Method of manufacturing prosthetic socket interface

a technology of prosthetic sockets and sockets, applied in the field of prosthetic limbs, can solve the problems of excessive thickness and no prior design has specifically allowed for tissue displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

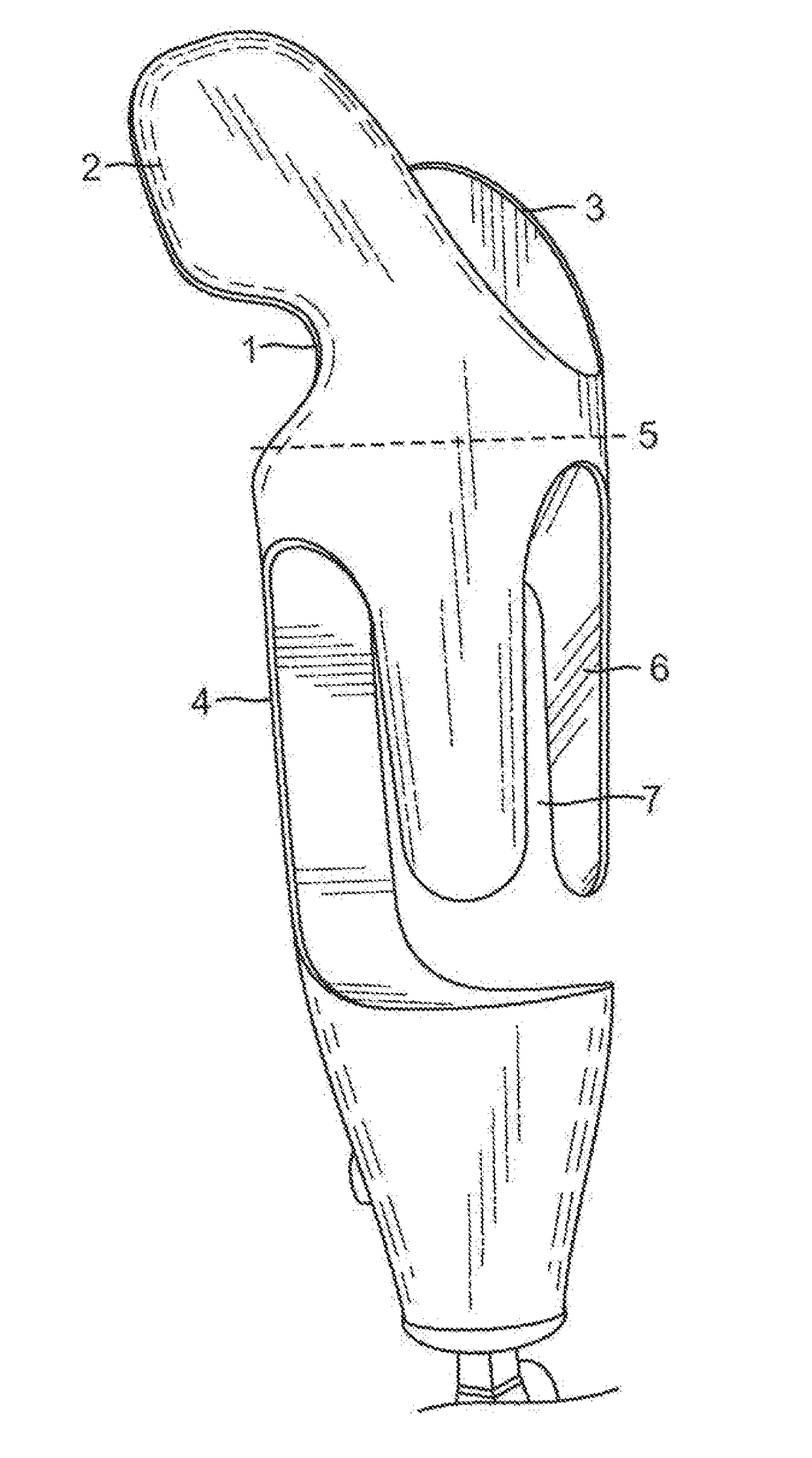

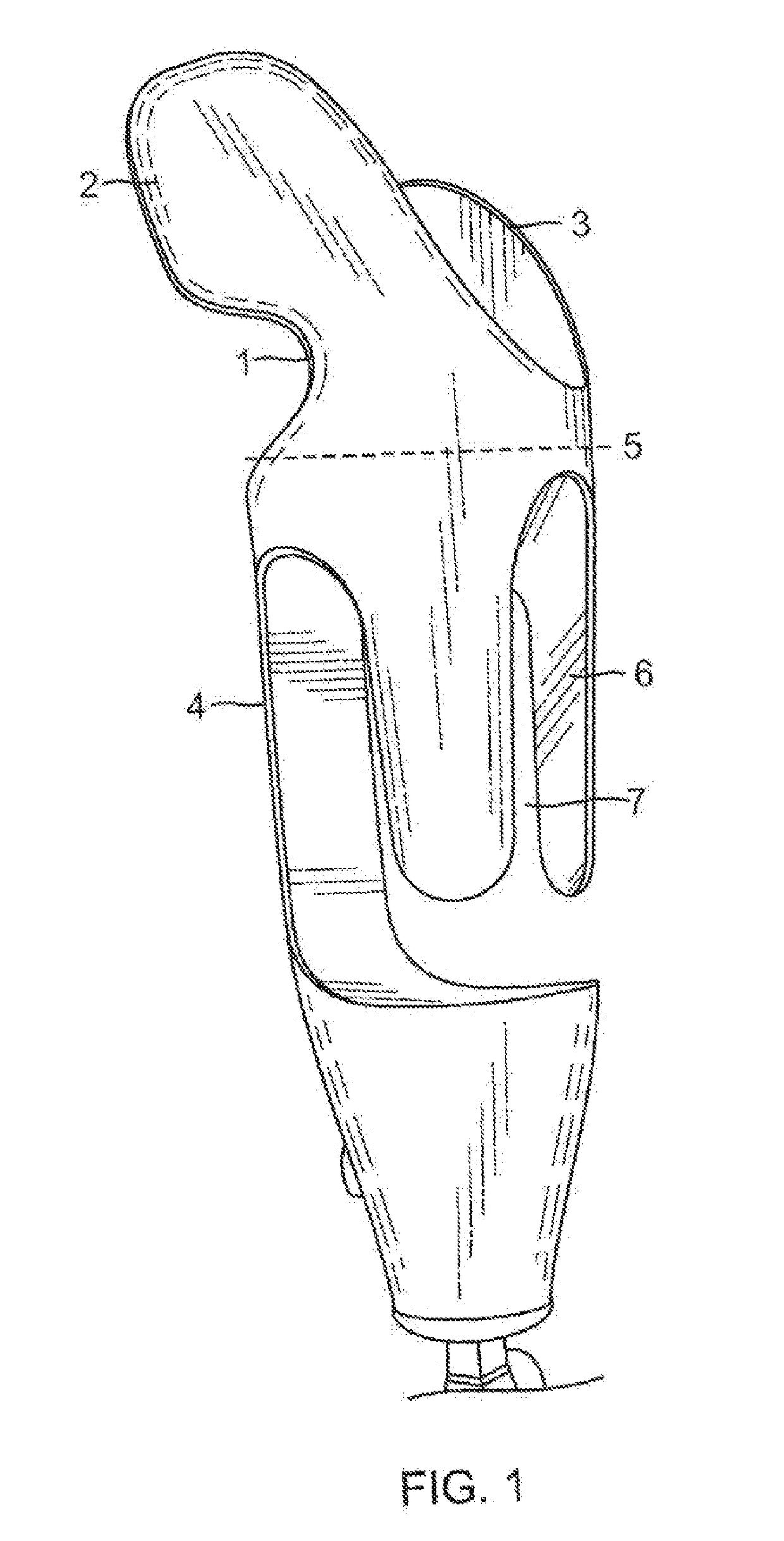

[0081]As shown in FIG. 1, a the transhumeral open-cage interface embodiment, there is an upper portion 1, which has both an anterior stabilizer 2 and a posterior stabilizer 3 and which extends in a proximal (in this case toward a patient's shoulder) and medial (toward a patient's midline) direction from a lower portion 4 to stabilize the interface on a patient's body. Although stabilizers 2 and 3 are not required, they are recommended to impart or enhance rotational stability. The lower portion 4 (below line 5) has an open-cage structure. Dashed horizontal line 5 demarcates the upper and lower portions. The lower portion 4 of this open-cage embodiment has multiple, e.g. three or four struts 6, which look like fingers that extend along the long axis of the residual limb and are designed to partially encompass the residual limb, allowing soft tissue to flow through windows 7.

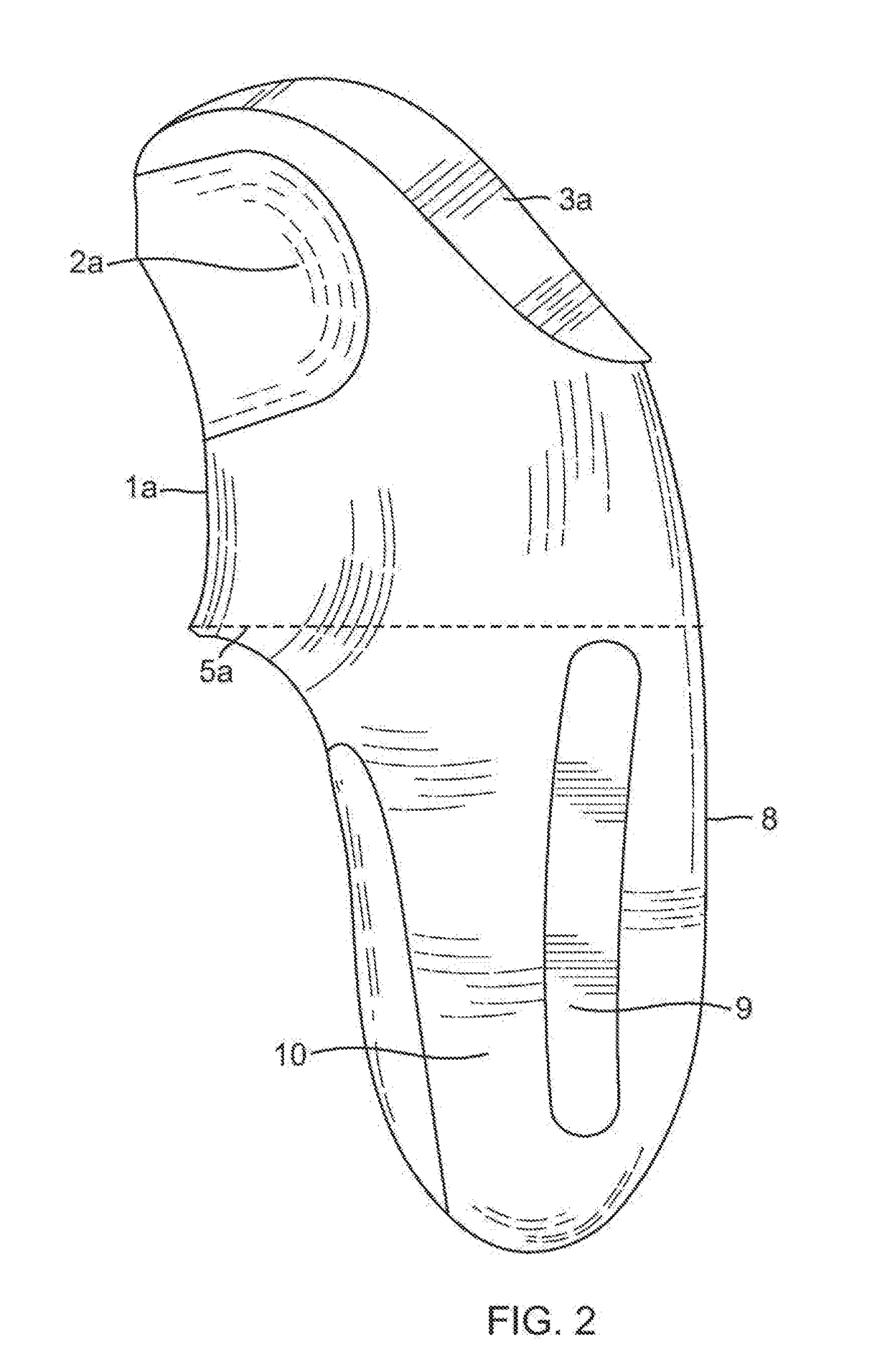

[0082]As shown in FIG. 2, a transhumeral solid-body interface embodiment, there is an upper portion la, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com