Power Winch Horizontal-Push Winch

a technology of power winch and horizontal push, which is applied in the direction of winding mechanism, hoisting equipment, etc., can solve the problems of affecting the operation of the power winch, and causing the operator to worry about the emergency situation, so as to achieve the effect of easy adjustment or change of the installation angle of the operating handl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The technical characteristics, contents, advantages and effects of the present invention will be apparent with the detailed description of a preferred embodiment accompanied with related drawings as follows.

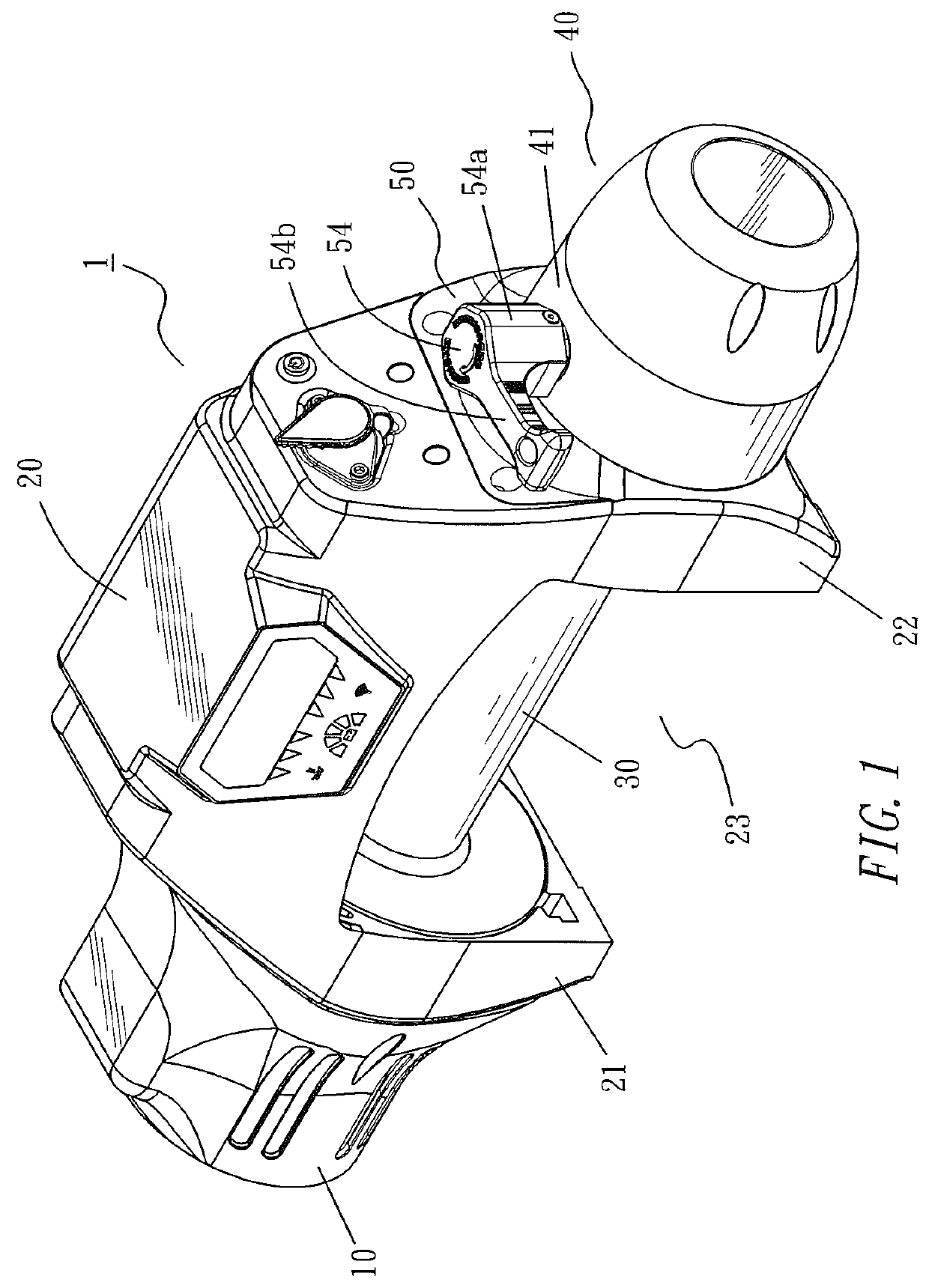

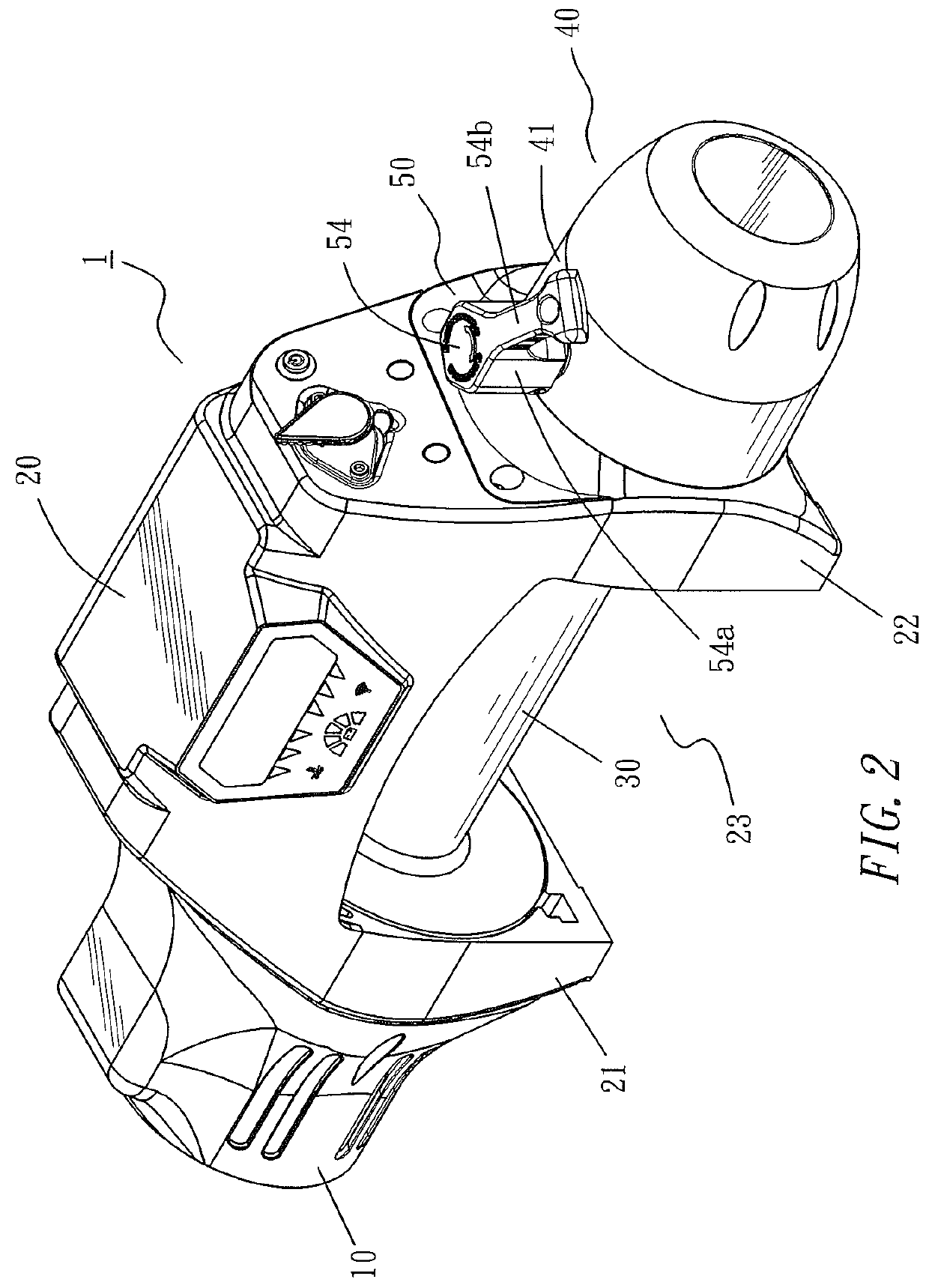

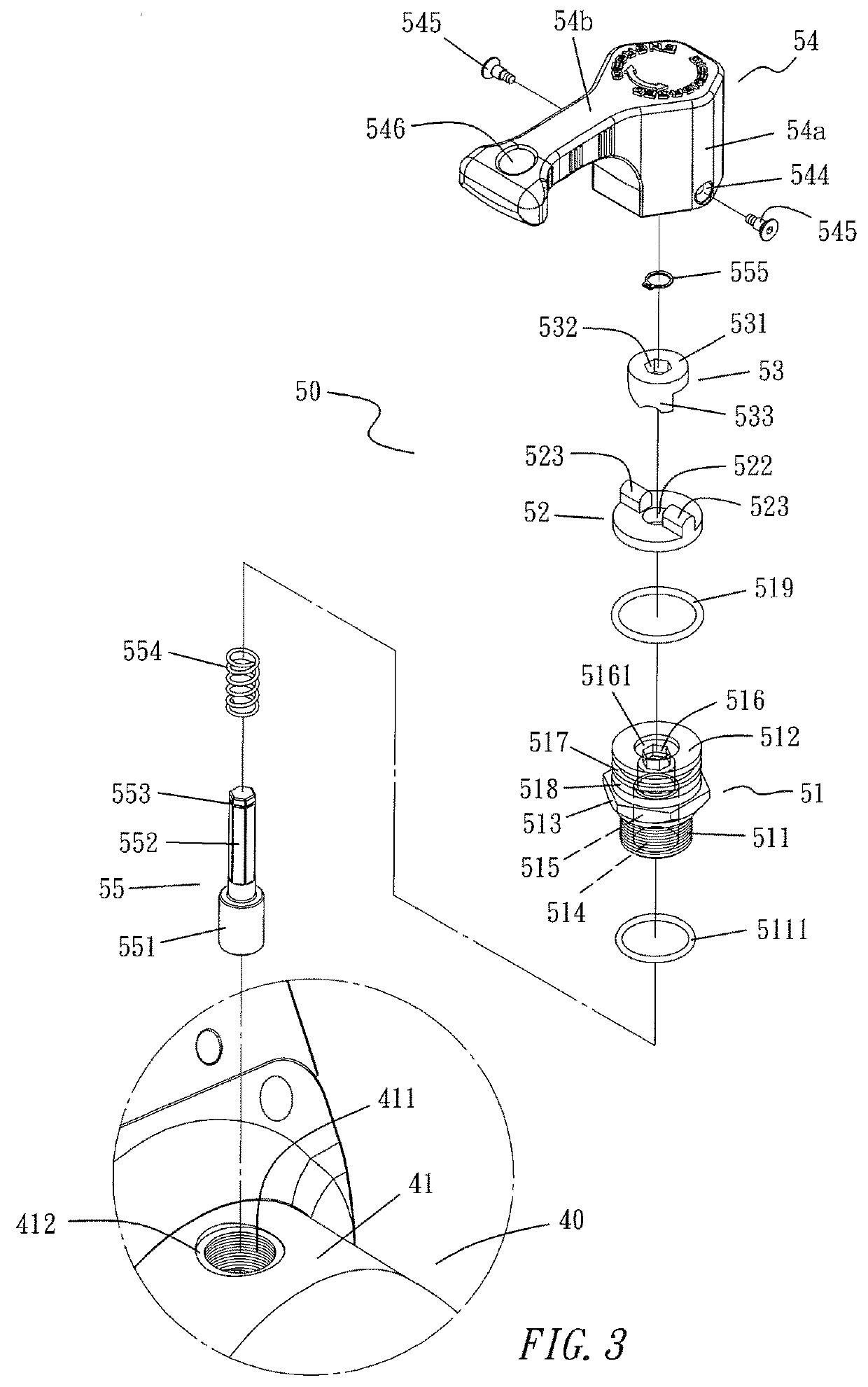

[0022]With reference to

[0023]FIGS. 1 and 2 for a power winch 1 in accordance with a preferred embodiment of the present invention, the power winch 1 comprises: a power source 10 (such as a motor) disposed on a side of the power winch 1; a main frame body 20 disposed at the middle of the top of the power winch 1, and a group of support bases 21, 22 being extended downwardly from both sides of the power winch 1 and a space 23 being formed between the two support bases 21, 22, and a side of the power source 10 being coupled to the outer side of the support base 21; a cable wheel 30, installed in the space 23 between the support bases 21, 22, but not structurally or electrically coupled with the support bases 21, 22, for winding a cable (not shown in the figure), and the outerm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com