Golf gear fitting system, golf gear fitting method, golf gear fitting program, golf swing classification method, golf shaft fitting system, golf shaft fitting method, and golf shaft fitting program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

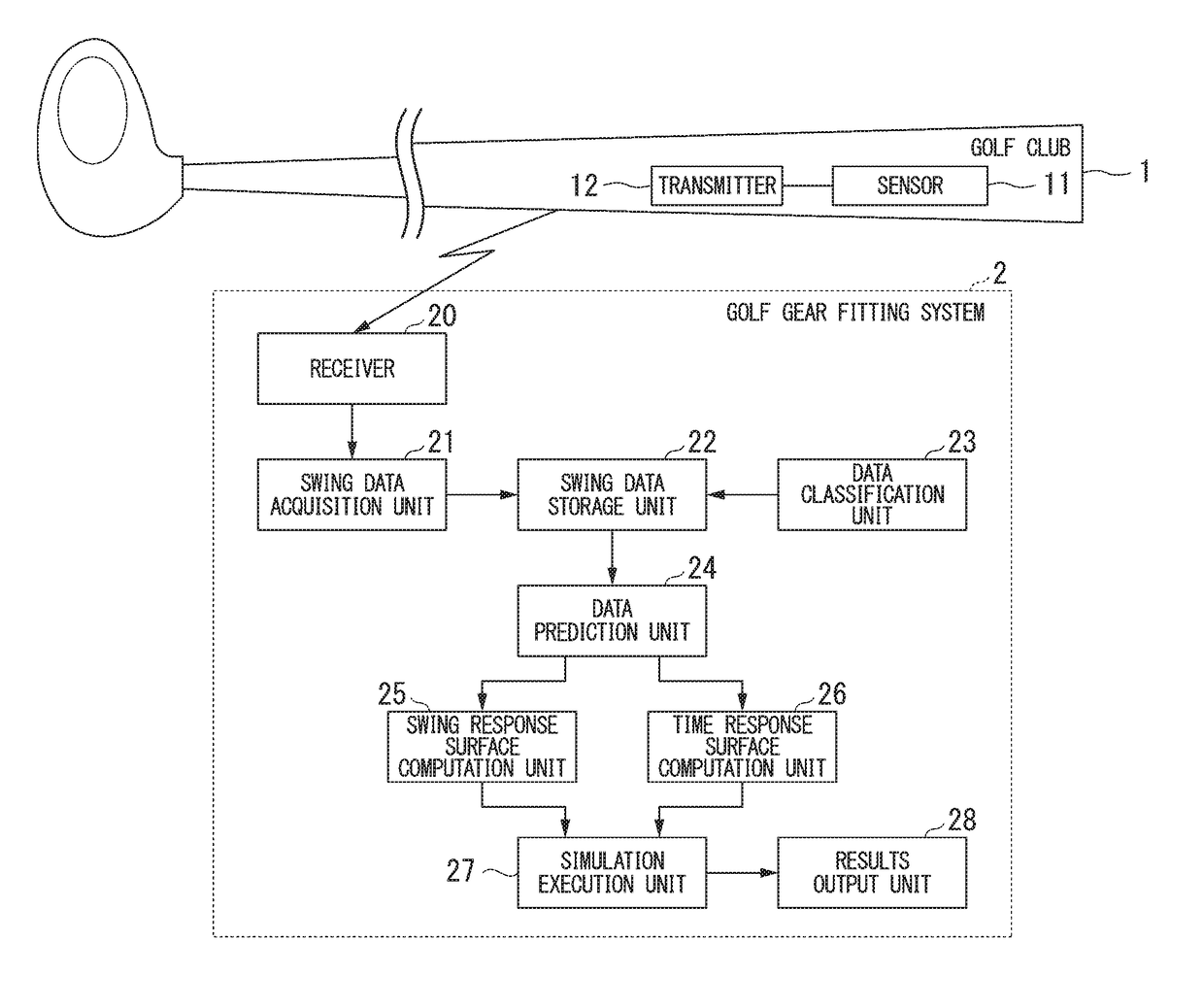

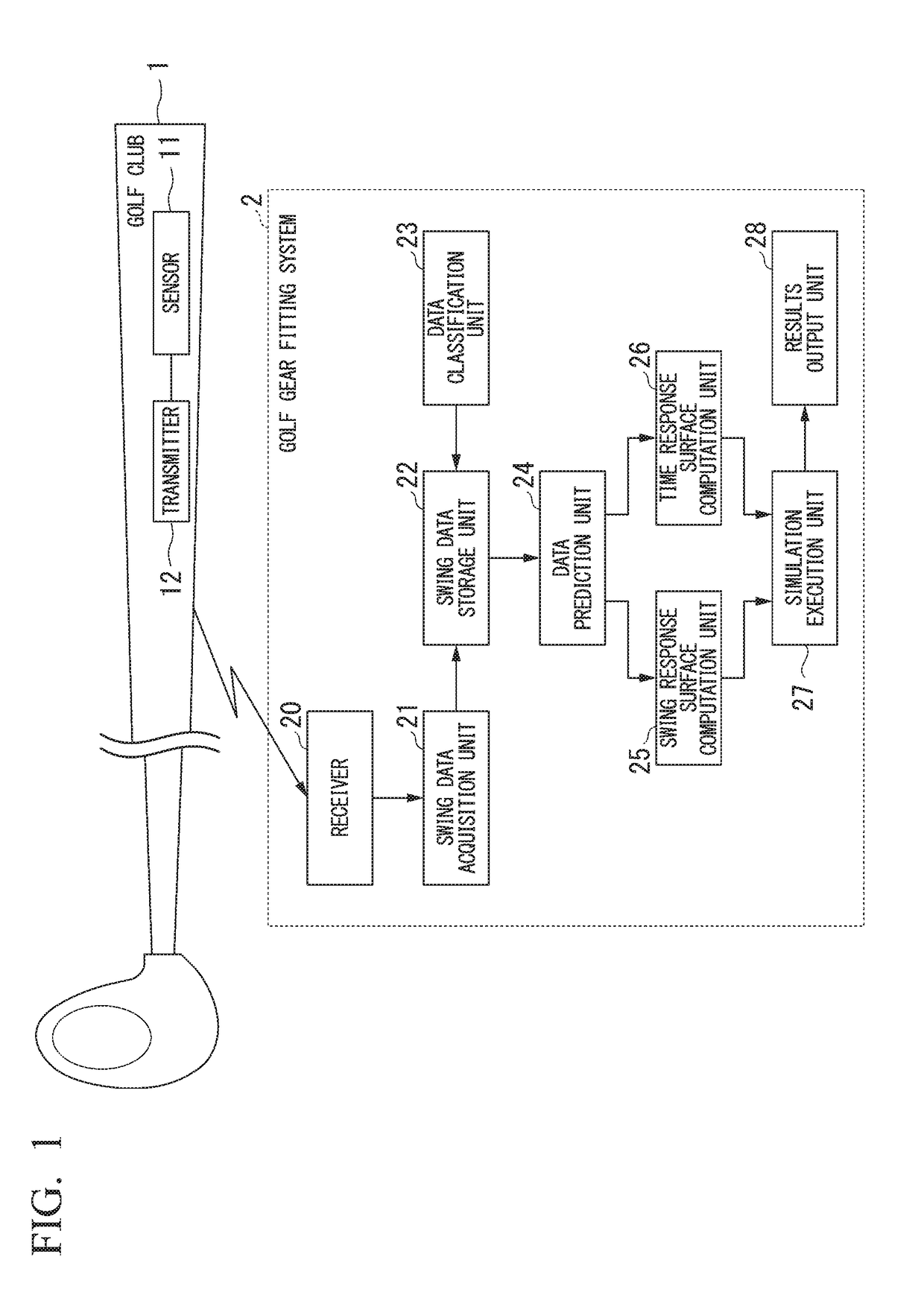

[0038]FIG. 1 is a block diagram showing a golf gear fitting system according to a first embodiment. In the diagram, golf club 1 is prepared in advance by installing a golf shaft with known specifications. Golf club 1 is equipped with sensor 11 and transmitter 12 inside the shaft at the grip portion. Transmitter 12 transmits the output from sensor 11 to the outside via wireless communication.

[0039]Sensor 11 may be installed outside of a shaft. For example, sensor 11 may be installed on the outer side of a shaft beneath the grip portion. By so setting, sensor 11 is installed on golf club 1 owned by a player. Alternatively, sensor 11 may also be installed inside a shaft of golf club 1 at the grip edge. By so setting, even more accurate swing data are obtained. Sensor 11 and transmitter 12 are preferred to be integrated. When sensor 11 and transmitter 12 are not integrated, it is preferred that transmitter 12 and the battery or the like built into the transmitter be set to be attachable...

second embodiment

[0134]Next, a second embodiment is described by referring to FIG. 1. In the first embodiment, head behavior is computed through the process of swing data acquisition unit 21, swing data storage unit 22, data classification unit 23, data prediction unit 24, swing response surface computation unit 25, time response surface computation unit 26 and simulation execution unit 27. Simulation execution unit 27 is set to compute the head behavior from the posture of the head and the coordinates of its position by simply assuming that the shaft is rigid. In the first embodiment, a high-performance computer is required as simulation execution unit 27. Therefore, a computer to operate as simulation execution unit 27 is preferred to be set at a server or the like, separately from swing data acquisition unit 21.

[0135]By contrast, in the second embodiment, head behavior is computed without using simulation execution unit 27. More specifically, swing data acquisition unit 21 is set to directly meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com