Attachment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

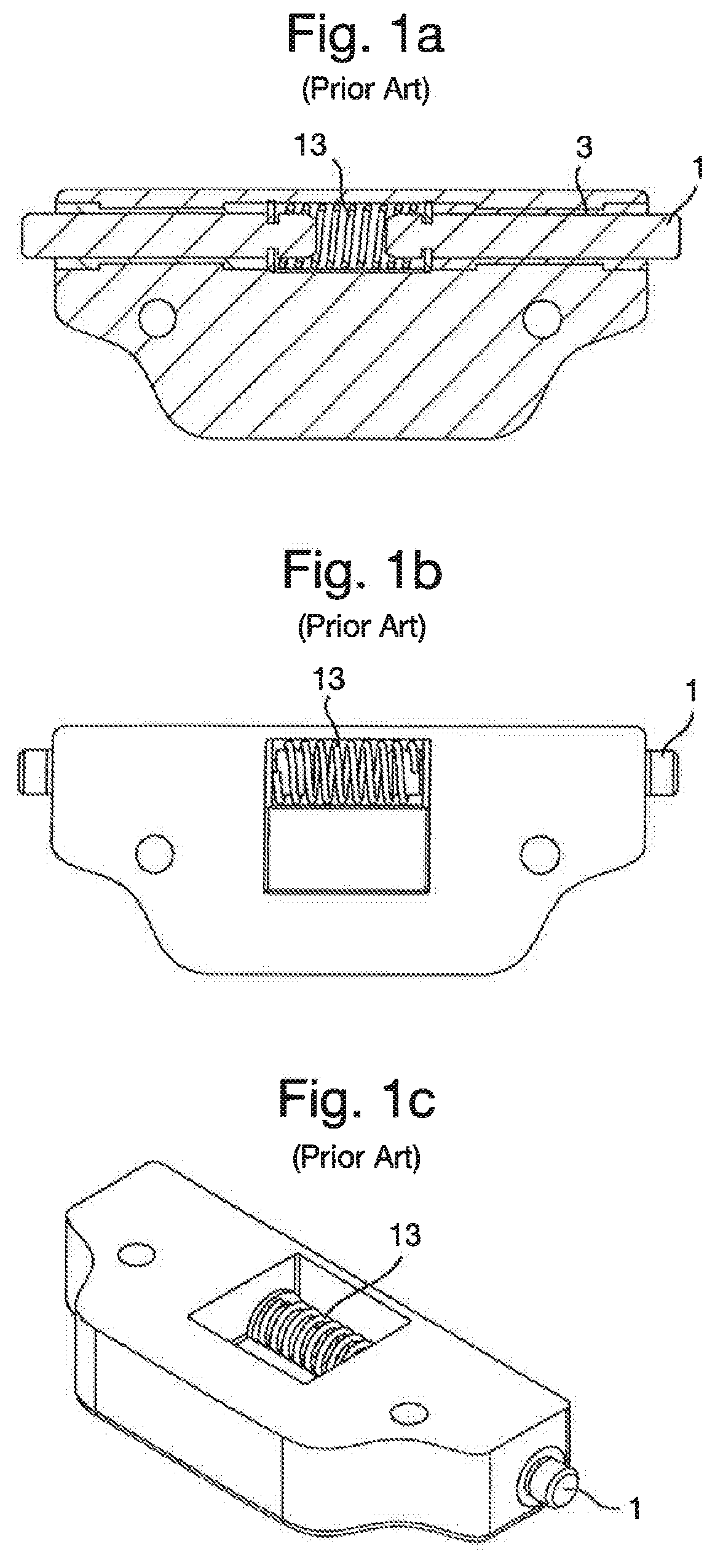

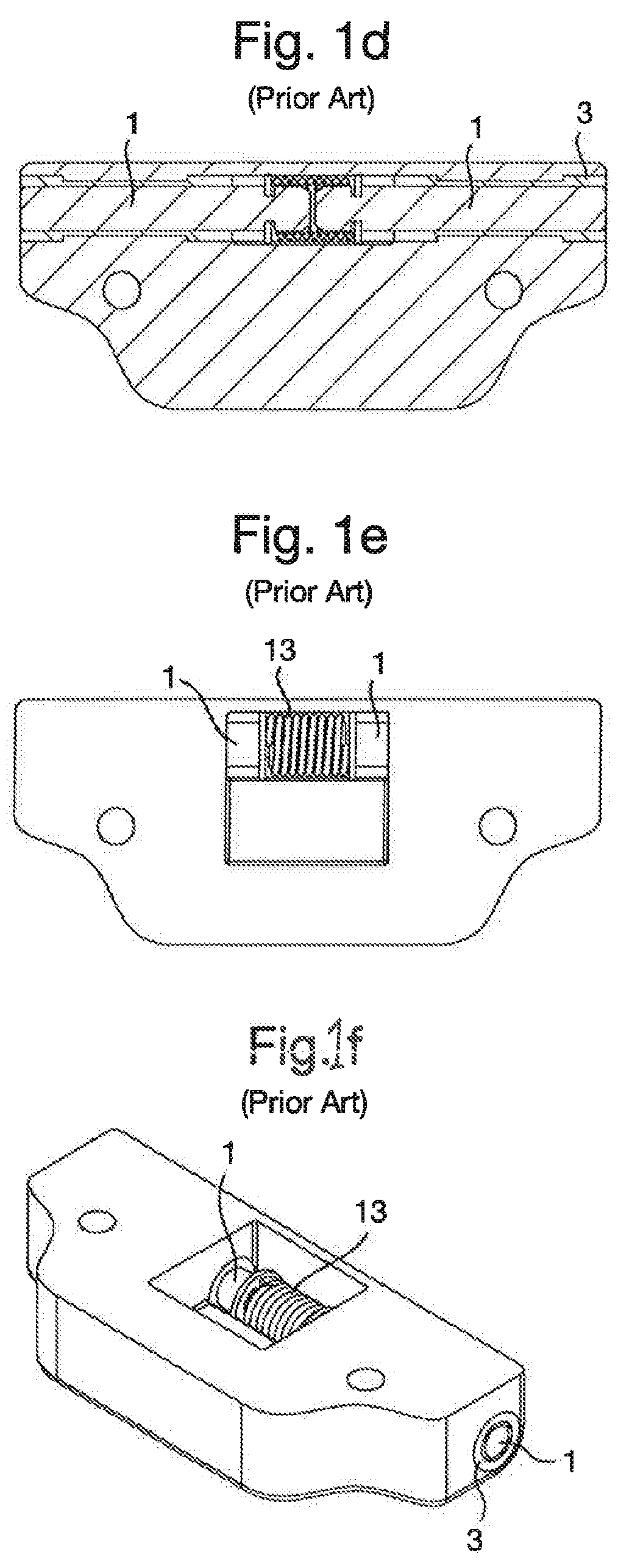

[0044]FIGS. 1a-f show prior art. A spring 13 is arranged such that it biases the pins 1 and presses them outwards. To press the pins inwards, they are squeezed together using the fingers, optionally via button sleeves that act as guides (not shown).

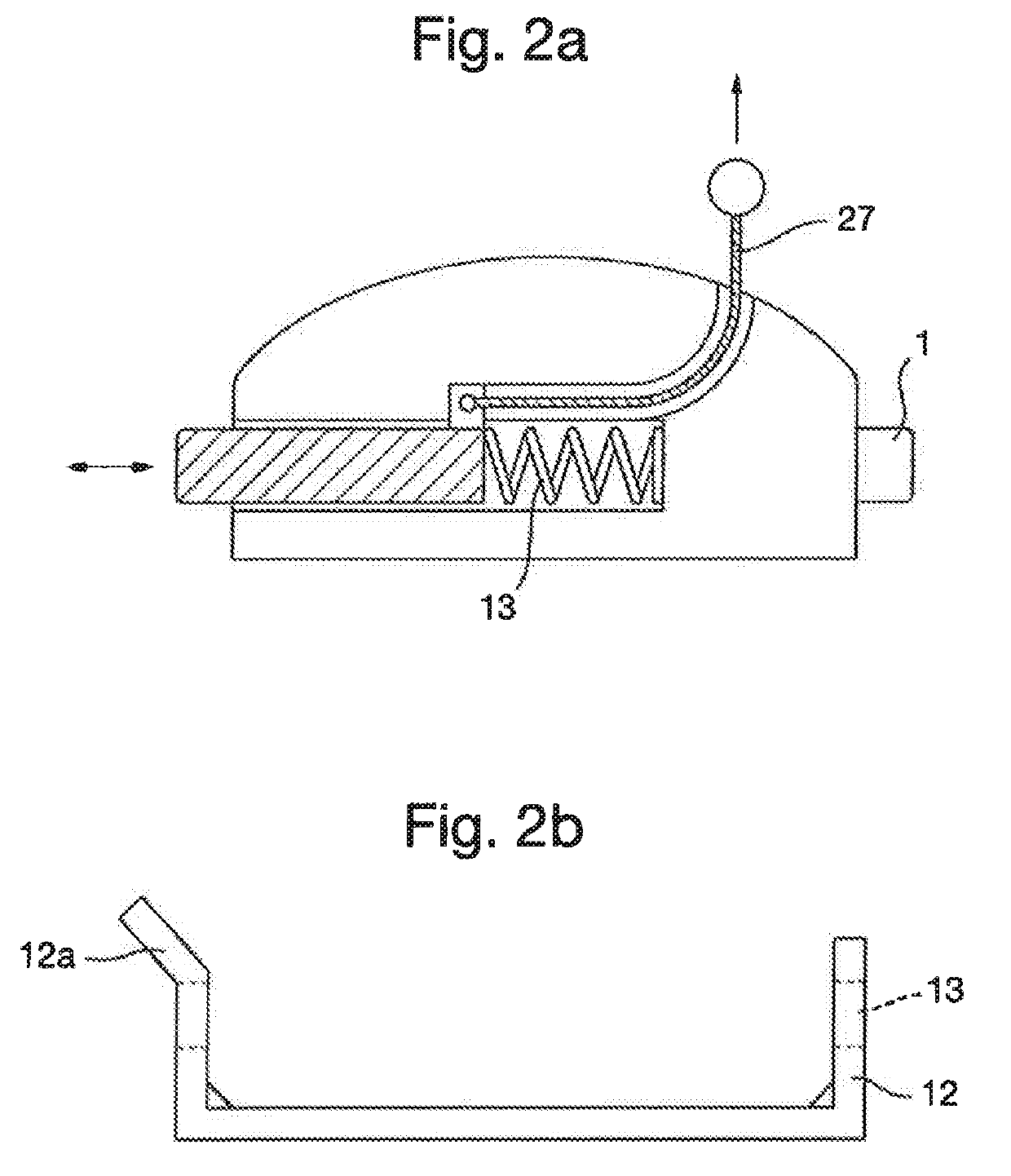

[0045]FIGS. 2a-b show a possible embodiment of the invention. The embodiment comprises a cord 27 that can be used to squeeze together a squeezing mechanism. The squeezing mechanism is designed to overcome a biasing force from a spring. In the embodiment shown in FIG. 1 a, the spring 13 forces one of the pins 1 outwards, whilst the other pin 1 projects statically. It will be understood that both pins 1 can be displaceable in an alternative embodiment, the spring 13 then forcing both pins 1 outwards in a starting position. In that case the squeezing mechanism will help to force both pins 1 together when it is operated or actuated. The cord 27 may also be made in the form of a loop and may comprise a wire 18, with or without sleeving. By pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com