Primary purified water treatment tank

A technology for primary treatment and purification of water, applied in chemical instruments and methods, filtration separation, fixed filter element filters, etc., can solve problems such as filter clogging and cleaning, and achieve the effect of ensuring accuracy and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

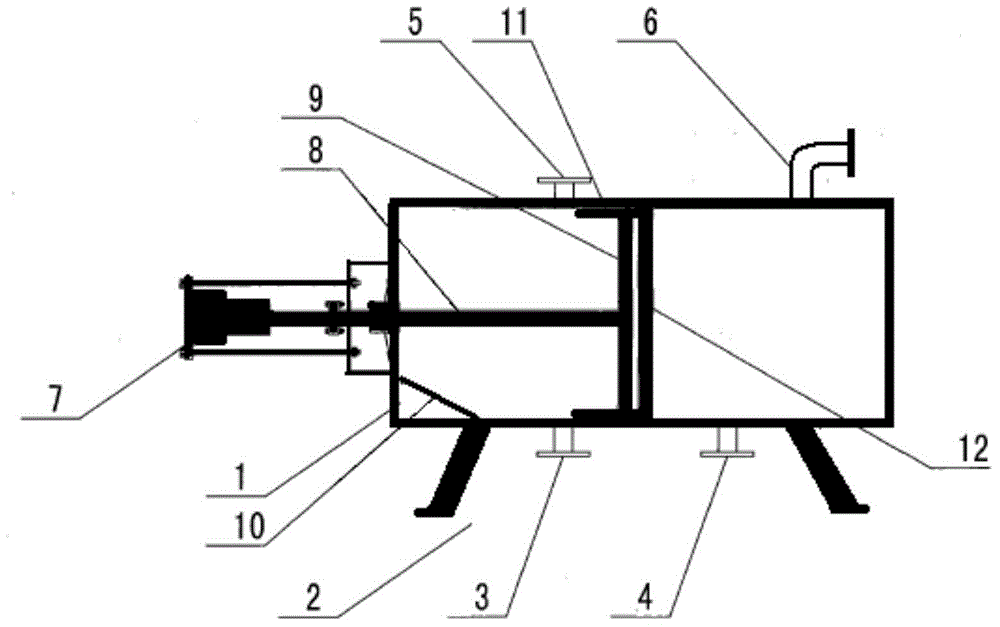

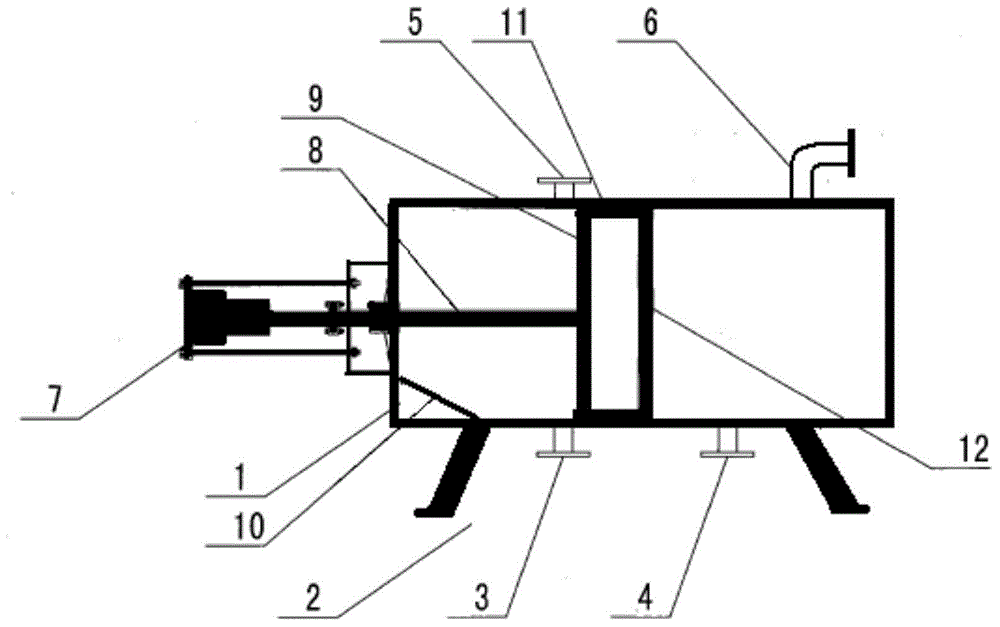

[0015] Attached below Figure 1-5 Further implementation instructions are given for the primary treatment tank of purified water.

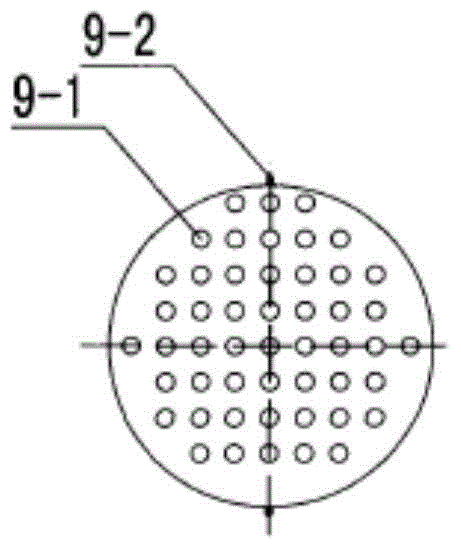

[0016] as attached Figure 1-5 As shown, the purified water preliminary treatment tank has a structure comprising a horizontally arranged purification tank 1, a support frame 2 is provided at the bottom of the purification tank 1, a fixed filter plate 12 is vertically arranged in the middle of the inner cavity of the purification tank 1, and the fixed filter plate 12 Several fixed filter plate openings 12-1 are evenly distributed on the top, and a square pollutant discharge hole 12-2 is provided at the bottom of the fixed filter plate 12. The purification tank 1 on the left side of the fixed filter plate 12 is vertically arranged with inlet holes 12-1. The water outlet 5 and the first sewage outlet 3, the top of the purification tank 1 on the right side of the fixed filter plate 12 is provided with a water outlet 6, and the bottom of the purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com