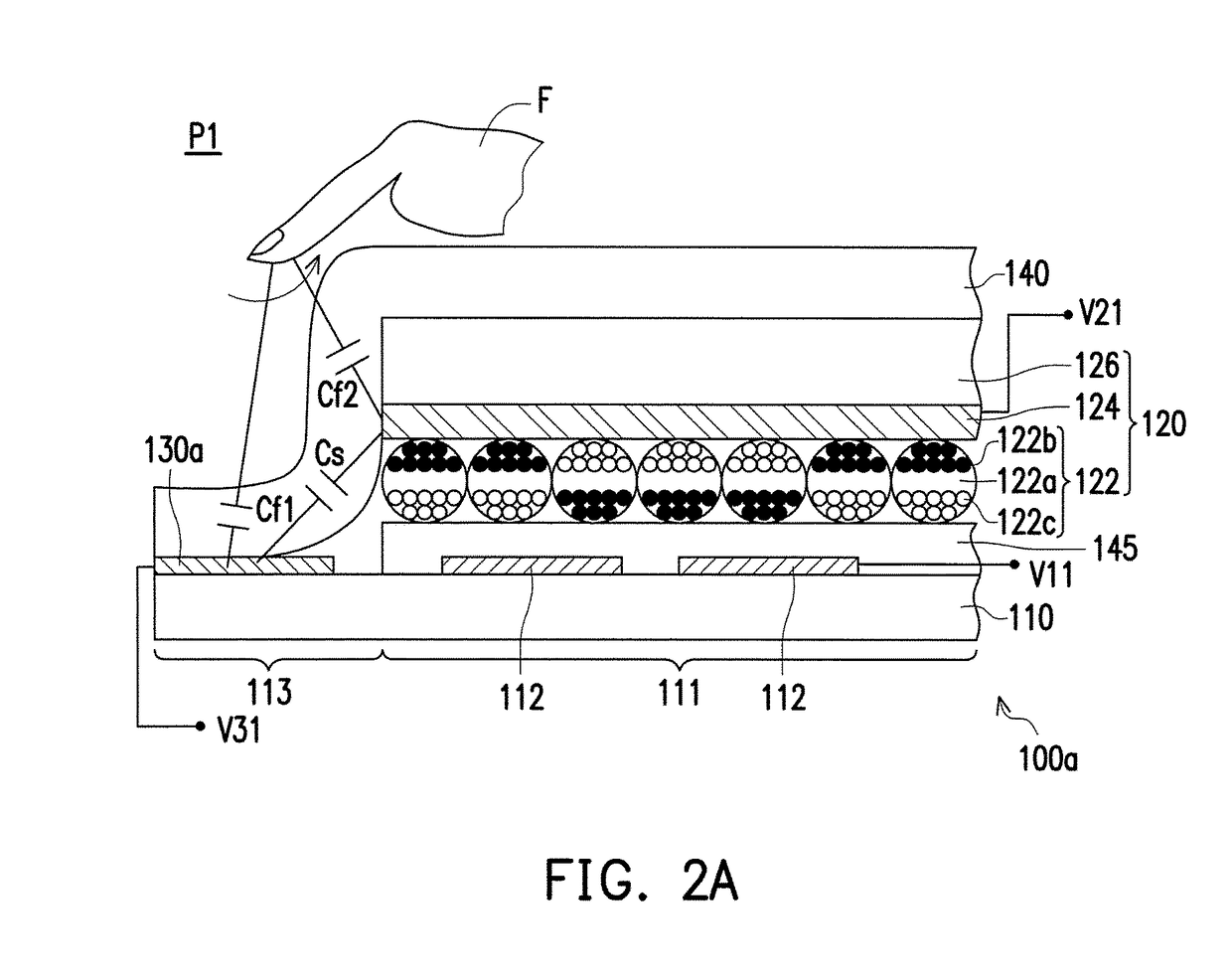

[0030]FIG. 1A illustrates a cross-sectional view of a touch display device according to an embodiment of the invention. FIG. 1B illustrates a top view of the touch display device of FIG. 1A. Referring to FIG. 1A and FIG. 1B together, in the present embodiment, a touch display device 100a includes a driving substrate 110, a display module 120, a touch electrode layer 130a and an insulating layer 140. The driving substrate 110 has a display area 111 and a non-display area 113, and the non-display area 113 is located outside the display area 111. The display module 120 includes a display medium layer 122, a transparent conductive layer 124 and a transparent cover plate 126 sequentially arranged on the driving substrate 110 and located in the display area 111. The touch electrode layer 130a is disposed in the non-display area 113 of the driving substrate 110. The insulating layer 140 covers an upper surface 121 of the display module 120 and extendedly covers a top surface 131 of the tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com