3d-printing device and process for producing an object with use of a 3d-printing device

a 3d printing and printing device technology, applied in the direction of additive manufacturing processes, manufacturing tools, additive manufacturing with liquids, etc., can solve the problems of affecting the quality of printed parts, the quality of objects achievable by the prior art known additive methods cannot reach the constant quality of comparable objects produced by injection molding,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The print material may be material for manufacture of a permanent component, especially silicone, or may be material which is required for temporarily manufactured parts or regions, especially support material in the form of polyethylene glycol (PEG), for example.

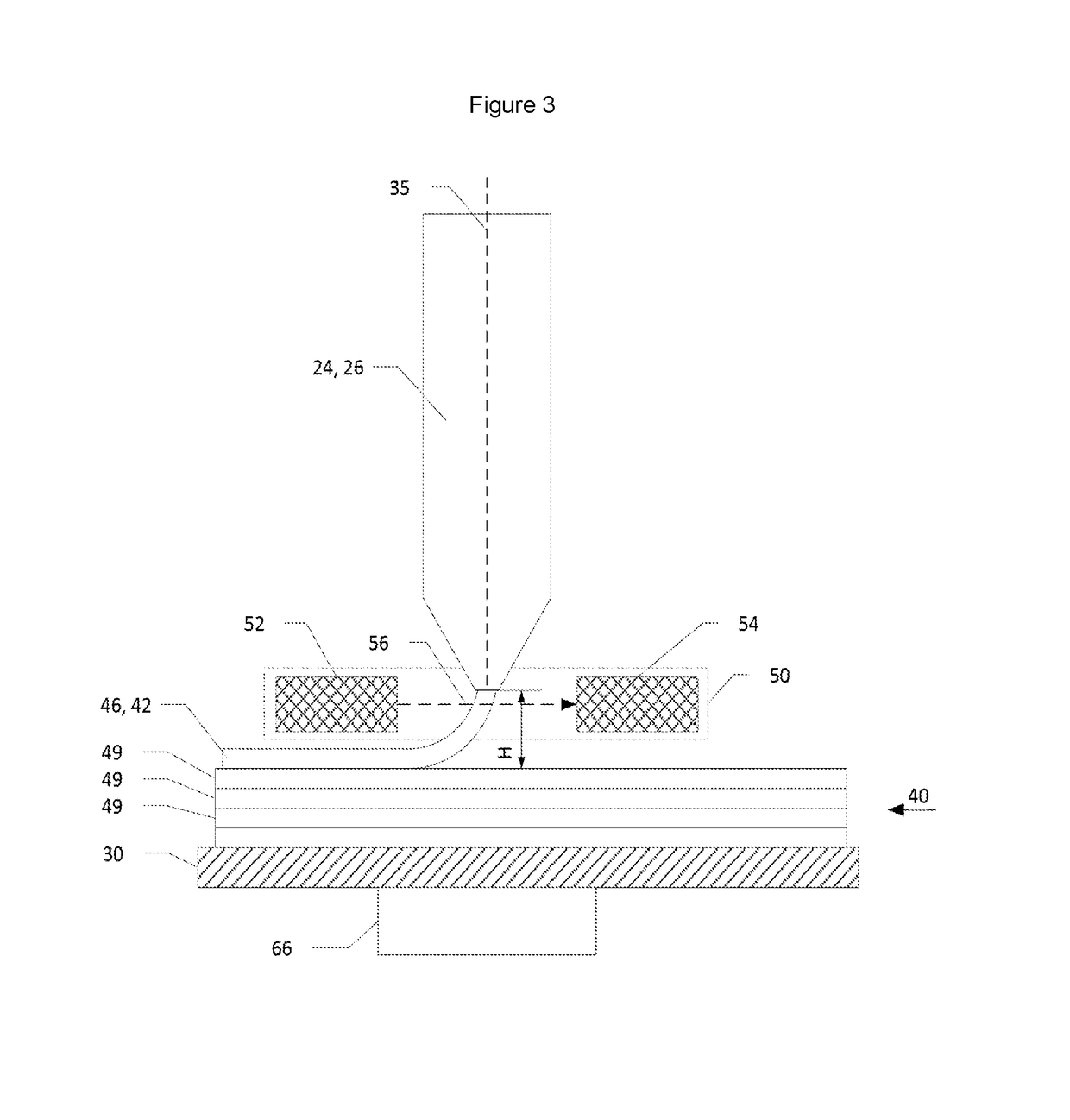

[0022]The discharge device is set up to release print materials in the form of individual isolated droplets, as a series of droplets or in the form of a strand in the direction of the discharge axis. Flowing transitions between these forms are possible. In the context of this description, a droplet of a print material discharged from the discharge device and placed on the baseplate or on the object is referred to as a voxel. A strand refers to both discharged and as yet unplaced print material and to placed print material. A placed print material is understood to mean either a voxel or a strand.

[0023]The print materials are detected and / or geometrically measured in the region of the discharge device, and so the measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com