Overmold direct attach sole

a technology of direct attaching and overmolding, which is applied in the direction of bootlegs, uppers, domestic applications, etc., can solve the problems of increasing manufacturing costs, potential quality concerns, and failures of adhesives in footwear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

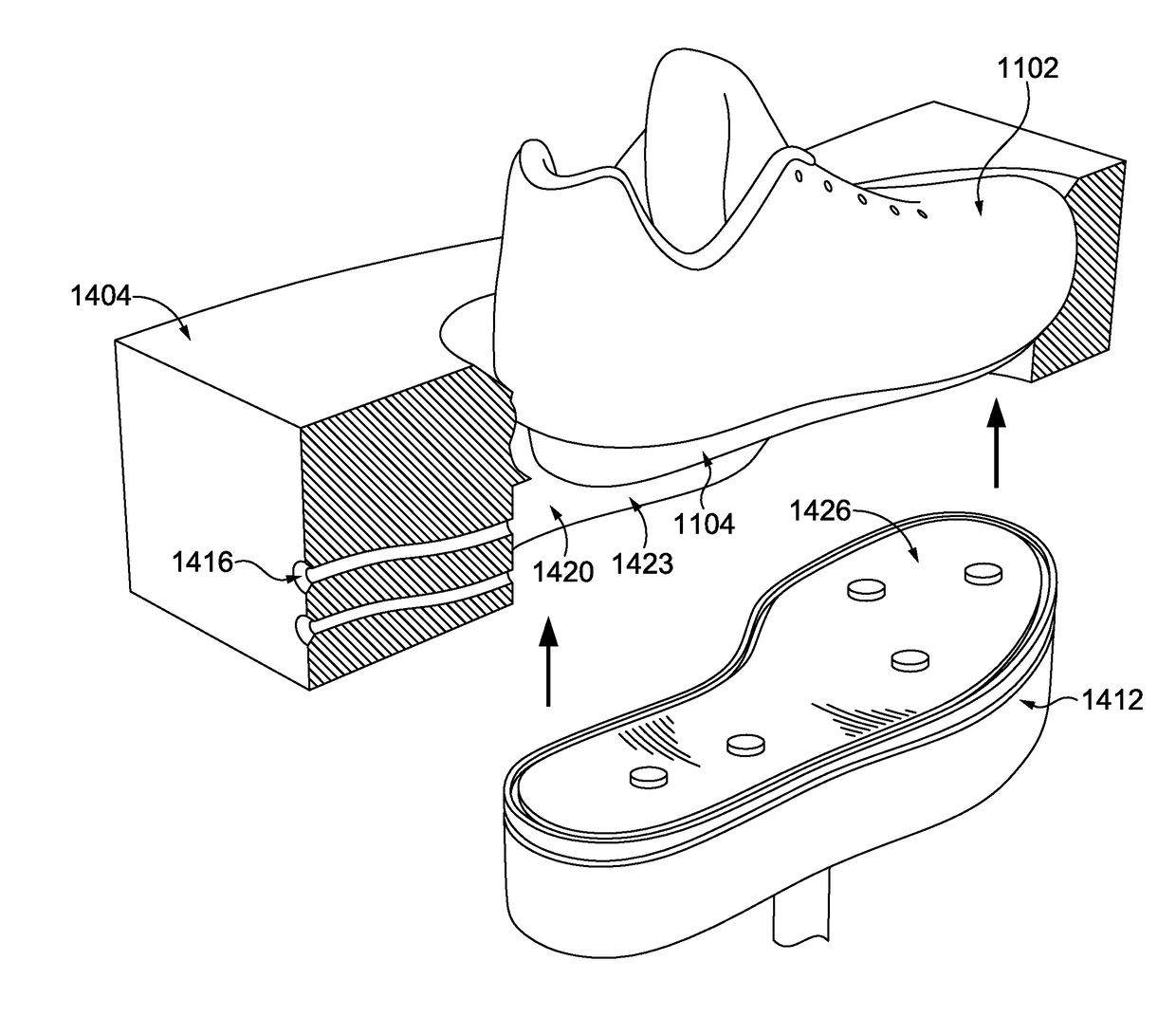

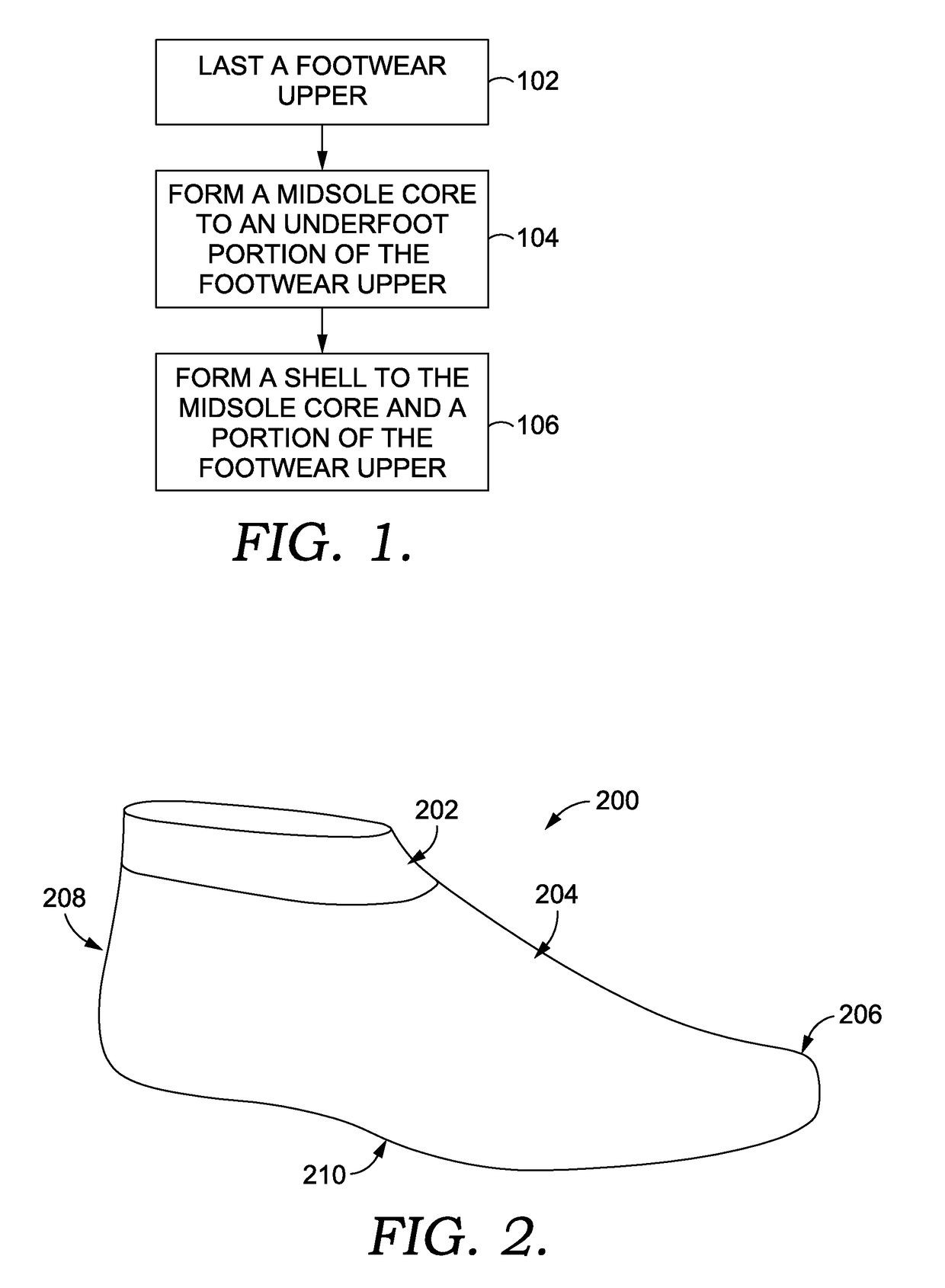

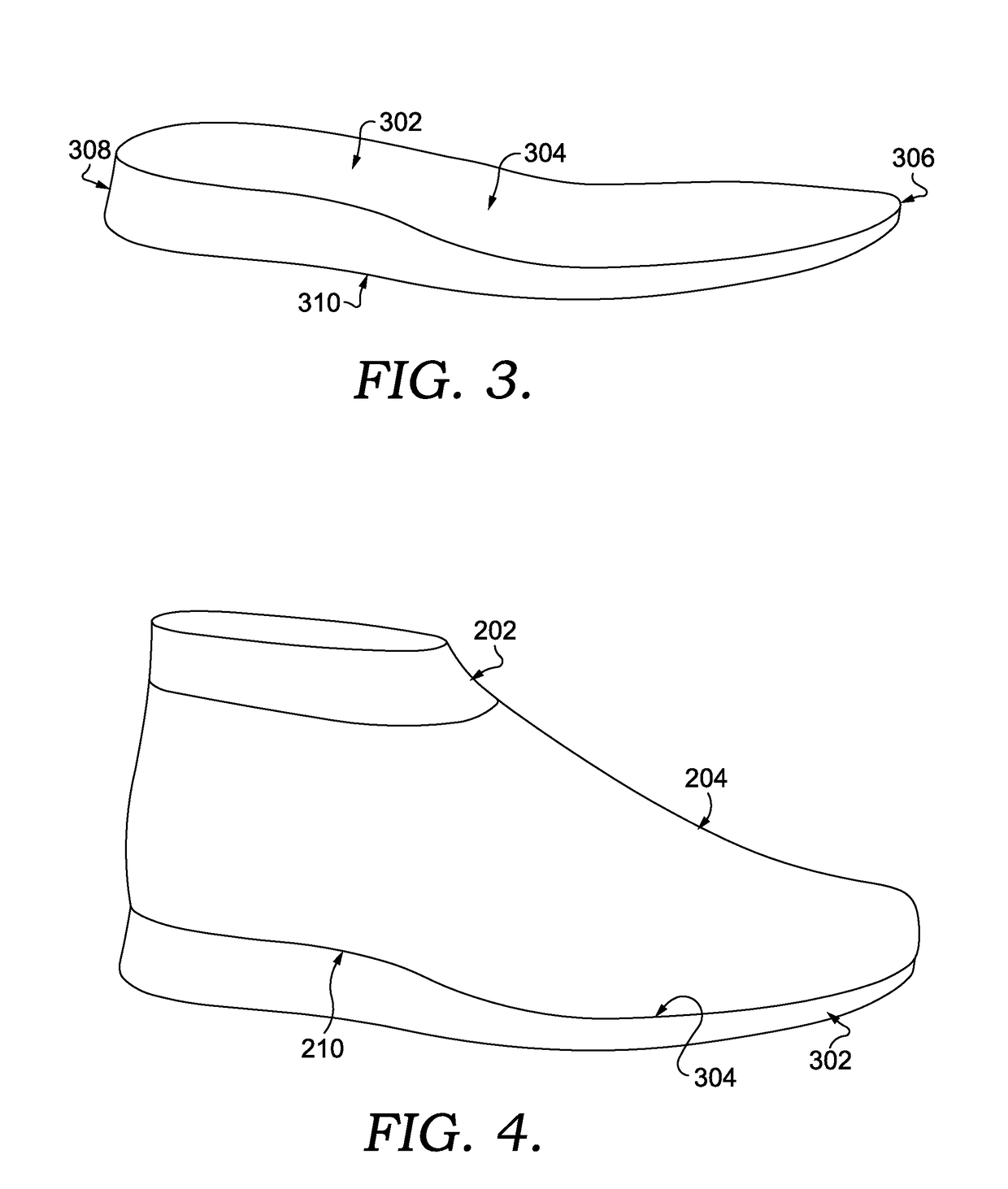

[0025]An article of footwear, such as a shoe, sandal, cleat, and the like, is comprised of one or more components. In the examples provided herein, a footwear upper and a bottom unit may form the footwear. A footwear upper, or referred to as an upper for short, is a foot-securing component of the footwear. The upper extends from the bottom unit and secures the bottom unit to a foot of a wearer. The upper may be formed from a variety of materials, such as leather, knit, woven, braided, felted, non-woven, and the like. Similarly, an upper may be made from a single material or a variety of materials. The upper may be a continuous material, a discontinuous material, a cut-and-sew combination, a cut-and-adhere combination, and the like. Therefore, it is contemplated herein that an upper may be formed from a variety of materials (e.g., organic, non-organic) and / or techniques.

[0026]A bottom unit is generally positioned between a wearer's foot and the ground. A bottom unit may be referred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com