Mounting device for pressure sensor calibration

A technology of pressure sensor and installation device, which is applied in the direction of measuring device, force/torque/power measuring instrument calibration/test, instrument, etc. It can solve the problems of insufficient portability, inability to directly use calibration work, bulky volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

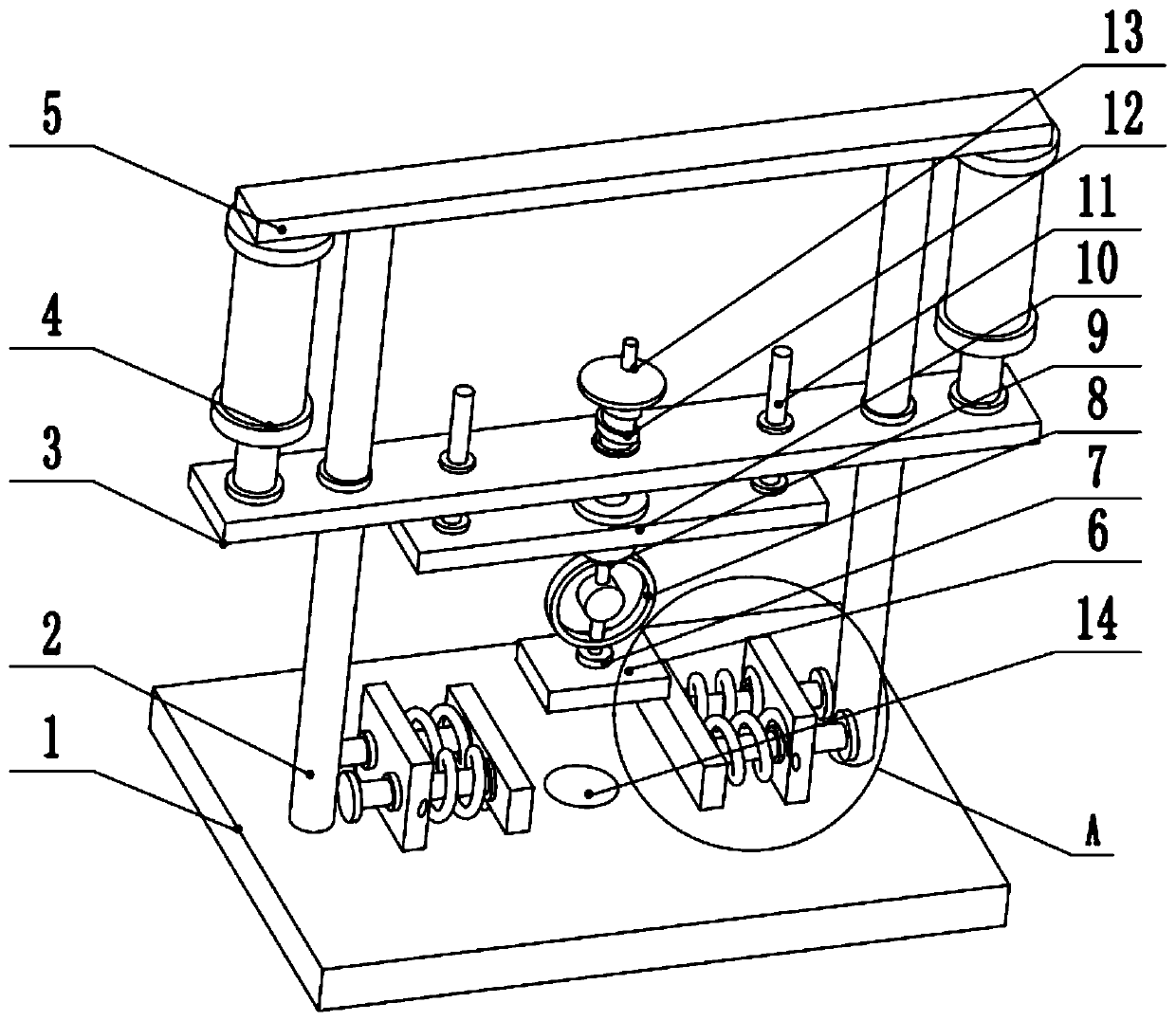

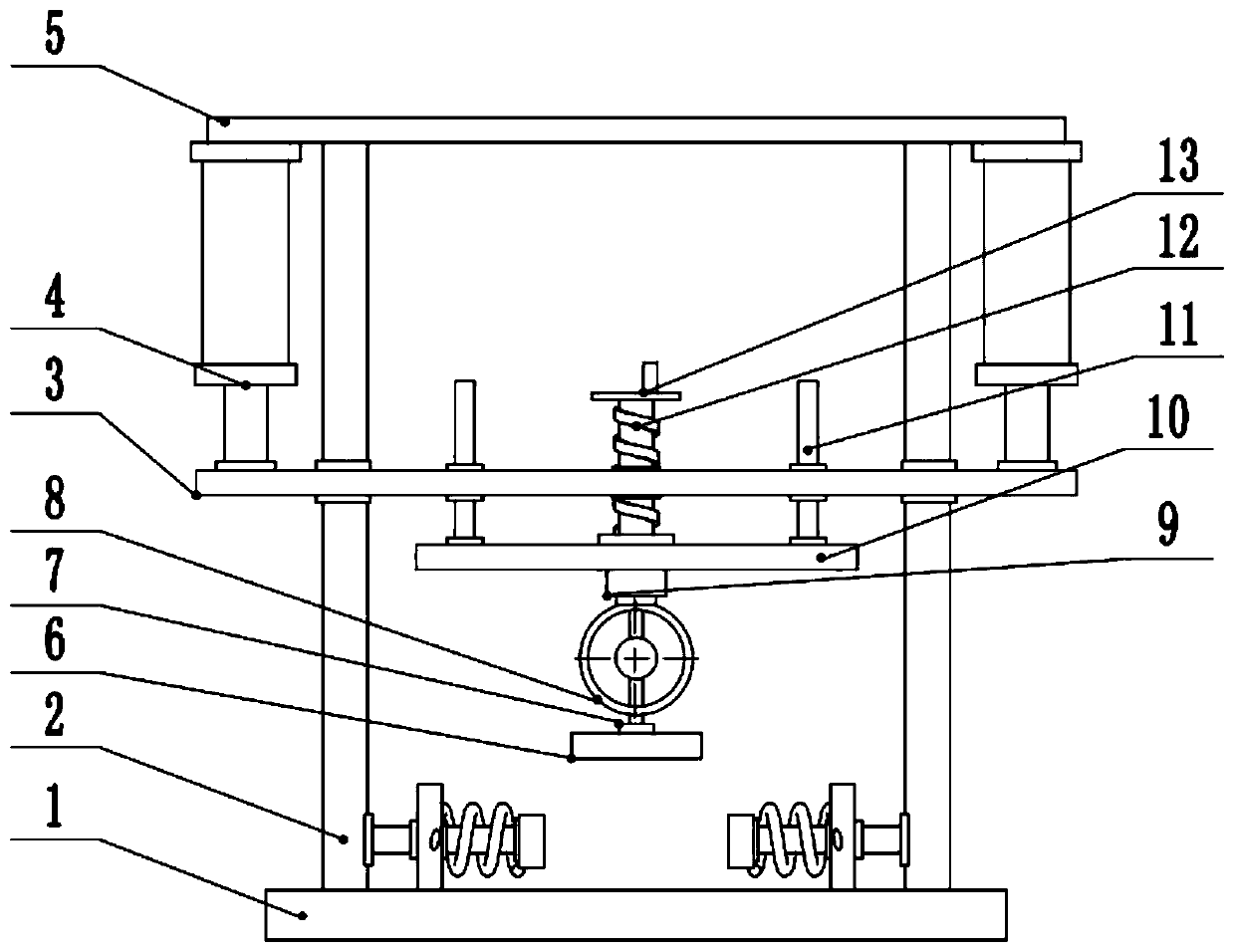

[0026] see Figure 1-3 , a mounting device for pressure sensor calibration, comprising a base plate 1, support columns 2 are provided at the left and right ends of the upper surface of the base plate 1, a top plate 5 is provided at the top of the support column 2, and a cylinder is provided at the left and right ends of the lower surface of the top plate 5 4. The piston rod of the cylinder 4 is fixedly connected to the lifting plate 3, the left and right sides of the lifting plate 3 are slidably connected to the support column 2, the middle part of the lifting plate 3 is slidably connected to the middle part of the first guide rod 11, and the lower end of the first guide rod 11 Fixedly connected to the fixed plate 10, the middle part of the upper surface of the fixed plate 10 rotates to connect the lower end of the screw mandrel 12, the upper end of the screw mandrel 12 is provided with a runner 13, the middle part of the screw mandrel 12 is threaded to connect the middle part ...

Embodiment 2

[0029] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the middle part of the bottom plate 1 is provided with a relief groove 14 . For some electronic sensors, an external data line is required during use, so a relief slot 14 is provided in the middle of the bottom plate 1, so that the data line of the sensor can pass through the relief slot 14 and connect to related equipment, avoiding on the one hand In the process of applying pressure, the data line is crushed, on the other hand, it can make the whole device look more neat.

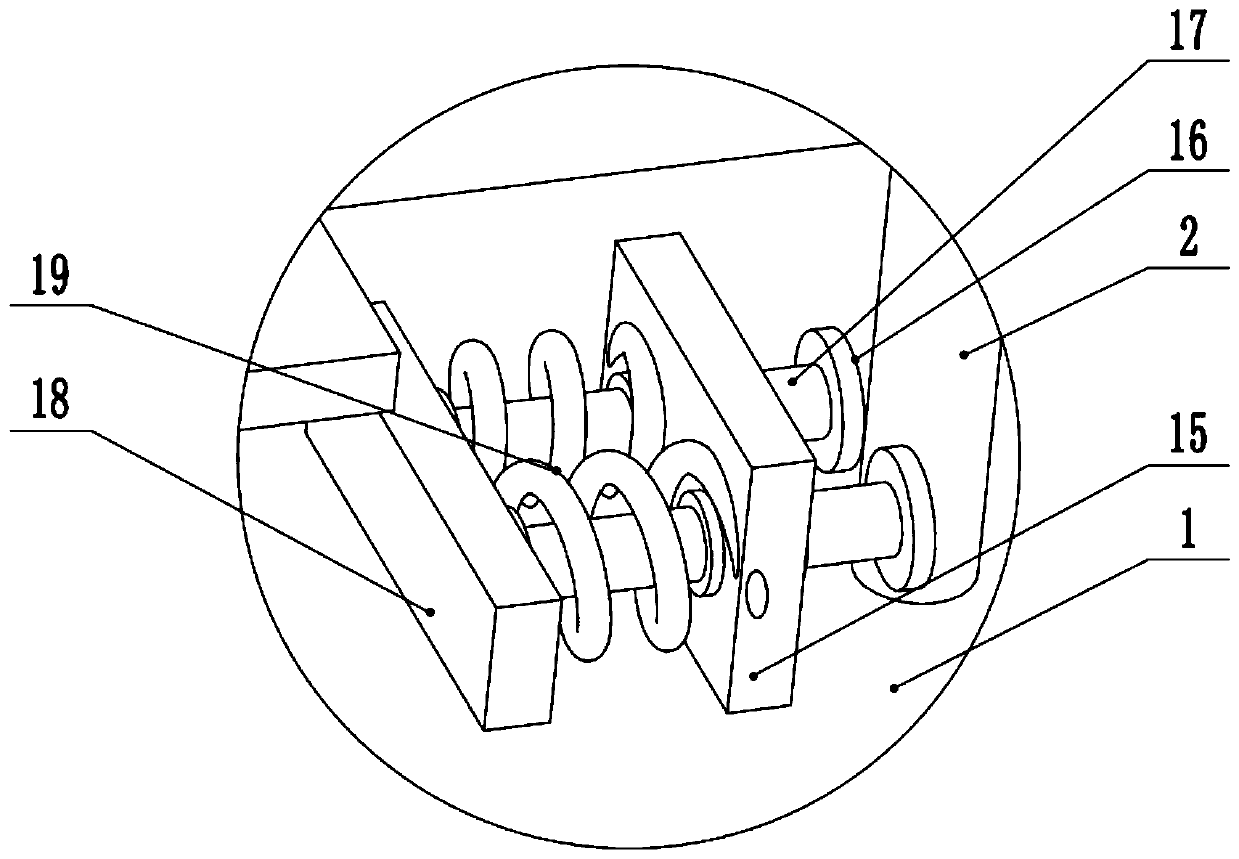

[0030] During the implementation of the present invention, first push the clamping plate 18 to both sides, place the sensor to be calibrated in the middle of the bottom plate 1, loosen the clamping plate 18, and under the action of the spring 19, the two clamping plates on both sides The clamping plate 18 slides toward the center of the device. At this time, the clamping plate 18 can fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com