Concurrent, adjacent heat treatment and cooling in metal annealing

a heat treatment and metal technology, applied in the field of heat treatment of metals for annealing, can solve the problems essentially of little use in the careful control of temperature required to prevent overheating and and heating resulting from inductive fields generated in aluminum and aluminum alloy workpieces. , the effect of deterioration of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The invention is now discussed with reference to the drawing figures and specific examples.

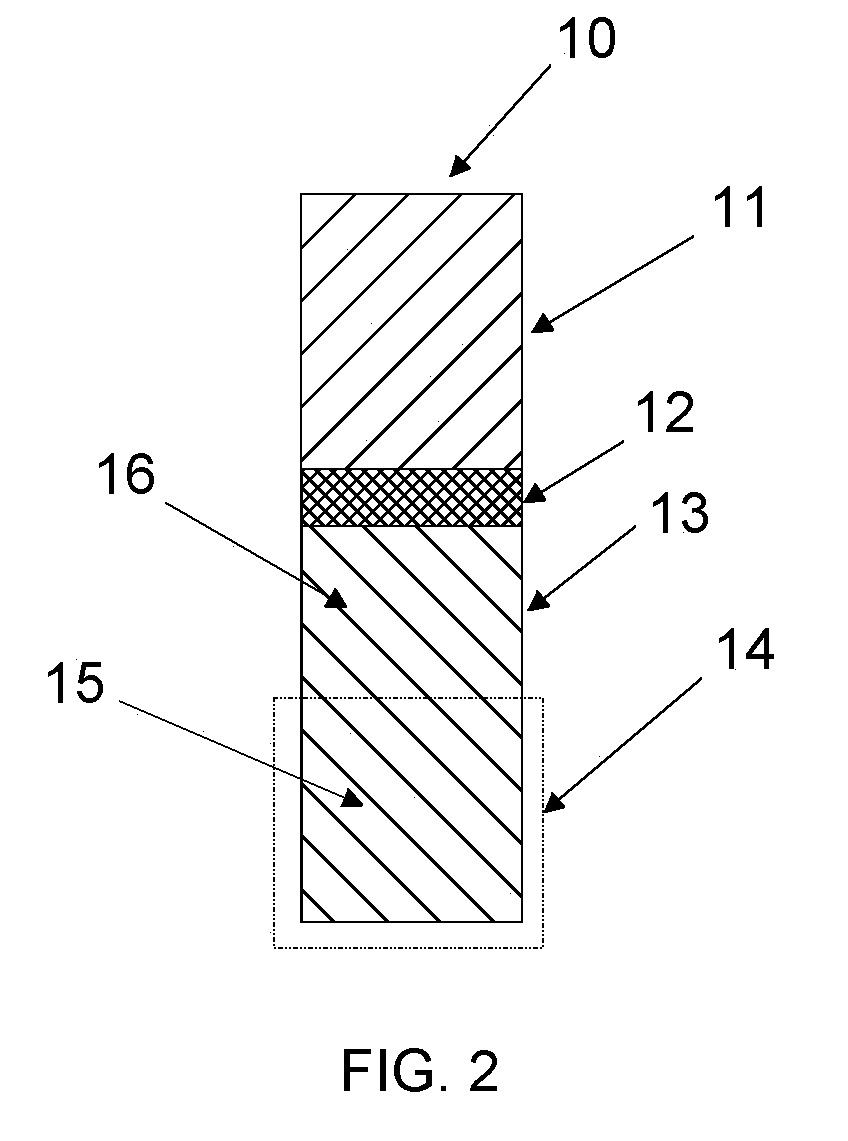

[0032]FIG. 2 is a generalized cross section of a metal workpiece 10, exemplary aluminum, showing heat treated zone 11, a cooling medium 14, a lower cooled zone 15, an upper cooled zone 16, and a transition zone 12, a relatively narrow band in workpiece 10. In transition zone 12, physical properties (such as hardness and related properties) of the workpiece transition far more rapidly than in zone 11 above and zone 13 below transition zone 12. In the invention process, heat transfer to an upper part of or all of zone 11 results in a significant change in the physical properties of at least an upper part of zone 11, resulting in rapid heating of zone 11. Heat transfer from zone 11 would rapidly take place into upper cooling zone 16, but for application of cooling medium 14 to a lower cooling zone 15 of cooling zone 13. Cooling medium 14 may be dry ice, cooled or liquid gases (such as nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| crystal structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com