Golf shoe outsole

a technology for golf shoes and outsoles, applied in the field of golf shoes, to achieve the effect of improving flexibility, traction with the turf, and balan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

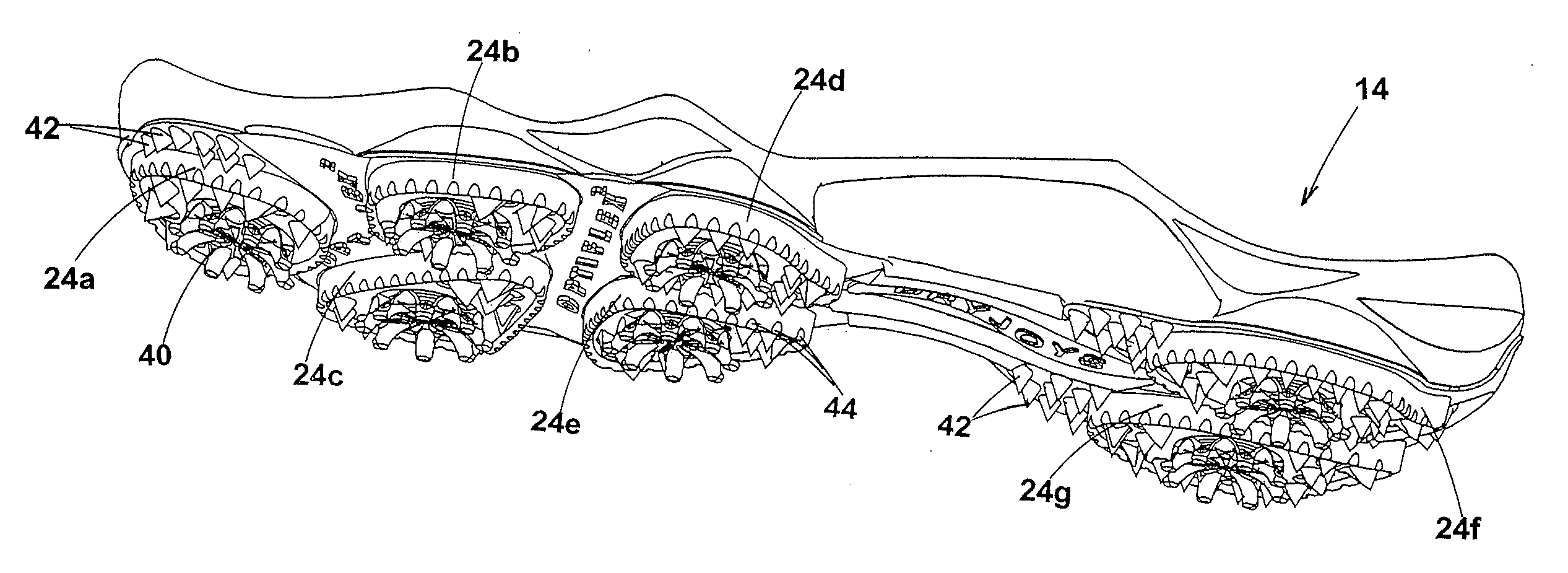

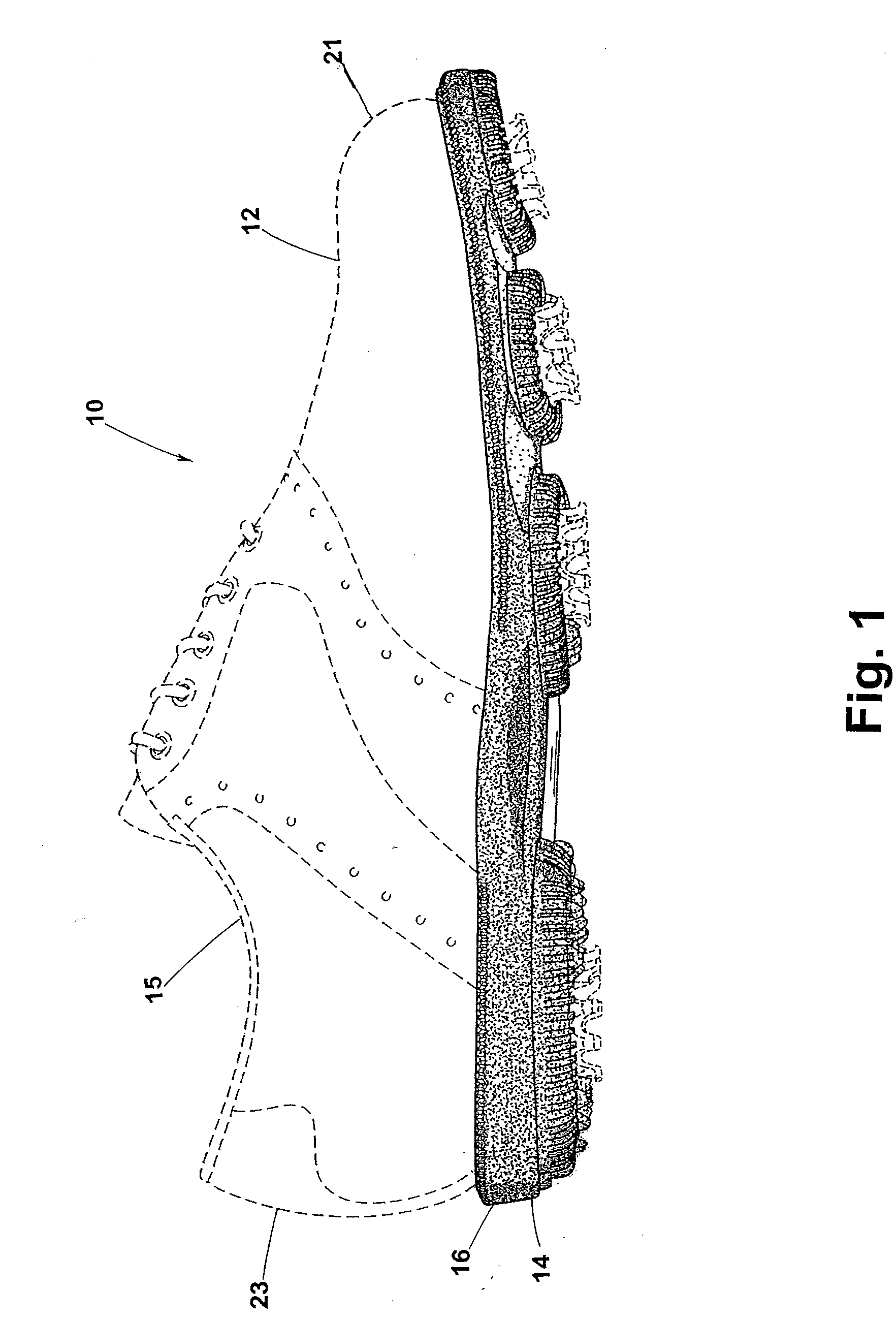

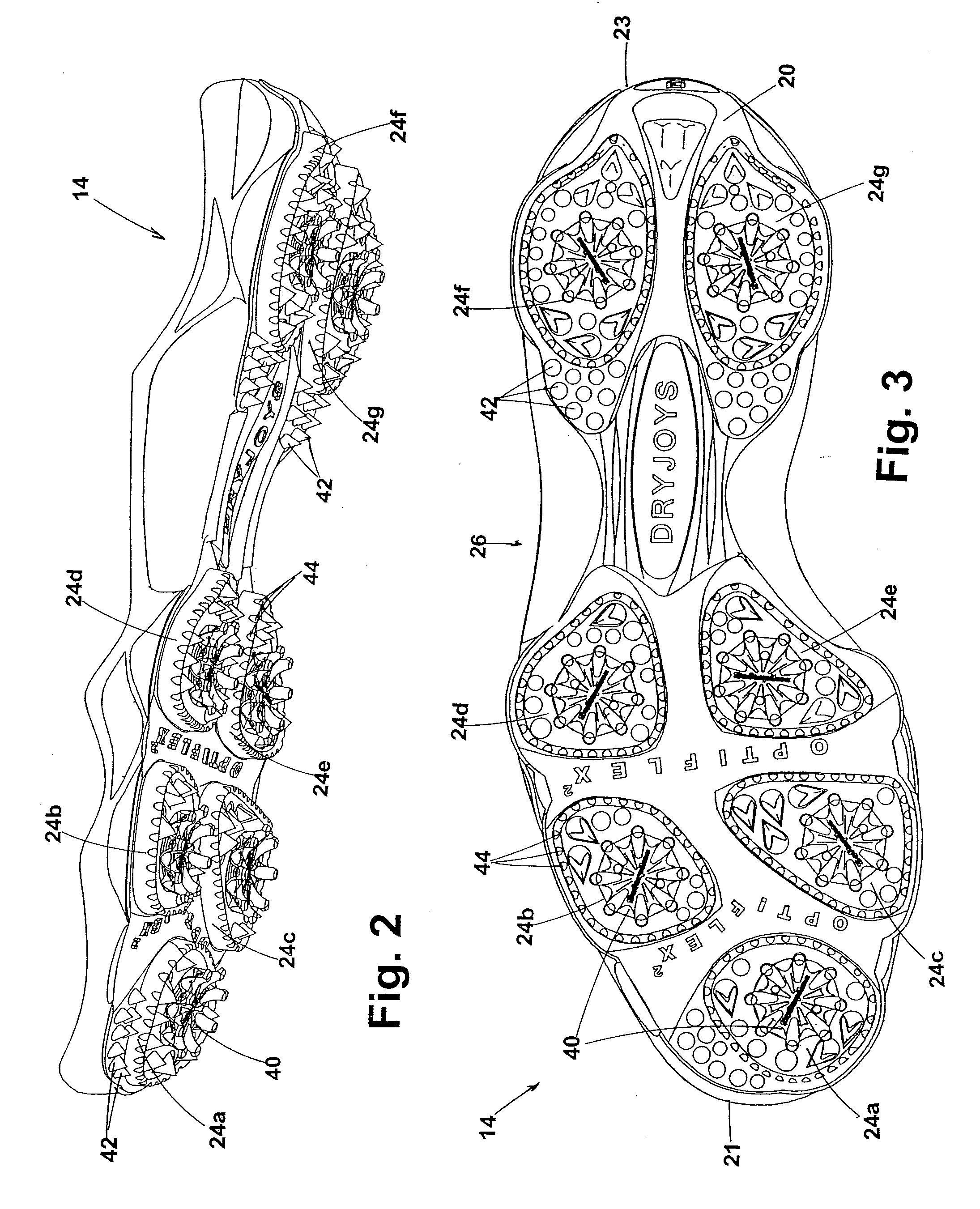

[0019]As shown in FIG. 1, a conventional golf shoe 10 usually includes an upper 12, an outsole 14, and typically a lightweight, cushioning mid-sole 16, which connects the upper 12 to the outsole 14. Golf shoes may have cleats 40 which can be metal or non-metal, but in discussing the present invention it is to be assumed that only non-metal cleats will be employed. The upper 12 has a generally conventional shape and is formed from a suitable upper material, such as leather or the like. An opening 15 is formed by the top portion of the upper 12 for receiving a user's foot. The mid-sole 16 provides cushioning to the wearer, and is formed of a material such as an ethylene vinyl acetate copolymer (EVA). Mid-soles 16 may be formed on and about outsole 14, but can be formed separately from the outsole 14 and joined thereto such as by adhesive. Once the mid-sole 16 and outsole 14 are joined, the outsole forms a substantial portion of the bottom of shoe 10. Upper 12 is preferably secured to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com